Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Sturtevant Model 3B Simpactor Mill, 16" Diameter. Carbon steel construction

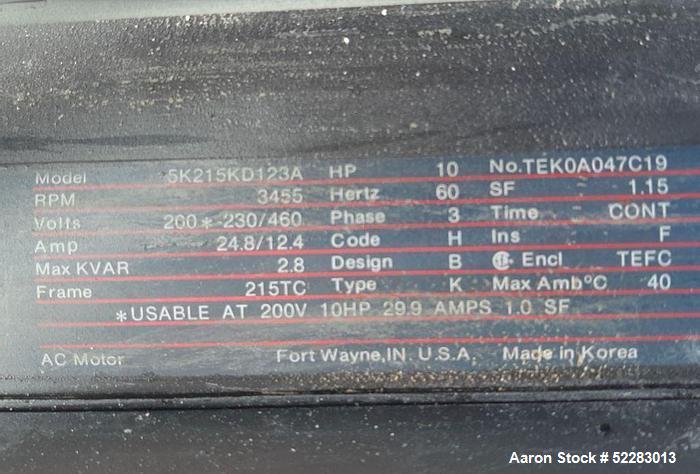

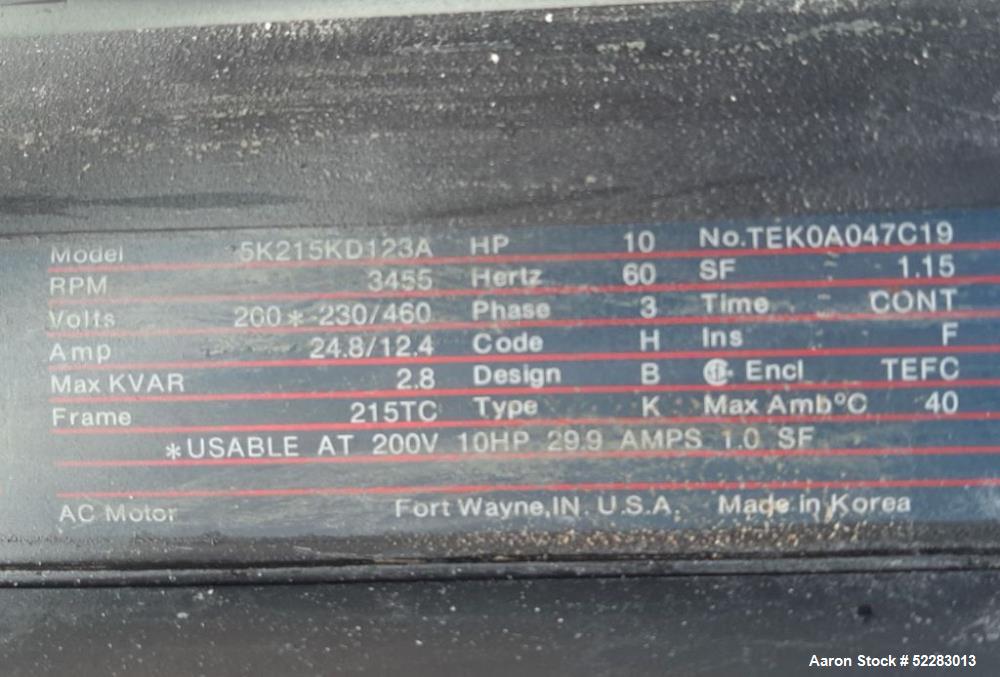

Used Sturtevant Model 3B Simpactor Mill, 16" Diameter. Carbon steel construction. Approximate capacity 3.5 tons per hour, depending on product. Set up with 6" x 6" flanged inlet with 6" diameter center bottom discharge. Includes 2-part rotating discs, driven by 10 HP inverter motor, rated for 230/460V, 3-phase, 60 Hz, 3455 RPM. Includes v-belt drive with guard. Serial# 703.

- Brand: Sturtevant

- Model: 3B Simpactor Mill

- Serial Number: 504

- Condition: Used

Description

The Sturtevant Model 3B Simpactor Mill is a high-speed impact mill, designed for size reduction, fine grinding, and particle processing across chemical, food, pharmaceutical, and industrial applications. Constructed from carbon steel, this mill provides durability and efficiency for high-capacity material processing.

The 16" diameter mill is set up with a 6" x 6" flanged inlet and a 6" center bottom discharge, allowing for efficient material flow and easy product collection. This unit includes two-part rotating discs, designed to maximize impact and shear forces for uniform particle size reduction.

Powered by a 10 HP inverter motor (230/460V, 3-phase, 60 Hz, 3425 RPM), the mill operates efficiently with adjustable speed control via a V-belt drive with guard for safe operation. The approximate throughput capacity is 3.5 tons per hour, depending on the material.

Specifications

- Mill Type: Simpactor Impact Mill

- Material: Carbon Steel

- Rotor Diameter: 16"

- Capacity: ~3.5 Tons Per Hour (Product Dependent)

- Inlet: 6" x 6" Flanged

- Discharge: 6" Center Bottom Outlet

- Drive System:

- Motor Power: 10 HP Inverter Motor

- Voltage: 230/460V, 3-Phase, 60 Hz

- Speed: 3425 RPM

- Drive Type: V-Belt with Guard

Applications

- Chemical Processing – Grinding and size reduction of powders and granular materials

- Food & Beverage Industry – Milling of ingredients, spices, and food additives

- Pharmaceutical & Biotech – Fine particle size control for active ingredients

- Industrial Minerals & Pigments – Powder processing for coatings and ceramics

- Agricultural & Biomass Processing – Size reduction of feed, grains, and organic materials

Compatible Products

- Industrial hammer mills and impact mills

- High-efficiency particle size reduction systems

- Food and pharmaceutical-grade grinding equipment

- Industrial processing equipment for bulk material handling

- Simpactor mill, impact mill, industrial grinder

- Used Sturtevant 3B Simpactor mill, high-capacity impact mill, fine grinding mill for industrial applications

- Sturtevant 3B Simpactor impact mill with 10 HP inverter motor, used industrial impact mill for food and chemical processing, high-speed particle size reduction mill for powder processing

Used Sturtevant Model 3B Simpactor Mill, 16" Diameter. Carbon steel construction. Approximate capacity 3.5 tons per hour, depending on product. Set up with 6" x 6" flanged inlet with 6" diameter center bottom discharge. Includes 2-part rotating discs, driven by 10 HP inverter motor, rated for 230/460V, 3-phase, 60 Hz, 3455 RPM. Includes v-belt drive with guard. Serial# 703.

- Brand: Sturtevant

- Model: 3B Simpactor Mill

- Serial Number: 504

- Condition: Used

Description

The Sturtevant Model 3B Simpactor Mill is a high-speed impact mill, designed for size reduction, fine grinding, and particle processing across chemical, food, pharmaceutical, and industrial applications. Constructed from carbon steel, this mill provides durability and efficiency for high-capacity material processing.

The 16" diameter mill is set up with a 6" x 6" flanged inlet and a 6" center bottom discharge, allowing for efficient material flow and easy product collection. This unit includes two-part rotating discs, designed to maximize impact and shear forces for uniform particle size reduction.

Powered by a 10 HP inverter motor (230/460V, 3-phase, 60 Hz, 3425 RPM), the mill operates efficiently with adjustable speed control via a V-belt drive with guard for safe operation. The approximate throughput capacity is 3.5 tons per hour, depending on the material.

Specifications

- Mill Type: Simpactor Impact Mill

- Material: Carbon Steel

- Rotor Diameter: 16"

- Capacity: ~3.5 Tons Per Hour (Product Dependent)

- Inlet: 6" x 6" Flanged

- Discharge: 6" Center Bottom Outlet

- Drive System:

- Motor Power: 10 HP Inverter Motor

- Voltage: 230/460V, 3-Phase, 60 Hz

- Speed: 3425 RPM

- Drive Type: V-Belt with Guard

Applications

- Chemical Processing – Grinding and size reduction of powders and granular materials

- Food & Beverage Industry – Milling of ingredients, spices, and food additives

- Pharmaceutical & Biotech – Fine particle size control for active ingredients

- Industrial Minerals & Pigments – Powder processing for coatings and ceramics

- Agricultural & Biomass Processing – Size reduction of feed, grains, and organic materials

Compatible Products

- Industrial hammer mills and impact mills

- High-efficiency particle size reduction systems

- Food and pharmaceutical-grade grinding equipment

- Industrial processing equipment for bulk material handling

- Simpactor mill, impact mill, industrial grinder

- Used Sturtevant 3B Simpactor mill, high-capacity impact mill, fine grinding mill for industrial applications

- Sturtevant 3B Simpactor impact mill with 10 HP inverter motor, used industrial impact mill for food and chemical processing, high-speed particle size reduction mill for powder processing

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory