Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Thermal Processing Solutions 36" Indirectly Heated Electric Rotary Calciner with 24" Convective Rotary Cooler

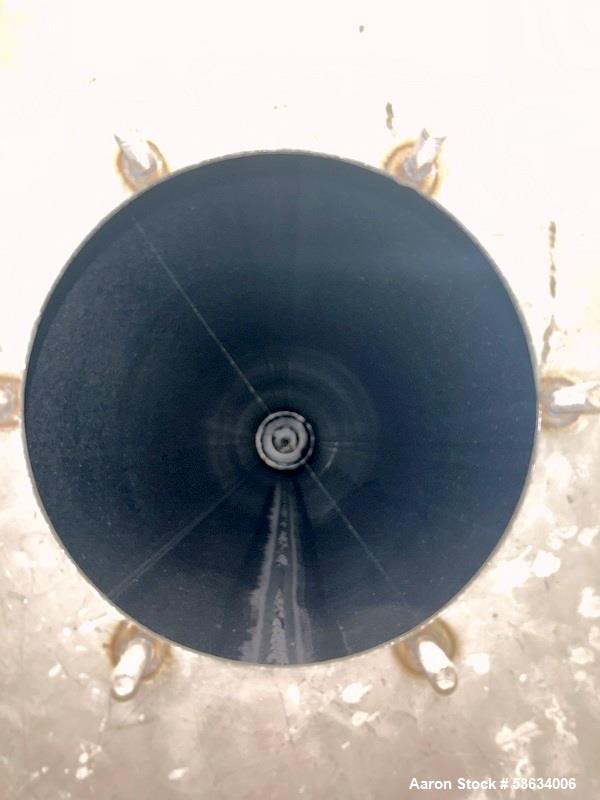

Used Thermal Processing Solutions 36" diameter Indirectly Heated Electric Rotary Calciner with Convective Rotary Cooler 24" diameter X 21-0". Calciner is approximately 36" diameter X 20' heated furnace zone X 35 long overall; 21-0" RA253MA furnace section that extends 6" out of each end of the furnace, and 300 series stainless steel ends, suitable for 1000 degree C operation. The cylinder has seal welded Blanchard ground fixed seal rings if an upgrade to a bellows type seal is needed; These are welded/X-ray inspected as per ASME Sec VIII unstamped vessel construction; Furnace casing is 9" thick Fiberfrax 2200 Dura blanket modules; Zone divider walls are Fiberfrax board; (2) thermocouple assemblies per zone; Heating elements are SiC ceramic, 1600 degrees C continuous duty construction; Heating element access is available on the sides of the furnace. Calciner is complete with freestanding 500 amp power/control panels using Watlow SCRs , F4 PID loop controllers with communication options and EZZone; Watlow High Limit controllers, each monitoring an independent furnace thermocouple in each zone; Includes variable slope support stands with an SCR drive and a dc variable speed screw conveyor; Calciner is set up to discharge directly into a 24" diameter x 21ft indirect convective Cooler, then optionally into a Kason Screener into a bulk bag and oversize/foreign object container.

Manufacturer Information:

- Manufacturer: Thermal Processing Solutions

- Equipment Type: Indirectly Heated Electric Rotary Calciner with Convective Rotary Cooler

- Condition: Used

- Construction Standard: ASME Sec VIII Unstamped Vessel

Manufacturing Data:

Rotary Calciner:

- Diameter: 36 inches

- Heated Furnace Zone Length: 20 feet

- Overall Length: 35 feet

- Furnace Material: RA253MA furnace section (extends 6" out of each end)

- End Material: 300 Series Stainless Steel

- Operating Temperature: Up to 1000°C

- Sealing System:

- Blanchard ground fixed seal rings

- Welded/X-ray inspected per ASME Sec VIII (unstamped)

- Optional upgrade to bellows-type seal

- Furnace Casing: 9-inch thick Fiberfrax 2200 Dura blanket modules

- Zone Divider Walls: Fiberfrax board

- Heating Elements:

- SiC ceramic heating elements

- 1600°C continuous duty construction

- Side access for element replacement

- Temperature Monitoring:

- (2) Thermocouple assemblies per zone

Power & Control Panel:

- Power Capacity: 500 Amp freestanding control panel

- Control System:

- Watlow SCRs

- F4 PID loop controllers (with communication options and EZZone)

- Watlow High Limit controllers (independent monitoring per zone)

Rotary Cooler:

- Diameter: 24 inches

- Length: 21 feet

- Cooling Method: Indirect Convective Cooling

- Additional Components:

- Variable slope support stands

- SCR drive & DC variable speed screw conveyor

- Direct discharge to Kason Screener

- Bulk bagging and oversize/foreign object containment options

Description:

The Used Thermal Processing Solutions 36" Indirectly Heated Electric Rotary Calciner is a high-temperature material processing system designed for precise thermal treatment of powders, granules, and specialty materials in metallurgy, ceramics, chemicals, and advanced materials production.

With an RA253MA furnace section, Blanchard ground fixed seal rings, and a 9" thick Fiberfrax insulation system, this electric rotary calciner ensures consistent temperature uniformity up to 1000°C. The SiC ceramic heating elements provide continuous duty performance at 1600°C, while the Watlow PID loop controllers and SCR power panels offer high-precision control over thermal processing conditions.

This system integrates an indirect 24" diameter x 21' convective rotary cooler, allowing for efficient material cooling before packaging or further processing. Designed for controlled heat treatment with minimal contamination risk, this industrial-grade calciner is ideal for advanced material processing applications.

Specifications:

Rotary Calciner:

- Diameter: 36 inches

- Furnace Length: 20 feet heated zone

- Total Length: 35 feet

- Construction Material: RA253MA furnace section, 300 Series SS ends

- Operating Temperature: Up to 1000°C

- Heating Elements: SiC ceramic, 1600°C continuous duty

- Thermocouples: (2) per zone

- Insulation: 9" thick Fiberfrax 2200 Dura blanket modules

- Control System: Watlow SCRs, PID loop controllers, high-limit controllers

Rotary Cooler:

- Diameter: 24 inches

- Length: 21 feet

- Cooling Type: Indirect Convective Cooling

Power & Control Panel:

- Freestanding 500 Amp power/control panels

- Watlow SCRs, PID controllers, EZZone communication options

- SCR drive with variable slope support stands & DC variable speed screw conveyor

Applications:

- Powder & bulk material thermal processing

- Metallurgical heat treatment

- Ceramic sintering & processing

- Chemical and catalyst processing

- Battery material production (e.g., lithium, graphite, rare earth materials)

- Nanomaterial and advanced material manufacturing

- Industrial waste treatment & recycling

- Pharmaceutical and biotech material processing

What Products Would This Be Used For?

- Powdered metals (nickel, cobalt, titanium, etc.)

- Ceramics and refractory materials

- Battery-grade lithium and anode/cathode materials

- Activated carbon and catalysts

- Nanopowders and high-performance coatings

- High-purity chemicals for semiconductor manufacturing

- Mineral processing and refining

- Synthetic graphite and carbon black production

- Used rotary calciner for sale

- High-temperature rotary furnace

- Industrial electric calciner

- 36-inch rotary kiln for material processing

- Powder processing calciner

- Used thermal processing rotary calciner

- Advanced material calciner with rotary cooler

- Electric rotary furnace for ceramic sintering

- Used 36-inch rotary calciner with 24-inch rotary cooler for sale

- Best industrial calciner for high-temperature powder processing

- Buy a used thermal processing calciner with electric heating elements

- Pre-owned rotary calciner for metallurgical and ceramic applications

- High-temperature rotary calciner for battery material processing

- Used rotary kiln for sintering and advanced material production

- Rotary furnace for lithium, nickel, and cobalt powder processing

- Industrial electric calciner for chemical and catalyst production

- 1600°C SiC heating elements for continuous-duty rotary furnace

- Automated PID control rotary calciner for material heat treatment

- Fiberfrax insulated rotary calciner for energy-efficient processing

- High-precision thermal processing with Watlow SCR controllers

Used Thermal Processing Solutions 36" diameter Indirectly Heated Electric Rotary Calciner with Convective Rotary Cooler 24" diameter X 21-0". Calciner is approximately 36" diameter X 20' heated furnace zone X 35 long overall; 21-0" RA253MA furnace section that extends 6" out of each end of the furnace, and 300 series stainless steel ends, suitable for 1000 degree C operation. The cylinder has seal welded Blanchard ground fixed seal rings if an upgrade to a bellows type seal is needed; These are welded/X-ray inspected as per ASME Sec VIII unstamped vessel construction; Furnace casing is 9" thick Fiberfrax 2200 Dura blanket modules; Zone divider walls are Fiberfrax board; (2) thermocouple assemblies per zone; Heating elements are SiC ceramic, 1600 degrees C continuous duty construction; Heating element access is available on the sides of the furnace. Calciner is complete with freestanding 500 amp power/control panels using Watlow SCRs , F4 PID loop controllers with communication options and EZZone; Watlow High Limit controllers, each monitoring an independent furnace thermocouple in each zone; Includes variable slope support stands with an SCR drive and a dc variable speed screw conveyor; Calciner is set up to discharge directly into a 24" diameter x 21ft indirect convective Cooler, then optionally into a Kason Screener into a bulk bag and oversize/foreign object container.

Manufacturer Information:

- Manufacturer: Thermal Processing Solutions

- Equipment Type: Indirectly Heated Electric Rotary Calciner with Convective Rotary Cooler

- Condition: Used

- Construction Standard: ASME Sec VIII Unstamped Vessel

Manufacturing Data:

Rotary Calciner:

- Diameter: 36 inches

- Heated Furnace Zone Length: 20 feet

- Overall Length: 35 feet

- Furnace Material: RA253MA furnace section (extends 6" out of each end)

- End Material: 300 Series Stainless Steel

- Operating Temperature: Up to 1000°C

- Sealing System:

- Blanchard ground fixed seal rings

- Welded/X-ray inspected per ASME Sec VIII (unstamped)

- Optional upgrade to bellows-type seal

- Furnace Casing: 9-inch thick Fiberfrax 2200 Dura blanket modules

- Zone Divider Walls: Fiberfrax board

- Heating Elements:

- SiC ceramic heating elements

- 1600°C continuous duty construction

- Side access for element replacement

- Temperature Monitoring:

- (2) Thermocouple assemblies per zone

Power & Control Panel:

- Power Capacity: 500 Amp freestanding control panel

- Control System:

- Watlow SCRs

- F4 PID loop controllers (with communication options and EZZone)

- Watlow High Limit controllers (independent monitoring per zone)

Rotary Cooler:

- Diameter: 24 inches

- Length: 21 feet

- Cooling Method: Indirect Convective Cooling

- Additional Components:

- Variable slope support stands

- SCR drive & DC variable speed screw conveyor

- Direct discharge to Kason Screener

- Bulk bagging and oversize/foreign object containment options

Description:

The Used Thermal Processing Solutions 36" Indirectly Heated Electric Rotary Calciner is a high-temperature material processing system designed for precise thermal treatment of powders, granules, and specialty materials in metallurgy, ceramics, chemicals, and advanced materials production.

With an RA253MA furnace section, Blanchard ground fixed seal rings, and a 9" thick Fiberfrax insulation system, this electric rotary calciner ensures consistent temperature uniformity up to 1000°C. The SiC ceramic heating elements provide continuous duty performance at 1600°C, while the Watlow PID loop controllers and SCR power panels offer high-precision control over thermal processing conditions.

This system integrates an indirect 24" diameter x 21' convective rotary cooler, allowing for efficient material cooling before packaging or further processing. Designed for controlled heat treatment with minimal contamination risk, this industrial-grade calciner is ideal for advanced material processing applications.

Specifications:

Rotary Calciner:

- Diameter: 36 inches

- Furnace Length: 20 feet heated zone

- Total Length: 35 feet

- Construction Material: RA253MA furnace section, 300 Series SS ends

- Operating Temperature: Up to 1000°C

- Heating Elements: SiC ceramic, 1600°C continuous duty

- Thermocouples: (2) per zone

- Insulation: 9" thick Fiberfrax 2200 Dura blanket modules

- Control System: Watlow SCRs, PID loop controllers, high-limit controllers

Rotary Cooler:

- Diameter: 24 inches

- Length: 21 feet

- Cooling Type: Indirect Convective Cooling

Power & Control Panel:

- Freestanding 500 Amp power/control panels

- Watlow SCRs, PID controllers, EZZone communication options

- SCR drive with variable slope support stands & DC variable speed screw conveyor

Applications:

- Powder & bulk material thermal processing

- Metallurgical heat treatment

- Ceramic sintering & processing

- Chemical and catalyst processing

- Battery material production (e.g., lithium, graphite, rare earth materials)

- Nanomaterial and advanced material manufacturing

- Industrial waste treatment & recycling

- Pharmaceutical and biotech material processing

What Products Would This Be Used For?

- Powdered metals (nickel, cobalt, titanium, etc.)

- Ceramics and refractory materials

- Battery-grade lithium and anode/cathode materials

- Activated carbon and catalysts

- Nanopowders and high-performance coatings

- High-purity chemicals for semiconductor manufacturing

- Mineral processing and refining

- Synthetic graphite and carbon black production

- Used rotary calciner for sale

- High-temperature rotary furnace

- Industrial electric calciner

- 36-inch rotary kiln for material processing

- Powder processing calciner

- Used thermal processing rotary calciner

- Advanced material calciner with rotary cooler

- Electric rotary furnace for ceramic sintering

- Used 36-inch rotary calciner with 24-inch rotary cooler for sale

- Best industrial calciner for high-temperature powder processing

- Buy a used thermal processing calciner with electric heating elements

- Pre-owned rotary calciner for metallurgical and ceramic applications

- High-temperature rotary calciner for battery material processing

- Used rotary kiln for sintering and advanced material production

- Rotary furnace for lithium, nickel, and cobalt powder processing

- Industrial electric calciner for chemical and catalyst production

- 1600°C SiC heating elements for continuous-duty rotary furnace

- Automated PID control rotary calciner for material heat treatment

- Fiberfrax insulated rotary calciner for energy-efficient processing

- High-precision thermal processing with Watlow SCR controllers

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory