Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Heat Transfer Systems Tube Reboiler/Heat Exchanger – 7062 Sq Ft, 304L SS, Vertical/Horizontal

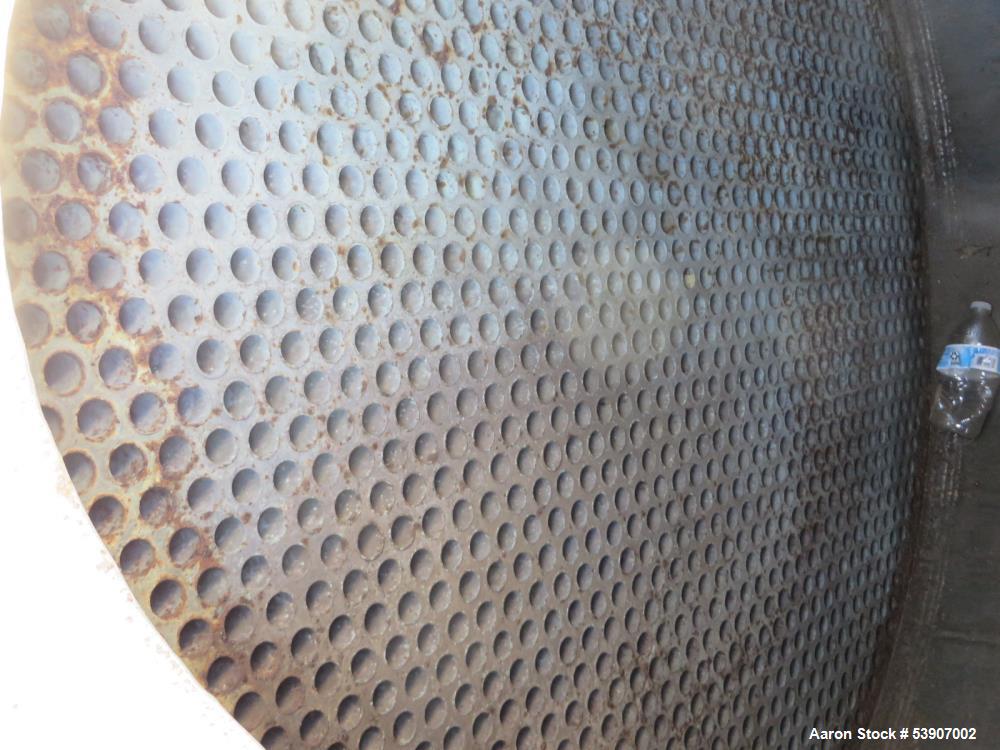

Used Heat Transfer Systems Inc. Stainless Steel Tube Reboiler/Heat Exchanger. 7062 square foot surface area; 57" diameter; Carbon steel steam shell; 304L stainless steel tubes and tube sheets; 16' shell length; 23'8" overall length; Vertical orientation (can be used horizontal); 75 PSI/FV @ 320F Shell Side (MAWP); 60 PSI/FV @ 320F Tube Side (MAWP); 31 Deg F/75 PSI Shell Side (MDMT); 31 Deg F/60 PSI Tube Side (MDMT); 15 PSI/FV @ 320F Shell Side (MAWP-External); 15 PSI/FV @ 320F Tube Side (MAWP-External). BEM exchanger configuration. S/N #13138-5. NB #2068. Built 2011. Unit is from ethanol distillation column system.

| Manufacturer | Heat Transfer SystemsHeat Transfer Systems |

| Serial # | 13138-5 |

| Category | Heat ExchangersHeat Exchangers |

| Subcategory | Shell & Tube StainlessShell & Tube Stainless |

Manufacturer Details

-

Manufacturer: Heat Transfer Systems Inc.

-

Serial Number: 13138-5

-

National Board Number: NB #2068

-

Year Built: 2011

Product Details

-

Type: BEM Configuration Shell & Tube Heat Exchanger / Tube Reboiler

-

Heat Transfer Surface Area: 7,062 sq. ft.

-

Orientation: Vertical (can also be used horizontally)

-

Shell Construction: Carbon Steel (steam shell)

-

Tube & Tube Sheets: 304L Stainless Steel

-

Shell Diameter: 57"

-

Shell Length: 16'

-

Overall Length: 23' 8"

-

Design Pressure & Temperature Ratings:

-

Shell Side:

-

MAWP Internal: 75 PSI / Full Vacuum @ 320°F

-

MAWP External: 15 PSI / Full Vacuum @ 320°F

-

MDMT: 31°F @ 75 PSI

-

-

Tube Side:

-

MAWP Internal: 60 PSI / Full Vacuum @ 320°F

-

MAWP External: 15 PSI / Full Vacuum @ 320°F

-

MDMT: 31°F @ 60 PSI

-

-

-

Previous Use: Ethanol distillation column system

What This Product Might Be Good For

-

Condensation and vaporization duties in distillation or refining operations

-

Ethanol or biofuel processing systems

-

High-efficiency heat recovery from vapor streams

-

Reboiling or preheating processes in chemical or petrochemical plants

-

Integration in food-grade or sanitary steam heating systems

-

Energy optimization in high-throughput processing plants

-

Replacing or upgrading large heat exchanger systems

-

Facilities needing stainless tube integrity with carbon shell economy

-

Heavy-duty steam or liquid heating under controlled pressure

-

Multi-orientation installations in modular process skids

-

tube reboiler

-

heat exchanger

-

stainless tubes

-

304L reboiler

-

ethanol system

-

used reboiler

-

steam exchanger

-

carbon shell

-

shell and tube

-

BEM exchanger

-

used tube reboiler for ethanol

-

shell and tube heat exchanger

-

Heat Transfer Systems reboiler

-

304L stainless tube exchanger

-

carbon steel shell heat exchanger

-

ethanol distillation reboiler

-

BEM style tube exchanger

-

vertical heat exchanger unit

-

reboiler with large surface area

-

7062 sq ft heat transfer unit

-

used Heat Transfer Systems stainless steel tube reboiler heat exchanger

-

7062 sq ft shell and tube exchanger with carbon steel shell and 304L tubes

-

vertical or horizontal reboiler with ethanol distillation column application

-

stainless steel tube heat exchanger with 75 PSI shell rating

-

large reboiler unit for steam condensation or ethanol evaporation

-

process heat exchanger with BEM configuration and dual orientation

-

shell and tube reboiler with full vacuum and high temp capacity

-

industrial stainless reboiler for biofuel or chemical distillation

-

carbon shell with 304L SS internals for sanitary and industrial use

-

used BEM reboiler with 23’8” overall length and 57” shell diameter

-

reboiler

-

exchanger

-

tube

-

shell

-

heat

-

stainless

-

carbon

-

ethanol

-

used

-

vertical

-

buy used reboiler

-

purchase tube heat exchanger

-

buy ethanol system reboiler

-

order stainless steel reboiler

-

used Heat Transfer Systems exchanger

-

purchase shell and tube system

-

buy 7062 sq ft reboiler unit

-

steam heat exchanger for sale

-

vertical reboiler system buy

-

BEM configuration exchanger purchase

-

sell used tube reboiler

-

list Heat Transfer Systems exchanger

-

market stainless ethanol reboiler

-

trade large shell and tube exchanger

-

offer used BEM reboiler

-

list steam processing equipment

-

sell vertical heat exchanger

-

resale carbon shell reboiler system

-

used ethanol distillation exchanger sale

-

used industrial reboiler listing

Used Heat Transfer Systems Inc. Stainless Steel Tube Reboiler/Heat Exchanger. 7062 square foot surface area; 57" diameter; Carbon steel steam shell; 304L stainless steel tubes and tube sheets; 16' shell length; 23'8" overall length; Vertical orientation (can be used horizontal); 75 PSI/FV @ 320F Shell Side (MAWP); 60 PSI/FV @ 320F Tube Side (MAWP); 31 Deg F/75 PSI Shell Side (MDMT); 31 Deg F/60 PSI Tube Side (MDMT); 15 PSI/FV @ 320F Shell Side (MAWP-External); 15 PSI/FV @ 320F Tube Side (MAWP-External). BEM exchanger configuration. S/N #13138-5. NB #2068. Built 2011. Unit is from ethanol distillation column system.

Manufacturer Details

-

Manufacturer: Heat Transfer Systems Inc.

-

Serial Number: 13138-5

-

National Board Number: NB #2068

-

Year Built: 2011

Product Details

-

Type: BEM Configuration Shell & Tube Heat Exchanger / Tube Reboiler

-

Heat Transfer Surface Area: 7,062 sq. ft.

-

Orientation: Vertical (can also be used horizontally)

-

Shell Construction: Carbon Steel (steam shell)

-

Tube & Tube Sheets: 304L Stainless Steel

-

Shell Diameter: 57"

-

Shell Length: 16'

-

Overall Length: 23' 8"

-

Design Pressure & Temperature Ratings:

-

Shell Side:

-

MAWP Internal: 75 PSI / Full Vacuum @ 320°F

-

MAWP External: 15 PSI / Full Vacuum @ 320°F

-

MDMT: 31°F @ 75 PSI

-

-

Tube Side:

-

MAWP Internal: 60 PSI / Full Vacuum @ 320°F

-

MAWP External: 15 PSI / Full Vacuum @ 320°F

-

MDMT: 31°F @ 60 PSI

-

-

-

Previous Use: Ethanol distillation column system

What This Product Might Be Good For

-

Condensation and vaporization duties in distillation or refining operations

-

Ethanol or biofuel processing systems

-

High-efficiency heat recovery from vapor streams

-

Reboiling or preheating processes in chemical or petrochemical plants

-

Integration in food-grade or sanitary steam heating systems

-

Energy optimization in high-throughput processing plants

-

Replacing or upgrading large heat exchanger systems

-

Facilities needing stainless tube integrity with carbon shell economy

-

Heavy-duty steam or liquid heating under controlled pressure

-

Multi-orientation installations in modular process skids

| Manufacturer | Heat Transfer Systems |

| Serial # | 13138-5 |

| Category | Heat Exchangers |

| Subcategory | Shell & Tube Stainless |

-

tube reboiler

-

heat exchanger

-

stainless tubes

-

304L reboiler

-

ethanol system

-

used reboiler

-

steam exchanger

-

carbon shell

-

shell and tube

-

BEM exchanger

-

used tube reboiler for ethanol

-

shell and tube heat exchanger

-

Heat Transfer Systems reboiler

-

304L stainless tube exchanger

-

carbon steel shell heat exchanger

-

ethanol distillation reboiler

-

BEM style tube exchanger

-

vertical heat exchanger unit

-

reboiler with large surface area

-

7062 sq ft heat transfer unit

-

used Heat Transfer Systems stainless steel tube reboiler heat exchanger

-

7062 sq ft shell and tube exchanger with carbon steel shell and 304L tubes

-

vertical or horizontal reboiler with ethanol distillation column application

-

stainless steel tube heat exchanger with 75 PSI shell rating

-

large reboiler unit for steam condensation or ethanol evaporation

-

process heat exchanger with BEM configuration and dual orientation

-

shell and tube reboiler with full vacuum and high temp capacity

-

industrial stainless reboiler for biofuel or chemical distillation

-

carbon shell with 304L SS internals for sanitary and industrial use

-

used BEM reboiler with 23’8” overall length and 57” shell diameter

-

reboiler

-

exchanger

-

tube

-

shell

-

heat

-

stainless

-

carbon

-

ethanol

-

used

-

vertical

-

buy used reboiler

-

purchase tube heat exchanger

-

buy ethanol system reboiler

-

order stainless steel reboiler

-

used Heat Transfer Systems exchanger

-

purchase shell and tube system

-

buy 7062 sq ft reboiler unit

-

steam heat exchanger for sale

-

vertical reboiler system buy

-

BEM configuration exchanger purchase

-

sell used tube reboiler

-

list Heat Transfer Systems exchanger

-

market stainless ethanol reboiler

-

trade large shell and tube exchanger

-

offer used BEM reboiler

-

list steam processing equipment

-

sell vertical heat exchanger

-

resale carbon shell reboiler system

-

used ethanol distillation exchanger sale

-

used industrial reboiler listing

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory