Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Natural Polymer Biomass Extraction Plant

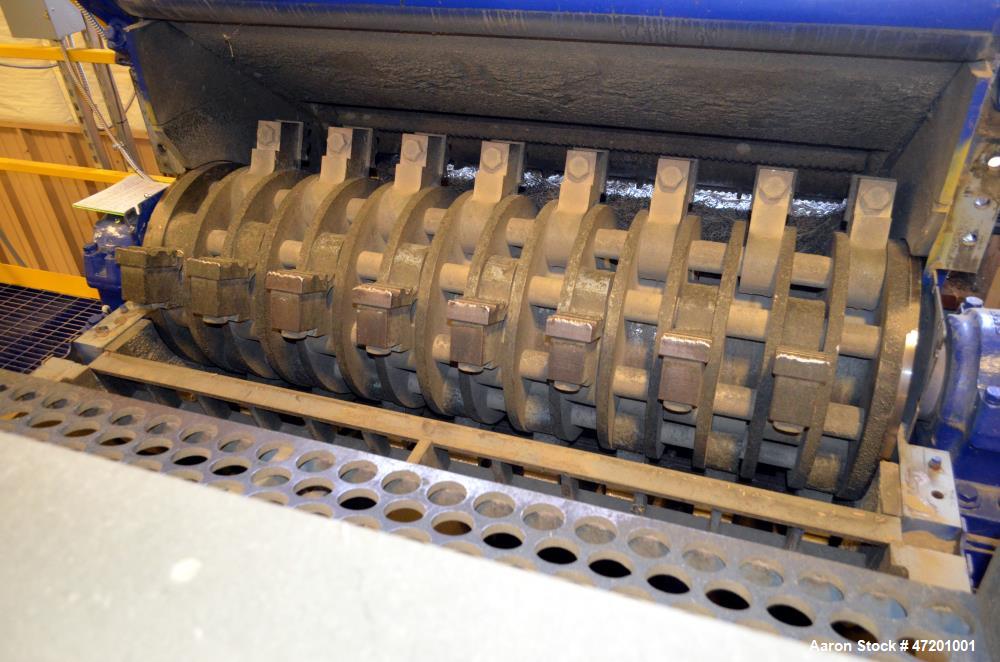

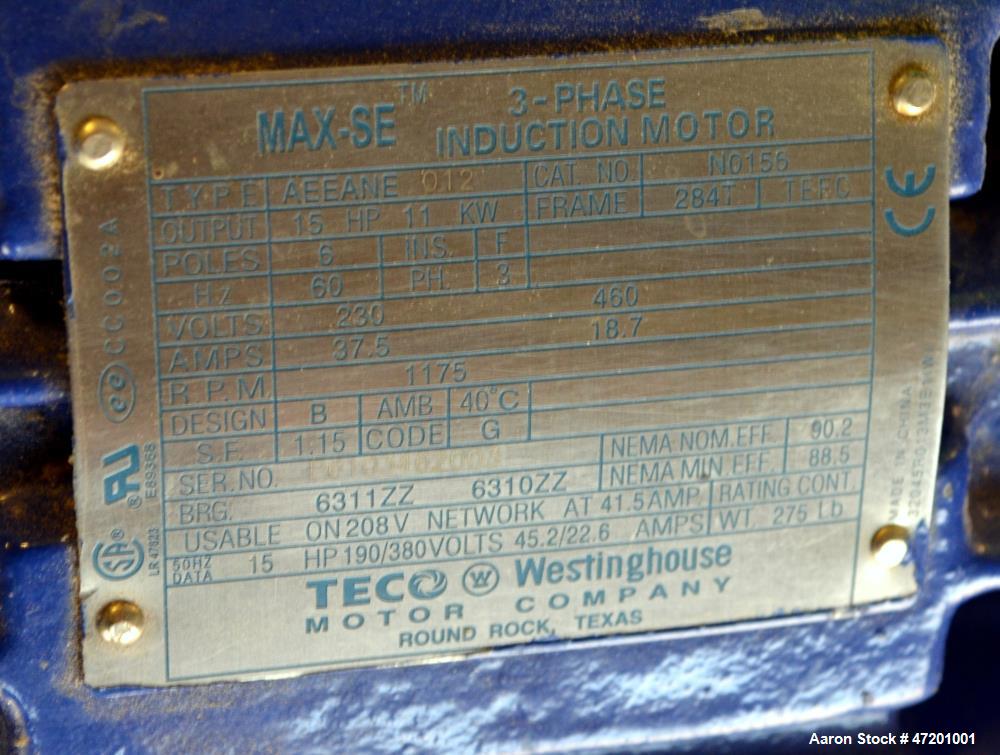

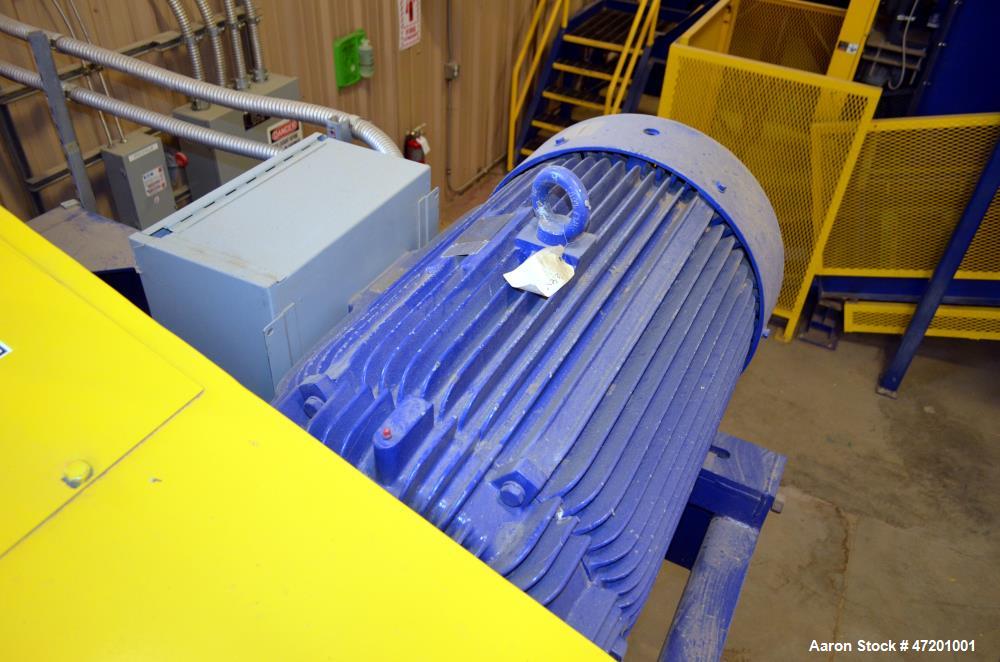

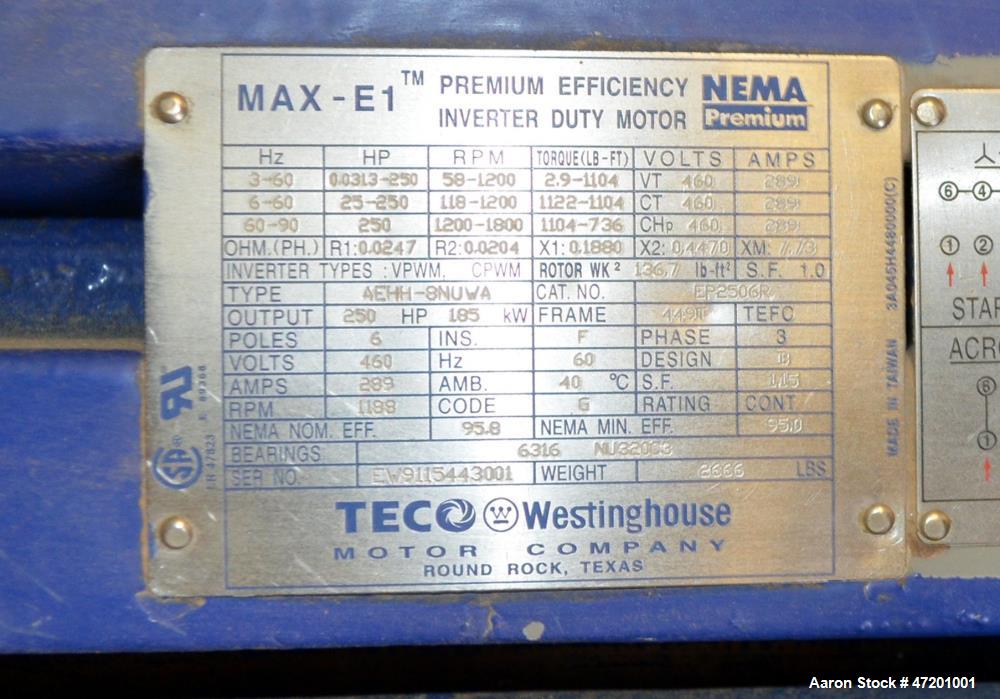

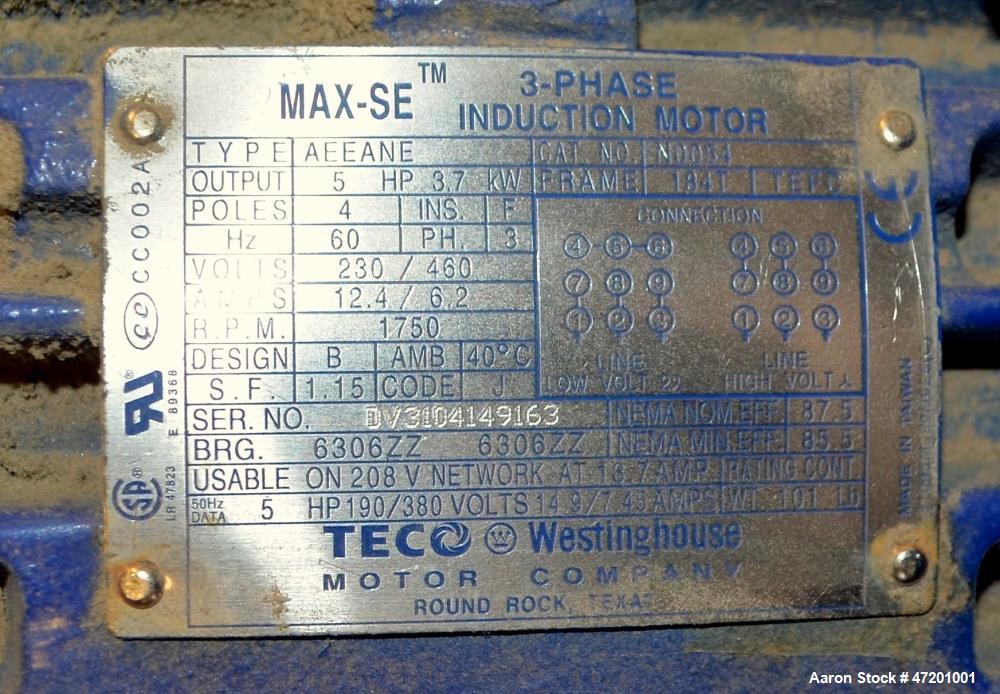

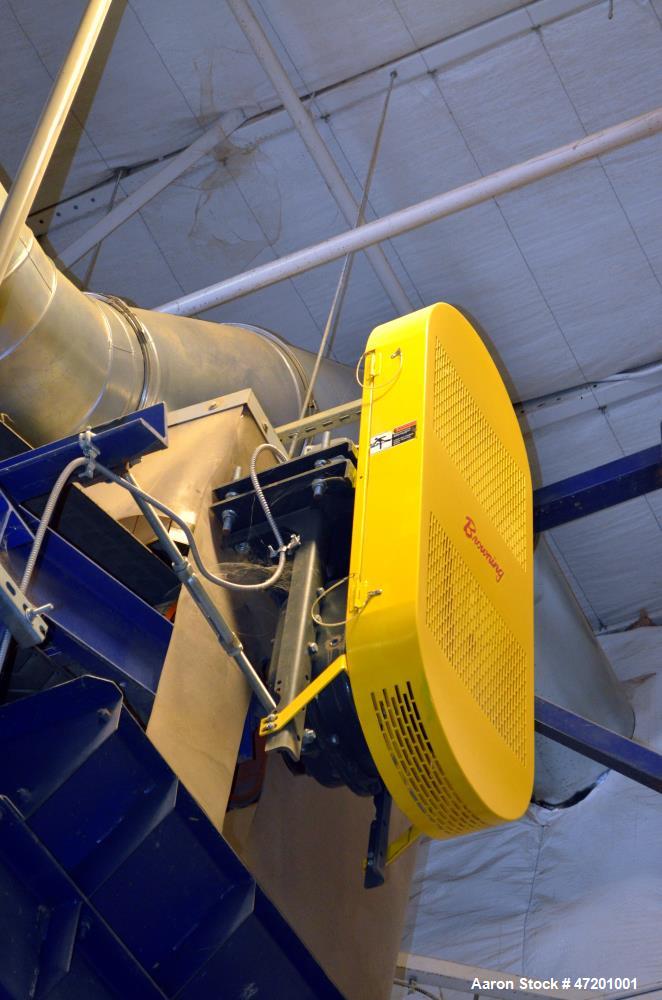

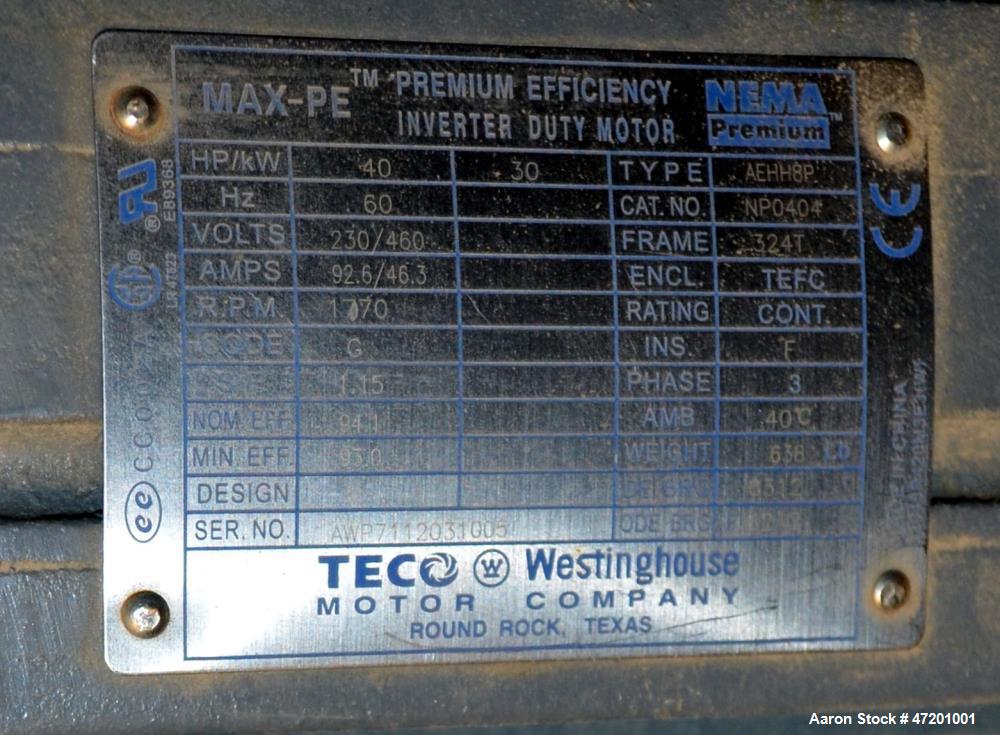

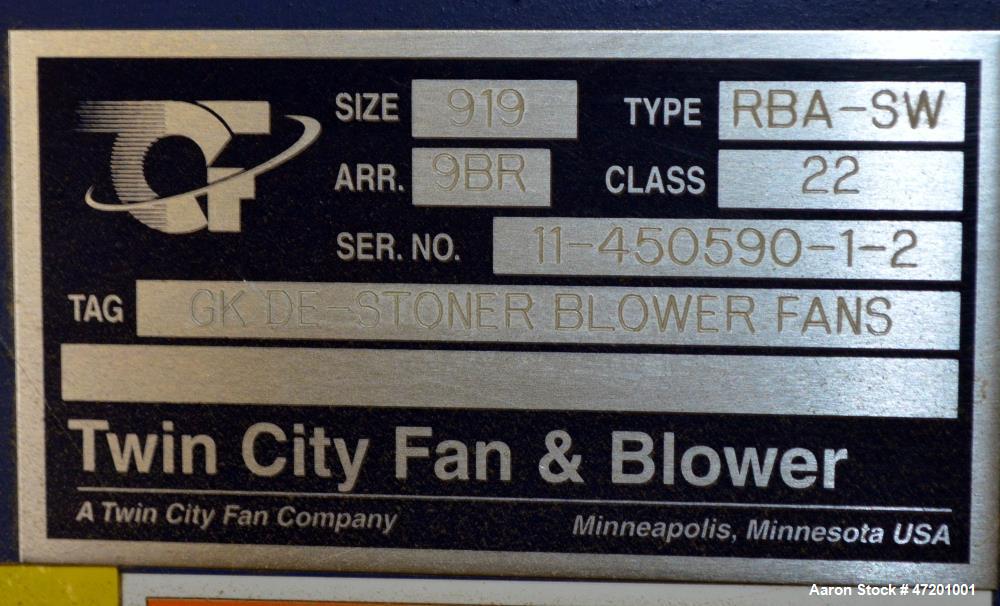

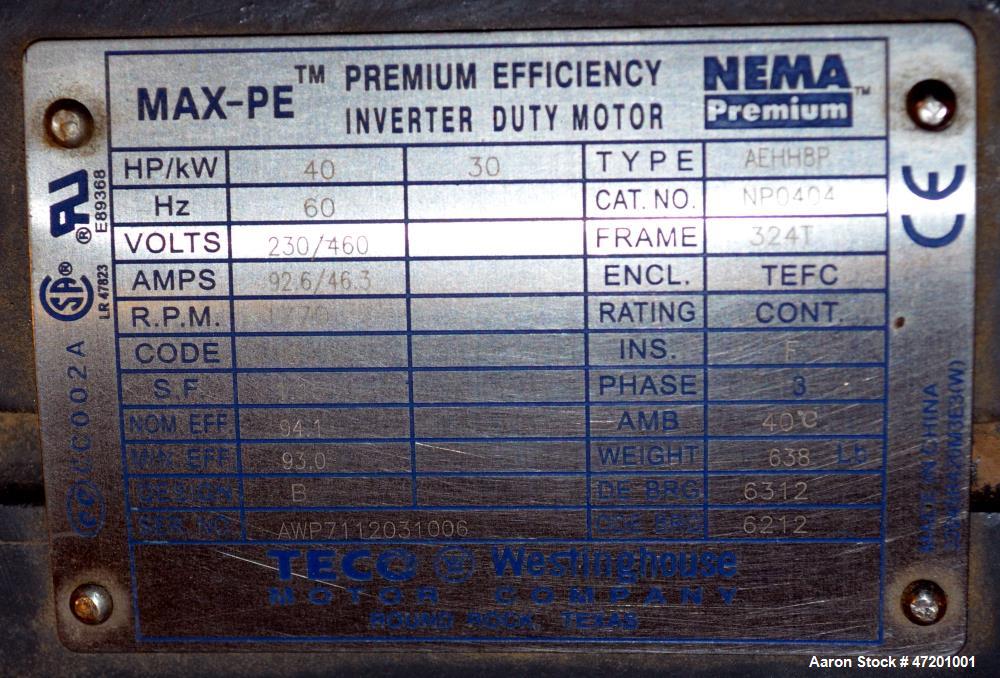

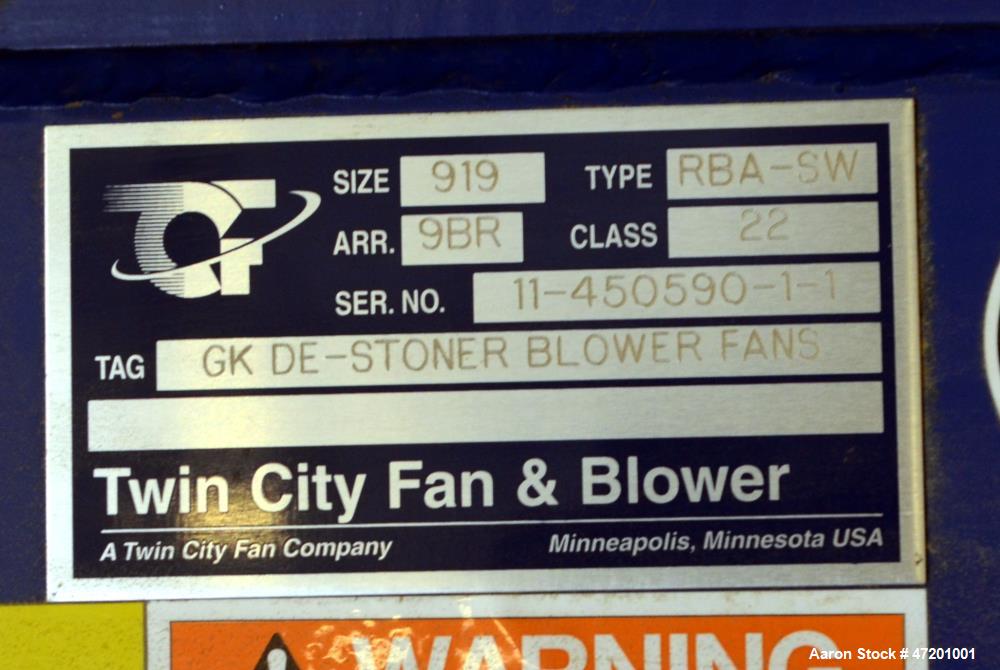

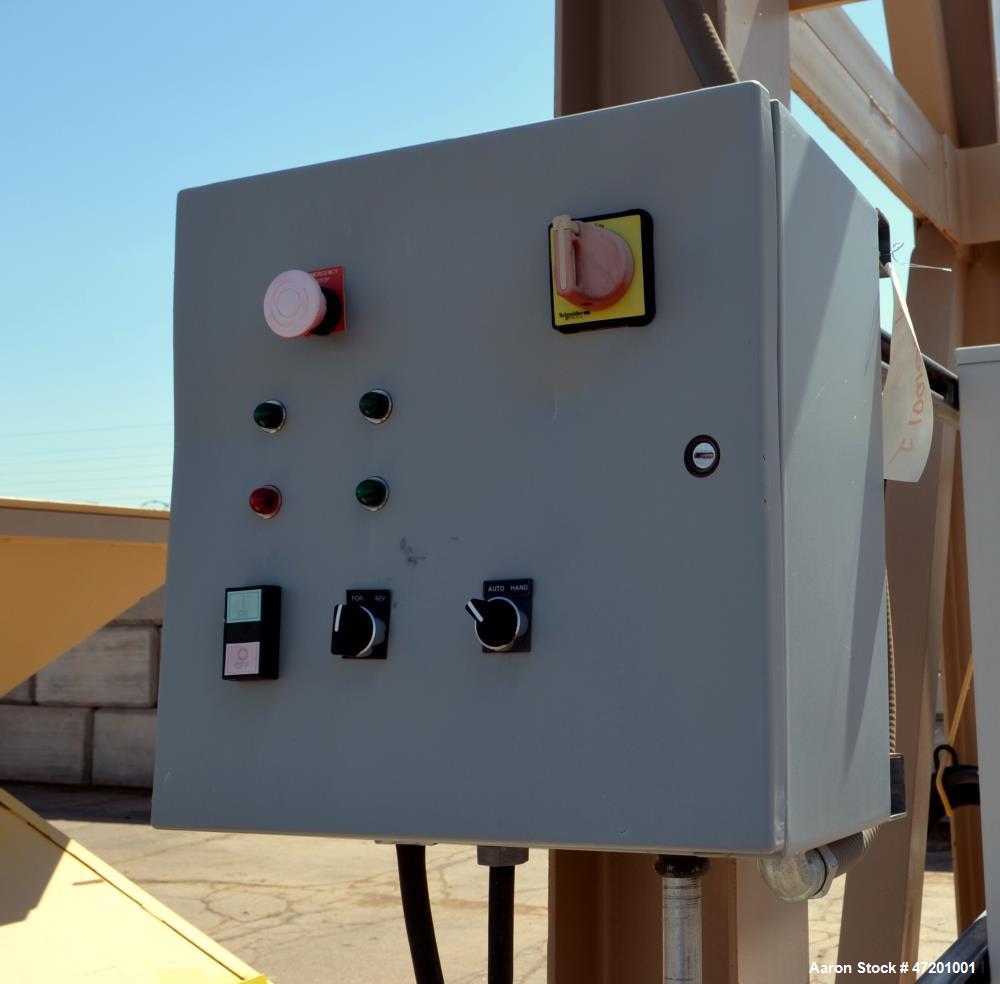

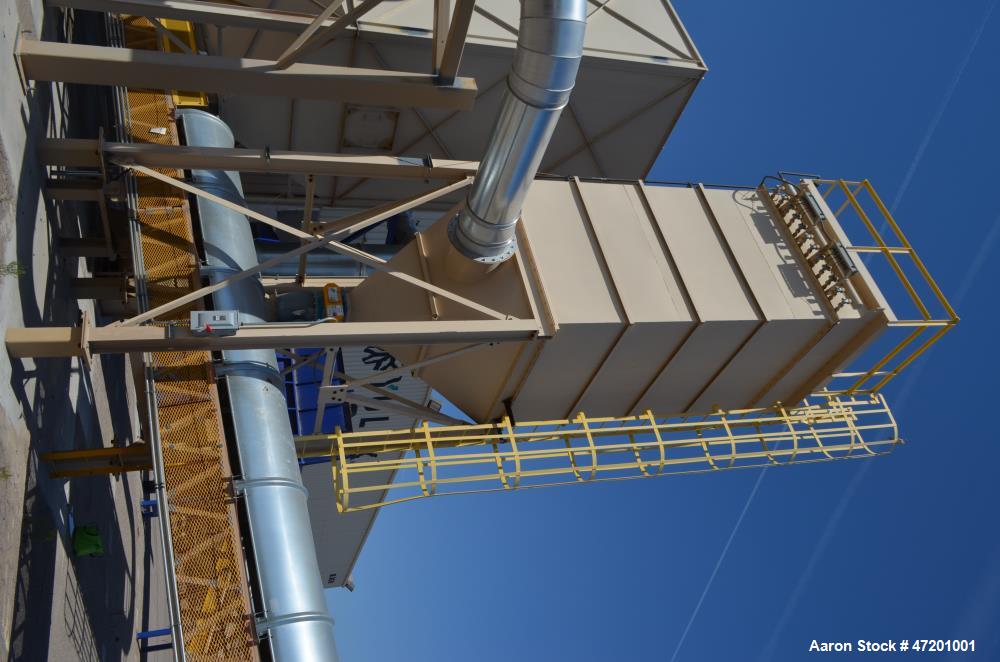

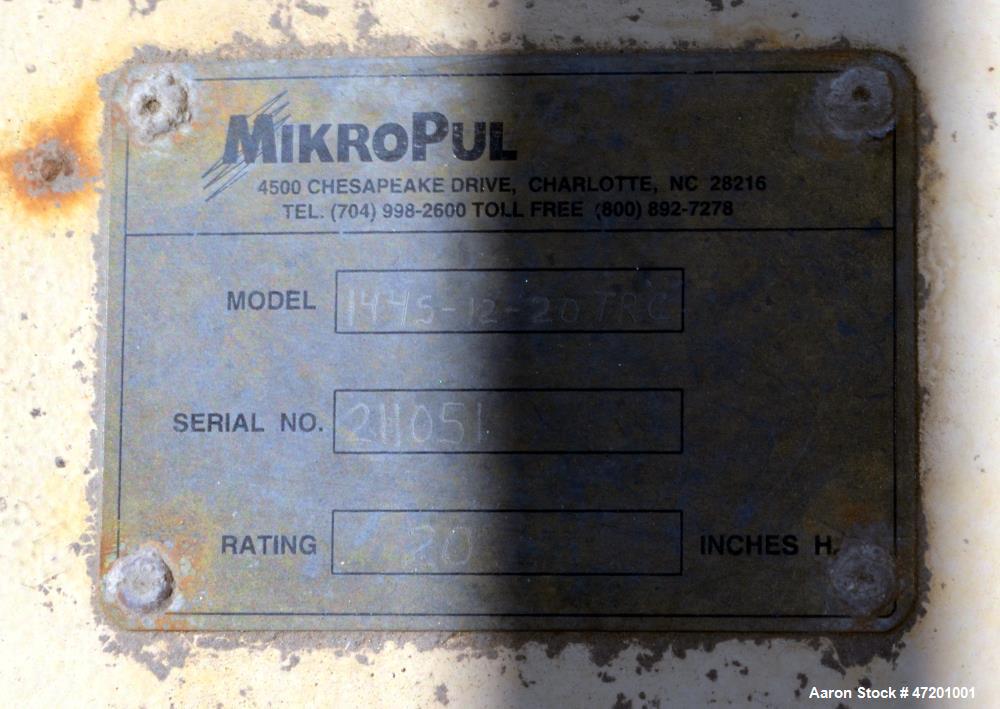

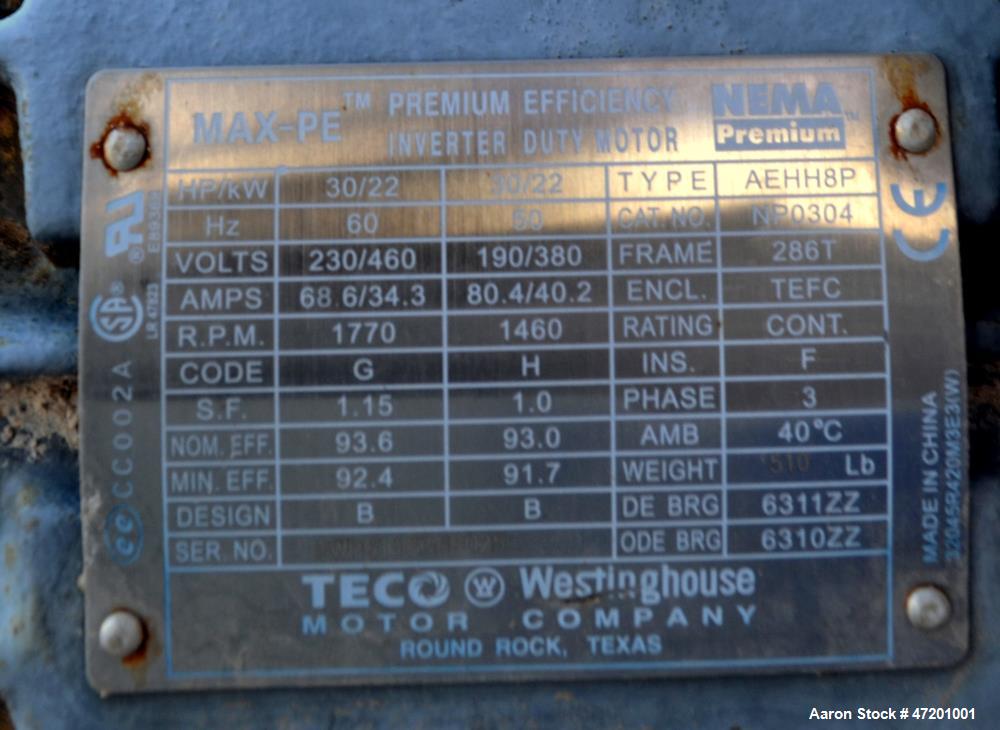

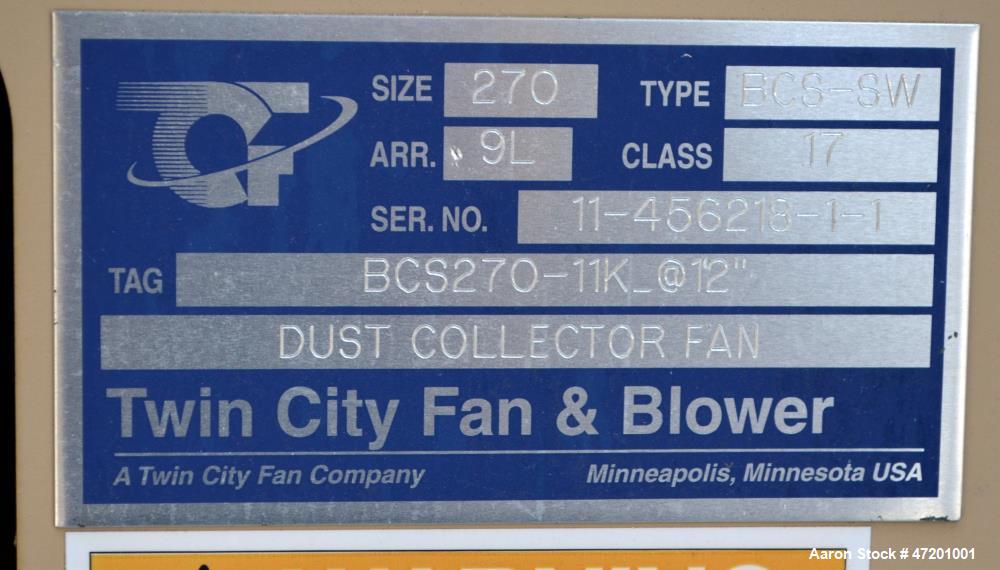

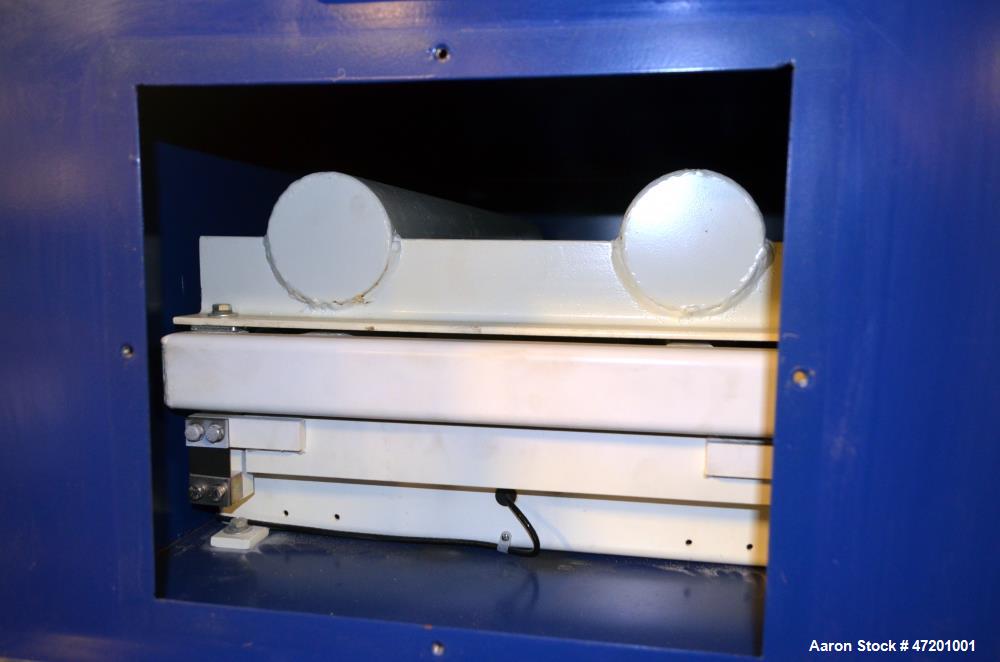

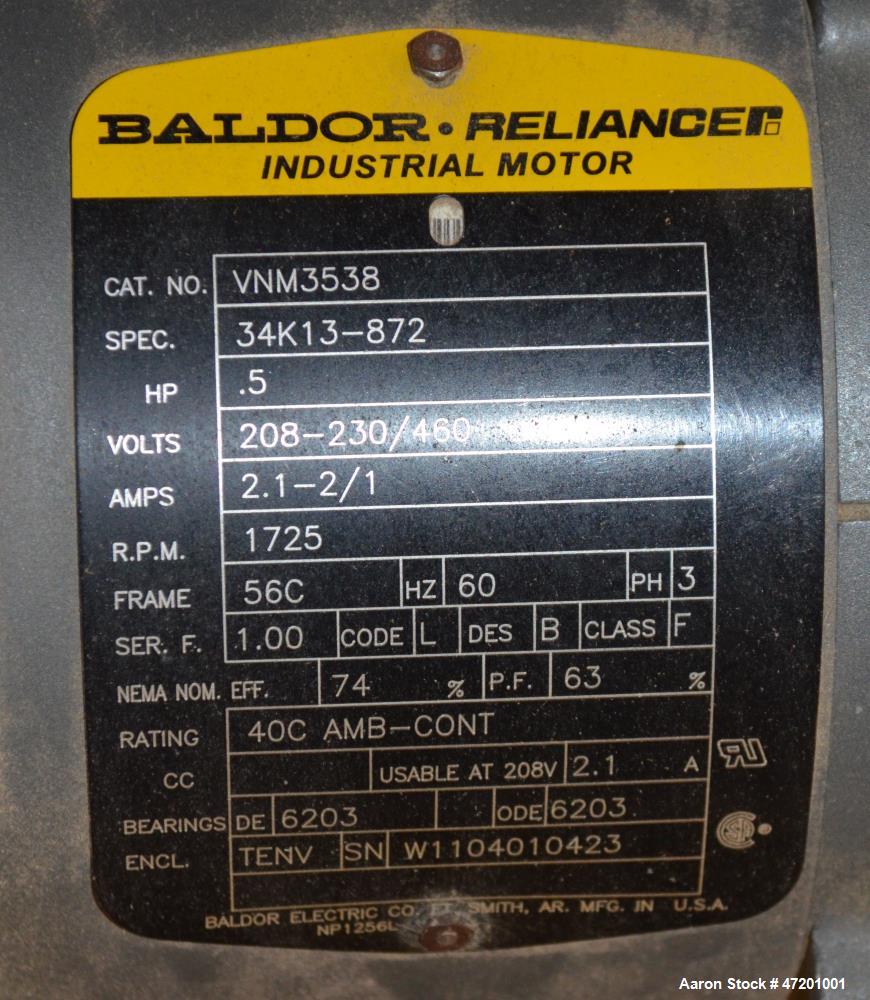

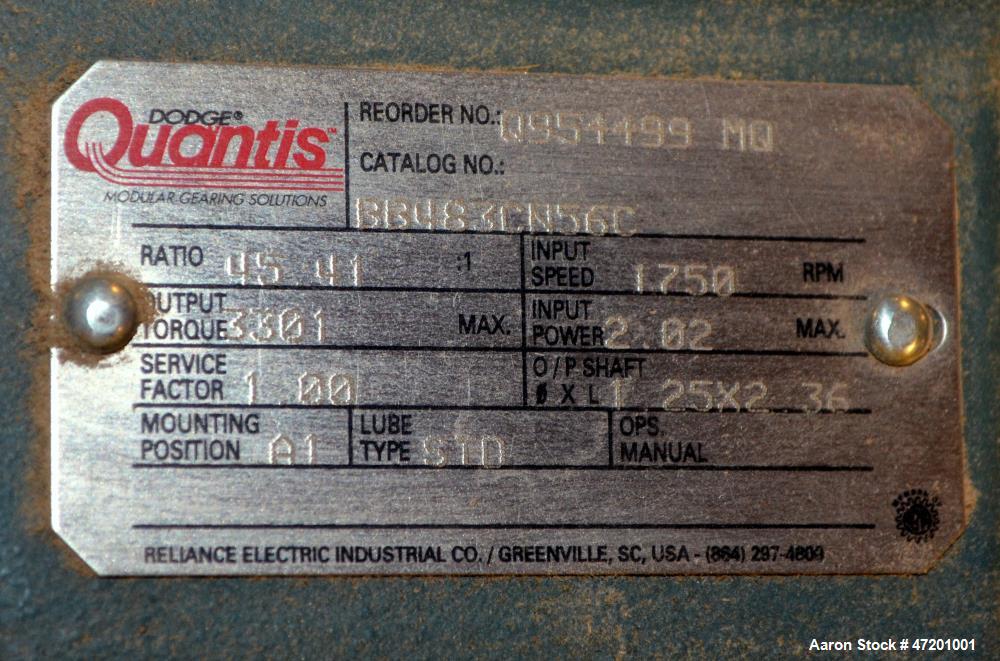

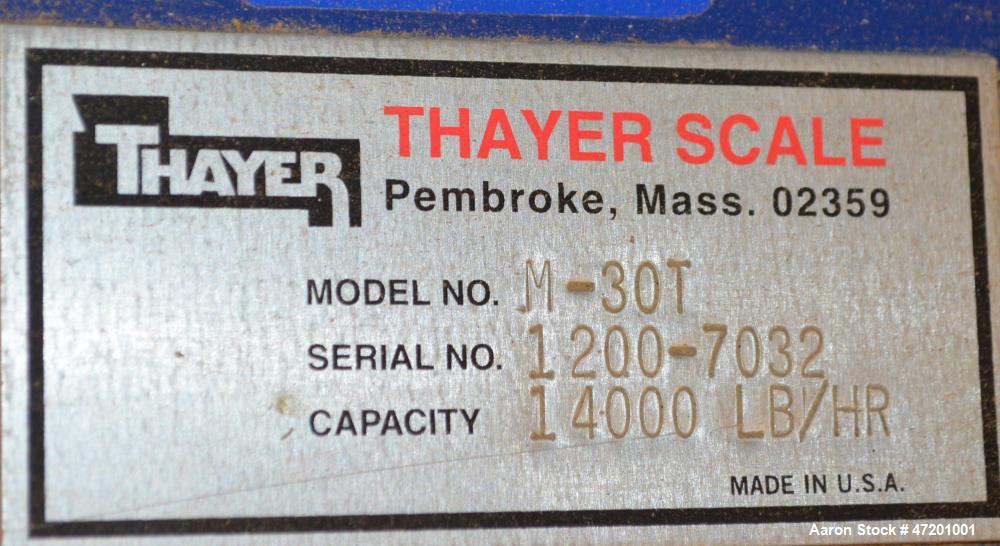

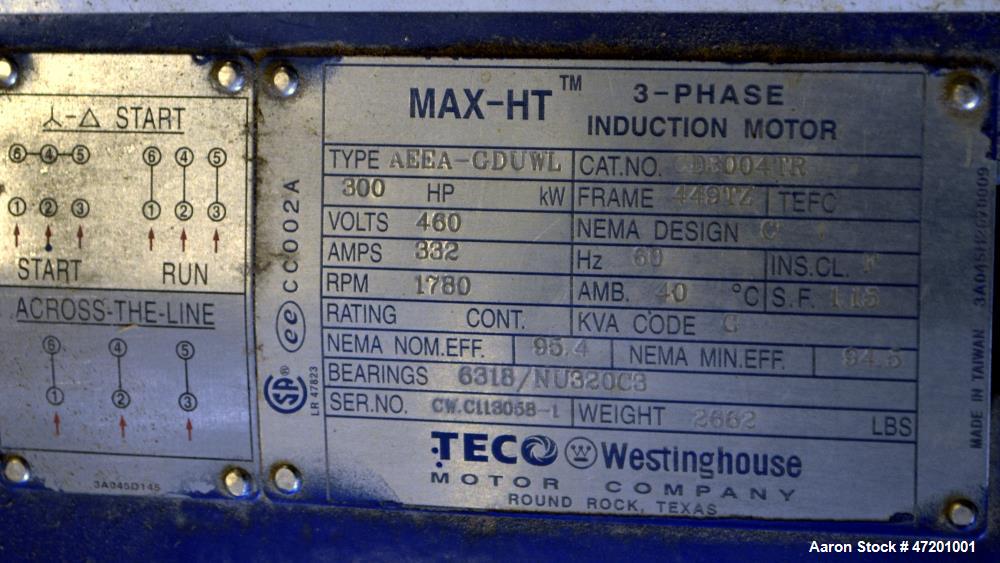

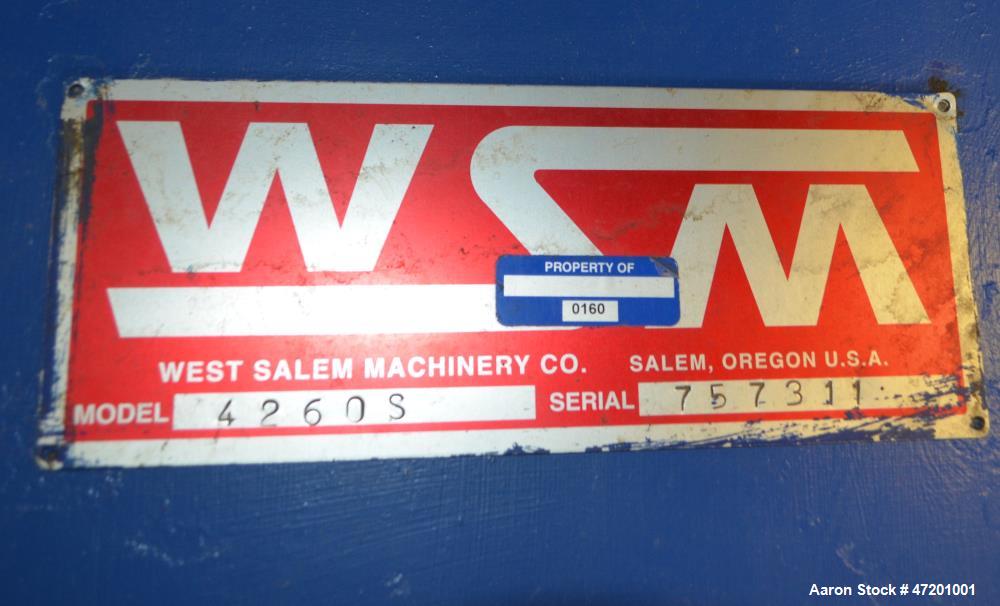

Used Natural Polymer Biomass Extraction Plant. Last running Guayule at approximate 20,000 pounds per hour capacity. Plant line consists of: (1) Brown International inclined feed conveyor, approximate 36" wide x 300" long rubber belt, with feed hopper and 5 hp gear motor. (1) WSM West Salem Machinery horizontal hog in feed conveyor, approximate 65" wide x 300" long rubber belt with 5 hp gear motor. (1) WSM West Salem Machinery BH series horizontal hog grinder, Model 3466BHBP, Serial# 756311. Feed opening 66" x 16" with 15 hp powered feed roller, and a bed plate speed up roll. Rotor 34" diameter tip to tip x 66" wide, driven by a 250 hp, 3/60/460 volt, 1200 rpm motor with VFD panel and 10 hp hydraulic power pack. (1) WSM West Salem Machinery grinder inclined discharge conveyor, Model 30-48I, Serial# 287311. Approximate 48" wide x 120" long bottom horizontal section x 240" inclined section rubber belt driven by a 5 hp motor with torque arm reducer. (1) WSM West Salem Machinery density separator inclined in feed conveyor. Approximate 36" wide x 516" long rubber belt driven by a motor with torque arm reducer. (1) Magnet belt separator. Approximate 30" wide x 60" long rubber belt, driven by a 1 hp gear motor. (1) General Kinematics dual air-knife De-Stoner Classifier Separator, Model DS-C 72X31.5, Serial# C10353-01, carbon steel. Approximate 72" wide x 378" long. Feed rate 10 tons per hour at 12 pounds per cubic feet, driven by an approximate 30 hp motor, includes (2) Twin City blowers, size 919, type RBA-SW, each driven by a 40 hp motor, Serial#s 11-450590-1-1 & 11-450590-1-2. (1) Fines bolt together collection hopper, carbon steel. Approximate 114" wide x 288" long x 192" straight side x coned bottom, 18" wide bottom outlet. (1) Trio fines incline rubber belt discharge conveyor. Approximate 24" wide x 1800" long belt with approximate 1488" section of top covers, motor with torque arm reducer, approximate 204" discharge height. (1) Trio pivot mounted distribution rubber belt discharge conveyor. Approximate 24" wide x 720" long belt with approximate 528" section of top covers, motor with torque arm reducer, (2) motorized wheels, and panel (1) MikroPul pulse jet dust collector, Model 144S-12-20-TRC, Serial# 211051, carbon steel. Approximate 2000 square feet filter area. Includes a Carolina Conveying rotary valve, Model 8"RVS, Serial# 59475 with 1/2 hp gear motor and a Twin City blower, size 270, type BCS-SW, driven by a 30 hp motor, Serial#s 11-456218-1-1. (1) WSM West Salem Machinery density separator stick collection discharge conveyor. Approximate 30" wide x 240" long rubber belt driven by a 3 hp motor with torque arm reducer, ratio 34.8154 to 1. (1) WSM West Salem Machinery weigh belt in feed conveyor. Approximate 36" wide x 600" long rubber belt driven by a 5 hp motor with torque arm reducer, ratio 34.82 to 1. (1) Thayer Scale M Series Low Density Weigh Belt Feeder, Model M-30T. Capacity 14000 pounds an hour. Approximate 30" wide x 132" long belt, driven by a 1/2 hp motor with reducer, ratio 45.41 to 1, with a Thayer S52i controller, Serial# 1200-7032. (1) Kase enclosed S incline conveyor. Approximate 36" wide belt x approximate 120" long bottom horizxotal section x 16" tall incline section x 5" long top horizontal section, driven by a motor with torque arm reducer, Serial# C-13H08. (1) Quad screw grinder feeder, approximate 84" long, with (2) motors thru torque arm reducers. (1) WSM West Salem Machinery 42 Series hammermill grinder, Model 4260S, Serial# 757311. Feed opening 26-7/8" x 63-12". Rotor 42" diameter tip to tip x 60" wide, driven by a 300 hp, 3/60/460 volt, 1780 rpm motor with VFD panel and 3 hp hydraulic power pack. (1) Twin shaft paddle mixer, stainless steel. (2) Approximate 4-1/2" diameter sfafts with 1/2" thick welded paddles. Approximate 10" pitched trough 66-1/2" wide x 160" long. Each shaft driven by a 5 hp motor with torque arm reducers.

Used Natural Polymer Biomass Extraction Plant. Last running Guayule at approximate 20,000 pounds per hour capacity. Plant line consists of: (1) Brown International inclined feed conveyor, approximate 36" wide x 300" long rubber belt, with feed hopper and 5 hp gear motor. (1) WSM West Salem Machinery horizontal hog in feed conveyor, approximate 65" wide x 300" long rubber belt with 5 hp gear motor. (1) WSM West Salem Machinery BH series horizontal hog grinder, Model 3466BHBP, Serial# 756311. Feed opening 66" x 16" with 15 hp powered feed roller, and a bed plate speed up roll. Rotor 34" diameter tip to tip x 66" wide, driven by a 250 hp, 3/60/460 volt, 1200 rpm motor with VFD panel and 10 hp hydraulic power pack. (1) WSM West Salem Machinery grinder inclined discharge conveyor, Model 30-48I, Serial# 287311. Approximate 48" wide x 120" long bottom horizontal section x 240" inclined section rubber belt driven by a 5 hp motor with torque arm reducer. (1) WSM West Salem Machinery density separator inclined in feed conveyor. Approximate 36" wide x 516" long rubber belt driven by a motor with torque arm reducer. (1) Magnet belt separator. Approximate 30" wide x 60" long rubber belt, driven by a 1 hp gear motor. (1) General Kinematics dual air-knife De-Stoner Classifier Separator, Model DS-C 72X31.5, Serial# C10353-01, carbon steel. Approximate 72" wide x 378" long. Feed rate 10 tons per hour at 12 pounds per cubic feet, driven by an approximate 30 hp motor, includes (2) Twin City blowers, size 919, type RBA-SW, each driven by a 40 hp motor, Serial#s 11-450590-1-1 & 11-450590-1-2. (1) Fines bolt together collection hopper, carbon steel. Approximate 114" wide x 288" long x 192" straight side x coned bottom, 18" wide bottom outlet. (1) Trio fines incline rubber belt discharge conveyor. Approximate 24" wide x 1800" long belt with approximate 1488" section of top covers, motor with torque arm reducer, approximate 204" discharge height. (1) Trio pivot mounted distribution rubber belt discharge conveyor. Approximate 24" wide x 720" long belt with approximate 528" section of top covers, motor with torque arm reducer, (2) motorized wheels, and panel (1) MikroPul pulse jet dust collector, Model 144S-12-20-TRC, Serial# 211051, carbon steel. Approximate 2000 square feet filter area. Includes a Carolina Conveying rotary valve, Model 8"RVS, Serial# 59475 with 1/2 hp gear motor and a Twin City blower, size 270, type BCS-SW, driven by a 30 hp motor, Serial#s 11-456218-1-1. (1) WSM West Salem Machinery density separator stick collection discharge conveyor. Approximate 30" wide x 240" long rubber belt driven by a 3 hp motor with torque arm reducer, ratio 34.8154 to 1. (1) WSM West Salem Machinery weigh belt in feed conveyor. Approximate 36" wide x 600" long rubber belt driven by a 5 hp motor with torque arm reducer, ratio 34.82 to 1. (1) Thayer Scale M Series Low Density Weigh Belt Feeder, Model M-30T. Capacity 14000 pounds an hour. Approximate 30" wide x 132" long belt, driven by a 1/2 hp motor with reducer, ratio 45.41 to 1, with a Thayer S52i controller, Serial# 1200-7032. (1) Kase enclosed S incline conveyor. Approximate 36" wide belt x approximate 120" long bottom horizxotal section x 16" tall incline section x 5" long top horizontal section, driven by a motor with torque arm reducer, Serial# C-13H08. (1) Quad screw grinder feeder, approximate 84" long, with (2) motors thru torque arm reducers. (1) WSM West Salem Machinery 42 Series hammermill grinder, Model 4260S, Serial# 757311. Feed opening 26-7/8" x 63-12". Rotor 42" diameter tip to tip x 60" wide, driven by a 300 hp, 3/60/460 volt, 1780 rpm motor with VFD panel and 3 hp hydraulic power pack. (1) Twin shaft paddle mixer, stainless steel. (2) Approximate 4-1/2" diameter sfafts with 1/2" thick welded paddles. Approximate 10" pitched trough 66-1/2" wide x 160" long. Each shaft driven by a 5 hp motor with torque arm reducers.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory