Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Kuipers Pellet Frying Line. Consists of: pellet feed and dosing system; Vibratory tray; Used-oil storage tank; Fresh oil supply tank

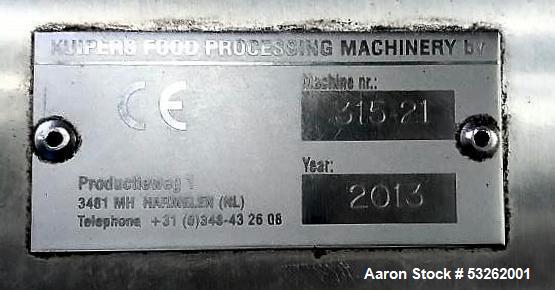

Used Kuipers Pellet Frying Line. Consists of: pellet feed and dosing system; Vibratory tray; Used-oil storage tank; Fresh oil supply tank; Defatting belt, Rotating mixing drum; Screw type flavor dosing system; Rotating vane type flavor spreader; Electric control board; Frame. Built 2013. Previously used to fry snack pellets. Pellet receipt and feeding system that allows the operator to supply pellets from floor level; The pellet feeding elevator brings the product to the vibrating sieve.This ensures a continuous flow into the fryer and sieves small particles. Kuipers universal pellet fryer helps produce any type of pellet snack in the most efficient way possible. Its innovative product belt transports the product and ensures minimal oil volume is used within the system. The frying oil can be heated electrically or with thermal oil.The defatting belt allows excessive frying oil on the product surface to drip off, after frying. For irregular shape product, the belt has a tipping point halfway. The drip-off frying oil is then returned to the fryer. Air knives can be added for further removal of oil. The product is then fed into the flavouring unit. This is a stand-alone, drum-shaped mixing system with accurately controlled speed and flavour or salt dosing. The unit has its own control board. The frying time and temperature are adjustable to allow producers to manufacture all types of pellets. The system is fully controlled via the PLC system. Specially developed dirt removal system, combined with gentle heat treatment the oil does not have to be replaced - and without the addition of any chemicals. Efficient removal of small particles begins before frying to prevent these from entering the frying system. This contributes to an extremely low frying oil turnover time, in most cases less than three hours.

Kuipers Food Processing Machinery specializes in turnkey pellet frying lines designed for producing a variety of snack products, including puffed pellets, prawn crackers, and pork rinds. These lines encompass the entire production process, from pellet infeed to flavoring, and feature advanced frying, defatting, cooling, and seasoning equipment.

Key Features:

-

Efficient Frying System: Kuipers' frying system ensures efficient product transportation, precise temperature control, and maintenance of frying oil quality, resulting in a high-quality end product.

-

Dirt Removal System: A unique dirt removal system, combined with gentle heat transfer, maintains oil quality without the need for chemical additives, contributing to a low frying oil turnover time—often less than three hours.

-

Turnkey Design: Each plant is fully pre-tested and pre-wired before delivery, mounted in a unique mainframe that conceals electric cabling and pneumatic air supply pipes for a clean and safe design. This setup facilitates rapid and efficient on-site startup.

-

Capacity Options: Kuipers offers pellet frying lines with capacities ranging from 50 kg/h to over 500 kg/h, accommodating various production scales.

These features make Kuipers' pellet frying lines a versatile and efficient solution for snack producers aiming to deliver high-quality pellet-based snacks.

Food Industry, Food Manufacturing, Food Plants, Food Processing, Food Production, Food Products, Foods, Fried Foods, Frying Oil, Pellet Production, Snack Chips, Snack Foods, Snacks

- Pellet Fryer

- Pre-Heating System: Ensures pellets are preheated for optimal frying

Used Kuipers Pellet Frying Line. Consists of: pellet feed and dosing system; Vibratory tray; Used-oil storage tank; Fresh oil supply tank; Defatting belt, Rotating mixing drum; Screw type flavor dosing system; Rotating vane type flavor spreader; Electric control board; Frame. Built 2013. Previously used to fry snack pellets. Pellet receipt and feeding system that allows the operator to supply pellets from floor level; The pellet feeding elevator brings the product to the vibrating sieve.This ensures a continuous flow into the fryer and sieves small particles. Kuipers universal pellet fryer helps produce any type of pellet snack in the most efficient way possible. Its innovative product belt transports the product and ensures minimal oil volume is used within the system. The frying oil can be heated electrically or with thermal oil.The defatting belt allows excessive frying oil on the product surface to drip off, after frying. For irregular shape product, the belt has a tipping point halfway. The drip-off frying oil is then returned to the fryer. Air knives can be added for further removal of oil. The product is then fed into the flavouring unit. This is a stand-alone, drum-shaped mixing system with accurately controlled speed and flavour or salt dosing. The unit has its own control board. The frying time and temperature are adjustable to allow producers to manufacture all types of pellets. The system is fully controlled via the PLC system. Specially developed dirt removal system, combined with gentle heat treatment the oil does not have to be replaced - and without the addition of any chemicals. Efficient removal of small particles begins before frying to prevent these from entering the frying system. This contributes to an extremely low frying oil turnover time, in most cases less than three hours.

Kuipers Food Processing Machinery specializes in turnkey pellet frying lines designed for producing a variety of snack products, including puffed pellets, prawn crackers, and pork rinds. These lines encompass the entire production process, from pellet infeed to flavoring, and feature advanced frying, defatting, cooling, and seasoning equipment.

Key Features:

-

Efficient Frying System: Kuipers' frying system ensures efficient product transportation, precise temperature control, and maintenance of frying oil quality, resulting in a high-quality end product.

-

Dirt Removal System: A unique dirt removal system, combined with gentle heat transfer, maintains oil quality without the need for chemical additives, contributing to a low frying oil turnover time—often less than three hours.

-

Turnkey Design: Each plant is fully pre-tested and pre-wired before delivery, mounted in a unique mainframe that conceals electric cabling and pneumatic air supply pipes for a clean and safe design. This setup facilitates rapid and efficient on-site startup.

-

Capacity Options: Kuipers offers pellet frying lines with capacities ranging from 50 kg/h to over 500 kg/h, accommodating various production scales.

These features make Kuipers' pellet frying lines a versatile and efficient solution for snack producers aiming to deliver high-quality pellet-based snacks.

Food Industry, Food Manufacturing, Food Plants, Food Processing, Food Production, Food Products, Foods, Fried Foods, Frying Oil, Pellet Production, Snack Chips, Snack Foods, Snacks

- Pellet Fryer

- Pre-Heating System: Ensures pellets are preheated for optimal frying

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory