Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Grote 613-VS2 Multi Slicer – 2-Lane | Bulk, Stack, Shingle | 1.25mm Slice | Built 2018

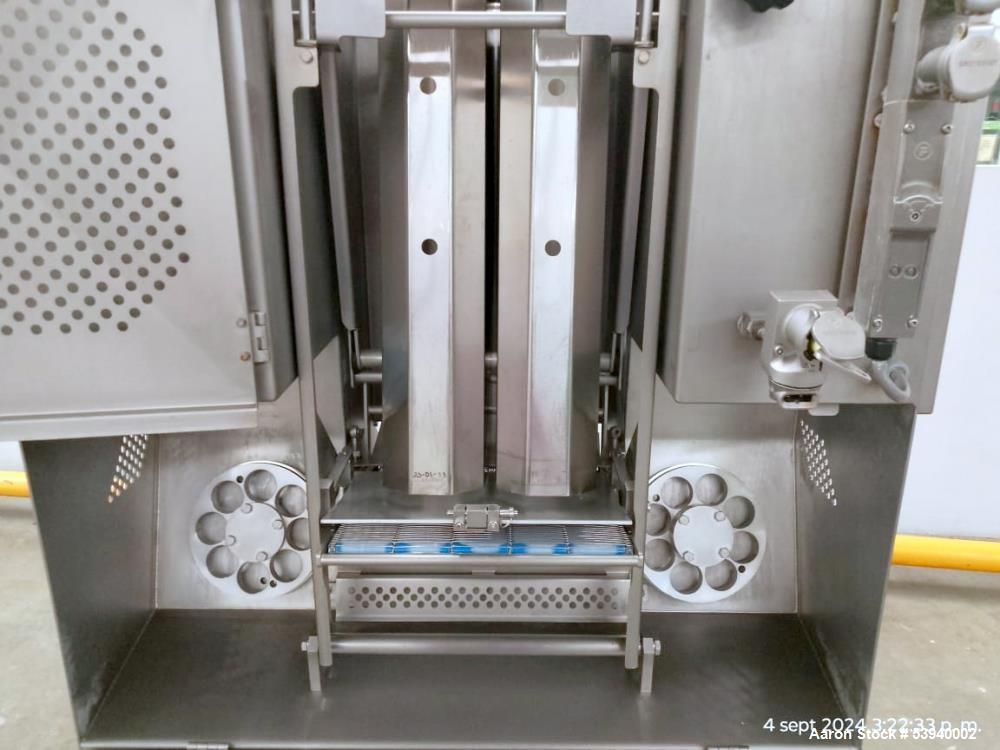

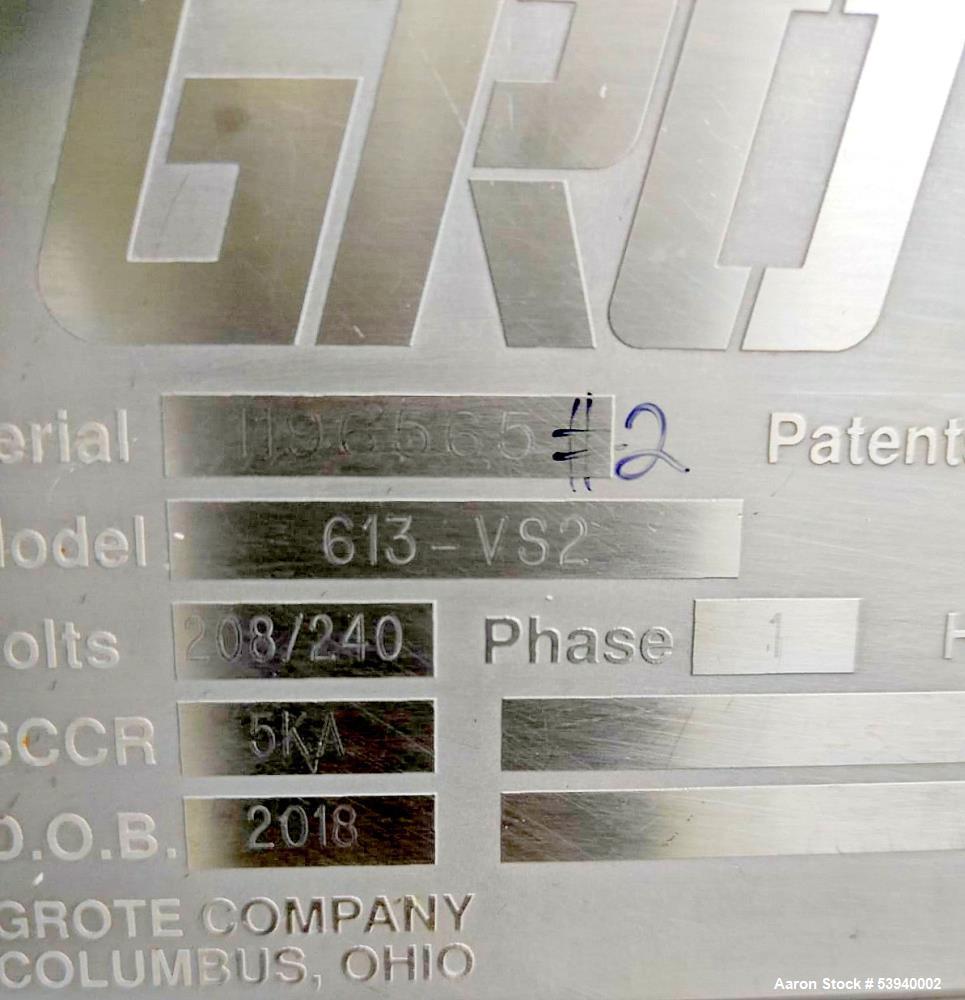

Used Grote Multi Slicer, Model 613-VS2. Operating Modes: Bulk slice, stacking, or shingling, (50 mm / 2" max height in stack mode. 154 mm stroke direction x 330 mm width (6.06" x 13") Maximum Product Size; 1 mm to 12.7 mm Slice Thickness Range; Adjustable from 762 mm to 800 mm (30" to 31.5") Discharge Height; 37 - 90 strokes/minute Slice Speed; 2 fixed casters, 2 swivel locking casters Standard base; Gravity feed with continuous loading during operation Feed Method; AccuBand band blade Cutting Method; Water injected blade guide with pump and reservoir Blade Lubrication; Toolless removal of product holders, tray assemblies, and blade guide sanitation; Door Guard Switch: Mechanical captive key locks for hinged guards and carry out conveyor; Standard Allen Bradley Controls; Standard Flatflex shuttle conveyor; Stainless steel thickness and exit tray; Plastic blade scraper; Cleartrac carryout belt conveyor, 76 meters (2.5 feet) of usable length; Knife Edge Blade: 25 Slice Thickness: 1.25 mm Number of Slicing Lanes: 2 Slice Presentation: Bulk - no overlap on carryout belt The multi slicer can be used to slice meat, cheese, and fresh produce. It was used for fresh produce production and is no longer needed. 1/60/208-240V; Serial # 1196565; Built 2018.

Manufacturer Information:

-

Brand: Grote

-

Model: 613-VS2

-

Serial Number: 1196565

-

Year Built: 2018

-

Voltage: 1/60/208–240V

-

Condition: Used

-

Previous Use: Fresh produce slicing

Description:

This Used Grote 613-VS2 Multi Slicer, built in 2018, is a dual-lane, high-throughput food slicing machine suitable for bulk slicing, stacking, or shingling of meat, cheese, or fresh produce. With a slice speed of up to 90 strokes per minute, it features AccuBand band blade cutting, a gravity feed system, and 1.25 mm knife edge thickness for precision slicing. The slicer allows toolless sanitation, includes a Cleartrac carryout belt conveyor, and supports easy integration into high-volume production lines.

Specifications:

-

Model: 613-VS2

-

Slice Thickness: 1 mm – 12.7 mm (knife edge used: 1.25 mm)

-

Slice Speed: 37 – 90 strokes/minute

-

Slicing Modes: Bulk slice, stacking (max 50 mm / 2"), or shingling

-

Number of Slicing Lanes: 2

-

Product Size Capacity: 154 mm (6.06") stroke x 330 mm (13") width

-

Discharge Height: Adjustable 762 mm to 800 mm (30" to 31.5")

-

Feed Method: Gravity feed, continuous load during operation

-

Cutting Method: AccuBand band blade

-

Blade Lubrication: Water-injected blade guide with pump & reservoir

-

Sanitation: Toolless removal of blade guide, trays, and holders

-

Carryout Conveyor:

-

Type: Cleartrac

-

Length: 76 cm / 2.5 ft usable

-

-

Shuttle Conveyor: Standard Flatflex

-

Safety:

-

Door guard switch

-

Mechanical captive key locks for hinged guards

-

-

Material: Stainless steel with plastic blade scraper

-

Controls: Allen Bradley

Features:

-

Dual-lane slicing for increased throughput

-

3-in-1 operation: bulk slicing, stacking, or shingling

-

Continuous product loading with gravity feed system

-

Water-injected blade lubrication for clean, smooth cuts

-

Precision-controlled slice thickness (1.25 mm knife edge in use)

-

Designed for quick disassembly and sanitation

-

Heavy-duty stainless steel construction

-

Fully integrated safety systems

-

Cleartrac carryout belt ensures gentle product handling

-

Compact footprint with locking swivel casters for mobility

Applications:

-

Slicing lettuce, onions, tomatoes, cucumbers, and other produce

-

Cheese block portioning

-

Deli meat slicing for retail and foodservice

-

Pre-packed tray line support

-

Sandwich or meal kit ingredient slicing

-

Food prep for salads and ready-to-eat meals

-

Bulk slicing operations in commercial kitchens

-

Nutritional, plant-based meat alternative slicing

-

Industrial slicing in processing plants

-

Co-packing or contract slicing services

What might this be used for?

-

Efficiently slicing fresh vegetables for salad kits

-

Shingling deli meats for retail display trays

-

Bulk slicing cheese for sandwich prep

-

Preparing fresh produce for pre-packaged meals

-

Reducing manual labor with automated slicing

-

Running high-throughput, dual-lane slicing for greater output

-

Integrating a reliable slicer into a hygienic, food-safe line

-

Offering flexible slice presentations with fast changeovers

-

Keeping up with variable product SKUs in food processing

-

Supporting operations requiring sanitation and food safety compliance

-

Grote slicer

-

Food slicer

-

Dual-lane slicer

-

Produce slicer

-

Used slicer

-

Tray slicer

-

613-VS2

-

Slicing machine

-

Cheese slicer

-

Bulk slicer

-

Used Grote 613-VS2 slicer

-

Dual-lane slicer for food production

-

Produce slicing equipment

-

Grote slicer for meat and cheese

-

Industrial slicer for sale

-

Two-lane food slicer

-

Gravity feed food slicer

-

1.25mm slicer

-

Commercial slicer for vegetables

-

Grote slicing machine used

-

Used Grote 613-VS2 multi slicer with 2 slicing lanes and 1.25mm blade edge

-

Dual-lane slicer for fresh produce, cheese, and deli meat with bulk and stack options

-

Industrial slicing machine with water-injected blade lubrication and Cleartrac belt

-

Food-grade slicer for tray production with AccuBand technology and gravity feed

-

Grote slicer with toolless sanitation and Allen Bradley controls

-

Compact tray line slicer with adjustable height and dual-lane bulk slicing

-

Slicer with 76 cm carryout belt and safety interlocks for commercial food production

-

Used slicing machine for plant-based, fresh, or prepared food slicing

-

90 strokes/minute food slicer with variable slice thickness

-

Versatile multi slicer for foodservice, processors, and co-packers

-

Buy used food slicer

-

Purchase Grote slicer

-

Industrial slicing machine buy

-

Dual-lane slicer for sale

-

Produce slicing machine

-

Used slicer with conveyor

-

Commercial food slicer

-

Buy tray slicer

-

Slicer for cheese and vegetables

-

Grote slicing system used

-

Sell Grote slicer

-

List used 613-VS2 slicer

-

Slicing machine resale

-

Used slicer equipment for sale

-

Liquidate food slicer

-

Sell industrial slicer

-

Grote tray line slicer resale

-

Resell commercial slicer

-

Tray slicer used equipment

-

Marketplace slicer listing

Used Grote Multi Slicer, Model 613-VS2. Operating Modes: Bulk slice, stacking, or shingling, (50 mm / 2" max height in stack mode. 154 mm stroke direction x 330 mm width (6.06" x 13") Maximum Product Size; 1 mm to 12.7 mm Slice Thickness Range; Adjustable from 762 mm to 800 mm (30" to 31.5") Discharge Height; 37 - 90 strokes/minute Slice Speed; 2 fixed casters, 2 swivel locking casters Standard base; Gravity feed with continuous loading during operation Feed Method; AccuBand band blade Cutting Method; Water injected blade guide with pump and reservoir Blade Lubrication; Toolless removal of product holders, tray assemblies, and blade guide sanitation; Door Guard Switch: Mechanical captive key locks for hinged guards and carry out conveyor; Standard Allen Bradley Controls; Standard Flatflex shuttle conveyor; Stainless steel thickness and exit tray; Plastic blade scraper; Cleartrac carryout belt conveyor, 76 meters (2.5 feet) of usable length; Knife Edge Blade: 25 Slice Thickness: 1.25 mm Number of Slicing Lanes: 2 Slice Presentation: Bulk - no overlap on carryout belt The multi slicer can be used to slice meat, cheese, and fresh produce. It was used for fresh produce production and is no longer needed. 1/60/208-240V; Serial # 1196565; Built 2018.

Manufacturer Information:

-

Brand: Grote

-

Model: 613-VS2

-

Serial Number: 1196565

-

Year Built: 2018

-

Voltage: 1/60/208–240V

-

Condition: Used

-

Previous Use: Fresh produce slicing

Description:

This Used Grote 613-VS2 Multi Slicer, built in 2018, is a dual-lane, high-throughput food slicing machine suitable for bulk slicing, stacking, or shingling of meat, cheese, or fresh produce. With a slice speed of up to 90 strokes per minute, it features AccuBand band blade cutting, a gravity feed system, and 1.25 mm knife edge thickness for precision slicing. The slicer allows toolless sanitation, includes a Cleartrac carryout belt conveyor, and supports easy integration into high-volume production lines.

Specifications:

-

Model: 613-VS2

-

Slice Thickness: 1 mm – 12.7 mm (knife edge used: 1.25 mm)

-

Slice Speed: 37 – 90 strokes/minute

-

Slicing Modes: Bulk slice, stacking (max 50 mm / 2"), or shingling

-

Number of Slicing Lanes: 2

-

Product Size Capacity: 154 mm (6.06") stroke x 330 mm (13") width

-

Discharge Height: Adjustable 762 mm to 800 mm (30" to 31.5")

-

Feed Method: Gravity feed, continuous load during operation

-

Cutting Method: AccuBand band blade

-

Blade Lubrication: Water-injected blade guide with pump & reservoir

-

Sanitation: Toolless removal of blade guide, trays, and holders

-

Carryout Conveyor:

-

Type: Cleartrac

-

Length: 76 cm / 2.5 ft usable

-

-

Shuttle Conveyor: Standard Flatflex

-

Safety:

-

Door guard switch

-

Mechanical captive key locks for hinged guards

-

-

Material: Stainless steel with plastic blade scraper

-

Controls: Allen Bradley

Features:

-

Dual-lane slicing for increased throughput

-

3-in-1 operation: bulk slicing, stacking, or shingling

-

Continuous product loading with gravity feed system

-

Water-injected blade lubrication for clean, smooth cuts

-

Precision-controlled slice thickness (1.25 mm knife edge in use)

-

Designed for quick disassembly and sanitation

-

Heavy-duty stainless steel construction

-

Fully integrated safety systems

-

Cleartrac carryout belt ensures gentle product handling

-

Compact footprint with locking swivel casters for mobility

Applications:

-

Slicing lettuce, onions, tomatoes, cucumbers, and other produce

-

Cheese block portioning

-

Deli meat slicing for retail and foodservice

-

Pre-packed tray line support

-

Sandwich or meal kit ingredient slicing

-

Food prep for salads and ready-to-eat meals

-

Bulk slicing operations in commercial kitchens

-

Nutritional, plant-based meat alternative slicing

-

Industrial slicing in processing plants

-

Co-packing or contract slicing services

What might this be used for?

-

Efficiently slicing fresh vegetables for salad kits

-

Shingling deli meats for retail display trays

-

Bulk slicing cheese for sandwich prep

-

Preparing fresh produce for pre-packaged meals

-

Reducing manual labor with automated slicing

-

Running high-throughput, dual-lane slicing for greater output

-

Integrating a reliable slicer into a hygienic, food-safe line

-

Offering flexible slice presentations with fast changeovers

-

Keeping up with variable product SKUs in food processing

-

Supporting operations requiring sanitation and food safety compliance

-

Grote slicer

-

Food slicer

-

Dual-lane slicer

-

Produce slicer

-

Used slicer

-

Tray slicer

-

613-VS2

-

Slicing machine

-

Cheese slicer

-

Bulk slicer

-

Used Grote 613-VS2 slicer

-

Dual-lane slicer for food production

-

Produce slicing equipment

-

Grote slicer for meat and cheese

-

Industrial slicer for sale

-

Two-lane food slicer

-

Gravity feed food slicer

-

1.25mm slicer

-

Commercial slicer for vegetables

-

Grote slicing machine used

-

Used Grote 613-VS2 multi slicer with 2 slicing lanes and 1.25mm blade edge

-

Dual-lane slicer for fresh produce, cheese, and deli meat with bulk and stack options

-

Industrial slicing machine with water-injected blade lubrication and Cleartrac belt

-

Food-grade slicer for tray production with AccuBand technology and gravity feed

-

Grote slicer with toolless sanitation and Allen Bradley controls

-

Compact tray line slicer with adjustable height and dual-lane bulk slicing

-

Slicer with 76 cm carryout belt and safety interlocks for commercial food production

-

Used slicing machine for plant-based, fresh, or prepared food slicing

-

90 strokes/minute food slicer with variable slice thickness

-

Versatile multi slicer for foodservice, processors, and co-packers

-

Buy used food slicer

-

Purchase Grote slicer

-

Industrial slicing machine buy

-

Dual-lane slicer for sale

-

Produce slicing machine

-

Used slicer with conveyor

-

Commercial food slicer

-

Buy tray slicer

-

Slicer for cheese and vegetables

-

Grote slicing system used

-

Sell Grote slicer

-

List used 613-VS2 slicer

-

Slicing machine resale

-

Used slicer equipment for sale

-

Liquidate food slicer

-

Sell industrial slicer

-

Grote tray line slicer resale

-

Resell commercial slicer

-

Tray slicer used equipment

-

Marketplace slicer listing

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory