Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Pallmann IPA400/40 Agglomerator – 250 kW | LDPE HDPE PP | With Zerma 700/1000 Granulator & Cyclone Separator

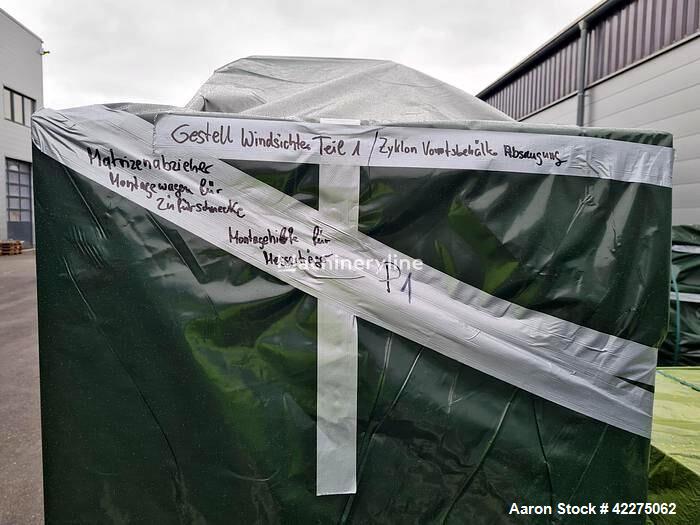

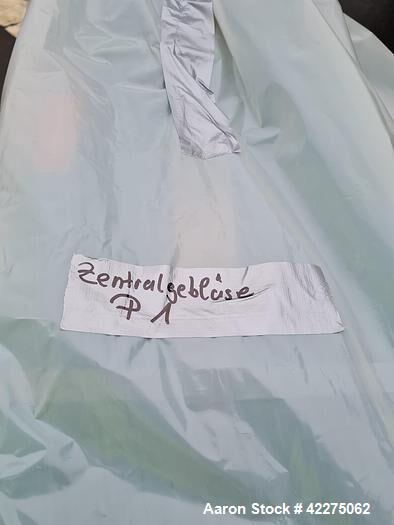

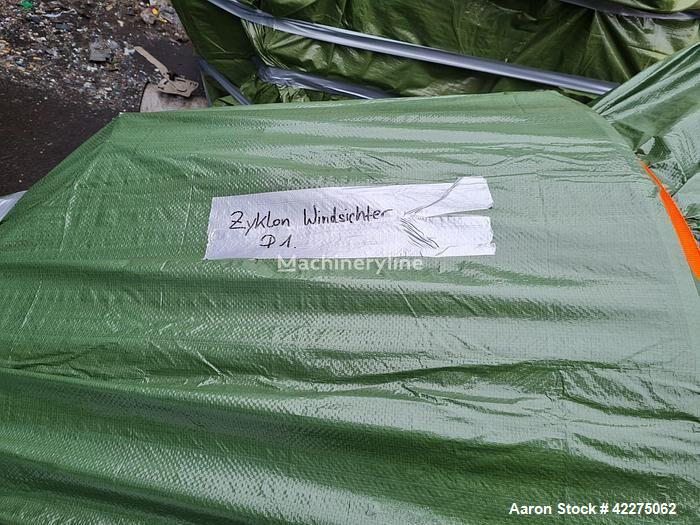

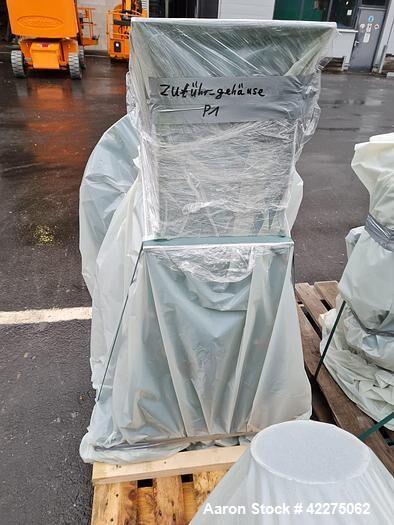

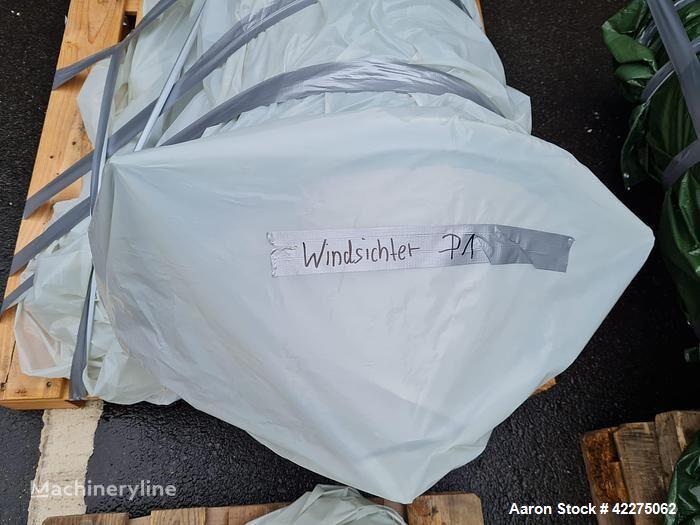

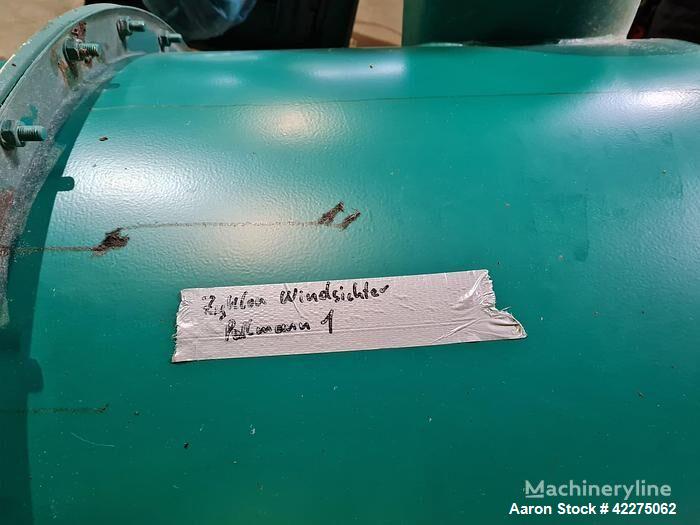

Used Pallmann Agglomerator, Model IPA400/40. For LDPE HDPE LLDPE PP, etc. 250 kw (335hp) drive on agglomerator 18,5 kw (24.8hp) drive on vent 55 kw drive on granulator The supply includes : ZERMA GRANULATOR 700/1000 (27.56"/39.37") cyclone fine separator 400V 3 ph.50Hz. Our freight specialists can assist you with door to door transportation and all customs documents needed to make the process go as smoothly as possible.

| Manufacturer | PallmannPallmann |

| Model | IPA400/40 |

| Category | Dryers - Drying EquipmentDryers - Drying Equipment |

| Subcategory | Fluid Bed ContinuousFluid Bed Continuous |

Manufacturer Information:

-

Brand: Pallmann

-

Model: IPA400/40

-

Type: Agglomerator System

-

Condition: Used

-

Power Supply: 400V, 3 Phase, 50 Hz

Description:

This Used Pallmann Agglomerator System, Model IPA400/40, is a heavy-duty plastic densifying system designed for processing thermoplastics like LDPE, HDPE, LLDPE, and PP. It features a powerful 250 kW (335 HP) main agglomerator drive, with additional drives for venting (18.5 kW) and downstream granulation (55 kW).

This system is offered as a complete setup, including a ZERMA Granulator Model 700/1000 (27.56" x 39.37") and a cyclone fine separator for high-efficiency output quality. Ideal for film, sheet, fiber, and regrind recycling, this unit transforms loose materials into dense, flowable granules ready for extrusion, compounding, or direct reuse.

Specifications:

-

Agglomerator Model: Pallmann IPA400/40

-

Agglomerator Drive Motor: 250 kW (335 HP)

-

Ventilation Drive Motor: 18.5 kW (24.8 HP)

-

Granulator Drive Motor: 55 kW

-

Granulator: Zerma 700/1000

-

Rotor Size: 27.56" x 39.37" (700 x 1000 mm)

-

-

Separator: Cyclone fine separator included

-

Voltage: 400V

-

Frequency: 50 Hz

-

Phase: 3 Phase

-

Condition: Used

Features:

-

Designed for LDPE, HDPE, LLDPE, PP, and similar thermoplastics

-

High-torque 250 kW agglomerator for densifying soft plastics

-

Zerma granulator for precision downstream size reduction

-

Cyclone separator ensures consistent and clean final granulate

-

Suitable for film, fiber, sheet, and light regrind recycling

-

Robust build quality for continuous operation in industrial environments

-

Integrated system ready for installation and immediate production

-

Reduces bulk density, improves flowability, and preps material for extrusion or pelletizing

Applications:

-

Post-consumer film recycling

-

In-house LDPE/HDPE scrap densification

-

Woven bag and big bag recycling

-

Plastic packaging and sheet recycling

-

Compounder prep for light plastic waste

-

Fiber and foam scrap reclamation

-

Plastic reclaim before extrusion or pelletizing

What might this be used for?

-

Densifying soft plastic film waste into flowable agglomerates

-

Preparing plastic materials for extrusion or compounding

-

Recovering and recycling post-industrial polyethylene and polypropylene waste

-

Replacing inefficient shredding/granulation processes with one-step densification and size reduction

-

Supporting closed-loop plastic recycling within production facilities

-

Feeding reprocessed material into pelletizing lines or extruders

-

Reducing storage and transport volume of low-bulk-density film waste

-

Upgrading a recycling line with a high-capacity agglomerator system

-

Minimizing fines and dust with integrated cyclone fine separation

-

Pallmann agglomerator

-

Used agglomerator

-

LDPE recycling

-

Plastic densifier

-

Zerma granulator

-

Cyclone separator

-

Plastic recycler

-

HDPE agglomerator

-

Film recycler

-

Agglomeration system

-

Used Pallmann IPA400/40 agglomerator

-

LDPE HDPE PP plastic recycling system

-

Plastic agglomerator with granulator

-

Zerma 700/1000 included

-

250 kW plastic agglomeration unit

-

Complete plastic recycling line used

-

Cyclone separator with granulator

-

High-power plastic recycling equipment

-

Used film and sheet densifier

-

Industrial plastic reclaimer system

-

Used Pallmann IPA400/40 agglomerator system with 250 kW motor, Zerma 700/1000 granulator, and cyclone separator

-

Industrial plastic densifier for LDPE, HDPE, LLDPE, and PP with venting and granulation stages

-

Plastic film, sheet, and fiber recycling system with high-output agglomeration and granulation

-

Heavy-duty Pallmann agglomerator with integrated cyclone separator and granulator for regrind prep

-

Complete thermoplastic recycling system for reducing volume and preparing material for extrusion

-

Used Pallmann plastic recycling line with 400V 3-phase motors for continuous production

-

Film recycling system with integrated cyclone separator and fine particle removal

-

LDPE and PP waste processing line with heavy-duty granulation and agglomeration

-

Second-hand plastic recycling system with 250 kW agglomerator and downstream size reducer

-

Turnkey soft plastic reprocessing solution with energy-efficient densification and air separation

-

Buy used agglomerator

-

Plastic film recycler for sale

-

Pallmann IPA400/40 purchase

-

Buy LDPE plastic recycling system

-

Used plastic agglomerator buy

-

Granulator and cyclone separator system

-

Zerma 700/1000 for sale

-

Plastic waste densifier buy

-

Film and bag recycler used

-

Complete plastic reclaim line

-

Sell used agglomerator

-

List Pallmann IPA400/40 for sale

-

Resell plastic recycling system

-

Liquidate Zerma granulator package

-

Agglomeration system resale

-

Used plastic reclaimer for sale

-

Second-hand film recycler

-

Sell LDPE HDPE recycling equipment

-

Used cyclone separator system

-

Plastic processing equipment listing

Used Pallmann Agglomerator, Model IPA400/40. For LDPE HDPE LLDPE PP, etc. 250 kw (335hp) drive on agglomerator 18,5 kw (24.8hp) drive on vent 55 kw drive on granulator The supply includes : ZERMA GRANULATOR 700/1000 (27.56"/39.37") cyclone fine separator 400V 3 ph.50Hz. Our freight specialists can assist you with door to door transportation and all customs documents needed to make the process go as smoothly as possible.

Manufacturer Information:

-

Brand: Pallmann

-

Model: IPA400/40

-

Type: Agglomerator System

-

Condition: Used

-

Power Supply: 400V, 3 Phase, 50 Hz

Description:

This Used Pallmann Agglomerator System, Model IPA400/40, is a heavy-duty plastic densifying system designed for processing thermoplastics like LDPE, HDPE, LLDPE, and PP. It features a powerful 250 kW (335 HP) main agglomerator drive, with additional drives for venting (18.5 kW) and downstream granulation (55 kW).

This system is offered as a complete setup, including a ZERMA Granulator Model 700/1000 (27.56" x 39.37") and a cyclone fine separator for high-efficiency output quality. Ideal for film, sheet, fiber, and regrind recycling, this unit transforms loose materials into dense, flowable granules ready for extrusion, compounding, or direct reuse.

Specifications:

-

Agglomerator Model: Pallmann IPA400/40

-

Agglomerator Drive Motor: 250 kW (335 HP)

-

Ventilation Drive Motor: 18.5 kW (24.8 HP)

-

Granulator Drive Motor: 55 kW

-

Granulator: Zerma 700/1000

-

Rotor Size: 27.56" x 39.37" (700 x 1000 mm)

-

-

Separator: Cyclone fine separator included

-

Voltage: 400V

-

Frequency: 50 Hz

-

Phase: 3 Phase

-

Condition: Used

Features:

-

Designed for LDPE, HDPE, LLDPE, PP, and similar thermoplastics

-

High-torque 250 kW agglomerator for densifying soft plastics

-

Zerma granulator for precision downstream size reduction

-

Cyclone separator ensures consistent and clean final granulate

-

Suitable for film, fiber, sheet, and light regrind recycling

-

Robust build quality for continuous operation in industrial environments

-

Integrated system ready for installation and immediate production

-

Reduces bulk density, improves flowability, and preps material for extrusion or pelletizing

Applications:

-

Post-consumer film recycling

-

In-house LDPE/HDPE scrap densification

-

Woven bag and big bag recycling

-

Plastic packaging and sheet recycling

-

Compounder prep for light plastic waste

-

Fiber and foam scrap reclamation

-

Plastic reclaim before extrusion or pelletizing

What might this be used for?

-

Densifying soft plastic film waste into flowable agglomerates

-

Preparing plastic materials for extrusion or compounding

-

Recovering and recycling post-industrial polyethylene and polypropylene waste

-

Replacing inefficient shredding/granulation processes with one-step densification and size reduction

-

Supporting closed-loop plastic recycling within production facilities

-

Feeding reprocessed material into pelletizing lines or extruders

-

Reducing storage and transport volume of low-bulk-density film waste

-

Upgrading a recycling line with a high-capacity agglomerator system

-

Minimizing fines and dust with integrated cyclone fine separation

| Manufacturer | Pallmann |

| Model | IPA400/40 |

| Category | Dryers - Drying Equipment |

| Subcategory | Fluid Bed Continuous |

-

Pallmann agglomerator

-

Used agglomerator

-

LDPE recycling

-

Plastic densifier

-

Zerma granulator

-

Cyclone separator

-

Plastic recycler

-

HDPE agglomerator

-

Film recycler

-

Agglomeration system

-

Used Pallmann IPA400/40 agglomerator

-

LDPE HDPE PP plastic recycling system

-

Plastic agglomerator with granulator

-

Zerma 700/1000 included

-

250 kW plastic agglomeration unit

-

Complete plastic recycling line used

-

Cyclone separator with granulator

-

High-power plastic recycling equipment

-

Used film and sheet densifier

-

Industrial plastic reclaimer system

-

Used Pallmann IPA400/40 agglomerator system with 250 kW motor, Zerma 700/1000 granulator, and cyclone separator

-

Industrial plastic densifier for LDPE, HDPE, LLDPE, and PP with venting and granulation stages

-

Plastic film, sheet, and fiber recycling system with high-output agglomeration and granulation

-

Heavy-duty Pallmann agglomerator with integrated cyclone separator and granulator for regrind prep

-

Complete thermoplastic recycling system for reducing volume and preparing material for extrusion

-

Used Pallmann plastic recycling line with 400V 3-phase motors for continuous production

-

Film recycling system with integrated cyclone separator and fine particle removal

-

LDPE and PP waste processing line with heavy-duty granulation and agglomeration

-

Second-hand plastic recycling system with 250 kW agglomerator and downstream size reducer

-

Turnkey soft plastic reprocessing solution with energy-efficient densification and air separation

-

Buy used agglomerator

-

Plastic film recycler for sale

-

Pallmann IPA400/40 purchase

-

Buy LDPE plastic recycling system

-

Used plastic agglomerator buy

-

Granulator and cyclone separator system

-

Zerma 700/1000 for sale

-

Plastic waste densifier buy

-

Film and bag recycler used

-

Complete plastic reclaim line

-

Sell used agglomerator

-

List Pallmann IPA400/40 for sale

-

Resell plastic recycling system

-

Liquidate Zerma granulator package

-

Agglomeration system resale

-

Used plastic reclaimer for sale

-

Second-hand film recycler

-

Sell LDPE HDPE recycling equipment

-

Used cyclone separator system

-

Plastic processing equipment listing

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory