Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Wolfe Mechanical Mix Tank. Approx.12,600 gallon

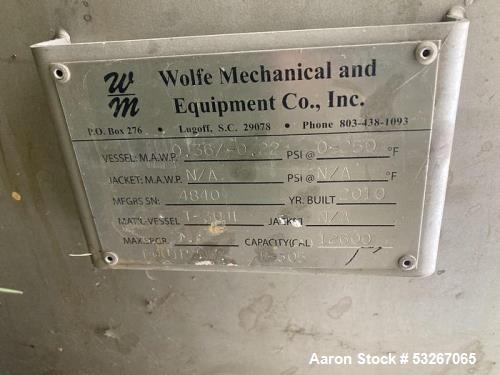

Used Wolfe Mechanical Mix Tank. Approx.12,600 gallons, 304L stainless steel vertical 12' diameter X 15' high straight side. Internal rated 0.36/-0.22 PSI @ 250 degrees F. Max S.P. 1.3. Flat top with 6" channel supports and flat bottom. Top fittings: (1) 10" center agitator nozzle, (1) 2", (2) 3", and (1) 6". (1) 2" and (1) 4" side top inlets. 24" side bottom manway, (3) 3" side bottom outlets. (1) 2" low point drain. Has (3) internal baffles. Equipped with ProQuip top entering agitator model 3ZEX25BP driven by a 3 HP,3/60/230/460v 1800 RPM Motor. Heavy duty agitator drive with dry well and oversized bearings, 3" and 2" diameter x 174" long two piece shaft 304 SS, two 39" diameter 3-blade HiFlow turbines rotating at 72 RPM with lower impeller 18" off tank bottom and upper impeller 80" above lower. Each turbine pumps 18,518 GPM providing an entrained flow of 37,040 GPM. Gear reducer service factor of 1.6 based on full motor horsepower and L-10 bearing life in excess of 100,000 hours. Shaft sealed by means of low pressure Viton vapor seal with two piece split 304 SS seal plate.. Weight 7900#, Built 2010.

| Manufacturer | Wolfe MechWolfe Mech |

| Serial # | 4840 |

| Category | TanksTanks |

| Subcategory | Stainless 5000 Gal and upStainless 5000 Gal and up |

| Gallons | 12600 |

| Material of Construction | 304L Stainless Steel |

| Horizontal or Vertical | Vertical |

| Diameter | 12' |

| Straight Side | 15' |

| Top Head Style | Flat Top |

| Bottom | Flat Bottom |

| Agitator HP | 3 |

| Agitator Phase | 3 |

| Agitator Cycle | 60 |

| Agitator Voltage | 208-230/460 Volt |

| Agitator Rpm | 1800 |

| Opening | Top fittings: (1) 10" center agitator nozzle, (1) 2", (2) 3", and (1) 6". (1) 2" and (1) 4" side top inlets. 24" side bottom manway, (3) 3" side bottom outlets |

| Opening Cover | Yes |

| Outlet Size | 2" |

| Outlet Location | Bottom |

| Year Built | 2010 |

Description

This used Wolfe Mechanical 12,600-gallon mix tank is a 304L stainless steel vertical mixing vessel, designed for high-capacity industrial processing. The tank features a 12' diameter and 15' straight side height, with an internal pressure rating of 0.36/-0.22 PSI at 250°F. It has a flat top with 6” channel supports and a flat bottom, making it suitable for heavy-duty applications.

Equipped with a ProQuip top-entering agitator (Model 3ZEX25BP), this system is powered by a 3 HP, 3-phase motor (230/460V, 1800 RPM). The heavy-duty agitator drive features a dry well, oversized bearings, and a two-piece 304 stainless steel shaft (3” & 2” diameter x 174” long). The dual 39” diameter HiFlow turbines rotate at 72 RPM, with the lower impeller positioned 18” from the bottom and the upper impeller 80” above it, generating an entrained flow of 37,040 GPM.

The agitator shaft is sealed using a low-pressure Viton vapor seal with a two-piece split 304 SS seal plate. The gear reducer has a service factor of 1.6, ensuring reliability and a bearing life exceeding 100,000 hours.

Specifications

- Capacity: 12,600 gallons

- Material: 304L Stainless Steel

- Internal Pressure Rating: 0.36/-0.22 PSI @ 250°F

- Max S.P.: 1.3

- Tank Dimensions: 12’ diameter x 15’ straight side height

- Tank Top: Flat top with 6” channel supports

- Tank Bottom: Flat bottom

- Top Fittings:

- (1) 10” center agitator nozzle

- (1) 2” fitting

- (2) 3” fittings

- (1) 6” fitting

- Side Top Inlets:

- (1) 2”

- (1) 4”

- Side Bottom Manway: 24”

- Side Bottom Outlets: (3) 3” outlets

- Low Point Drain: (1) 2”

- Internal Baffles: (3)

Agitator System – ProQuip Model 3ZEX25BP

- Motor: 3 HP, 3/60/230/460V, 1800 RPM

- Shaft: 304 SS, 3” & 2” diameter x 174” long (two-piece)

- Impellers: (2) 39” diameter 3-blade HiFlow turbines

- Lower impeller: 18” off tank bottom

- Upper impeller: 80” above lower

- Turbine flow rate: 18,518 GPM each, 37,040 GPM entrained flow

- Gear Reducer Service Factor: 1.6

- Bearing Life Expectancy: Over 100,000 hours

- Seal Type: Low-pressure Viton vapor seal with two-piece split 304 SS seal plate

Applications

This high-capacity stainless steel mix tank is designed for:

- Food & Beverage Processing – High-volume liquid mixing and blending.

- Pharmaceutical Manufacturing – Sterile mixing and batch processing.

- Chemical Processing – Homogenization of industrial chemical solutions.

- Water Treatment & Wastewater Processing – High-flow liquid agitation.

- Cosmetic & Personal Care – Large-scale formulation of creams and liquids.

Compatible Products

This Wolfe Mechanical mixing tank is ideal for processing:

- Liquid food and beverage ingredients

- Pharmaceutical solutions and chemical compounds

- High-viscosity emulsions and suspensions

- Water treatment chemicals and industrial fluids

- Fermentation and bio-processing applications

Beer, beer, brewery, Beverage, Beverage / Brewing Industry, Food Oils, Food Packaging, Food Plants, Food Processing, Food Production, Food Products, Pharmaceutical, Pharmaceutical Industries, Pharmaceuticals, Waste Management, Waste Water, Wastewater Treatment, Water, Water Recycle & Reuse

- Used Wolfe Mechanical Mix Tank

- 12,600-Gallon Stainless Steel Mixing Tank

- Industrial Agitated Mixing Vessel

- ProQuip Agitator Tank for Sale

- High-Capacity Stainless Steel Process Tank

- Used 12,600-Gallon Stainless Steel Mixing Tank for Sale

- Wolfe Mechanical Mixing Vessel with ProQuip Agitator

- High-Volume Stainless Steel Tank with Agitation

- 304L Stainless Steel Industrial Mixing Tank

- Large Capacity Mixing Tank with Dual HiFlow Turbines

- Used Wolfe Mechanical 12,600-Gallon Stainless Steel Mixing Tank with Agitation

- Industrial 304L Stainless Steel Mixing Tank with ProQuip Agitator System

- High-Flow Mixing Tank with 3-Blade HiFlow Turbines and Baffles

- Large-Capacity Stainless Steel Agitated Vessel for Food, Chemical, and Pharma Processing

- Wolfe Mechanical Stainless Steel Mixing Tank with Low-Pressure Viton Vapor Seal

Used Wolfe Mechanical Mix Tank. Approx.12,600 gallons, 304L stainless steel vertical 12' diameter X 15' high straight side. Internal rated 0.36/-0.22 PSI @ 250 degrees F. Max S.P. 1.3. Flat top with 6" channel supports and flat bottom. Top fittings: (1) 10" center agitator nozzle, (1) 2", (2) 3", and (1) 6". (1) 2" and (1) 4" side top inlets. 24" side bottom manway, (3) 3" side bottom outlets. (1) 2" low point drain. Has (3) internal baffles. Equipped with ProQuip top entering agitator model 3ZEX25BP driven by a 3 HP,3/60/230/460v 1800 RPM Motor. Heavy duty agitator drive with dry well and oversized bearings, 3" and 2" diameter x 174" long two piece shaft 304 SS, two 39" diameter 3-blade HiFlow turbines rotating at 72 RPM with lower impeller 18" off tank bottom and upper impeller 80" above lower. Each turbine pumps 18,518 GPM providing an entrained flow of 37,040 GPM. Gear reducer service factor of 1.6 based on full motor horsepower and L-10 bearing life in excess of 100,000 hours. Shaft sealed by means of low pressure Viton vapor seal with two piece split 304 SS seal plate.. Weight 7900#, Built 2010.

Description

This used Wolfe Mechanical 12,600-gallon mix tank is a 304L stainless steel vertical mixing vessel, designed for high-capacity industrial processing. The tank features a 12' diameter and 15' straight side height, with an internal pressure rating of 0.36/-0.22 PSI at 250°F. It has a flat top with 6” channel supports and a flat bottom, making it suitable for heavy-duty applications.

Equipped with a ProQuip top-entering agitator (Model 3ZEX25BP), this system is powered by a 3 HP, 3-phase motor (230/460V, 1800 RPM). The heavy-duty agitator drive features a dry well, oversized bearings, and a two-piece 304 stainless steel shaft (3” & 2” diameter x 174” long). The dual 39” diameter HiFlow turbines rotate at 72 RPM, with the lower impeller positioned 18” from the bottom and the upper impeller 80” above it, generating an entrained flow of 37,040 GPM.

The agitator shaft is sealed using a low-pressure Viton vapor seal with a two-piece split 304 SS seal plate. The gear reducer has a service factor of 1.6, ensuring reliability and a bearing life exceeding 100,000 hours.

Specifications

- Capacity: 12,600 gallons

- Material: 304L Stainless Steel

- Internal Pressure Rating: 0.36/-0.22 PSI @ 250°F

- Max S.P.: 1.3

- Tank Dimensions: 12’ diameter x 15’ straight side height

- Tank Top: Flat top with 6” channel supports

- Tank Bottom: Flat bottom

- Top Fittings:

- (1) 10” center agitator nozzle

- (1) 2” fitting

- (2) 3” fittings

- (1) 6” fitting

- Side Top Inlets:

- (1) 2”

- (1) 4”

- Side Bottom Manway: 24”

- Side Bottom Outlets: (3) 3” outlets

- Low Point Drain: (1) 2”

- Internal Baffles: (3)

Agitator System – ProQuip Model 3ZEX25BP

- Motor: 3 HP, 3/60/230/460V, 1800 RPM

- Shaft: 304 SS, 3” & 2” diameter x 174” long (two-piece)

- Impellers: (2) 39” diameter 3-blade HiFlow turbines

- Lower impeller: 18” off tank bottom

- Upper impeller: 80” above lower

- Turbine flow rate: 18,518 GPM each, 37,040 GPM entrained flow

- Gear Reducer Service Factor: 1.6

- Bearing Life Expectancy: Over 100,000 hours

- Seal Type: Low-pressure Viton vapor seal with two-piece split 304 SS seal plate

Applications

This high-capacity stainless steel mix tank is designed for:

- Food & Beverage Processing – High-volume liquid mixing and blending.

- Pharmaceutical Manufacturing – Sterile mixing and batch processing.

- Chemical Processing – Homogenization of industrial chemical solutions.

- Water Treatment & Wastewater Processing – High-flow liquid agitation.

- Cosmetic & Personal Care – Large-scale formulation of creams and liquids.

Compatible Products

This Wolfe Mechanical mixing tank is ideal for processing:

- Liquid food and beverage ingredients

- Pharmaceutical solutions and chemical compounds

- High-viscosity emulsions and suspensions

- Water treatment chemicals and industrial fluids

- Fermentation and bio-processing applications

Beer, beer, brewery, Beverage, Beverage / Brewing Industry, Food Oils, Food Packaging, Food Plants, Food Processing, Food Production, Food Products, Pharmaceutical, Pharmaceutical Industries, Pharmaceuticals, Waste Management, Waste Water, Wastewater Treatment, Water, Water Recycle & Reuse

| Manufacturer | Wolfe Mech |

| Serial # | 4840 |

| Category | Tanks |

| Subcategory | Stainless 5000 Gal and up |

| Gallons | 12600 |

| Material of Construction | 304L Stainless Steel |

| Horizontal or Vertical | Vertical |

| Diameter | 12' |

| Straight Side | 15' |

| Top Head Style | Flat Top |

| Bottom | Flat Bottom |

| Agitator HP | 3 |

| Agitator Phase | 3 |

| Agitator Cycle | 60 |

| Agitator Voltage | 208-230/460 Volt |

| Agitator Rpm | 1800 |

| Opening | Top fittings: (1) 10" center agitator nozzle, (1) 2", (2) 3", and (1) 6". (1) 2" and (1) 4" side top inlets. 24" side bottom manway, (3) 3" side bottom outlets |

| Opening Cover | Yes |

| Outlet Size | 2" |

| Outlet Location | Bottom |

| Year Built | 2010 |

- Used Wolfe Mechanical Mix Tank

- 12,600-Gallon Stainless Steel Mixing Tank

- Industrial Agitated Mixing Vessel

- ProQuip Agitator Tank for Sale

- High-Capacity Stainless Steel Process Tank

- Used 12,600-Gallon Stainless Steel Mixing Tank for Sale

- Wolfe Mechanical Mixing Vessel with ProQuip Agitator

- High-Volume Stainless Steel Tank with Agitation

- 304L Stainless Steel Industrial Mixing Tank

- Large Capacity Mixing Tank with Dual HiFlow Turbines

- Used Wolfe Mechanical 12,600-Gallon Stainless Steel Mixing Tank with Agitation

- Industrial 304L Stainless Steel Mixing Tank with ProQuip Agitator System

- High-Flow Mixing Tank with 3-Blade HiFlow Turbines and Baffles

- Large-Capacity Stainless Steel Agitated Vessel for Food, Chemical, and Pharma Processing

- Wolfe Mechanical Stainless Steel Mixing Tank with Low-Pressure Viton Vapor Seal

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory