Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

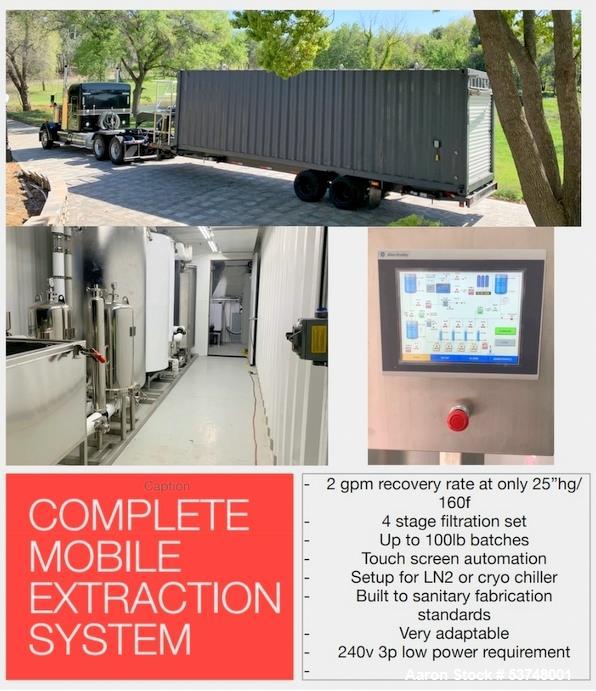

Used Gloe Corporation Mobile Extraction System – Automated Cryoethanol Processing

Used Gloe Corporation Mobile Extraction System. Recovery rates of 2 gpm at only 160f and 25"hg (more heat + more vacuum = faster recovery) ability to recirculate to further concentrate crude. Can batch 100lbs of ground material or about 60lbs flower at a time. Easy production of oil; Easy scalability; No building required; Automated cryoethanol extraction system.120 gallon batch tank; 4 stage filtration/remediation system; 300gallon vacuum jacketed cold storage tank; 300 gallon hot water jacketed tincture tank; 4 - 70"by 10" 150 tube falling film evaporators (3,500+sqft of surface area!) automated and manifolded together; 300 gallon reclaim tank. Designed and built by experienced process food/beverage system builders; All stainless sanitary build out; Welded by certified welders and passivated after fabrication for safe consumption products. Utilities included: 1;000;000 BTU water heater system; 40t cooling tower; Becker27"hg vacuum pump; Sullair 185 scroll air compressor; mq 70kw whisper watt generator; Completer 20l rotary evaporator with vacuum pump and chiller.

| Category | Cannabis EquipmentCannabis Equipment |

| Subcategory | Extraction & Processing EquipmentExtraction & Processing Equipment |

Manufacturer Information:

- Brand: Gloe Corporation

- Type: Mobile Extraction System

- Extraction Method: Automated Cryoethanol Extraction

- Recovery Rate: 2 GPM at 160°F and 25”Hg

- Batch Capacity:

- 100 lbs of ground material

- 60 lbs of flower

- Construction: All stainless steel, sanitary build

- Fabrication: Welded by certified welders & passivated for safe consumption

Description:

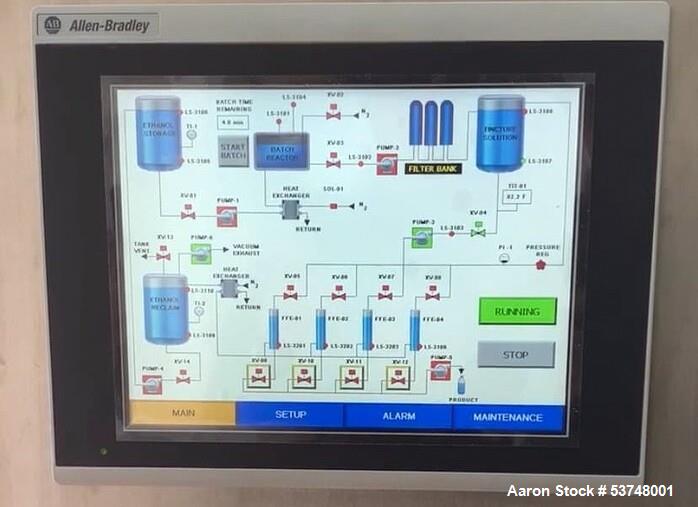

The Used Gloe Corporation Mobile Extraction System is a fully automated cryoethanol extraction unit designed for high-efficiency oil extraction and crude concentration. With a scalable and mobile design, this system enables on-site processing without the need for a permanent facility, making it ideal for commercial extraction operations.

This system is capable of processing 100 lbs of ground material or 60 lbs of flower per batch, with a recovery rate of 2 GPM at 160°F and 25”Hg vacuum. The ability to recirculate the extract for further concentration provides greater yield efficiency. Featuring a 4-stage filtration/remediation system, 300-gallon vacuum jacketed cold storage tank, and a 300-gallon hot water jacketed tincture tank, this unit offers high-volume processing capacity.

At the core of this system are four 70” x 10” 150-tube falling film evaporators, delivering 3,500+ sq. ft. of surface area, ensuring high-speed solvent recovery. The unit is fully automated and manifolded together for seamless operation.

Key Features & Components:

- Automated Cryoethanol Extraction System – High-speed solvent recovery

- 120-Gallon Batch Tank – Large capacity for efficient material processing

- 4-Stage Filtration & Remediation System – Ensures purity & consistency

- 300-Gallon Vacuum Jacketed Cold Storage Tank – Maintains low-temperature processing

- 300-Gallon Hot Water Jacketed Tincture Tank – Enhances crude concentration

- 4 x 70” x 10” 150-Tube Falling Film Evaporators – 3,500+ sq. ft. of surface area

- 300-Gallon Reclaim Tank – Optimized solvent recovery

- Becker 27”Hg Vacuum Pump – High-efficiency vacuum system

- Sullair 185 Scroll Air Compressor – Industrial-grade compressed air supply

- MQ 70kW WhisperWatt Generator – Reliable power source

- Complete 20L Rotary Evaporator w/ Vacuum Pump & Chiller – Secondary distillation for final product refinement

- 1,000,000 BTU Water Heater System – Provides precise thermal control

- 40-Ton Cooling Tower – Optimized system cooling for continuous operation

Applications:

The Gloe Corporation Mobile Extraction System is ideal for:

- Cannabis & Hemp Extraction – High-purity crude oil and distillate production

- Botanical & Herbal Extraction – Essential oils, terpenes, and plant-based compounds

- Food & Beverage Processing – Alcohol and solvent recovery for flavored extracts

- Pharmaceutical & Nutraceutical Production – Precision extraction for medicinal applications

- Solvent Recovery & Purification – Large-scale ethanol recovery and filtration

- CBD & THC Extraction – Full-spectrum, broad-spectrum, and isolate production

- Essential Oils & Terpenes – Natural botanical extracts

- Plant-Based Medicinal Compounds – Herbal and nutraceutical extracts

- Food-Grade Alcohol Recovery – Beverage and flavoring applications

- Solvent-Based Concentrates – Tinctures, distillates, and purified extracts

- Used Gloe Corporation mobile extraction system

- Automated cryoethanol extraction machine for sale

- High-capacity ethanol recovery system

- 100 lb batch oil extraction equipment

- Falling film evaporator extraction system

- 4-stage filtration and remediation extraction unit

- Cannabis and hemp ethanol extraction system

- Solvent recovery system with vacuum jacketed storage

- Used Gloe Corporation cryoethanol extraction system for sale

- Mobile extraction system for cannabis, hemp, and botanical oils

- 100 lb batch ethanol extraction equipment with falling film evaporators

- High-speed ethanol recovery and crude oil refinement system

- Large-scale botanical oil extraction with vacuum and thermal control

- Solvent recovery and purification system for plant-based extracts

- Industrial-grade mobile ethanol extraction unit with full automation

Used Gloe Corporation Mobile Extraction System. Recovery rates of 2 gpm at only 160f and 25"hg (more heat + more vacuum = faster recovery) ability to recirculate to further concentrate crude. Can batch 100lbs of ground material or about 60lbs flower at a time. Easy production of oil; Easy scalability; No building required; Automated cryoethanol extraction system.120 gallon batch tank; 4 stage filtration/remediation system; 300gallon vacuum jacketed cold storage tank; 300 gallon hot water jacketed tincture tank; 4 - 70"by 10" 150 tube falling film evaporators (3,500+sqft of surface area!) automated and manifolded together; 300 gallon reclaim tank. Designed and built by experienced process food/beverage system builders; All stainless sanitary build out; Welded by certified welders and passivated after fabrication for safe consumption products. Utilities included: 1;000;000 BTU water heater system; 40t cooling tower; Becker27"hg vacuum pump; Sullair 185 scroll air compressor; mq 70kw whisper watt generator; Completer 20l rotary evaporator with vacuum pump and chiller.

Manufacturer Information:

- Brand: Gloe Corporation

- Type: Mobile Extraction System

- Extraction Method: Automated Cryoethanol Extraction

- Recovery Rate: 2 GPM at 160°F and 25”Hg

- Batch Capacity:

- 100 lbs of ground material

- 60 lbs of flower

- Construction: All stainless steel, sanitary build

- Fabrication: Welded by certified welders & passivated for safe consumption

Description:

The Used Gloe Corporation Mobile Extraction System is a fully automated cryoethanol extraction unit designed for high-efficiency oil extraction and crude concentration. With a scalable and mobile design, this system enables on-site processing without the need for a permanent facility, making it ideal for commercial extraction operations.

This system is capable of processing 100 lbs of ground material or 60 lbs of flower per batch, with a recovery rate of 2 GPM at 160°F and 25”Hg vacuum. The ability to recirculate the extract for further concentration provides greater yield efficiency. Featuring a 4-stage filtration/remediation system, 300-gallon vacuum jacketed cold storage tank, and a 300-gallon hot water jacketed tincture tank, this unit offers high-volume processing capacity.

At the core of this system are four 70” x 10” 150-tube falling film evaporators, delivering 3,500+ sq. ft. of surface area, ensuring high-speed solvent recovery. The unit is fully automated and manifolded together for seamless operation.

Key Features & Components:

- Automated Cryoethanol Extraction System – High-speed solvent recovery

- 120-Gallon Batch Tank – Large capacity for efficient material processing

- 4-Stage Filtration & Remediation System – Ensures purity & consistency

- 300-Gallon Vacuum Jacketed Cold Storage Tank – Maintains low-temperature processing

- 300-Gallon Hot Water Jacketed Tincture Tank – Enhances crude concentration

- 4 x 70” x 10” 150-Tube Falling Film Evaporators – 3,500+ sq. ft. of surface area

- 300-Gallon Reclaim Tank – Optimized solvent recovery

- Becker 27”Hg Vacuum Pump – High-efficiency vacuum system

- Sullair 185 Scroll Air Compressor – Industrial-grade compressed air supply

- MQ 70kW WhisperWatt Generator – Reliable power source

- Complete 20L Rotary Evaporator w/ Vacuum Pump & Chiller – Secondary distillation for final product refinement

- 1,000,000 BTU Water Heater System – Provides precise thermal control

- 40-Ton Cooling Tower – Optimized system cooling for continuous operation

Applications:

The Gloe Corporation Mobile Extraction System is ideal for:

- Cannabis & Hemp Extraction – High-purity crude oil and distillate production

- Botanical & Herbal Extraction – Essential oils, terpenes, and plant-based compounds

- Food & Beverage Processing – Alcohol and solvent recovery for flavored extracts

- Pharmaceutical & Nutraceutical Production – Precision extraction for medicinal applications

- Solvent Recovery & Purification – Large-scale ethanol recovery and filtration

| Category | Cannabis Equipment |

| Subcategory | Extraction & Processing Equipment |

- CBD & THC Extraction – Full-spectrum, broad-spectrum, and isolate production

- Essential Oils & Terpenes – Natural botanical extracts

- Plant-Based Medicinal Compounds – Herbal and nutraceutical extracts

- Food-Grade Alcohol Recovery – Beverage and flavoring applications

- Solvent-Based Concentrates – Tinctures, distillates, and purified extracts

- Used Gloe Corporation mobile extraction system

- Automated cryoethanol extraction machine for sale

- High-capacity ethanol recovery system

- 100 lb batch oil extraction equipment

- Falling film evaporator extraction system

- 4-stage filtration and remediation extraction unit

- Cannabis and hemp ethanol extraction system

- Solvent recovery system with vacuum jacketed storage

- Used Gloe Corporation cryoethanol extraction system for sale

- Mobile extraction system for cannabis, hemp, and botanical oils

- 100 lb batch ethanol extraction equipment with falling film evaporators

- High-speed ethanol recovery and crude oil refinement system

- Large-scale botanical oil extraction with vacuum and thermal control

- Solvent recovery and purification system for plant-based extracts

- Industrial-grade mobile ethanol extraction unit with full automation

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory