Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

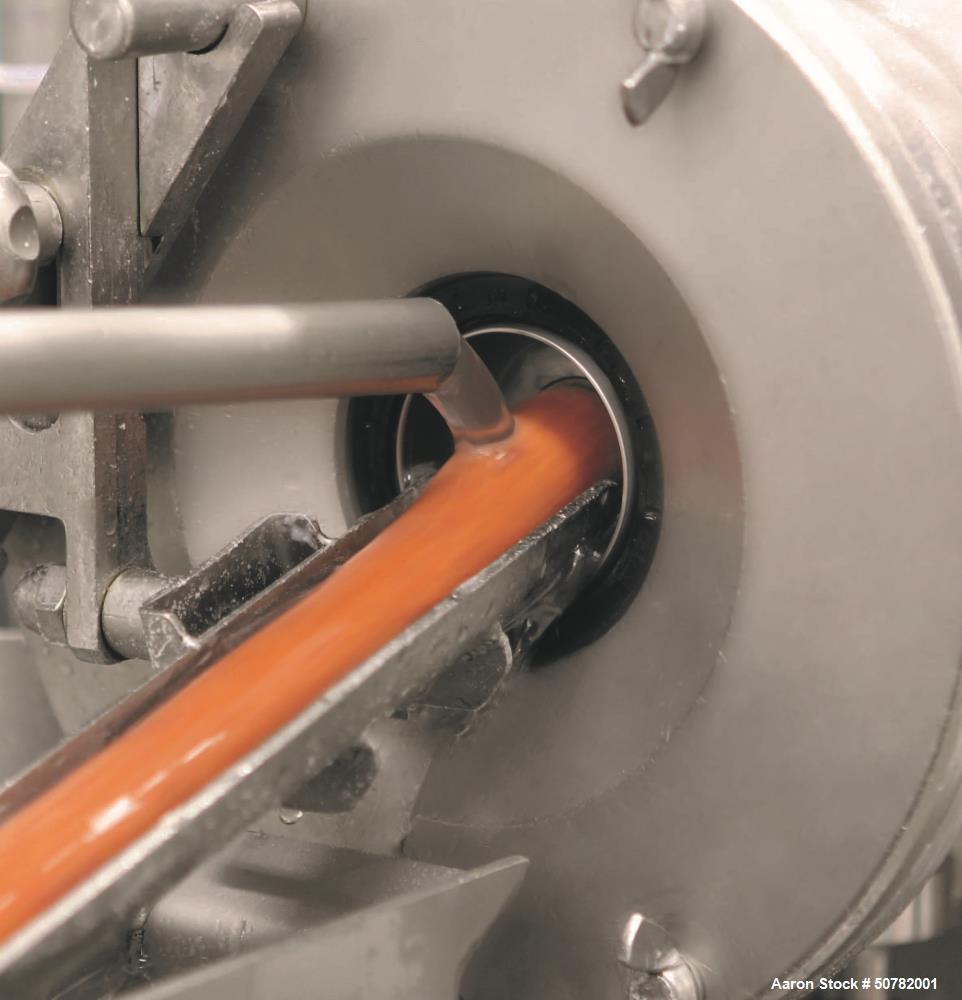

Used Townsend Stork Food Systems QX Cooked Smoked Co-Extrusion Sausage Line

Used Townsend Stork Food Systems QX Cooked Smoked Co-Extrusion Continuous/Automated Sausage Line/System. For hotdog and Frankfurter type of endless rope sausage rope with a casing gel around with a capacity of 2-2.5 tons (depending of the type of sausage (thinner/thicker). Consisting of 4 zones: Zone 1: Townsend Stork Co-Extrusion unit and Transfer unit. Zone 2: Townsend Stork Predrying and Smoking. Zone 3: Townsend Stork QX loading or manual loading. Zone 4: Townsend Stork Cooker-Cooler and Drying Conveyor. Equipment: (1) Townsend Stork meat dough vacuum filler, Type RobotHP 17C. (1) Townsend Stork/Rico meat dough stuffer, Type RS 505 CP, 8KW-400Volt/50Cycle. Includes loader, (1) Townsend Stork, Type J109703 casing gel stuffer, 2.2 KW-400volt/50cycle includes lift, (1) Townsend Stork Inline mixing unit, (2) Townsend Stork Co-Extrusion units, Type QXU includes nozzle assemblies from 18-32 mm diameter includes touch controls, (1) Townsend Stork cooling water chiller, Type CWCU includes circulating units, (1) Townsend Stork single bringing/Transfer unit, 62.4" (1600 mm), (1) Townsend Stork single crimpling units, Type CU for 18-32 mm diameter, (2) Townsend Stork single transfer conveyors, type DC-CU, (1) Townsend Stork double transfer conveyors, type TTU, (1) Townsend Stork basket rinsing unit, (1) Townsend Stork pre-drying cabinet includes air handling equipment, (1) Townsend Stork smoking unit, Type SU+SCU incl.udes liquid smoke circulation unit, (1) Townsend Stork post-drying unit includes air handling unit, (1) Townsend Stork basket rinsing unit, (1) Townsend Stork post-dryer, Type POST-DC, incl. air handling system, (1) Townsend Stork cooling conveyer, Type CC, (1) Townsend Stork Double line up conveyer, Type CC, (1) Townsend Stork Loading unit for automatic loading to thermoformer/vacuum packing machine, includes (1) Townsend Stork Thermoformer/Vacuum Packing machine for double layer packing, (1) Townsend Stork Metal detector, (4) Townsend Stork conveyors, (1) Townsend Stork Cooker/Cooler, Type 2600/WCS/WChS, (1) Townsend Stork vibrating conveyer, (1) Townsend Stork water blow off conveyer. Complete with CWS controls, piping, valves, sensors and further infrastructure. New year 2009. Can manufacture all cooked-smoked sausages currently on the market, such as e.g. Hot Dogs and Frankfurters, calibers from 1832 mm (0.511.25") diameter and lengths from 36430 mm (1.4-16.9").

Used Townsend Stork Food Systems QX Cooked Smoked Co-Extrusion Continuous/Automated Sausage Line/System. For hotdog and Frankfurter type of endless rope sausage rope with a casing gel around with a capacity of 2-2.5 tons (depending of the type of sausage (thinner/thicker). Consisting of 4 zones: Zone 1: Townsend Stork Co-Extrusion unit and Transfer unit. Zone 2: Townsend Stork Predrying and Smoking. Zone 3: Townsend Stork QX loading or manual loading. Zone 4: Townsend Stork Cooker-Cooler and Drying Conveyor. Equipment: (1) Townsend Stork meat dough vacuum filler, Type RobotHP 17C. (1) Townsend Stork/Rico meat dough stuffer, Type RS 505 CP, 8KW-400Volt/50Cycle. Includes loader, (1) Townsend Stork, Type J109703 casing gel stuffer, 2.2 KW-400volt/50cycle includes lift, (1) Townsend Stork Inline mixing unit, (2) Townsend Stork Co-Extrusion units, Type QXU includes nozzle assemblies from 18-32 mm diameter includes touch controls, (1) Townsend Stork cooling water chiller, Type CWCU includes circulating units, (1) Townsend Stork single bringing/Transfer unit, 62.4" (1600 mm), (1) Townsend Stork single crimpling units, Type CU for 18-32 mm diameter, (2) Townsend Stork single transfer conveyors, type DC-CU, (1) Townsend Stork double transfer conveyors, type TTU, (1) Townsend Stork basket rinsing unit, (1) Townsend Stork pre-drying cabinet includes air handling equipment, (1) Townsend Stork smoking unit, Type SU+SCU incl.udes liquid smoke circulation unit, (1) Townsend Stork post-drying unit includes air handling unit, (1) Townsend Stork basket rinsing unit, (1) Townsend Stork post-dryer, Type POST-DC, incl. air handling system, (1) Townsend Stork cooling conveyer, Type CC, (1) Townsend Stork Double line up conveyer, Type CC, (1) Townsend Stork Loading unit for automatic loading to thermoformer/vacuum packing machine, includes (1) Townsend Stork Thermoformer/Vacuum Packing machine for double layer packing, (1) Townsend Stork Metal detector, (4) Townsend Stork conveyors, (1) Townsend Stork Cooker/Cooler, Type 2600/WCS/WChS, (1) Townsend Stork vibrating conveyer, (1) Townsend Stork water blow off conveyer. Complete with CWS controls, piping, valves, sensors and further infrastructure. New year 2009. Can manufacture all cooked-smoked sausages currently on the market, such as e.g. Hot Dogs and Frankfurters, calibers from 1832 mm (0.511.25") diameter and lengths from 36430 mm (1.4-16.9").

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory