Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: [email protected]

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

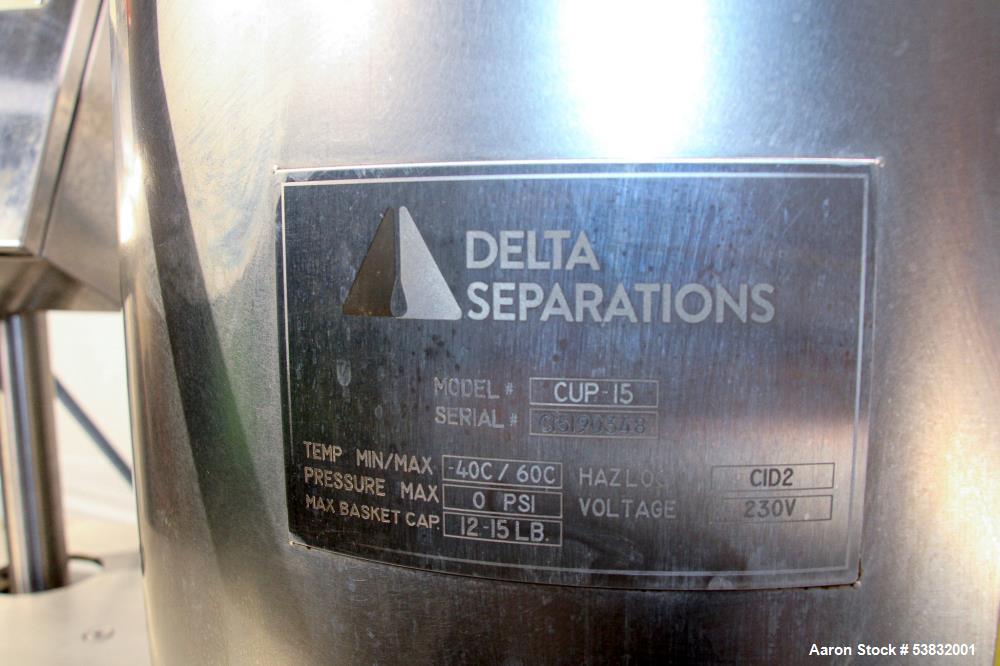

Used Delta Separations Ethanol Extraction System – Model CUP-15

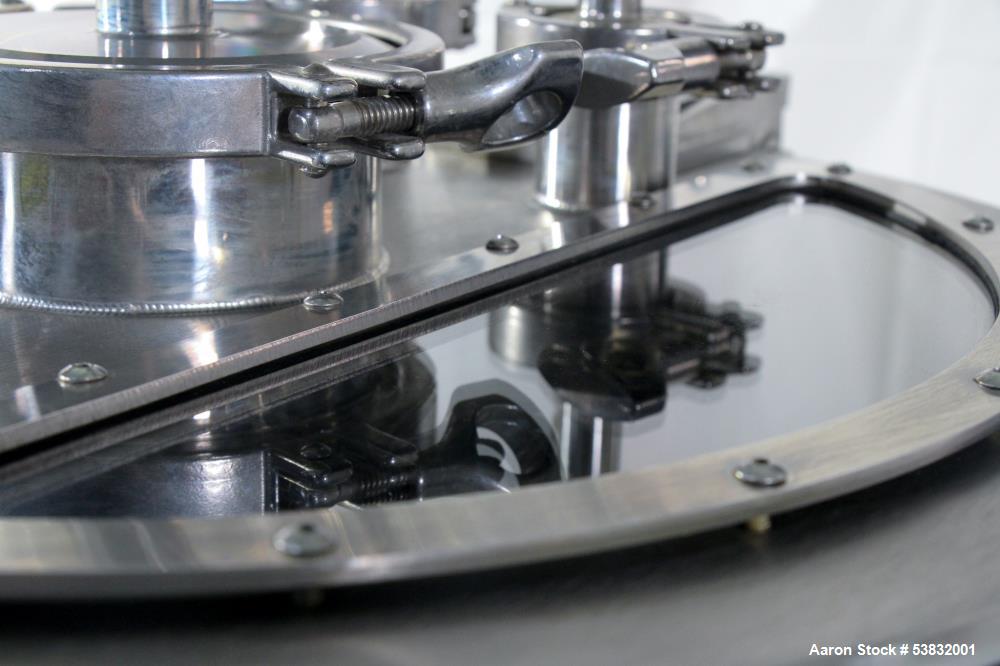

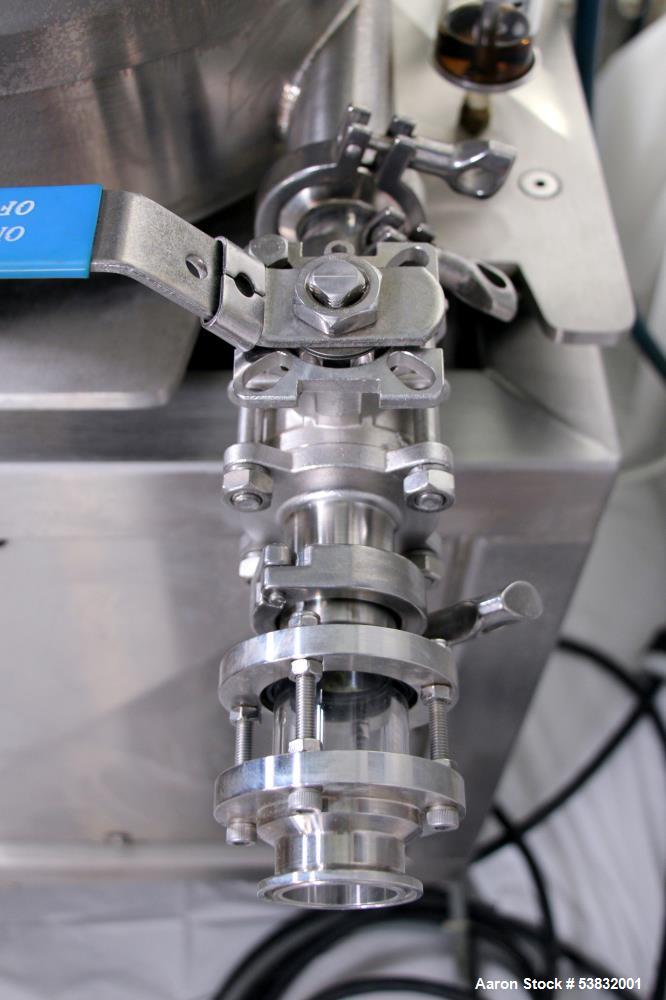

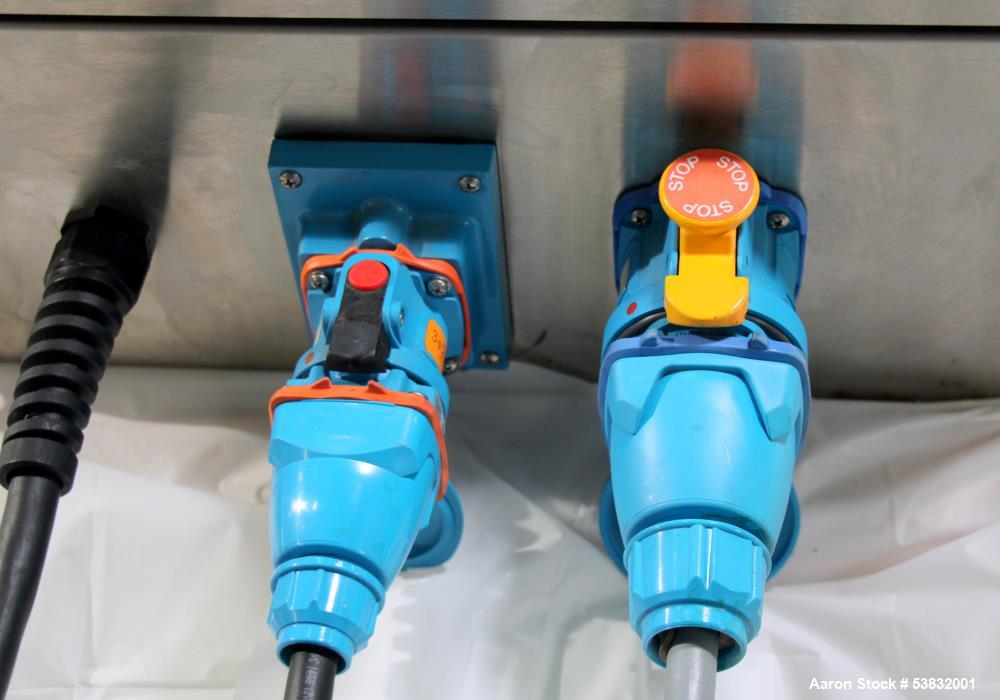

Used Delta Separations Ethanol Extraction System, Model CUP-15. 1015 lbs (4.56.8 kg) of plant material, depending on mill size processing capacity per batch; 1315 gallons (4956 liters) ethanol requirement per run; Approximately 300 lbs (136 kg) of biomass processed per 8-hour shift throughput; Temperature minimum and maximum, -40C / 60C; 0 psi maximum pressure; 12-15 lb maximum basket capacity; Liquid/vapor tight vessel with EPDM lid seal; 1 gallon jacket volume with 1/2" NPT male jacket ports; Industrial Hazardous Location (HazLoc) control panel; Touchscreen HMI; Dual emergency stop (system & control panel. This system combines closed-loop, cold alcohol extraction with mechanical centrifugation, ensuring high-purity extractions. Serial # C15190348.

Description

The Delta Separations CUP-15 Ethanol Extraction System is an industrial-grade closed-loop ethanol extraction system designed for high-efficiency botanical oil extraction. It integrates cold alcohol extraction with mechanical centrifugation, ensuring high-purity yields while maximizing solvent recovery.

With a batch capacity of 10–15 lbs (4.5–6.8 kg) of plant material, this system operates efficiently, requiring 13–15 gallons (49–56 liters) of ethanol per run. Its high-throughput capability allows for processing approximately 300 lbs (136 kg) of biomass per 8-hour shift.

Designed to operate within a temperature range of -40°C to 60°C, this system features a liquid/vapor-tight vessel with an EPDM lid seal and a 1-gallon jacket volume with ½” NPT male jacket ports, ensuring precise temperature control. The Hazardous Location (HazLoc) industrial control panel with touchscreen HMI and dual emergency stops provides safe, reliable, and user-friendly operation.

Specifications

- Processing Capacity Per Batch: 10–15 lbs (4.5–6.8 kg)

- Ethanol Requirement Per Run: 13–15 gallons (49–56 liters)

- Throughput: ~300 lbs (136 kg) of biomass per 8-hour shift

- Temperature Range: -40°C to 60°C

- Maximum Pressure: 0 psi

- Basket Capacity: 12–15 lbs

- Vessel Type: Liquid/vapor tight with EPDM lid seal

- Jacket Volume: 1 gallon

- Jacket Ports: ½” NPT male

- Control Panel: Industrial Hazardous Location (HazLoc) with touchscreen HMI

- Safety Features: Dual emergency stop (system & control panel)

- Extraction Method: Closed-loop ethanol extraction with mechanical centrifugation

- Condition: Used

Applications

- Botanical Oil Extraction: Hemp, cannabis, essential oils, plant extracts

- Pharmaceutical & Nutraceutical Processing

- Food & Beverage Industry: Flavor and fragrance extraction

- Cosmetic & Skincare Industry: Active ingredient extraction

- Chemical Solvent-Based Extraction Processes

Compatible Products & Uses

- Ethanol-Based Cannabis and Hemp Extraction

- CBD and THC Oil Production

- Essential Oil and Botanical Extract Processing

- Industrial-Grade Ethanol Extraction for Herbal and Plant-Based Ingredients

- Solvent Recovery and Purification for High-Purity Extracts

- Delta Separations ethanol extraction system

- Used CUP-15 extraction machine for sale

- Industrial ethanol extraction equipment

- Cold alcohol extraction system

- Botanical oil ethanol extractor

- Hazardous location extraction system

- Closed-loop centrifuge extraction machine

- Used Delta Separations CUP-15 ethanol extraction unit

- Industrial ethanol extraction system for hemp and cannabis

- Closed-loop ethanol extraction with mechanical centrifuge

- CUP-15 botanical oil extraction system for sale

- High-purity ethanol extraction equipment with touchscreen HMI

- Used Delta Separations CUP-15 closed-loop ethanol extraction system for botanical oils

- Industrial cold ethanol extraction machine with mechanical centrifugation for cannabis and hemp

- High-throughput ethanol extraction system with HazLoc control panel and touchscreen interface

- Best ethanol extraction equipment for botanical oil processing and solvent recovery

- Used ethanol extraction system with dual emergency stop and liquid/vapor tight vessel

Used Delta Separations Ethanol Extraction System, Model CUP-15. 1015 lbs (4.56.8 kg) of plant material, depending on mill size processing capacity per batch; 1315 gallons (4956 liters) ethanol requirement per run; Approximately 300 lbs (136 kg) of biomass processed per 8-hour shift throughput; Temperature minimum and maximum, -40C / 60C; 0 psi maximum pressure; 12-15 lb maximum basket capacity; Liquid/vapor tight vessel with EPDM lid seal; 1 gallon jacket volume with 1/2" NPT male jacket ports; Industrial Hazardous Location (HazLoc) control panel; Touchscreen HMI; Dual emergency stop (system & control panel. This system combines closed-loop, cold alcohol extraction with mechanical centrifugation, ensuring high-purity extractions. Serial # C15190348.

Description

The Delta Separations CUP-15 Ethanol Extraction System is an industrial-grade closed-loop ethanol extraction system designed for high-efficiency botanical oil extraction. It integrates cold alcohol extraction with mechanical centrifugation, ensuring high-purity yields while maximizing solvent recovery.

With a batch capacity of 10–15 lbs (4.5–6.8 kg) of plant material, this system operates efficiently, requiring 13–15 gallons (49–56 liters) of ethanol per run. Its high-throughput capability allows for processing approximately 300 lbs (136 kg) of biomass per 8-hour shift.

Designed to operate within a temperature range of -40°C to 60°C, this system features a liquid/vapor-tight vessel with an EPDM lid seal and a 1-gallon jacket volume with ½” NPT male jacket ports, ensuring precise temperature control. The Hazardous Location (HazLoc) industrial control panel with touchscreen HMI and dual emergency stops provides safe, reliable, and user-friendly operation.

Specifications

- Processing Capacity Per Batch: 10–15 lbs (4.5–6.8 kg)

- Ethanol Requirement Per Run: 13–15 gallons (49–56 liters)

- Throughput: ~300 lbs (136 kg) of biomass per 8-hour shift

- Temperature Range: -40°C to 60°C

- Maximum Pressure: 0 psi

- Basket Capacity: 12–15 lbs

- Vessel Type: Liquid/vapor tight with EPDM lid seal

- Jacket Volume: 1 gallon

- Jacket Ports: ½” NPT male

- Control Panel: Industrial Hazardous Location (HazLoc) with touchscreen HMI

- Safety Features: Dual emergency stop (system & control panel)

- Extraction Method: Closed-loop ethanol extraction with mechanical centrifugation

- Condition: Used

Applications

- Botanical Oil Extraction: Hemp, cannabis, essential oils, plant extracts

- Pharmaceutical & Nutraceutical Processing

- Food & Beverage Industry: Flavor and fragrance extraction

- Cosmetic & Skincare Industry: Active ingredient extraction

- Chemical Solvent-Based Extraction Processes

Compatible Products & Uses

- Ethanol-Based Cannabis and Hemp Extraction

- CBD and THC Oil Production

- Essential Oil and Botanical Extract Processing

- Industrial-Grade Ethanol Extraction for Herbal and Plant-Based Ingredients

- Solvent Recovery and Purification for High-Purity Extracts

- Delta Separations ethanol extraction system

- Used CUP-15 extraction machine for sale

- Industrial ethanol extraction equipment

- Cold alcohol extraction system

- Botanical oil ethanol extractor

- Hazardous location extraction system

- Closed-loop centrifuge extraction machine

- Used Delta Separations CUP-15 ethanol extraction unit

- Industrial ethanol extraction system for hemp and cannabis

- Closed-loop ethanol extraction with mechanical centrifuge

- CUP-15 botanical oil extraction system for sale

- High-purity ethanol extraction equipment with touchscreen HMI

- Used Delta Separations CUP-15 closed-loop ethanol extraction system for botanical oils

- Industrial cold ethanol extraction machine with mechanical centrifugation for cannabis and hemp

- High-throughput ethanol extraction system with HazLoc control panel and touchscreen interface

- Best ethanol extraction equipment for botanical oil processing and solvent recovery

- Used ethanol extraction system with dual emergency stop and liquid/vapor tight vessel

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory