Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Pre-Owned Barr Rosin Fluid Bed Dryer – Natural Gas Heater, 744 lb/hr Evaporation

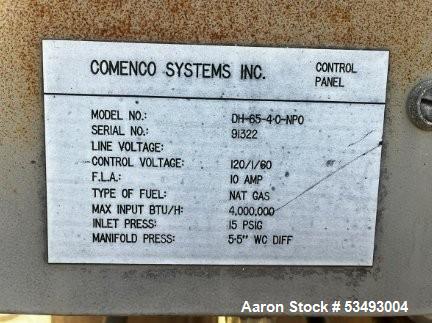

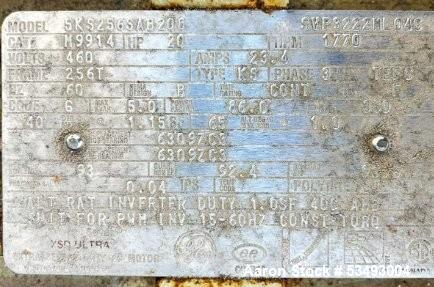

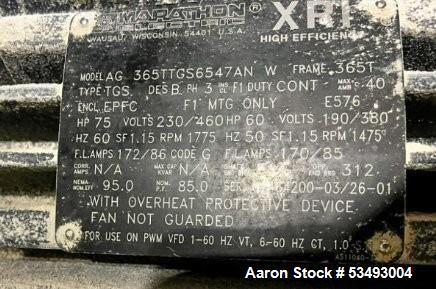

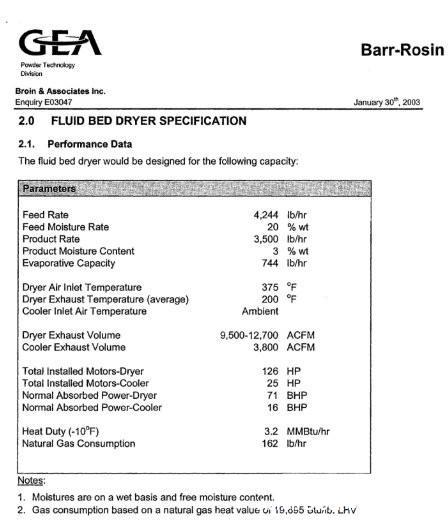

Used Barr Rosin Fluid Bed Dryer. Design rate 4,244 lb/hr with infeed moisture at 20% by wt, and final product output at 3% by wt; 744 lb/hr evaporation capacity; Carbon steel construction; Comenco systems Model DH-65-4-0-NPO natural gas duct heater/burner and control panel, maximum input 4,000,000 BTU/hr; 3 x 12 static fluid bed size; 921-CW Twin Cities blower driven by 1475 RPM, 3/60/460V, 75 HP motor, rated 15,879 cfm at 13" sp; Forced draft fan missing but housing and inlet ducting is still there (previously a 3/60/460V, 1800 RPM, 50 HP Twin Cities blower rated 7897 cfm at 16 sp); Forced Draft Cooler Fan: 3/60/460V, 1800 RPM, 20 HP Twin Cities blower, rated 3039 cfm at 12 sp; (4) Tru-Balance sifter screen units, (2) 40-7/8" sq, and (2) 30-7/8" sq; Ducting included. Built 2003. Last used for corn germ drying - product density at 32 PCF.

| Manufacturer | GEA Barr-RosinGEA Barr-Rosin |

| Category | Dryers - Drying EquipmentDryers - Drying Equipment |

| Subcategory | Fluid Bed ContinuousFluid Bed Continuous |

Manufacturer Information

- Brand: Barr Rosin

- Model: Fluid Bed Dryer

- Construction: Carbon steel

- Built: 2003

- Heat Source: Comenco Systems Model DH-65-4-0-NPO natural gas burner

- Burner Input: 4,000,000 BTU/hr max

Description

The Barr Rosin Fluid Bed Dryer is an industrial-grade fluidized bed drying system with a design rate of 4,244 lb/hr based on an infeed moisture of 20% by weight, producing a dried product with 3% moisture by weight. The system features a 744 lb/hr evaporation capacity, constructed from durable carbon steel, and includes a 3’ x 12’ static fluid bed section.

The heating system is powered by a Comenco Systems natural gas duct heater and burner (4M BTU/hr max), complete with a control panel. Airflow is managed by a 921-CW Twin Cities blower driven by a 75 HP motor, delivering 15,879 CFM at 13" static pressure. While the forced draft fan is missing, the housing and inlet ducting remain, previously supporting a 50 HP blower.

Cooling is handled by a 20 HP forced draft cooler fan with 3,039 CFM at 12" static pressure. Additional components include (4) Tru-Balance sifter screen units in two sizes and all necessary ducting. The unit was last used for corn germ drying with a product density of 32 PCF.

Specifications

- Design Rate: 4,244 lb/hr

- Evaporation Capacity: 744 lb/hr

- Infeed Moisture: 20% by weight

- Output Moisture: 3% by weight

- Dryer Bed Size: 3’ x 12’ static fluid bed

- Construction: Carbon steel

- Heat Source: Comenco Systems Model DH-65-4-0-NPO natural gas heater

- Burner Capacity: 4,000,000 BTU/hr max

- Main Blower:

- 921-CW Twin Cities blower

- 75 HP motor, 1475 RPM

- 15,879 CFM @ 13” SP

- Forced Draft Fan: Missing (previous blower rated 7,897 CFM @ 16” SP, 50 HP)

- Forced Draft Cooler Fan:

- Twin Cities blower

- 20 HP motor, 1800 RPM

- 3,039 CFM @ 12” SP

- Sifters: (4) Tru-Balance sifter screens: (2) 40-7/8" sq, (2) 30-7/8" sq

- Ducting: Included

- Product Density (last use): 32 PCF (corn germ drying)

- Built: 2003

Applications

- Corn germ drying

- Grain and seed drying

- Food processing powder drying

- Agricultural product drying

- Industrial chemical drying

- Nutraceutical and animal feed ingredient drying

Compatible Products & Uses

- Corn germ

- Grains and cereals

- Starches and powders

- Oilseed meals

- Agricultural biomass

- Barr Rosin dryer

- Fluid bed dryer

- Used fluid bed dryer

- Industrial dryer

- Corn germ dryer

- Natural gas dryer

- Large capacity dryer

- Industrial drying equipment

- Blower drying system

- Food processing dryer

- Barr Rosin fluid bed dryer for sale

- Large-scale fluid bed drying system

- Used industrial natural gas dryer

- Fluid bed dryer with 4M BTU burner

- High-volume drying system for corn germ

- Agricultural drying equipment fluid bed

- Carbon steel fluid bed dryer

- Corn germ and grain drying machine

- High capacity blower dryer system

- Industrial powder drying solution

- Buy used Barr Rosin fluid bed dryer with 4,244 lb/hr design rate

- Industrial fluid bed dryer for corn germ and agricultural products

- Used carbon steel fluid bed dryer with natural gas burner

- Large scale industrial drying system with blower and sifter

- Fluid bed dryer with 744 lb/hr evaporation capacity for food products

- Industrial agricultural product dryer with forced draft cooler

- High-capacity grain and seed dryer with sifter screens

- Used fluid bed drying equipment for corn processing facilities

- Heavy-duty industrial fluid bed dryer with ducting included

- Reliable fluid bed dryer for chemical and feed ingredient processing

- Used Barr Rosin fluid bed dryer

- Industrial fluid bed dryer

- Corn germ drying equipment

- Natural gas fluid bed dryer

- High capacity industrial dryer

- Agricultural fluid bed dryer

- Large blower dryer system

- Used food processing dryer

- Heavy-duty fluid bed drying machine

- Industrial powder drying system

- Buy used fluid bed dryer

- Sell industrial fluid bed dryer

- Used drying equipment for sale

- Large capacity industrial dryers

- Agricultural dryer equipment marketplace

- Used blower dryers for sale

- Industrial drying machine suppliers

- Buy and sell fluid bed dryers

- Best deals on used fluid bed dryers

- Industrial dryer marketplace

Used Barr Rosin Fluid Bed Dryer. Design rate 4,244 lb/hr with infeed moisture at 20% by wt, and final product output at 3% by wt; 744 lb/hr evaporation capacity; Carbon steel construction; Comenco systems Model DH-65-4-0-NPO natural gas duct heater/burner and control panel, maximum input 4,000,000 BTU/hr; 3 x 12 static fluid bed size; 921-CW Twin Cities blower driven by 1475 RPM, 3/60/460V, 75 HP motor, rated 15,879 cfm at 13" sp; Forced draft fan missing but housing and inlet ducting is still there (previously a 3/60/460V, 1800 RPM, 50 HP Twin Cities blower rated 7897 cfm at 16 sp); Forced Draft Cooler Fan: 3/60/460V, 1800 RPM, 20 HP Twin Cities blower, rated 3039 cfm at 12 sp; (4) Tru-Balance sifter screen units, (2) 40-7/8" sq, and (2) 30-7/8" sq; Ducting included. Built 2003. Last used for corn germ drying - product density at 32 PCF.

Manufacturer Information

- Brand: Barr Rosin

- Model: Fluid Bed Dryer

- Construction: Carbon steel

- Built: 2003

- Heat Source: Comenco Systems Model DH-65-4-0-NPO natural gas burner

- Burner Input: 4,000,000 BTU/hr max

Description

The Barr Rosin Fluid Bed Dryer is an industrial-grade fluidized bed drying system with a design rate of 4,244 lb/hr based on an infeed moisture of 20% by weight, producing a dried product with 3% moisture by weight. The system features a 744 lb/hr evaporation capacity, constructed from durable carbon steel, and includes a 3’ x 12’ static fluid bed section.

The heating system is powered by a Comenco Systems natural gas duct heater and burner (4M BTU/hr max), complete with a control panel. Airflow is managed by a 921-CW Twin Cities blower driven by a 75 HP motor, delivering 15,879 CFM at 13" static pressure. While the forced draft fan is missing, the housing and inlet ducting remain, previously supporting a 50 HP blower.

Cooling is handled by a 20 HP forced draft cooler fan with 3,039 CFM at 12" static pressure. Additional components include (4) Tru-Balance sifter screen units in two sizes and all necessary ducting. The unit was last used for corn germ drying with a product density of 32 PCF.

Specifications

- Design Rate: 4,244 lb/hr

- Evaporation Capacity: 744 lb/hr

- Infeed Moisture: 20% by weight

- Output Moisture: 3% by weight

- Dryer Bed Size: 3’ x 12’ static fluid bed

- Construction: Carbon steel

- Heat Source: Comenco Systems Model DH-65-4-0-NPO natural gas heater

- Burner Capacity: 4,000,000 BTU/hr max

- Main Blower:

- 921-CW Twin Cities blower

- 75 HP motor, 1475 RPM

- 15,879 CFM @ 13” SP

- Forced Draft Fan: Missing (previous blower rated 7,897 CFM @ 16” SP, 50 HP)

- Forced Draft Cooler Fan:

- Twin Cities blower

- 20 HP motor, 1800 RPM

- 3,039 CFM @ 12” SP

- Sifters: (4) Tru-Balance sifter screens: (2) 40-7/8" sq, (2) 30-7/8" sq

- Ducting: Included

- Product Density (last use): 32 PCF (corn germ drying)

- Built: 2003

Applications

- Corn germ drying

- Grain and seed drying

- Food processing powder drying

- Agricultural product drying

- Industrial chemical drying

- Nutraceutical and animal feed ingredient drying

Compatible Products & Uses

- Corn germ

- Grains and cereals

- Starches and powders

- Oilseed meals

- Agricultural biomass

| Manufacturer | GEA Barr-Rosin |

| Category | Dryers - Drying Equipment |

| Subcategory | Fluid Bed Continuous |

- Barr Rosin dryer

- Fluid bed dryer

- Used fluid bed dryer

- Industrial dryer

- Corn germ dryer

- Natural gas dryer

- Large capacity dryer

- Industrial drying equipment

- Blower drying system

- Food processing dryer

- Barr Rosin fluid bed dryer for sale

- Large-scale fluid bed drying system

- Used industrial natural gas dryer

- Fluid bed dryer with 4M BTU burner

- High-volume drying system for corn germ

- Agricultural drying equipment fluid bed

- Carbon steel fluid bed dryer

- Corn germ and grain drying machine

- High capacity blower dryer system

- Industrial powder drying solution

- Buy used Barr Rosin fluid bed dryer with 4,244 lb/hr design rate

- Industrial fluid bed dryer for corn germ and agricultural products

- Used carbon steel fluid bed dryer with natural gas burner

- Large scale industrial drying system with blower and sifter

- Fluid bed dryer with 744 lb/hr evaporation capacity for food products

- Industrial agricultural product dryer with forced draft cooler

- High-capacity grain and seed dryer with sifter screens

- Used fluid bed drying equipment for corn processing facilities

- Heavy-duty industrial fluid bed dryer with ducting included

- Reliable fluid bed dryer for chemical and feed ingredient processing

- Used Barr Rosin fluid bed dryer

- Industrial fluid bed dryer

- Corn germ drying equipment

- Natural gas fluid bed dryer

- High capacity industrial dryer

- Agricultural fluid bed dryer

- Large blower dryer system

- Used food processing dryer

- Heavy-duty fluid bed drying machine

- Industrial powder drying system

- Buy used fluid bed dryer

- Sell industrial fluid bed dryer

- Used drying equipment for sale

- Large capacity industrial dryers

- Agricultural dryer equipment marketplace

- Used blower dryers for sale

- Industrial drying machine suppliers

- Buy and sell fluid bed dryers

- Best deals on used fluid bed dryers

- Industrial dryer marketplace

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory