Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

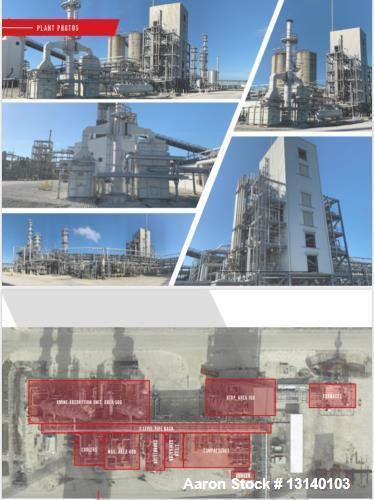

Used RTI Warm Syngas Cleanup Plant

Used RTI Warm Syngas Cleanup Plant. Utilizing an integration of RTIs Warm Gas Desulfurization Process and Carbon Capture Technologies. The plant is capable of producing desulfurized syngas with a total sulfur (H2S + COS) concentration that is reduced by approximately 99.9% at temperatures as high as 650 degrees Celsius and converts sufficient CO to CO2 to allow 90% CO2 capture. Plant has 6,000 run hours and most equipment built 2012 and 2013. The Desulfurization plant includes (2) Tulsa Heaters for Regeneration Startup and Absorbent Startup, as well as Absorber and Regenerator Reactors. These units use sorbent that has high sulfur capacity and excellent attrition resistance. Through regeneration, this sorbent goes through multiple cycles. This part of the plant also has several sorbent hoppers, a 4,123 square foot Inconel 600 heat exchanger, and a large filter housing. The Water Gas Shift Reactor Plant consists of (3) large shift gas reactors, several large heat exchangers, compressors, and support tanks for converting the CO to CO2. Through this conversion, the plant allows for a very high purity hydrogen product to be produced. The activated Amine Process plant consists of a Calgon Carbon filter skid, a 63,000 gallon Carbon Steel Amine Tank, a 6 diameter x 90 stripper column, a 10 x 148 absorber column, (2) 10,222 square foot heat exchangers, and a 6,343 square foot heat exchanger that allows for CO2 extraction along with any residual H2S or other sulfur compounds. This allows the entire process to create an extremely clean fuel with high purity hydrogen content.

Used RTI Warm Syngas Cleanup Plant. Utilizing an integration of RTIs Warm Gas Desulfurization Process and Carbon Capture Technologies. The plant is capable of producing desulfurized syngas with a total sulfur (H2S + COS) concentration that is reduced by approximately 99.9% at temperatures as high as 650 degrees Celsius and converts sufficient CO to CO2 to allow 90% CO2 capture. Plant has 6,000 run hours and most equipment built 2012 and 2013. The Desulfurization plant includes (2) Tulsa Heaters for Regeneration Startup and Absorbent Startup, as well as Absorber and Regenerator Reactors. These units use sorbent that has high sulfur capacity and excellent attrition resistance. Through regeneration, this sorbent goes through multiple cycles. This part of the plant also has several sorbent hoppers, a 4,123 square foot Inconel 600 heat exchanger, and a large filter housing. The Water Gas Shift Reactor Plant consists of (3) large shift gas reactors, several large heat exchangers, compressors, and support tanks for converting the CO to CO2. Through this conversion, the plant allows for a very high purity hydrogen product to be produced. The activated Amine Process plant consists of a Calgon Carbon filter skid, a 63,000 gallon Carbon Steel Amine Tank, a 6 diameter x 90 stripper column, a 10 x 148 absorber column, (2) 10,222 square foot heat exchangers, and a 6,343 square foot heat exchanger that allows for CO2 extraction along with any residual H2S or other sulfur compounds. This allows the entire process to create an extremely clean fuel with high purity hydrogen content.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory