Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used GPE Groen DR Series Scraped Surface Heat Exchanger Evaporator, Model DR-36

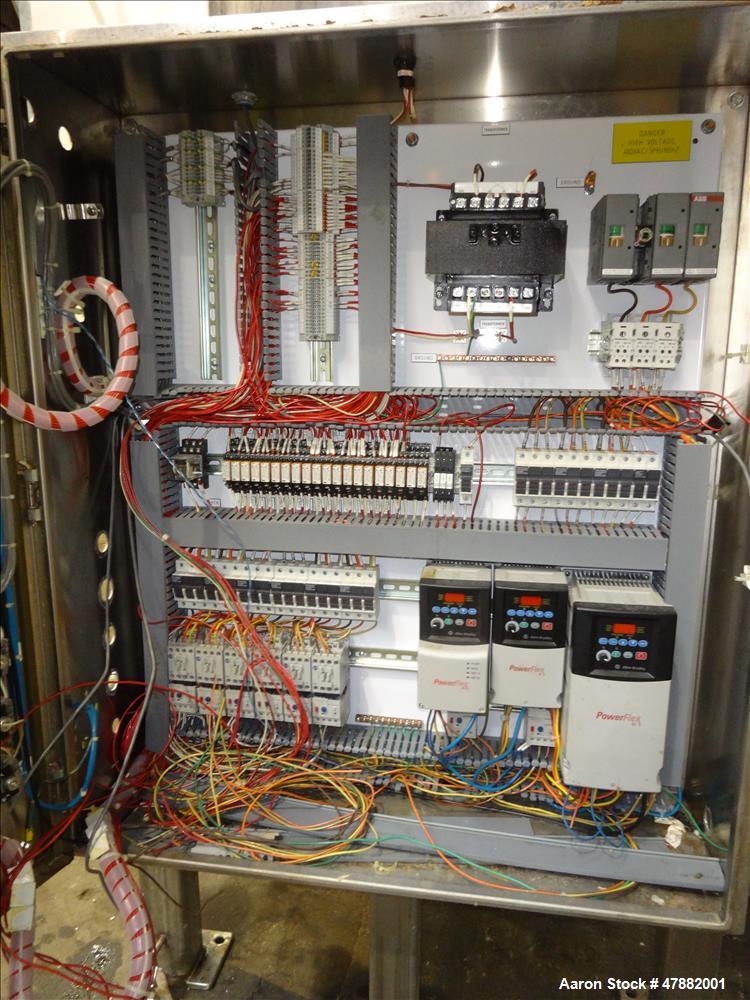

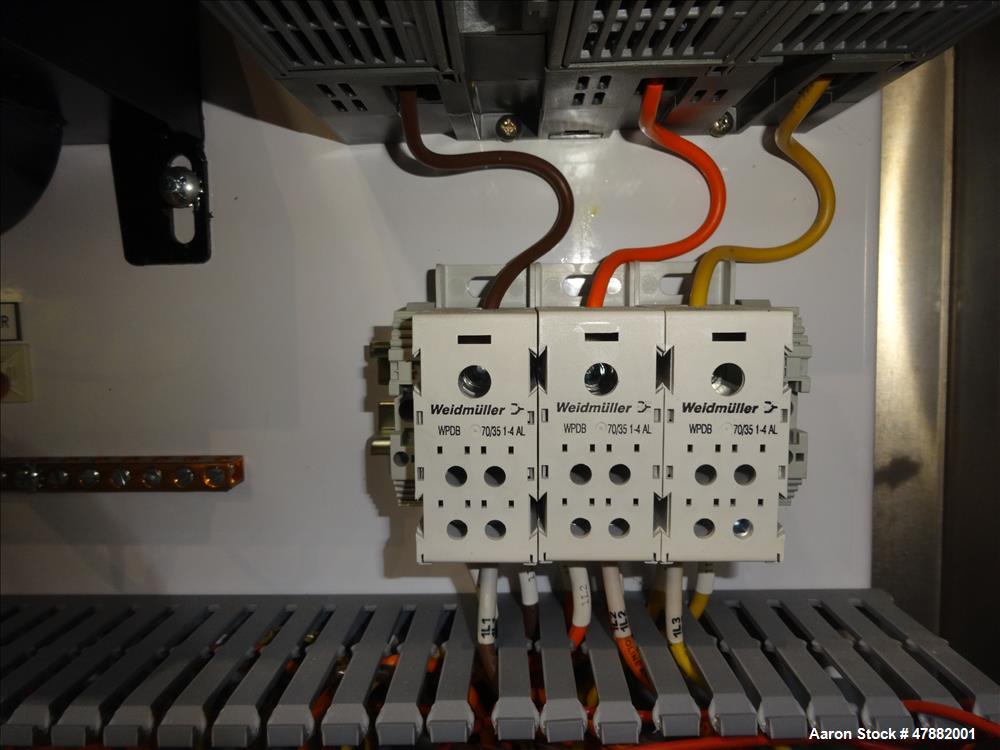

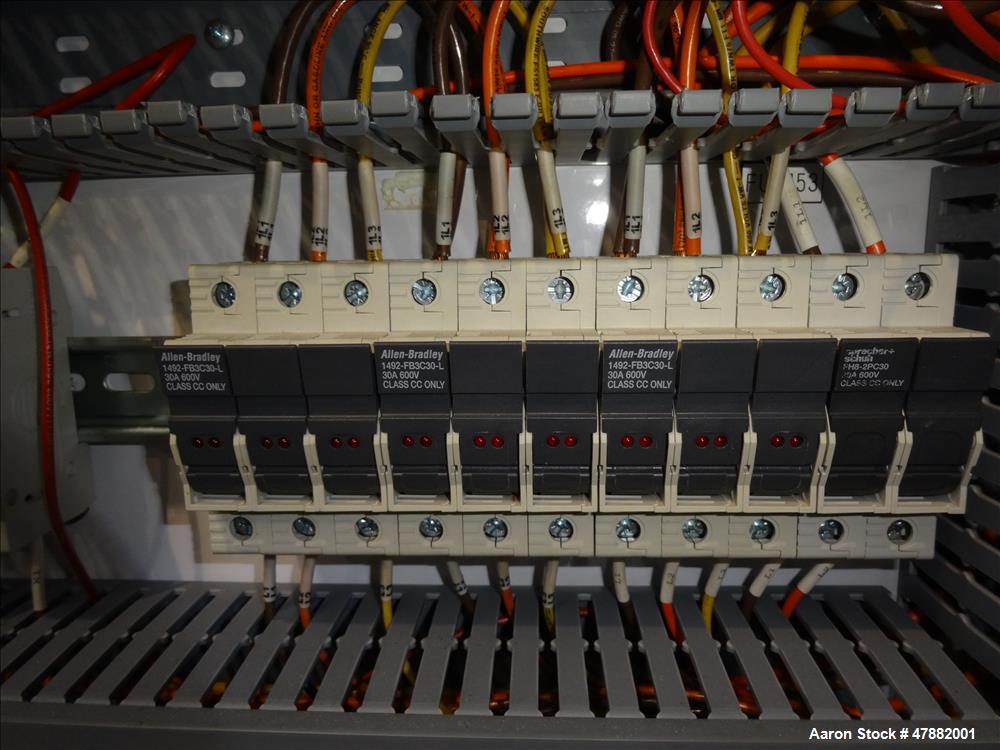

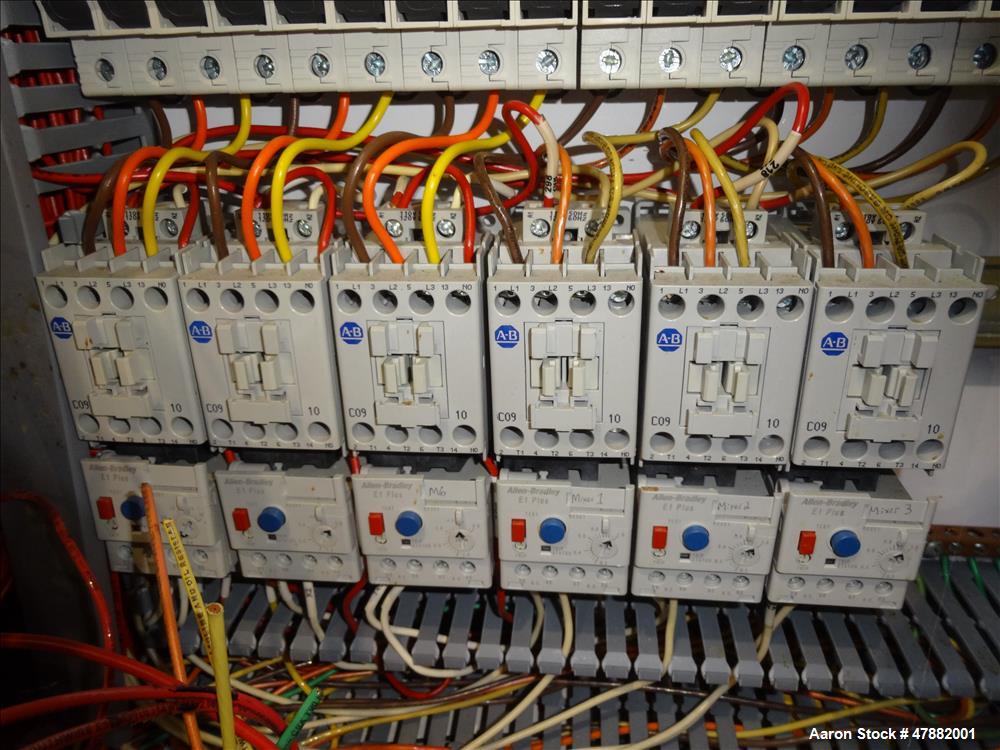

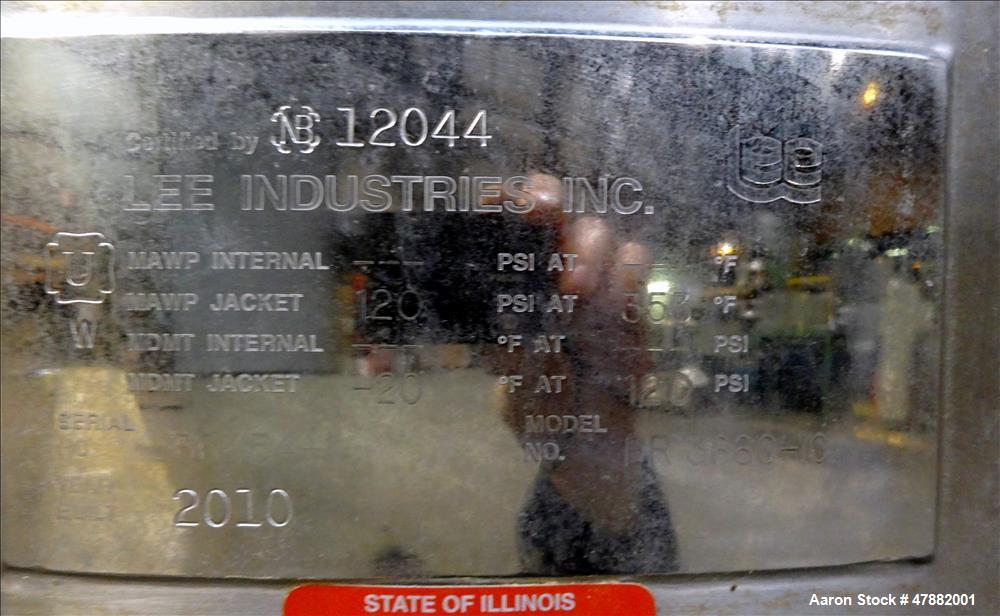

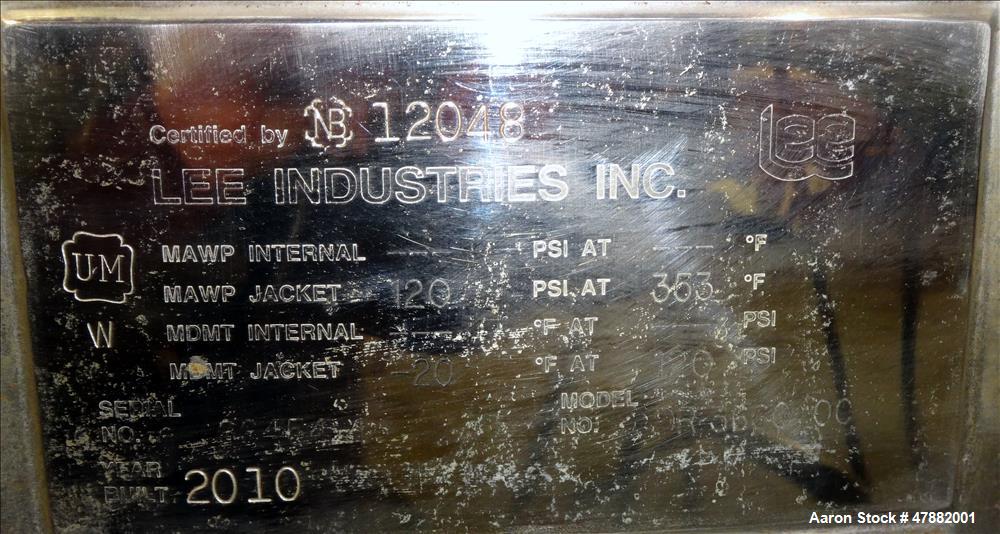

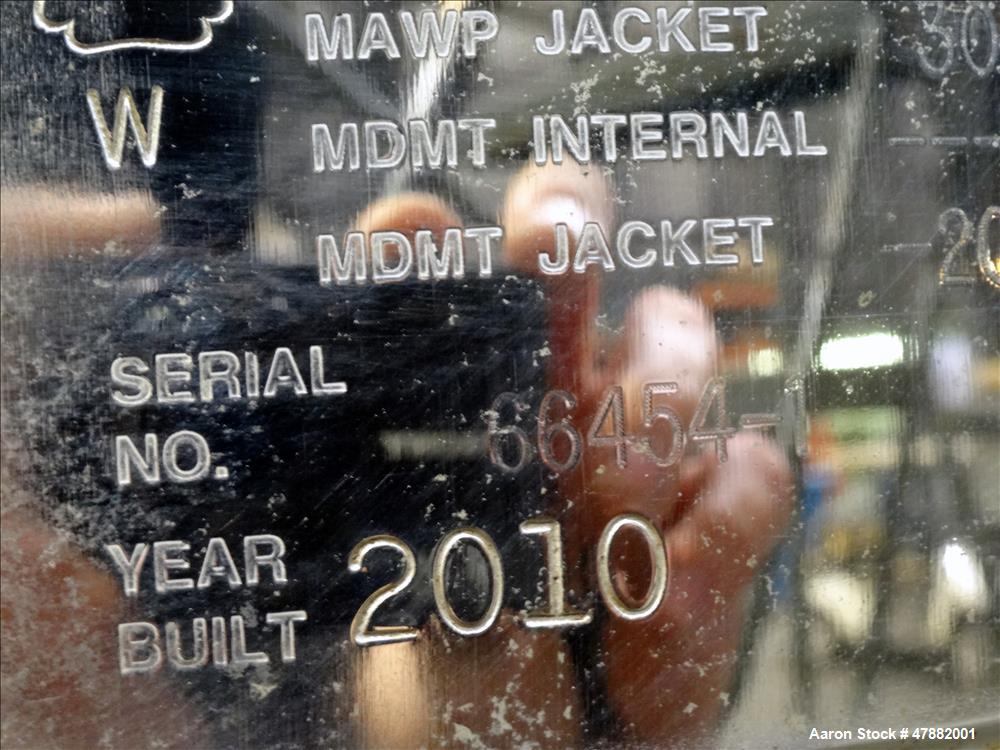

Used GPE Groen DR Series Scraped Surface Heat Exchanger Evaporator, Model DR-3660, Approximately 94 Square Feet, 316 Stainless Steel. The DR Series scraped surface heat exchanger / evaporator is designed to heat, cool, or concentrate a wide variety of products, including highly viscous or heat sensitive products such as caramel. Extremely high heat transfer rates by incorporating jackets on both the inner and outer walls of a narrow product annulus. This dual-jacketed design provides twice the heat transfer area of conventional scraped surface heat exchangers of the same size. During operation, the inner and outer wall of the product annulus are continuously scraped by rotor mounted blades, which prevents sticking or product scorching. These scraper blades also provide even heat transfer and homogeneity of product during continuous processing batch runs. Approximately 36" diameter x 60" straight side, dished bolt on top, flat bottom. Jackets rated 120 psi at -20 to 353 degrees F. and 30 psi at -20 to 275 degrees F. Inner rotor with wiper blades. 2" Bottom inlet, 12" top vapor outlet, 4" top side outlet. Rotor bottom driven by an approximate 7.5 hp, 3/60/230/460 volt motor. Includes a control panel. Mounted on a stainless steel frame. Certified by Lee Industries National Board# 12044, 12048, 12049, serial# 66454-1, built 2010.

Used GPE Groen DR Series Scraped Surface Heat Exchanger Evaporator, Model DR-3660, Approximately 94 Square Feet, 316 Stainless Steel. The DR Series scraped surface heat exchanger / evaporator is designed to heat, cool, or concentrate a wide variety of products, including highly viscous or heat sensitive products such as caramel. Extremely high heat transfer rates by incorporating jackets on both the inner and outer walls of a narrow product annulus. This dual-jacketed design provides twice the heat transfer area of conventional scraped surface heat exchangers of the same size. During operation, the inner and outer wall of the product annulus are continuously scraped by rotor mounted blades, which prevents sticking or product scorching. These scraper blades also provide even heat transfer and homogeneity of product during continuous processing batch runs. Approximately 36" diameter x 60" straight side, dished bolt on top, flat bottom. Jackets rated 120 psi at -20 to 353 degrees F. and 30 psi at -20 to 275 degrees F. Inner rotor with wiper blades. 2" Bottom inlet, 12" top vapor outlet, 4" top side outlet. Rotor bottom driven by an approximate 7.5 hp, 3/60/230/460 volt motor. Includes a control panel. Mounted on a stainless steel frame. Certified by Lee Industries National Board# 12044, 12048, 12049, serial# 66454-1, built 2010.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory