Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Feldmeier 20,000 Gallon Vertical Insulated 304 Stainless Steel Tank. 96" diameter x 660" high straight side. Shell is 12 GA, top and bottom heads are 10 GA. Insulated and covered with 304 stainl...

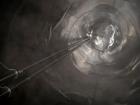

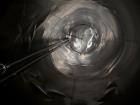

Used Feldmeier 20,000 Gallon Vertical Insulated 304 Stainless Steel Tank. 96" diameter x 660" high straight side. Shell is 12 GA, top and bottom heads are 10 GA. Insulated and covered with 304 stainless steel sheathing. Internal has #4 finish, welds 150 grit minimum. External has 2B finish. dome top, sloping bottom. Has 304 stainless steel dimpled jacket on bottom 5' of side wall, rated 150 PSI at -20 to 175 degrees F. Tank is rated ATM. All inlets and outlets are located in alcove area (16" x 20") standard elliptical swing in manway with sample valve. (2) 3" sanitary inlet and outlet, (2) 4" sanitary connections to internal 4" vent tube and overflow tube. 1.5" sanitary connection at bottom of overflow tube, 2.5" sanitary connection to patented 3A approved "spray up" CIP nozzle, and (1) 1/2" thermowell. Tank was drained, without proper venting. This has caused some slight buckling of the interior. The buckles have appeared as 3 distinct rings around the interior of the tank. The first is located at 16' above the bottom of the tank, the next ring is 31' from the bottom of the tank, and the last ring is 42' from the bottom of the tank. (The last ring has a couple of hard buckles, but see no visual cracks). Would be excellent tank to repair for sanitary service or use "as is" for non-sanitary service. Built 2006.

Used Feldmeier 20,000 Gallon Vertical Insulated 304 Stainless Steel Tank. 96" diameter x 660" high straight side. Shell is 12 GA, top and bottom heads are 10 GA. Insulated and covered with 304 stainless steel sheathing. Internal has #4 finish, welds 150 grit minimum. External has 2B finish. dome top, sloping bottom. Has 304 stainless steel dimpled jacket on bottom 5' of side wall, rated 150 PSI at -20 to 175 degrees F. Tank is rated ATM. All inlets and outlets are located in alcove area (16" x 20") standard elliptical swing in manway with sample valve. (2) 3" sanitary inlet and outlet, (2) 4" sanitary connections to internal 4" vent tube and overflow tube. 1.5" sanitary connection at bottom of overflow tube, 2.5" sanitary connection to patented 3A approved "spray up" CIP nozzle, and (1) 1/2" thermowell. Tank was drained, without proper venting. This has caused some slight buckling of the interior. The buckles have appeared as 3 distinct rings around the interior of the tank. The first is located at 16' above the bottom of the tank, the next ring is 31' from the bottom of the tank, and the last ring is 42' from the bottom of the tank. (The last ring has a couple of hard buckles, but see no visual cracks). Would be excellent tank to repair for sanitary service or use "as is" for non-sanitary service. Built 2006.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory