Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Ultrasonic Ethanol Extractor

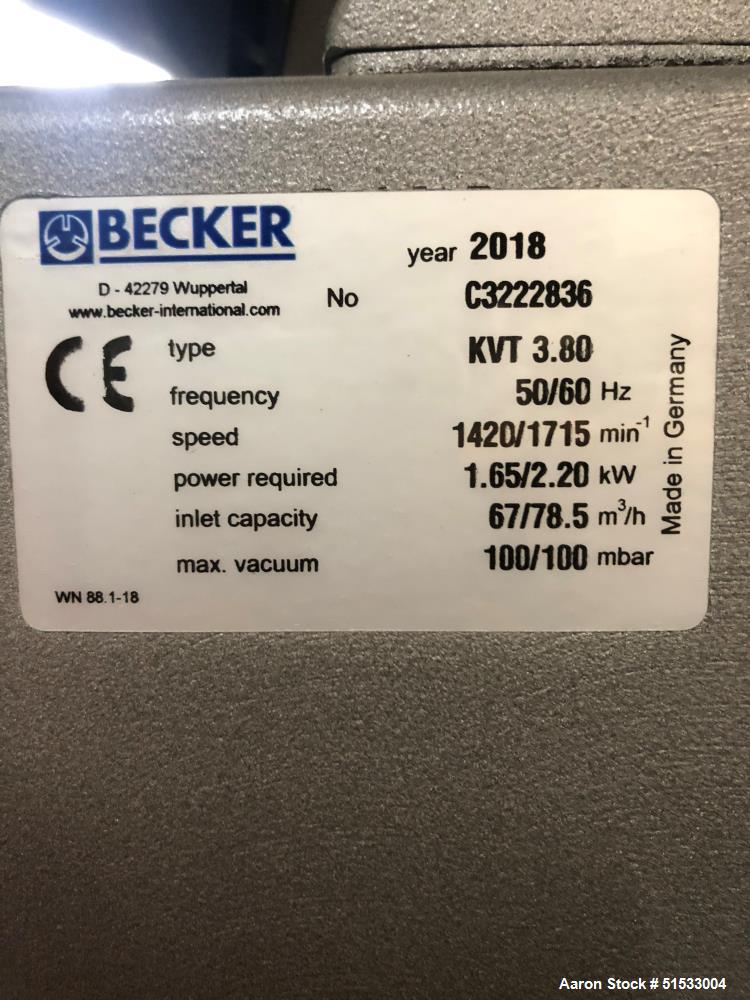

Used Ultrasonic Ethanol Extractor, 20lb high purity ultrasonic extraction system previously used in CBD extraction from hemp. System operates on vacuum only for fluid transfer and consists of two 10lb columns run in series. Each column has 500 watt transducers mounted vertically down the length of the column. Transducers are assembled and isolated in a fully welded enclosure manufactured by ultrasonic power corporation. Each column has a tri-clamp top cap and hinged bottom cap for easy load and unload. Built in flow control allows the columns to completely fill and remain full while simultaneously flowing for a continuous full saturation and rinse process. Columns are mounted on an aluminum cart for mobility. Cart can be lifted by pneumatic lift for unloading. Pneumatic lift operates by a small, low maintenance 0.5 hp oilless Senco air compressor which can be placed outside the hazardous area. Purification system consists of a 6 stage filter system utilizing (5) 20" BB filter cartridges mounted on a rolling stand and (1) 20" standard cartridge for polishing mounted on the vacuum tank. Color and chlorophyll removal was previously done using (3) of the five stages with Pentair carbon fibredyne 0.5 micron cartridges model 455906-43. Polishing filter can go down to 0.2 micron without diminishing flow. Vacuum tank is 10 gauge 304 stainless steel with electro polished interior and exterior. It has a removable hinged lid for easy access and cleaning. Narrow design with handle and wheels allows for mobility by a single operator. It has a working capacity of 80 gallons with an overall capacity of 100 gallons. Includes internal ball float to control overflow. It has an external ball float for additional protection and visual inspection. Vacuum is generated by a Becker model KVT-3.80, 46 cfm, oilless rotary vane pump which can be placed outside the hazardous area. Pump comes mounted on rolling cart for mobility and includes ball float, check valve and camlock exhaust connection. Typical run times were reported by the previous operator at 20 minutes for 30 gallons. Primary components included: (2) 10lb Ultrasonic material columns with cart; Pneumatic lift with Senco air compressor; Purification cart with (5) 20" BB Pentair filter housings; Stainless Steel vacuum tank with (1) 20" standard Pentair filter housing; Becker KVT-3.80 vacuum pump with stand and power control. Overall features: Full saturation with continuous flow/rinse; Ultrasonic extraction technology; All food grade and ethanol compatible construction; 20lb capacity; Vacuum only operation; Small foot print; Mobile friendly design. Electrical requirements: Air compressor 120v, 4amp; Vacuum pump 3 phase, 240v, 2.2kw. . Requirements to operate / assembly: All hose connections are by quick connect; Ultrasonic generator NOT INCLUDED. Transducers require 1,000 watt (dual 500) generator to operate which can be purchased at Ultrasonic Power Corporation. Recommended model 5300.

Used Ultrasonic Ethanol Extractor, 20lb high purity ultrasonic extraction system previously used in CBD extraction from hemp. System operates on vacuum only for fluid transfer and consists of two 10lb columns run in series. Each column has 500 watt transducers mounted vertically down the length of the column. Transducers are assembled and isolated in a fully welded enclosure manufactured by ultrasonic power corporation. Each column has a tri-clamp top cap and hinged bottom cap for easy load and unload. Built in flow control allows the columns to completely fill and remain full while simultaneously flowing for a continuous full saturation and rinse process. Columns are mounted on an aluminum cart for mobility. Cart can be lifted by pneumatic lift for unloading. Pneumatic lift operates by a small, low maintenance 0.5 hp oilless Senco air compressor which can be placed outside the hazardous area. Purification system consists of a 6 stage filter system utilizing (5) 20" BB filter cartridges mounted on a rolling stand and (1) 20" standard cartridge for polishing mounted on the vacuum tank. Color and chlorophyll removal was previously done using (3) of the five stages with Pentair carbon fibredyne 0.5 micron cartridges model 455906-43. Polishing filter can go down to 0.2 micron without diminishing flow. Vacuum tank is 10 gauge 304 stainless steel with electro polished interior and exterior. It has a removable hinged lid for easy access and cleaning. Narrow design with handle and wheels allows for mobility by a single operator. It has a working capacity of 80 gallons with an overall capacity of 100 gallons. Includes internal ball float to control overflow. It has an external ball float for additional protection and visual inspection. Vacuum is generated by a Becker model KVT-3.80, 46 cfm, oilless rotary vane pump which can be placed outside the hazardous area. Pump comes mounted on rolling cart for mobility and includes ball float, check valve and camlock exhaust connection. Typical run times were reported by the previous operator at 20 minutes for 30 gallons. Primary components included: (2) 10lb Ultrasonic material columns with cart; Pneumatic lift with Senco air compressor; Purification cart with (5) 20" BB Pentair filter housings; Stainless Steel vacuum tank with (1) 20" standard Pentair filter housing; Becker KVT-3.80 vacuum pump with stand and power control. Overall features: Full saturation with continuous flow/rinse; Ultrasonic extraction technology; All food grade and ethanol compatible construction; 20lb capacity; Vacuum only operation; Small foot print; Mobile friendly design. Electrical requirements: Air compressor 120v, 4amp; Vacuum pump 3 phase, 240v, 2.2kw. . Requirements to operate / assembly: All hose connections are by quick connect; Ultrasonic generator NOT INCLUDED. Transducers require 1,000 watt (dual 500) generator to operate which can be purchased at Ultrasonic Power Corporation. Recommended model 5300.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory