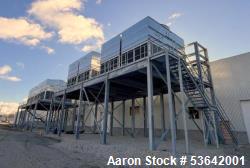

Used Cooling Towers

Aaron Equipment has an inventory of reconditioned, unused, and used industrial cooling towers. Industrial cooling towers are large heat rejection devices used to remove excess heat from industrial processes, power plants, or large HVAC systems. These towers help maintain the efficiency and safety of equipment by cooling water used in various processes before it is recirculated. Cooling towers are critical in industries such as manufacturing, energy production, petrochemicals, and HVAC systems. Industrial cooling towers play a vital role in cooling water used in industrial processes and power generation, promoting efficient operations while managing heat and water resources. If you are looking to sell your used cooling towers submit a request online or contact Erik Eichert at 630-238-7480.

Your Guide To Understanding Industrial Cooling Towers

Maintaining optimal temperatures is crucial in industrial operations and one component can be cooling towers. These towering structures, often seen as part of the skyline in industrial areas, play a vital role in managing heat and maintaining the efficiency of various processes. In this guide, we will explore the ins and outs of industrial cooling towers, focusing on their purpose, operation, and maintenance.

What Are Industrial Cooling Towers?

Industrial cooling towers are heat dissipation systems that remove excess heat from industrial processes. They circulate water and use evaporative cooling technology to lower the water's temperature. This process is essential for industries that produce significant heat, such as power plants, chemical processing facilities, and manufacturing plants.

How Cooling Towers Work

Cooling towers operate on a simple principle: hot water from the industrial process is pumped into the tower, spraying over a large surface area. As the water flows over this area, it is exposed to air. The interaction between water and air causes a small portion of the water to evaporate, and this evaporation process removes heat from the remaining water. The cooled water is then recirculated into the system to absorb more heat.

Types of Cooling Towers

There are several types of cooling towers, each designed for specific applications and environments. Understanding these types can help you select the right system for your needs.

- Natural Draft Cooling Towers: Natural draft cooling towers use the natural flow of air to cool water. These towers are typically large and rely on the buoyancy of warm air to move through the tower. As the warm air rises, it draws in cooler air from the bottom, facilitating the cooling process.

- Mechanical Draft Cooling Towers: Mechanical draft cooling towers use fans to move air through the tower. This type of tower is more compact and used in areas where space is limited. The fans increase airflow, making cooling more efficient, especially in hot climates or enclosed spaces.

- Crossflow vs. Counterflow: Cooling towers can also be categorized based on air and water flow direction. In crossflow towers, air moves horizontally across the falling water. In counterflow towers, air moves upward against the falling water. Each design has advantages and is chosen based on specific cooling needs and space constraints.

Benefits of Industrial Cooling Towers

Cooling towers offer numerous benefits to industrial operations. Here are some key advantages:

- Energy Efficiency: A key benefit of using cooling towers is their energy efficiency. Using the natural evaporation process to cool water reduces the need for additional energy-intensive cooling methods, thus lowering operational costs.

- Environmental Impact: By efficiently managing heat, cooling towers help reduce industrial processes' environmental impact. They minimize the release of heat into the atmosphere and reduce the need for water from external sources, contributing to water conservation efforts.

- Cost-Effective Cooling Solution: For industries that generate large amounts of heat, cooling towers provide a cost-effective solution for maintaining safe and efficient operating temperatures. Your initial investment can be offset by savings in energy costs and reduced equipment wear and tear.

Maintenance and Upkeep

Regular maintenance of cooling towers is essential to ensure their longevity and efficiency. Here are some maintenance tips:

- Routine Inspections: Conduct regular inspections to check for signs of wear and tear, corrosion, or blockages. Early detection of issues can prevent costly repairs and downtime.

- Cleaning and Disinfection: Keep the cooling tower clean to prevent the buildup of algae, bacteria, and other contaminants. Regular cleaning and disinfection are crucial for maintaining water quality and preventing health risks like Legionnaires' disease.

- Water Treatment: Implement a water treatment program to control scale, corrosion, and biological growth. Proper water treatment ensures the cooling tower operates efficiently and extends the life of the equipment.

- Fan and Motor Maintenance: Regularly inspect and maintain the fans and motors to ensure they are operating efficiently. Check for any unusual noises or vibrations that could indicate mechanical issues.

Choosing the Right Cooling Tower System

When selecting a cooling tower system, consider the following factors:

- Capacity and Size: Determine the cooling capacity needed for your industrial process. The cooling tower size should match the heat load requirements to ensure efficient operation.

- Location and Space: Consider the location and available space for the cooling tower. Some systems require more space than others, so choosing a design that fits your facility's layout is essential.

- Environmental Conditions: Take into account the local climate and environmental conditions. Some cooling tower designs perform better in specific climates, so select a system that aligns with your environmental needs.

- Budget and Cost: Evaluate the initial investment and long-term operational costs. While some systems may have a higher upfront cost, they offer greater energy efficiency and lower maintenance expenses over time.

Industrial cooling towers are vital to many industrial operations, providing an efficient and cost-effective solution for managing excess heat. By understanding how these systems work, the types available, and the maintenance required, you can ensure that your cooling tower operates efficiently and effectively. Whether you're selecting a new system or maintaining an existing one, keeping these factors in mind will help you make informed decisions and optimize your industrial cooling processes.