Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

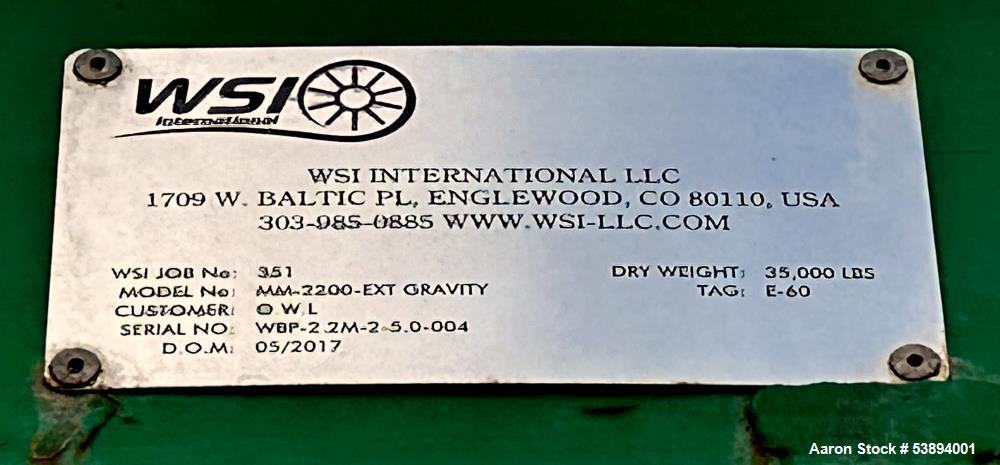

Used WSI 2.2 Meter Extended Gravity Twin Wire Mud Press, Model MM-2200-EXT

Used WSI 2.2 Meter Extended Gravity Twin Wire Mud Press, Model MM-2200-EXT Gravity. Designed and built to receive pre-processed conditioned" mud sludge flow and remove a major portion of the water (Filtrate) from the mud. The average design flow of the 2.2 meter unit is 250 gallons per minute (gpm). Unit functions to dewater sludge by entrapping a uniform thin layer of conditioned sludge between two endless, porous synthetic belts. The feed box receives conditioned mud sludge flow from the upstream sludge conditioning system and distributes it in a uniform layer over the belt as the belt moves the sludge layer forward from feed box onto the gravity zone. The sludge moving through gravity zone is initially dewatered as gravity pulls the filtrate from the sludge layer through the porous belt to the catchment pan below. The wedge zone entraps the gravity thickened sludge forming a sludge sheet between the two belts. Filtrate (liquid extracted from the sludge) is pressed from the entrapped sludge cake as it traverses the length of the wedge zone to the Doctor blades. Mechanical pressure is applied to the belts to force a major portion filtrate from the sludge as it traverses the machine experiencing ever increasing pressure along its path to the dried sludge discharge point. Dry weight is 35,000 lbs; Serial # WBP-2.2M-25.0-004, New in 2017.

| Model | MM-2200-EXT Gravity |

| Serial # | WBP-2.2M-25.0-004 |

| Category | FiltersFilters |

| Subcategory | Horizontal Belt ExtractorHorizontal Belt Extractor |

Manufacturer Information

- Manufacturer: WSI

- Model: MM-2200-EXT Gravity

- Serial Number: WBP-2.2M-25.0-004

- Year: 2017

Description

The WSI 2.2 Meter Extended Gravity Twin Wire Mud Press is an industrial-grade dewatering system designed to remove a significant portion of water from pre-processed, conditioned mud sludge. With an average design flow rate of 250 gallons per minute (GPM), this unit operates by entrapping a uniform layer of conditioned sludge between two endless, porous synthetic belts. It utilizes gravity, mechanical pressure, and filtrate extraction to progressively dewater sludge, ensuring efficient sludge separation and reduction in moisture content before final discharge.

Specifications

- Unit Type: Twin Wire Mud Press

- Processing Width: 2.2 meters

- Flow Rate: 250 GPM

- Belts: Porous synthetic endless belts

- Dewatering Process: Gravity zone, wedge zone, mechanical pressure application

- Filtrate Removal: Via doctor blades and pressure application

- Dry Weight: 35,000 lbs

- Construction: Heavy-duty industrial-grade frame and components

- Function: Water separation and sludge dewatering

Applications

- Wastewater treatment plants

- Industrial sludge dewatering

- Mining and mineral processing

- Oil and gas sludge management

- Paper and pulp industry

- Chemical processing waste management

- Food processing wastewater treatment

- Municipal sludge treatment

- Agricultural waste processing

- Environmental remediation projects

- Mud press

- Sludge dewatering

- Twin wire press

- WSI MM-2200-EXT

- Industrial dewatering

- Sludge filtration

- Wastewater treatment

- Gravity belt press

- Dewatering system

- Filtrate extraction

- Used WSI twin wire mud press

- 2.2-meter gravity belt press

- Industrial sludge dewatering machine

- Heavy-duty sludge filtration press

- Gravity sludge removal system

- Wastewater sludge treatment press

- Belt press for sludge dewatering

- High-capacity mud sludge press

- Twin belt sludge filter press

- Industrial waste dewatering equipment

- Used industrial twin wire gravity mud press for sale

- WSI MM-2200-EXT sludge dewatering press unit

- Heavy-duty sludge dewatering system with gravity filtration

- Best mud press for wastewater sludge treatment

- Industrial twin belt sludge dewatering press machine

- Gravity-fed sludge dewatering system with mechanical pressure

- 2.2-meter wide sludge filtration press for wastewater plants

- High-capacity sludge dewatering equipment for industrial use

- Used sludge treatment press with synthetic porous belts

- Twin wire belt press for mining and industrial sludge management

- Used twin wire mud press

- Industrial sludge dewatering machine

- High-capacity sludge press

- Gravity dewatering belt press

- Filtrate extraction system

- Wastewater treatment sludge press

- WSI MM-2200-EXT for sale

- Belt filter press for sludge removal

- Industrial wastewater filtration equipment

- Used WSI dewatering press

- Buy used sludge dewatering press

- Used twin wire mud press for sale

- WSI MM-2200-EXT price

- Industrial dewatering press supplier

- Purchase heavy-duty sludge press

- Affordable used belt filter press

- High-capacity dewatering machine for sale

- Where to buy industrial sludge press

- Best deals on used sludge presses

- Used industrial filtration equipment

- Sell used twin wire mud press

- Industrial sludge press for sale

- WSI MM-2200-EXT used press seller

- Marketplace for sludge dewatering machines

- Trade-in industrial belt press

- Best resale value for used sludge presses

- Used gravity mud press buyer

- Find buyers for industrial sludge press

- Selling high-capacity dewatering equipment

- Used WSI mud press sale price

Used WSI 2.2 Meter Extended Gravity Twin Wire Mud Press, Model MM-2200-EXT Gravity. Designed and built to receive pre-processed conditioned" mud sludge flow and remove a major portion of the water (Filtrate) from the mud. The average design flow of the 2.2 meter unit is 250 gallons per minute (gpm). Unit functions to dewater sludge by entrapping a uniform thin layer of conditioned sludge between two endless, porous synthetic belts. The feed box receives conditioned mud sludge flow from the upstream sludge conditioning system and distributes it in a uniform layer over the belt as the belt moves the sludge layer forward from feed box onto the gravity zone. The sludge moving through gravity zone is initially dewatered as gravity pulls the filtrate from the sludge layer through the porous belt to the catchment pan below. The wedge zone entraps the gravity thickened sludge forming a sludge sheet between the two belts. Filtrate (liquid extracted from the sludge) is pressed from the entrapped sludge cake as it traverses the length of the wedge zone to the Doctor blades. Mechanical pressure is applied to the belts to force a major portion filtrate from the sludge as it traverses the machine experiencing ever increasing pressure along its path to the dried sludge discharge point. Dry weight is 35,000 lbs; Serial # WBP-2.2M-25.0-004, New in 2017.

Manufacturer Information

- Manufacturer: WSI

- Model: MM-2200-EXT Gravity

- Serial Number: WBP-2.2M-25.0-004

- Year: 2017

Description

The WSI 2.2 Meter Extended Gravity Twin Wire Mud Press is an industrial-grade dewatering system designed to remove a significant portion of water from pre-processed, conditioned mud sludge. With an average design flow rate of 250 gallons per minute (GPM), this unit operates by entrapping a uniform layer of conditioned sludge between two endless, porous synthetic belts. It utilizes gravity, mechanical pressure, and filtrate extraction to progressively dewater sludge, ensuring efficient sludge separation and reduction in moisture content before final discharge.

Specifications

- Unit Type: Twin Wire Mud Press

- Processing Width: 2.2 meters

- Flow Rate: 250 GPM

- Belts: Porous synthetic endless belts

- Dewatering Process: Gravity zone, wedge zone, mechanical pressure application

- Filtrate Removal: Via doctor blades and pressure application

- Dry Weight: 35,000 lbs

- Construction: Heavy-duty industrial-grade frame and components

- Function: Water separation and sludge dewatering

Applications

- Wastewater treatment plants

- Industrial sludge dewatering

- Mining and mineral processing

- Oil and gas sludge management

- Paper and pulp industry

- Chemical processing waste management

- Food processing wastewater treatment

- Municipal sludge treatment

- Agricultural waste processing

- Environmental remediation projects

| Model | MM-2200-EXT Gravity |

| Serial # | WBP-2.2M-25.0-004 |

| Category | Filters |

| Subcategory | Horizontal Belt Extractor |

- Mud press

- Sludge dewatering

- Twin wire press

- WSI MM-2200-EXT

- Industrial dewatering

- Sludge filtration

- Wastewater treatment

- Gravity belt press

- Dewatering system

- Filtrate extraction

- Used WSI twin wire mud press

- 2.2-meter gravity belt press

- Industrial sludge dewatering machine

- Heavy-duty sludge filtration press

- Gravity sludge removal system

- Wastewater sludge treatment press

- Belt press for sludge dewatering

- High-capacity mud sludge press

- Twin belt sludge filter press

- Industrial waste dewatering equipment

- Used industrial twin wire gravity mud press for sale

- WSI MM-2200-EXT sludge dewatering press unit

- Heavy-duty sludge dewatering system with gravity filtration

- Best mud press for wastewater sludge treatment

- Industrial twin belt sludge dewatering press machine

- Gravity-fed sludge dewatering system with mechanical pressure

- 2.2-meter wide sludge filtration press for wastewater plants

- High-capacity sludge dewatering equipment for industrial use

- Used sludge treatment press with synthetic porous belts

- Twin wire belt press for mining and industrial sludge management

- Used twin wire mud press

- Industrial sludge dewatering machine

- High-capacity sludge press

- Gravity dewatering belt press

- Filtrate extraction system

- Wastewater treatment sludge press

- WSI MM-2200-EXT for sale

- Belt filter press for sludge removal

- Industrial wastewater filtration equipment

- Used WSI dewatering press

- Buy used sludge dewatering press

- Used twin wire mud press for sale

- WSI MM-2200-EXT price

- Industrial dewatering press supplier

- Purchase heavy-duty sludge press

- Affordable used belt filter press

- High-capacity dewatering machine for sale

- Where to buy industrial sludge press

- Best deals on used sludge presses

- Used industrial filtration equipment

- Sell used twin wire mud press

- Industrial sludge press for sale

- WSI MM-2200-EXT used press seller

- Marketplace for sludge dewatering machines

- Trade-in industrial belt press

- Best resale value for used sludge presses

- Used gravity mud press buyer

- Find buyers for industrial sludge press

- Selling high-capacity dewatering equipment

- Used WSI mud press sale price

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory