Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used - Schutte-Buffalo-Astec Hammermill, Model AHM-20, 600 HP, Carbon Steel

Used Schutte-Buffalo-Astec Hammermill, Model AHM-20, Carbon Steel. Approximate (2) 48" diameter x 24" wide rotors. 2-3/4"w x 4"L x 5/16" thick swinging hammers, approximately 7 rows of (14 hammers) 2 sections, 3/16" screen. 15"W x 60" Long Top feed with hopper, 60-1/2"L x 11"T bottom discharge. Driven by a 600 HP, 3/60/460 volt, 1790 rpm motor. Mounted on a frame. Includes a Twin City blower, Type RBR-SW, size 926, driven by a 200 HP, 3/60/230/460 volt, 1785 rpm motor.

| Manufacturer | SchutteSchutte |

| Model | AHM-20 |

| Category | MillsMills |

| Subcategory | Hammer MillHammer Mill |

Manufacturer Information

- Manufacturer: Schutte-Buffalo-Astec

- Model: AHM-20

- Material: Carbon Steel

- Condition: Used

Description

The Schutte-Buffalo-Astec Hammermill Model AHM-20 is a heavy-duty industrial grinding machine designed for high-capacity size reduction and material processing. This unit features (2) 48” diameter x 24” wide rotors equipped with swinging hammers (2-3/4” W x 4” L x 5/16” thick), configured in 7 rows of 14 hammers per row across 2 sections.

The hammermill operates with a 3/16” screen and has a top feed opening measuring 15” wide x 60” long with a hopper. The bottom discharge measures 60-1/2” long x 11” tall, allowing for efficient material output.

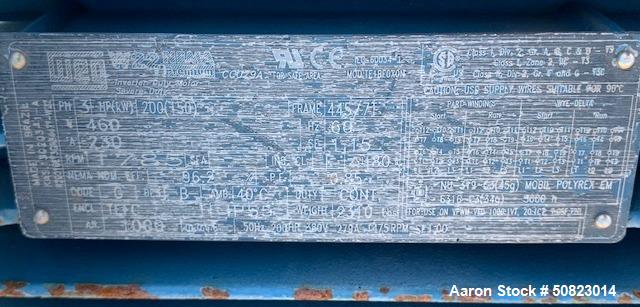

This unit is powered by a robust 600 HP motor (3/60/460V, 1790 RPM) and is mounted on a frame for stability. It also includes a Twin City blower, Type RBR-SW, size 926, driven by a 200 HP motor (3/60/230/460V, 1785 RPM), enhancing material movement and dust collection.

Specifications

- Model: AHM-20

- Material: Carbon Steel

- Rotor Size: (2) 48” Diameter x 24” Wide

- Hammers: 2-3/4” W x 4” L x 5/16” Thick

- Hammer Configuration: 7 Rows of 14 Hammers per Section (2 Sections)

- Screen Size: 3/16”

- Top Feed Opening: 15” W x 60” L with Hopper

- Bottom Discharge: 60-1/2” L x 11” T

- Main Motor: 600 HP, 3/60/460V, 1790 RPM

- Blower: Twin City Blower, Type RBR-SW, Size 926

- Blower Motor: 200 HP, 3/60/230/460V, 1785 RPM

- Mounting: Frame-mounted

- Condition: Used

Applications

This Schutte-Buffalo-Astec Hammermill is ideal for high-volume material processing, including:

- Wood Grinding: Pallets, logs, and biomass processing

- Recycling Industry: Shredding wood, plastic, and rubber

- Agricultural Processing: Grinding feedstock, crop waste, and husks

- Biomass & Renewable Energy: Preparing materials for pellet fuel and biofuel

- Paper & Pulp Industry: Grinding fiber for pulping processes

- Mining & Minerals: Crushing ores and raw materials

Compatible Products & Uses

- High-volume wood waste reduction

- Biomass material preparation for fuel production

- Agricultural byproduct grinding

- Shredding and grinding for recycling processes

- Industrial material size reduction

Animal Bedding, Bark, Biodiesel Production, Biomass, Boiler Fuel, Briquette Production, Dry Woods Chips, Green Wood Chips, Landscape Mulch, Pellet Production, Playground Cover, Pre-hogged Wood Scrap, Sawdust, Torrefied Biomass, Wood Bark

- Schutte-Buffalo hammermill

- Used industrial hammermill

- 600 HP hammermill

- High-capacity grinder

- Twin rotor hammermill

- Industrial wood grinder

- Schutte-Buffalo-Astec AHM-20

- Heavy-duty hammermill

- Biomass processing machine

- Used carbon steel hammermill

- Used Schutte-Buffalo AHM-20 hammermill for sale

- High-volume industrial grinding machine

- 600 HP industrial hammermill for biomass processing

- Twin rotor hammermill for material size reduction

- Used Schutte-Buffalo hammermill with blower system

- Carbon steel hammermill with Twin City blower

- Large-scale wood grinding and recycling machine

- Used hammermill for pellet fuel processing

- Heavy-duty agricultural feed grinding machine

- Industrial shredder and hammermill for sale

- Buy used Schutte-Buffalo AHM-20 hammermill with blower system

- 600 HP industrial hammermill for biomass and recycling applications

- Used high-capacity hammermill for wood waste and feed processing

- Twin rotor hammermill for agricultural and industrial applications

- Best heavy-duty industrial hammermill for material reduction

- Where to buy used Schutte-Buffalo hammermills for wood grinding

- Used carbon steel hammermill with 600 HP motor and blower

- Industrial hammermill for high-speed material processing

- High-performance hammermill for large-scale pellet fuel production

- Used Schutte-Buffalo-Astec hammermill with Twin City blower system

- Used Schutte-Buffalo hammermill

- Industrial hammermill for sale

- 600 HP high-speed hammermill

- Carbon steel material processing grinder

- Schutte-Buffalo-Astec hammermill AHM-20

- Biomass and recycling hammermill

- Heavy-duty industrial shredder

- Twin rotor hammermill for sale

- Used pellet fuel processing hammermill

- High-performance grinding machine

- Buy used Schutte-Buffalo hammermill

- Sell industrial hammermill

- Used hammermill for biomass processing

- Heavy-duty industrial shredder for sale

- Used 600 HP hammermill available

- Best price for used industrial hammermill

- Used wood and recycling hammermill supplier

- Second-hand Schutte-Buffalo hammermill for sale

- Large-scale hammermill for wood waste processing

- Industrial hammermill with blower system

Used Schutte-Buffalo-Astec Hammermill, Model AHM-20, Carbon Steel. Approximate (2) 48" diameter x 24" wide rotors. 2-3/4"w x 4"L x 5/16" thick swinging hammers, approximately 7 rows of (14 hammers) 2 sections, 3/16" screen. 15"W x 60" Long Top feed with hopper, 60-1/2"L x 11"T bottom discharge. Driven by a 600 HP, 3/60/460 volt, 1790 rpm motor. Mounted on a frame. Includes a Twin City blower, Type RBR-SW, size 926, driven by a 200 HP, 3/60/230/460 volt, 1785 rpm motor.

Manufacturer Information

- Manufacturer: Schutte-Buffalo-Astec

- Model: AHM-20

- Material: Carbon Steel

- Condition: Used

Description

The Schutte-Buffalo-Astec Hammermill Model AHM-20 is a heavy-duty industrial grinding machine designed for high-capacity size reduction and material processing. This unit features (2) 48” diameter x 24” wide rotors equipped with swinging hammers (2-3/4” W x 4” L x 5/16” thick), configured in 7 rows of 14 hammers per row across 2 sections.

The hammermill operates with a 3/16” screen and has a top feed opening measuring 15” wide x 60” long with a hopper. The bottom discharge measures 60-1/2” long x 11” tall, allowing for efficient material output.

This unit is powered by a robust 600 HP motor (3/60/460V, 1790 RPM) and is mounted on a frame for stability. It also includes a Twin City blower, Type RBR-SW, size 926, driven by a 200 HP motor (3/60/230/460V, 1785 RPM), enhancing material movement and dust collection.

Specifications

- Model: AHM-20

- Material: Carbon Steel

- Rotor Size: (2) 48” Diameter x 24” Wide

- Hammers: 2-3/4” W x 4” L x 5/16” Thick

- Hammer Configuration: 7 Rows of 14 Hammers per Section (2 Sections)

- Screen Size: 3/16”

- Top Feed Opening: 15” W x 60” L with Hopper

- Bottom Discharge: 60-1/2” L x 11” T

- Main Motor: 600 HP, 3/60/460V, 1790 RPM

- Blower: Twin City Blower, Type RBR-SW, Size 926

- Blower Motor: 200 HP, 3/60/230/460V, 1785 RPM

- Mounting: Frame-mounted

- Condition: Used

Applications

This Schutte-Buffalo-Astec Hammermill is ideal for high-volume material processing, including:

- Wood Grinding: Pallets, logs, and biomass processing

- Recycling Industry: Shredding wood, plastic, and rubber

- Agricultural Processing: Grinding feedstock, crop waste, and husks

- Biomass & Renewable Energy: Preparing materials for pellet fuel and biofuel

- Paper & Pulp Industry: Grinding fiber for pulping processes

- Mining & Minerals: Crushing ores and raw materials

Compatible Products & Uses

- High-volume wood waste reduction

- Biomass material preparation for fuel production

- Agricultural byproduct grinding

- Shredding and grinding for recycling processes

- Industrial material size reduction

Animal Bedding, Bark, Biodiesel Production, Biomass, Boiler Fuel, Briquette Production, Dry Woods Chips, Green Wood Chips, Landscape Mulch, Pellet Production, Playground Cover, Pre-hogged Wood Scrap, Sawdust, Torrefied Biomass, Wood Bark

| Manufacturer | Schutte |

| Model | AHM-20 |

| Category | Mills |

| Subcategory | Hammer Mill |

- Schutte-Buffalo hammermill

- Used industrial hammermill

- 600 HP hammermill

- High-capacity grinder

- Twin rotor hammermill

- Industrial wood grinder

- Schutte-Buffalo-Astec AHM-20

- Heavy-duty hammermill

- Biomass processing machine

- Used carbon steel hammermill

- Used Schutte-Buffalo AHM-20 hammermill for sale

- High-volume industrial grinding machine

- 600 HP industrial hammermill for biomass processing

- Twin rotor hammermill for material size reduction

- Used Schutte-Buffalo hammermill with blower system

- Carbon steel hammermill with Twin City blower

- Large-scale wood grinding and recycling machine

- Used hammermill for pellet fuel processing

- Heavy-duty agricultural feed grinding machine

- Industrial shredder and hammermill for sale

- Buy used Schutte-Buffalo AHM-20 hammermill with blower system

- 600 HP industrial hammermill for biomass and recycling applications

- Used high-capacity hammermill for wood waste and feed processing

- Twin rotor hammermill for agricultural and industrial applications

- Best heavy-duty industrial hammermill for material reduction

- Where to buy used Schutte-Buffalo hammermills for wood grinding

- Used carbon steel hammermill with 600 HP motor and blower

- Industrial hammermill for high-speed material processing

- High-performance hammermill for large-scale pellet fuel production

- Used Schutte-Buffalo-Astec hammermill with Twin City blower system

- Used Schutte-Buffalo hammermill

- Industrial hammermill for sale

- 600 HP high-speed hammermill

- Carbon steel material processing grinder

- Schutte-Buffalo-Astec hammermill AHM-20

- Biomass and recycling hammermill

- Heavy-duty industrial shredder

- Twin rotor hammermill for sale

- Used pellet fuel processing hammermill

- High-performance grinding machine

- Buy used Schutte-Buffalo hammermill

- Sell industrial hammermill

- Used hammermill for biomass processing

- Heavy-duty industrial shredder for sale

- Used 600 HP hammermill available

- Best price for used industrial hammermill

- Used wood and recycling hammermill supplier

- Second-hand Schutte-Buffalo hammermill for sale

- Large-scale hammermill for wood waste processing

- Industrial hammermill with blower system

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory