Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Automated Biodiesel Reactor; Model R475

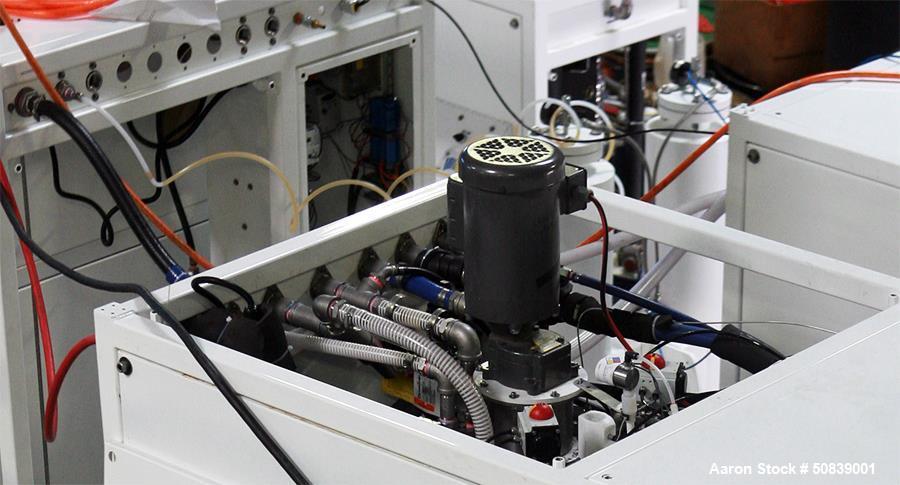

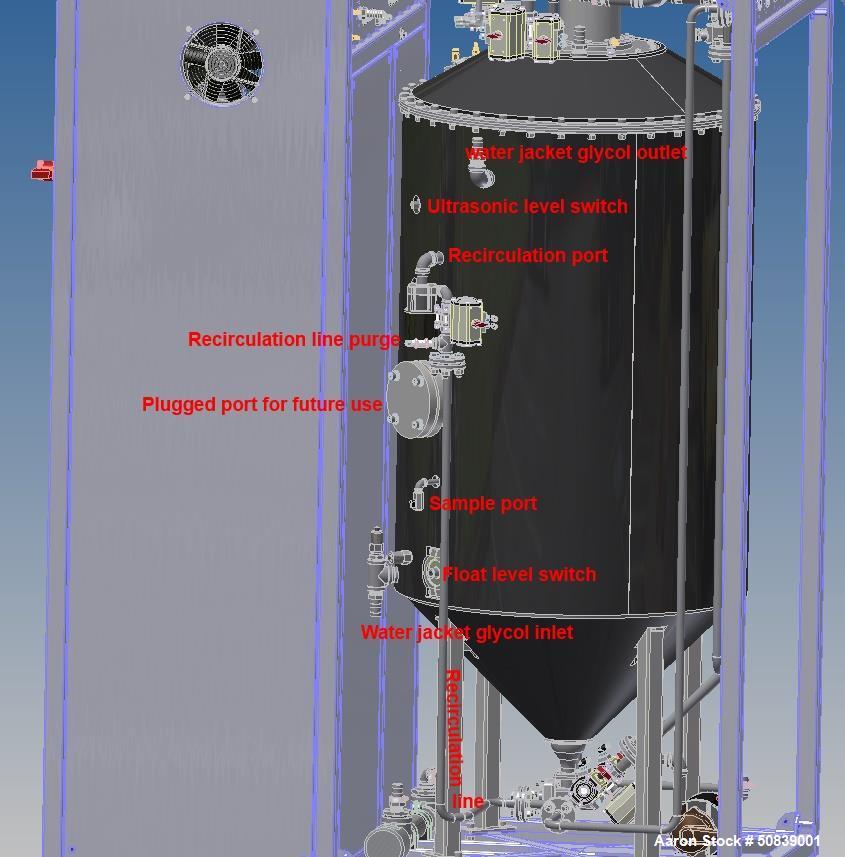

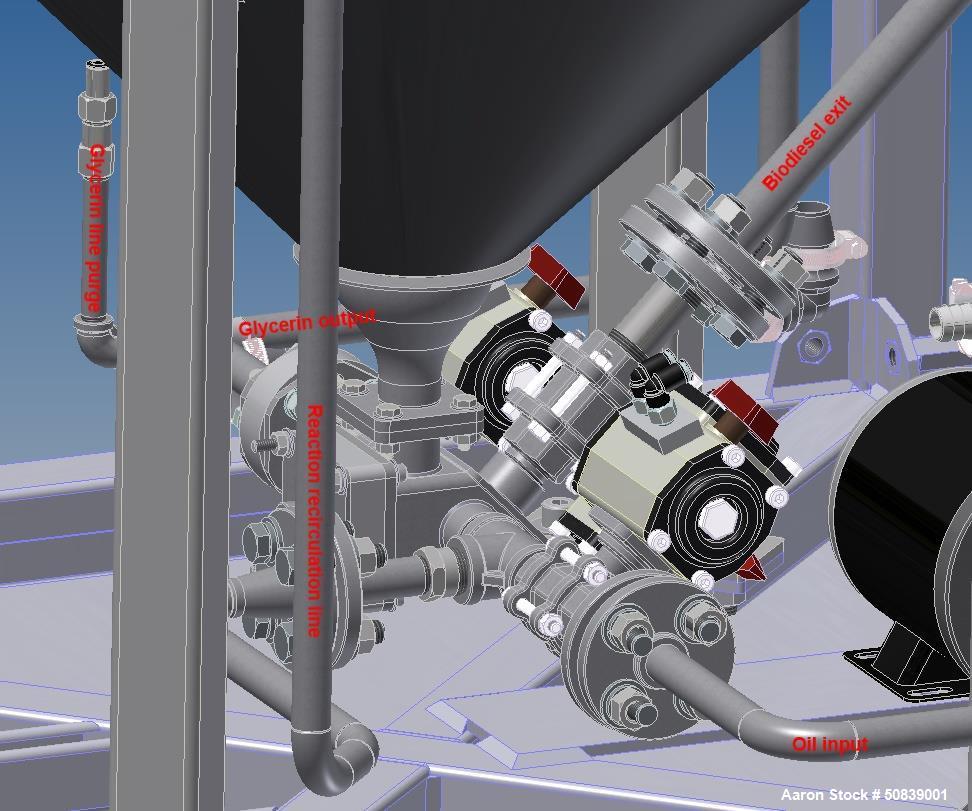

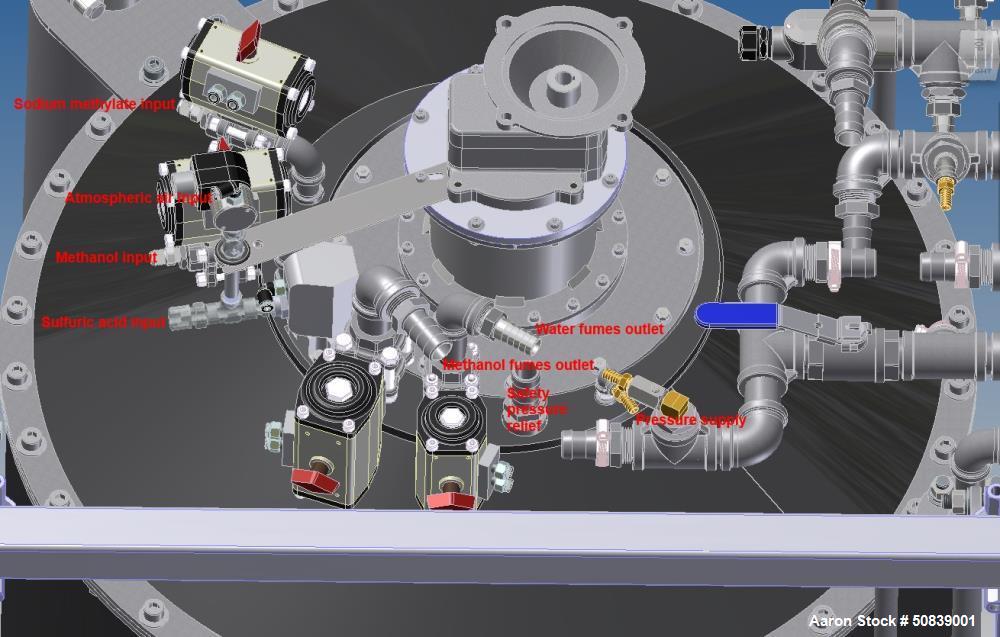

Used World Class Small-Scale Biodiesel Equipment Manufacturer, Springboard Biodiesel, is offering for sale a $2.5M grant funded CLL Production system. This Automated Biodiesel Skidded System consisting of (4) of each Reactor, Model R475. Part of Closed Local Loop Biodiesel Production System, Designed to produce 1,000 gallons of ASTM-D6751, B-100 biodiesel per day (extendible to 2000 gallons with 2nd work shift). Processes any vegetable and/or animal oil (feed stock) that is less than or equal to 10% Free Fatty Acid (FFA). Compact footprint requiring a 40 x 60 dedicated production area. Part of a fully closed loop system: a Modular system designed to be customized to specific requirements (capacity) of the operator. The system comes with dual touch screen operating center, reactors, coding, oil and biodiesel buffers, and includes all drawings and plans for completion of and maintenance of system.

Manufacturer Information

- Brand: Springboard Biodiesel

- Model: CLL Production System with R475 Reactors

- Condition: Used

Description

Springboard Biodiesel, a world-class small-scale biodiesel equipment manufacturer, is offering for sale a $2.5M grant-funded Closed Local Loop (CLL) Production System. This automated biodiesel skidded system includes (4) R475 reactors, designed to produce 1,000 gallons of ASTM-D6751 B-100 biodiesel per day, with the ability to extend production to 2,000 gallons per day with a second work shift.

The system is capable of processing any vegetable and/or animal oil (feedstock) with an FFA (free fatty acid) content of ≤5%. It is an efficient, scalable, and sustainable biodiesel production solution ideal for businesses looking to produce high-quality biodiesel while reducing operational costs.

Specifications

- System Type: Automated Biodiesel Skidded System

- Reactors: (4) R475 Reactors

- Production Capacity:

- 1,000 gallons/day (Single Shift)

- 2,000 gallons/day (With Second Shift)

- Biodiesel Standard: ASTM-D6751 B-100

- Feedstock Compatibility: Any vegetable and/or animal oil ≤5% FFA

- Funding Source: $2.5M Grant-Funded System

Applications

This Springboard Biodiesel CLL Production System is ideal for:

- Biodiesel Production Facilities – Small to mid-scale renewable fuel production

- Agricultural & Farming Operations – On-site biodiesel production for equipment fuel

- Municipal & Government Fleets – Sustainable fuel for public transportation and waste management fleets

- Universities & Research Centers – Renewable energy studies and biofuel innovation

- Waste Oil Recycling Facilities – Conversion of used cooking oil into biodiesel

- Energy & Sustainability Programs – Green energy production initiatives

- Automated biodiesel skidded system for sale

- 1,000 gallons/day biodiesel production

- 2,000 gallons/day extended biodiesel system

- ASTM-D6751 B-100 biodiesel production

- Closed Local Loop (CLL) biodiesel system

- Small-scale biodiesel equipment manufacturer

- Vegetable and animal oil biodiesel processor

- Grant-funded biodiesel production system

- R475 reactor biodiesel system

Used World Class Small-Scale Biodiesel Equipment Manufacturer, Springboard Biodiesel, is offering for sale a $2.5M grant funded CLL Production system. This Automated Biodiesel Skidded System consisting of (4) of each Reactor, Model R475. Part of Closed Local Loop Biodiesel Production System, Designed to produce 1,000 gallons of ASTM-D6751, B-100 biodiesel per day (extendible to 2000 gallons with 2nd work shift). Processes any vegetable and/or animal oil (feed stock) that is less than or equal to 10% Free Fatty Acid (FFA). Compact footprint requiring a 40 x 60 dedicated production area. Part of a fully closed loop system: a Modular system designed to be customized to specific requirements (capacity) of the operator. The system comes with dual touch screen operating center, reactors, coding, oil and biodiesel buffers, and includes all drawings and plans for completion of and maintenance of system.

Manufacturer Information

- Brand: Springboard Biodiesel

- Model: CLL Production System with R475 Reactors

- Condition: Used

Description

Springboard Biodiesel, a world-class small-scale biodiesel equipment manufacturer, is offering for sale a $2.5M grant-funded Closed Local Loop (CLL) Production System. This automated biodiesel skidded system includes (4) R475 reactors, designed to produce 1,000 gallons of ASTM-D6751 B-100 biodiesel per day, with the ability to extend production to 2,000 gallons per day with a second work shift.

The system is capable of processing any vegetable and/or animal oil (feedstock) with an FFA (free fatty acid) content of ≤5%. It is an efficient, scalable, and sustainable biodiesel production solution ideal for businesses looking to produce high-quality biodiesel while reducing operational costs.

Specifications

- System Type: Automated Biodiesel Skidded System

- Reactors: (4) R475 Reactors

- Production Capacity:

- 1,000 gallons/day (Single Shift)

- 2,000 gallons/day (With Second Shift)

- Biodiesel Standard: ASTM-D6751 B-100

- Feedstock Compatibility: Any vegetable and/or animal oil ≤5% FFA

- Funding Source: $2.5M Grant-Funded System

Applications

This Springboard Biodiesel CLL Production System is ideal for:

- Biodiesel Production Facilities – Small to mid-scale renewable fuel production

- Agricultural & Farming Operations – On-site biodiesel production for equipment fuel

- Municipal & Government Fleets – Sustainable fuel for public transportation and waste management fleets

- Universities & Research Centers – Renewable energy studies and biofuel innovation

- Waste Oil Recycling Facilities – Conversion of used cooking oil into biodiesel

- Energy & Sustainability Programs – Green energy production initiatives

- Automated biodiesel skidded system for sale

- 1,000 gallons/day biodiesel production

- 2,000 gallons/day extended biodiesel system

- ASTM-D6751 B-100 biodiesel production

- Closed Local Loop (CLL) biodiesel system

- Small-scale biodiesel equipment manufacturer

- Vegetable and animal oil biodiesel processor

- Grant-funded biodiesel production system

- R475 reactor biodiesel system

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory