Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

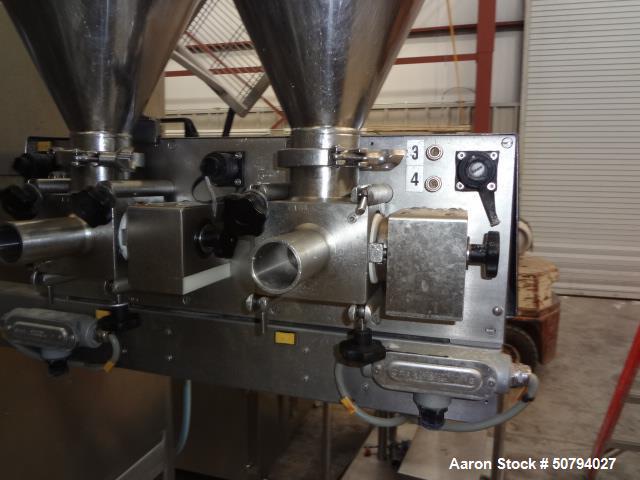

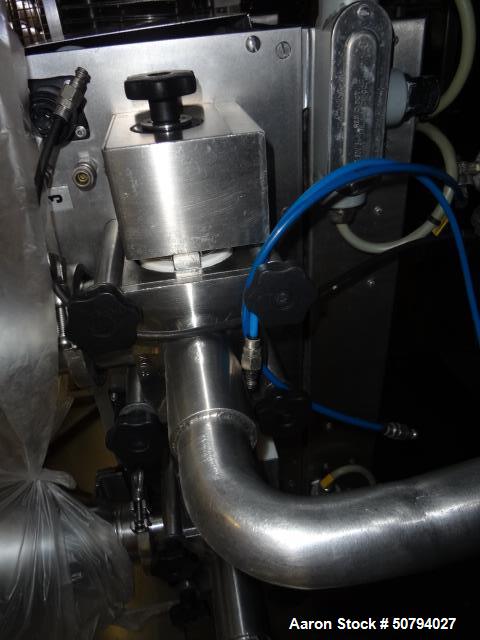

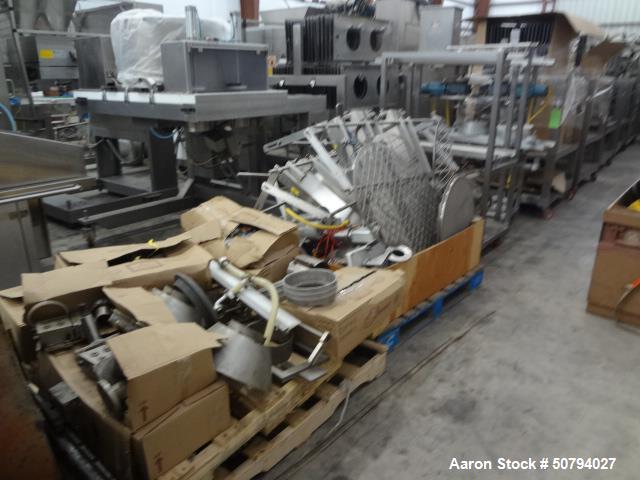

Used Comas Dual-lane Cheese Cake Line

Used Comas Dual-lane Cheese Cake Line. Includes: (3) Volumetric Depositors fed by level activated pumps, Volumetric crust depositor, crust press, platen conveyor segmented belt with holes for pans (specific for pan diameters), 5-door Stainless Steel control panel with Mitsubishi E 500 controllers, (1) spreading motion unit, vibration nut depositor, portable depositor pump, hydraulic main drive power pack, oil spray unit, crumb depositor, hydraulic press, and ejector. Pan size capability: 10" pans (2", 3", and 4" deep), 8" pans (2" deep), 8" foil fundraiser pans, 9" foil coco pans, 12" foil pans. Pump can deposit a wide range of viscosity, (from cake batter to fudge), and can handle a limited amount of soft solids in suspension (ie. Strawberries). Can deposit up to 4 pound of cheese batter, but also has smaller cylinders that allow accurate deposits of smaller weights. Each depositor can be adapted to attachments to deposit numerous viscosities, and given the proper viscosity and density of material, can be used in unison to provide layering. Volumetric Crust Depositor: Crust must be granular and able to flow. Deposits pile in middle of pan. Have volumetric cups that will deposit the following weights (in pounds): .12, .20, .30, .40, .45, .50, .60, .75, 1.10, 1.20. Crust Press: Crust must be granular and able to flow. Will press crust on the bottom or spin up the side in all 8" and 10" pans. Can regulate the height of the crust up the side with the use of limiting rings. Will only put crust on the bottom of the 8" foil. Will only spin crust up the side of the 9" foil. Will only spin up the side of the 12" foil. Comas Speed: 16-24/min. (dependent on complexity). Mfg. 2004.

Used Comas Dual-lane Cheese Cake Line. Includes: (3) Volumetric Depositors fed by level activated pumps, Volumetric crust depositor, crust press, platen conveyor segmented belt with holes for pans (specific for pan diameters), 5-door Stainless Steel control panel with Mitsubishi E 500 controllers, (1) spreading motion unit, vibration nut depositor, portable depositor pump, hydraulic main drive power pack, oil spray unit, crumb depositor, hydraulic press, and ejector. Pan size capability: 10" pans (2", 3", and 4" deep), 8" pans (2" deep), 8" foil fundraiser pans, 9" foil coco pans, 12" foil pans. Pump can deposit a wide range of viscosity, (from cake batter to fudge), and can handle a limited amount of soft solids in suspension (ie. Strawberries). Can deposit up to 4 pound of cheese batter, but also has smaller cylinders that allow accurate deposits of smaller weights. Each depositor can be adapted to attachments to deposit numerous viscosities, and given the proper viscosity and density of material, can be used in unison to provide layering. Volumetric Crust Depositor: Crust must be granular and able to flow. Deposits pile in middle of pan. Have volumetric cups that will deposit the following weights (in pounds): .12, .20, .30, .40, .45, .50, .60, .75, 1.10, 1.20. Crust Press: Crust must be granular and able to flow. Will press crust on the bottom or spin up the side in all 8" and 10" pans. Can regulate the height of the crust up the side with the use of limiting rings. Will only put crust on the bottom of the 8" foil. Will only spin crust up the side of the 9" foil. Will only spin up the side of the 12" foil. Comas Speed: 16-24/min. (dependent on complexity). Mfg. 2004.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory