Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Air Separation Unit (ASU) Plant

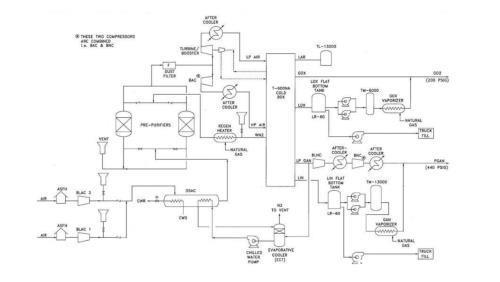

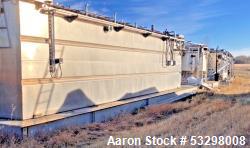

Used Air Separation Unit (ASU) Plant. Produces 400 KSCFH of Gaseous Oxygen (GOX) at 200 psig and another 100 KSCFH of Gaseous Oxygen (GOX) at 3 psig, Oxygen Purity 99.5%, N2 Purity less than 10 PPM O2. This ASU plant also makes 100 KSCFH of Liquid Oxygen (LOX) & 200 KSCFH of Gaseous Nitrogen (GAN) at 400 psig, plus 69.2 KSCFH of Liquid Nitrogen (LIN) and 23.9 KSCFH of Liquid Argon (LAR) Less than 1 PPM 02 and less than 1 PPM N2. The plant has a film-type main vaporizer with two BAHX closed cores supplied by Sumitomo and is equipped with an alumina/CaBaX air purification system. The natural gas fired heater provides heat for regeneration. HP column has trays. LP column and two argon columns have packing. Argon production is cryo-argon" type. Liquid dumping is through forced air dump vaporizer. The LP liquid products are stored in two 525,000-gallon LOX and LIN flat-bottomed storage tanks. LAR is stored in an 11,000-gallon tank. The HP LOX and HP LIN are stored in a 6000-gallon tank and 13,000-gallon tank, respectively. The backup system is a hot water bath vaporizer with an estimated capacity of 1000 KSCFH and multiple coils (GOX, GAN, and Tank pressurization coils). The two hot water boilers are natural gas fired. LOX, LIN, and LAR trailers are loaded by pumps in one load-out station. A single scale provides Gross & Tare weights of trailers. The control system is comprised of (5) AB PLC5 processors with remote IO in 11 cabinets. The HMI was iFix32 installed on Windows XP. There are very few pneumatic and single-loop electronic controllers. However, no local panels are present at the compressors. Electricity is delivered to the site via aerial cable by Axiell/Westlake. The electrical system includes main plant, 34.5 KV high voltage electrical substation and overhead distribution lines from Axiall/Westlake cogen units to the substation. The distribution substation consists of a 34.5 KV to 13.8 KV 20MVA Transformer, an elevated PDC building containing a 13.8 KV Switc.

Used Air Separation Unit (ASU) Plant. Produces 400 KSCFH of Gaseous Oxygen (GOX) at 200 psig and another 100 KSCFH of Gaseous Oxygen (GOX) at 3 psig, Oxygen Purity 99.5%, N2 Purity less than 10 PPM O2. This ASU plant also makes 100 KSCFH of Liquid Oxygen (LOX) & 200 KSCFH of Gaseous Nitrogen (GAN) at 400 psig, plus 69.2 KSCFH of Liquid Nitrogen (LIN) and 23.9 KSCFH of Liquid Argon (LAR) Less than 1 PPM 02 and less than 1 PPM N2. The plant has a film-type main vaporizer with two BAHX closed cores supplied by Sumitomo and is equipped with an alumina/CaBaX air purification system. The natural gas fired heater provides heat for regeneration. HP column has trays. LP column and two argon columns have packing. Argon production is cryo-argon" type. Liquid dumping is through forced air dump vaporizer. The LP liquid products are stored in two 525,000-gallon LOX and LIN flat-bottomed storage tanks. LAR is stored in an 11,000-gallon tank. The HP LOX and HP LIN are stored in a 6000-gallon tank and 13,000-gallon tank, respectively. The backup system is a hot water bath vaporizer with an estimated capacity of 1000 KSCFH and multiple coils (GOX, GAN, and Tank pressurization coils). The two hot water boilers are natural gas fired. LOX, LIN, and LAR trailers are loaded by pumps in one load-out station. A single scale provides Gross & Tare weights of trailers. The control system is comprised of (5) AB PLC5 processors with remote IO in 11 cabinets. The HMI was iFix32 installed on Windows XP. There are very few pneumatic and single-loop electronic controllers. However, no local panels are present at the compressors. Electricity is delivered to the site via aerial cable by Axiell/Westlake. The electrical system includes main plant, 34.5 KV high voltage electrical substation and overhead distribution lines from Axiall/Westlake cogen units to the substation. The distribution substation consists of a 34.5 KV to 13.8 KV 20MVA Transformer, an elevated PDC building containing a 13.8 KV Switc.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory