Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

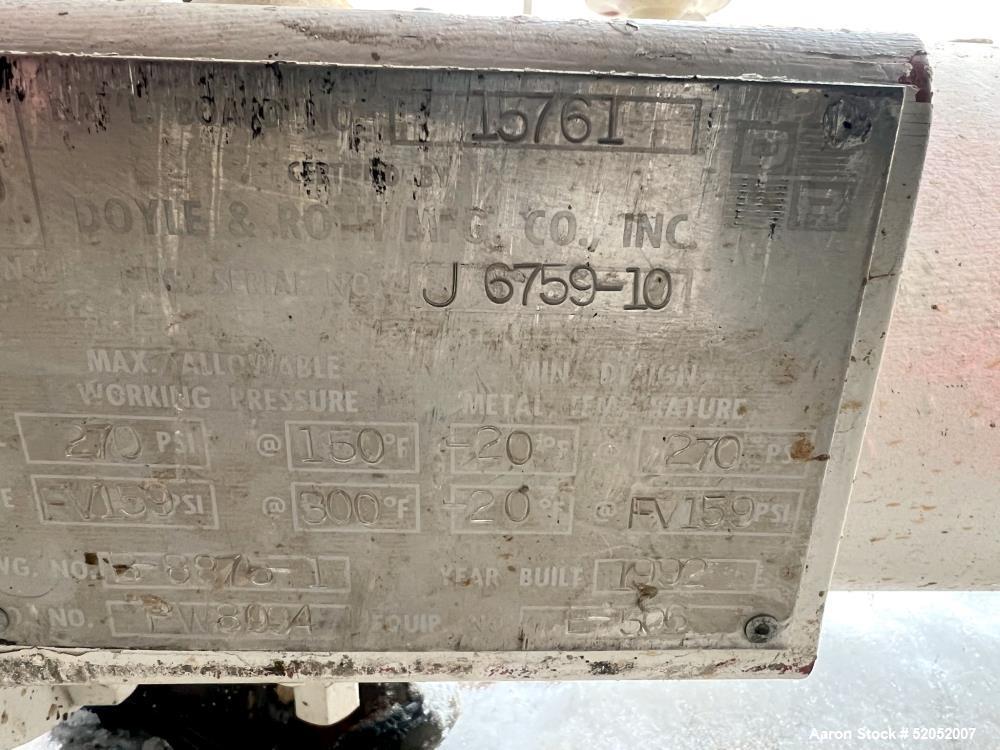

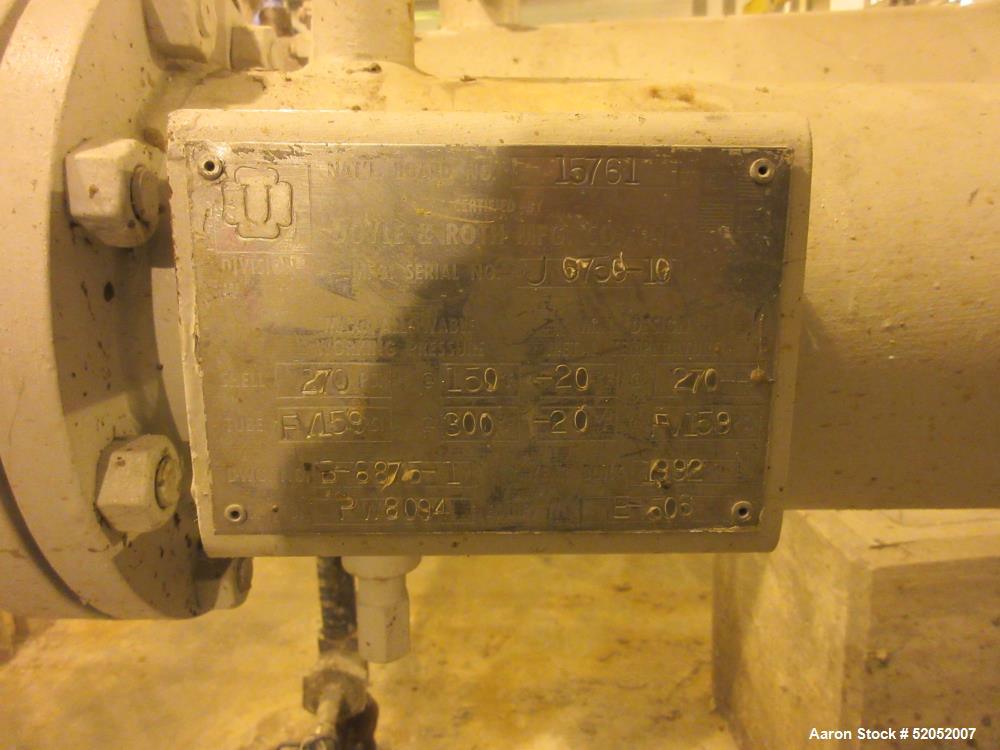

Industrial Heat Exchanger - Doyle & Roth, Carbon Steel Shell, 304 SS Tubes

$1,900.00

Used Doyle & Roth Shell & Tube Heat Exchanger, Horizontal. Approximate 108 Square Feet. Carbon steel shell rated 270 psi at -20 to 150 degrees F. (55) 304 Stainless steel 3/4" diameter x 10' long straight tubes, rated 159 psi/FV at -20 to 300 degrees F. Openings: shell side (2) 1-1/2", tube side (2) 4", (1) 2". Saddle mounted. Serial# J-6750-10, National Board# 15761.

| Manufacturer | Doyle & RothDoyle & Roth |

| Serial # | J-6759-10 |

| Category | Heat ExchangersHeat Exchangers |

| Subcategory | Shell & Tube StainlessShell & Tube Stainless |

| Square Footage | 108 |

| Horizontal or Vertical | Horizontal |

| Shell Material | Carbon Steel |

| Shell Pressure | 270 psi |

| Shell Temperature | -20 to 150 degrees F. |

| Tube Material | 304 Stainless Steel |

| Tube Pressure | 159 psi/FV |

| Tube Temperature | -20 to 300 degrees F. |

| Number of Tube Openings | 55 |

| Size of Tube Openings | 3/4" |

| Head Material | Carbon Steel |

| Mounted | Saddle Mounted |

| National Board No. | 15761 |

| Year Built | 1992 |

| Tube Length | 10' |

Manufacturer Information:

- Manufacturer: Doyle & Roth

- Type: Shell & Tube Heat Exchanger

- Orientation: Horizontal

- Condition: Used

- Heat Transfer Surface Area: 108 Square Feet

- Shell Material: Carbon Steel

- Shell Pressure Rating: 270 PSI at -20 to 150°F

- Tube Material: 304 Stainless Steel

- Tube Specifications:

- (55) 3/4” Diameter x 10’ Long Straight Tubes

- Rated 159 PSI/FV at -20 to 300°F

- Openings:

- Shell Side: (2) 1-1/2” Ports

- Tube Side: (2) 4” Ports, (1) 2” Port

- Mounting: Saddle Mounted

- Serial Number: J-6750-10

- National Board Number: 15761

Description:

The Doyle & Roth Shell & Tube Heat Exchanger is a high-efficiency thermal transfer system, designed for industrial heating and cooling applications in chemical, pharmaceutical, food processing, and HVAC systems.

This horizontal shell & tube heat exchanger has a heat transfer surface area of 108 square feet, ensuring efficient heat exchange performance.

The carbon steel shell is rated at 270 PSI and operates between -20 to 150°F, providing high durability for industrial applications.

Inside, the (55) 304 stainless steel tubes (3/4” diameter x 10’ long) are rated at 159 PSI/FV, handling temperatures from -20 to 300°F, making it ideal for corrosion-resistant and high-pressure applications.

With multiple inlet/outlet ports and a saddle-mounted design, this unit is built for stability and long-term reliability in chemical processing, oil & gas, power plants, and cooling systems.

Specifications:

- Manufacturer: Doyle & Roth

- Type: Shell & Tube Heat Exchanger

- Orientation: Horizontal

- Condition: Used

- Heat Transfer Surface Area: 108 Square Feet

- Shell Material: Carbon Steel

- Shell Pressure Rating: 270 PSI at -20 to 150°F

- Tube Material: 304 Stainless Steel

- Tube Specifications:

- (55) 3/4” Diameter x 10’ Long Straight Tubes

- Rated 159 PSI/FV at -20 to 300°F

- Openings:

- Shell Side: (2) 1-1/2” Ports

- Tube Side: (2) 4” Ports, (1) 2” Port

- Mounting: Saddle Mounted

- Serial Number: J-6750-10

- National Board Number: 15761

Applications:

This Doyle & Roth Shell & Tube Heat Exchanger is ideal for:

- Chemical Processing: Heat transfer in chemical and petrochemical plants

- Pharmaceutical & Biotech Manufacturing: Precision heating and cooling of fluids

- Food & Beverage Processing: Thermal control of liquid ingredients

- HVAC & Cooling Systems: Chilled water and thermal energy management

- Oil & Gas Industry: Cooling lubricants, refining processes, and heat recovery

- Power Plants & Energy Systems: Heat recovery in industrial power generation

- Metal & Manufacturing Industries: Temperature control in metalworking processes

Compatible Products & Uses:

- Industrial cooling and heating applications

- High-pressure heat exchange systems

- Oil and gas processing equipment

- Thermal energy recovery in power plants

- Pharmaceutical and food-grade processing systems

- Corrosion-resistant heat exchangers for chemical applications

- Buy shell and tube heat exchanger

- Sell shell and tube heat exchanger

- Shell and tube heat exchanger for sale

- Shell and tube heat exchanger price

- Best shell and tube heat exchanger supplier

- Where to buy shell and tube heat exchanger

- Where to sell shell and tube heat exchanger

- Shell and tube heat exchanger dealers

- Stainless steel shell and tube heat exchanger

- Carbon steel shell and tube heat exchanger

- High-pressure shell and tube heat exchanger

- Custom shell and tube heat exchanger

- Industrial shell and tube heat exchanger

- Single-pass shell and tube heat exchanger

- Multi-pass shell and tube heat exchanger

- Shell and tube heat exchanger for chemical processing

- Food-grade shell and tube heat exchanger

- Heat exchanger for oil and gas industry

- Pharmaceutical shell and tube heat exchanger

- Marine shell and tube heat exchanger

- HVAC shell and tube heat exchanger

- High-efficiency shell and tube heat exchanger

- shell and tube heat exchanger

- shell and tube heat exchanger

- Best heat exchanger for steam applications

- Large capacity shell and tube heat exchanger

- Compact shell and tube heat exchanger

- Affordable shell and tube heat exchanger

- Shell and tube heat exchanger price comparison

- Best budget shell and tube heat exchanger

- Cost of shell and tube heat exchanger installation

- Cheap heat exchangers for sale

- Buy used shell and tube heat exchanger

- Sell used shell and tube heat exchanger

- Refurbished shell and tube heat exchanger

- Second-hand shell and tube heat exchanger buyers

- Surplus shell and tube heat exchanger for sale

- Shell and tube heat exchanger suppliers near me

- Best shell and tube heat exchanger dealers in city

- Used shell and tube heat exchanger for sale in country

- Local shell and tube heat exchanger buyers and sellers

- Alfa Laval shell and tube heat exchanger suppliers

- Tranter shell and tube heat exchanger dealers

- Kelvion shell and tube heat exchanger distributors

- API Heat Transfer shell and tube heat exchanger for sale

- Custom-built shell and tube heat exchanger

- Heat exchanger with removable tube bundle

- Shell and tube heat exchanger for high-pressure applications

- Heat exchanger for high-temperature applications

- Industrial shell and tube heat exchanger with corrosion resistance

- Best platform to buy shell and tube heat exchanger

- Wholesale shell and tube heat exchanger suppliers

- Industrial shell and tube heat exchanger manufacturers

- Leading shell and tube heat exchanger distributors

- Used shell & tube heat exchanger

- Industrial heat exchanger

- Doyle & Roth heat exchanger

- 108 sq. ft. heat exchanger

- Stainless steel tube heat exchanger

- Carbon steel shell heat exchanger

- Saddle-mounted heat exchanger

- High-pressure heat exchanger

- Used Doyle & Roth equipment

- Industrial heat transfer unit

- Used Doyle & Roth shell & tube heat exchanger for sale

- High-efficiency heat exchanger with 304 stainless tubes

- 108 sq. ft. shell & tube heat exchanger for industrial use

- Used industrial heat exchanger with carbon steel shell

- Doyle & Roth heat exchanger with 3/4” x 10’ stainless tubes

- High-pressure industrial heat exchanger for sale

- Saddle-mounted heat exchanger for chemical processing

- Used shell & tube heat exchanger with multiple inlet/outlet ports

- Industrial cooling heat exchanger for oil & gas applications

- Doyle & Roth heat exchanger with 270 PSI carbon steel shell

- Buy used Doyle & Roth shell & tube heat exchanger with 108 sq. ft. surface area

- Industrial shell & tube heat exchanger for high-pressure applications

- Best used Doyle & Roth heat exchanger for chemical and HVAC industries

- Where to buy a used heat exchanger with stainless steel tubes

- High-efficiency thermal heat exchanger for power plants and cooling systems

- Saddle-mounted industrial heat exchanger for food and beverage processing

- Used shell & tube heat exchanger with carbon steel shell and stainless tubes

- Heavy-duty Doyle & Roth heat exchanger for chemical and manufacturing applications

- Used heat exchanger with 270 PSI carbon steel shell and 159 PSI stainless tubes

- Best price for used industrial shell & tube heat exchangers

- Used Doyle & Roth shell & tube heat exchanger for sale

- Industrial heat exchanger with 108 sq. ft. capacity

- Stainless steel tube heat exchanger with carbon steel shell

- High-pressure industrial heat exchanger for oil & gas

- Used high-efficiency shell & tube heat exchanger

- Saddle-mounted industrial heat exchanger for sale

- Chemical processing heat exchanger with 270 PSI rating

- Best used Doyle & Roth heat exchanger for HVAC applications

- Stainless steel and carbon steel heat exchanger for industrial use

- Large-capacity shell & tube heat exchanger for sale

- Buy used Doyle & Roth heat exchanger

- Sell industrial shell & tube heat exchanger

- Used high-efficiency heat exchanger for sale

- Where to buy Doyle & Roth heat exchangers

- Best price for used industrial heat exchanger

- Large-capacity shell & tube heat exchanger available

- Used stainless steel tube heat exchanger for chemical applications

- Buy industrial heat exchanger with saddle-mounted design

- Used heat exchanger for power plants and HVAC systems

- Industrial thermal heat exchanger with 108 sq. ft. surface area

Used Doyle & Roth Shell & Tube Heat Exchanger, Horizontal. Approximate 108 Square Feet. Carbon steel shell rated 270 psi at -20 to 150 degrees F. (55) 304 Stainless steel 3/4" diameter x 10' long straight tubes, rated 159 psi/FV at -20 to 300 degrees F. Openings: shell side (2) 1-1/2", tube side (2) 4", (1) 2". Saddle mounted. Serial# J-6750-10, National Board# 15761.

Manufacturer Information:

- Manufacturer: Doyle & Roth

- Type: Shell & Tube Heat Exchanger

- Orientation: Horizontal

- Condition: Used

- Heat Transfer Surface Area: 108 Square Feet

- Shell Material: Carbon Steel

- Shell Pressure Rating: 270 PSI at -20 to 150°F

- Tube Material: 304 Stainless Steel

- Tube Specifications:

- (55) 3/4” Diameter x 10’ Long Straight Tubes

- Rated 159 PSI/FV at -20 to 300°F

- Openings:

- Shell Side: (2) 1-1/2” Ports

- Tube Side: (2) 4” Ports, (1) 2” Port

- Mounting: Saddle Mounted

- Serial Number: J-6750-10

- National Board Number: 15761

Description:

The Doyle & Roth Shell & Tube Heat Exchanger is a high-efficiency thermal transfer system, designed for industrial heating and cooling applications in chemical, pharmaceutical, food processing, and HVAC systems.

This horizontal shell & tube heat exchanger has a heat transfer surface area of 108 square feet, ensuring efficient heat exchange performance.

The carbon steel shell is rated at 270 PSI and operates between -20 to 150°F, providing high durability for industrial applications.

Inside, the (55) 304 stainless steel tubes (3/4” diameter x 10’ long) are rated at 159 PSI/FV, handling temperatures from -20 to 300°F, making it ideal for corrosion-resistant and high-pressure applications.

With multiple inlet/outlet ports and a saddle-mounted design, this unit is built for stability and long-term reliability in chemical processing, oil & gas, power plants, and cooling systems.

Specifications:

- Manufacturer: Doyle & Roth

- Type: Shell & Tube Heat Exchanger

- Orientation: Horizontal

- Condition: Used

- Heat Transfer Surface Area: 108 Square Feet

- Shell Material: Carbon Steel

- Shell Pressure Rating: 270 PSI at -20 to 150°F

- Tube Material: 304 Stainless Steel

- Tube Specifications:

- (55) 3/4” Diameter x 10’ Long Straight Tubes

- Rated 159 PSI/FV at -20 to 300°F

- Openings:

- Shell Side: (2) 1-1/2” Ports

- Tube Side: (2) 4” Ports, (1) 2” Port

- Mounting: Saddle Mounted

- Serial Number: J-6750-10

- National Board Number: 15761

Applications:

This Doyle & Roth Shell & Tube Heat Exchanger is ideal for:

- Chemical Processing: Heat transfer in chemical and petrochemical plants

- Pharmaceutical & Biotech Manufacturing: Precision heating and cooling of fluids

- Food & Beverage Processing: Thermal control of liquid ingredients

- HVAC & Cooling Systems: Chilled water and thermal energy management

- Oil & Gas Industry: Cooling lubricants, refining processes, and heat recovery

- Power Plants & Energy Systems: Heat recovery in industrial power generation

- Metal & Manufacturing Industries: Temperature control in metalworking processes

Compatible Products & Uses:

- Industrial cooling and heating applications

- High-pressure heat exchange systems

- Oil and gas processing equipment

- Thermal energy recovery in power plants

- Pharmaceutical and food-grade processing systems

- Corrosion-resistant heat exchangers for chemical applications

| Manufacturer | Doyle & Roth |

| Serial # | J-6759-10 |

| Category | Heat Exchangers |

| Subcategory | Shell & Tube Stainless |

| Square Footage | 108 |

| Horizontal or Vertical | Horizontal |

| Shell Material | Carbon Steel |

| Shell Pressure | 270 psi |

| Shell Temperature | -20 to 150 degrees F. |

| Tube Material | 304 Stainless Steel |

| Tube Pressure | 159 psi/FV |

| Tube Temperature | -20 to 300 degrees F. |

| Number of Tube Openings | 55 |

| Size of Tube Openings | 3/4" |

| Head Material | Carbon Steel |

| Mounted | Saddle Mounted |

| National Board No. | 15761 |

| Year Built | 1992 |

| Tube Length | 10' |

- Buy shell and tube heat exchanger

- Sell shell and tube heat exchanger

- Shell and tube heat exchanger for sale

- Shell and tube heat exchanger price

- Best shell and tube heat exchanger supplier

- Where to buy shell and tube heat exchanger

- Where to sell shell and tube heat exchanger

- Shell and tube heat exchanger dealers

- Stainless steel shell and tube heat exchanger

- Carbon steel shell and tube heat exchanger

- High-pressure shell and tube heat exchanger

- Custom shell and tube heat exchanger

- Industrial shell and tube heat exchanger

- Single-pass shell and tube heat exchanger

- Multi-pass shell and tube heat exchanger

- Shell and tube heat exchanger for chemical processing

- Food-grade shell and tube heat exchanger

- Heat exchanger for oil and gas industry

- Pharmaceutical shell and tube heat exchanger

- Marine shell and tube heat exchanger

- HVAC shell and tube heat exchanger

- High-efficiency shell and tube heat exchanger

- shell and tube heat exchanger

- shell and tube heat exchanger

- Best heat exchanger for steam applications

- Large capacity shell and tube heat exchanger

- Compact shell and tube heat exchanger

- Affordable shell and tube heat exchanger

- Shell and tube heat exchanger price comparison

- Best budget shell and tube heat exchanger

- Cost of shell and tube heat exchanger installation

- Cheap heat exchangers for sale

- Buy used shell and tube heat exchanger

- Sell used shell and tube heat exchanger

- Refurbished shell and tube heat exchanger

- Second-hand shell and tube heat exchanger buyers

- Surplus shell and tube heat exchanger for sale

- Shell and tube heat exchanger suppliers near me

- Best shell and tube heat exchanger dealers in city

- Used shell and tube heat exchanger for sale in country

- Local shell and tube heat exchanger buyers and sellers

- Alfa Laval shell and tube heat exchanger suppliers

- Tranter shell and tube heat exchanger dealers

- Kelvion shell and tube heat exchanger distributors

- API Heat Transfer shell and tube heat exchanger for sale

- Custom-built shell and tube heat exchanger

- Heat exchanger with removable tube bundle

- Shell and tube heat exchanger for high-pressure applications

- Heat exchanger for high-temperature applications

- Industrial shell and tube heat exchanger with corrosion resistance

- Best platform to buy shell and tube heat exchanger

- Wholesale shell and tube heat exchanger suppliers

- Industrial shell and tube heat exchanger manufacturers

- Leading shell and tube heat exchanger distributors

- Used shell & tube heat exchanger

- Industrial heat exchanger

- Doyle & Roth heat exchanger

- 108 sq. ft. heat exchanger

- Stainless steel tube heat exchanger

- Carbon steel shell heat exchanger

- Saddle-mounted heat exchanger

- High-pressure heat exchanger

- Used Doyle & Roth equipment

- Industrial heat transfer unit

- Used Doyle & Roth shell & tube heat exchanger for sale

- High-efficiency heat exchanger with 304 stainless tubes

- 108 sq. ft. shell & tube heat exchanger for industrial use

- Used industrial heat exchanger with carbon steel shell

- Doyle & Roth heat exchanger with 3/4” x 10’ stainless tubes

- High-pressure industrial heat exchanger for sale

- Saddle-mounted heat exchanger for chemical processing

- Used shell & tube heat exchanger with multiple inlet/outlet ports

- Industrial cooling heat exchanger for oil & gas applications

- Doyle & Roth heat exchanger with 270 PSI carbon steel shell

- Buy used Doyle & Roth shell & tube heat exchanger with 108 sq. ft. surface area

- Industrial shell & tube heat exchanger for high-pressure applications

- Best used Doyle & Roth heat exchanger for chemical and HVAC industries

- Where to buy a used heat exchanger with stainless steel tubes

- High-efficiency thermal heat exchanger for power plants and cooling systems

- Saddle-mounted industrial heat exchanger for food and beverage processing

- Used shell & tube heat exchanger with carbon steel shell and stainless tubes

- Heavy-duty Doyle & Roth heat exchanger for chemical and manufacturing applications

- Used heat exchanger with 270 PSI carbon steel shell and 159 PSI stainless tubes

- Best price for used industrial shell & tube heat exchangers

- Used Doyle & Roth shell & tube heat exchanger for sale

- Industrial heat exchanger with 108 sq. ft. capacity

- Stainless steel tube heat exchanger with carbon steel shell

- High-pressure industrial heat exchanger for oil & gas

- Used high-efficiency shell & tube heat exchanger

- Saddle-mounted industrial heat exchanger for sale

- Chemical processing heat exchanger with 270 PSI rating

- Best used Doyle & Roth heat exchanger for HVAC applications

- Stainless steel and carbon steel heat exchanger for industrial use

- Large-capacity shell & tube heat exchanger for sale

- Buy used Doyle & Roth heat exchanger

- Sell industrial shell & tube heat exchanger

- Used high-efficiency heat exchanger for sale

- Where to buy Doyle & Roth heat exchangers

- Best price for used industrial heat exchanger

- Large-capacity shell & tube heat exchanger available

- Used stainless steel tube heat exchanger for chemical applications

- Buy industrial heat exchanger with saddle-mounted design

- Used heat exchanger for power plants and HVAC systems

- Industrial thermal heat exchanger with 108 sq. ft. surface area

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory