Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

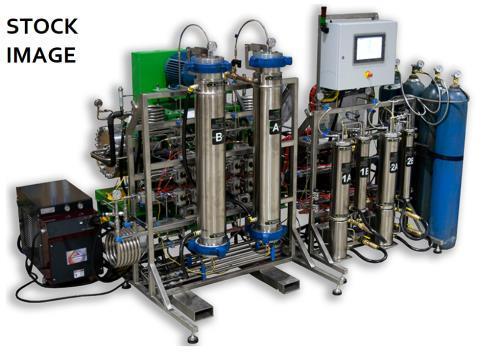

Unused - Apeks "Duplex" Subcritical High Production Extraction System

Unused - Apeks "Duplex" Subcritical High Production Extraction System, 20Lx20L Vessel Combination. Flow rate of 6.1kg per minute, Process 126-180 pounds per day, Continuous batch operation. Closed loop system recovers 95% of the CO2, Four separators and two separator cups support continuous batch. The system only uses 39.8hp, including the chillers, More energy efficient than liquid-pumping systems, The control panels are future-proof and built to be part of a connected enterprise, Interfaces with a SQL database. Integrated chiller control completes the automation package, new control panel, Powered by Rockwell Automation, Our Industrial Control panels are UL Listed, HMI (Human Machine Interface) is now written to ANSI/ISA 101 standards. The system is cGMP (current Good Manufacturing Processes) friendly. The system is optimized for subcritical extraction. can also process supercritically (high pressure/high temperature). Extraction Vessel: Volume 80L vessel holds around 40 pounds of dry, ground material; Pressure maximum pressure = 2000 psi (137 bar); Temperature max 160F (71C); Materials 304 stainless steel. Vessel interior is polished to food grade level; Closures Hammer Union (commonly used in oil and gas industry for temporary piping), top with integral hinge; Sealing mechanism spring energized cup seal; Filter integral filters on closure heads. 20 micron; Temperature measurement internal K type thermocouple senses actual extraction temperature; Safety non-isolable spring loaded safety relief valve prevents accidental over-pressurization. CO2 Recirculation Pump: Electric motor driven diaphragm compressor; Flowrate 2.9

Unused - Apeks "Duplex" Subcritical High Production Extraction System, 20Lx20L Vessel Combination. Flow rate of 6.1kg per minute, Process 126-180 pounds per day, Continuous batch operation. Closed loop system recovers 95% of the CO2, Four separators and two separator cups support continuous batch. The system only uses 39.8hp, including the chillers, More energy efficient than liquid-pumping systems, The control panels are future-proof and built to be part of a connected enterprise, Interfaces with a SQL database. Integrated chiller control completes the automation package, new control panel, Powered by Rockwell Automation, Our Industrial Control panels are UL Listed, HMI (Human Machine Interface) is now written to ANSI/ISA 101 standards. The system is cGMP (current Good Manufacturing Processes) friendly. The system is optimized for subcritical extraction. can also process supercritically (high pressure/high temperature). Extraction Vessel: Volume 80L vessel holds around 40 pounds of dry, ground material; Pressure maximum pressure = 2000 psi (137 bar); Temperature max 160F (71C); Materials 304 stainless steel. Vessel interior is polished to food grade level; Closures Hammer Union (commonly used in oil and gas industry for temporary piping), top with integral hinge; Sealing mechanism spring energized cup seal; Filter integral filters on closure heads. 20 micron; Temperature measurement internal K type thermocouple senses actual extraction temperature; Safety non-isolable spring loaded safety relief valve prevents accidental over-pressurization. CO2 Recirculation Pump: Electric motor driven diaphragm compressor; Flowrate 2.9

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory