Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Pace Converting Equipment Converting Die Cutter

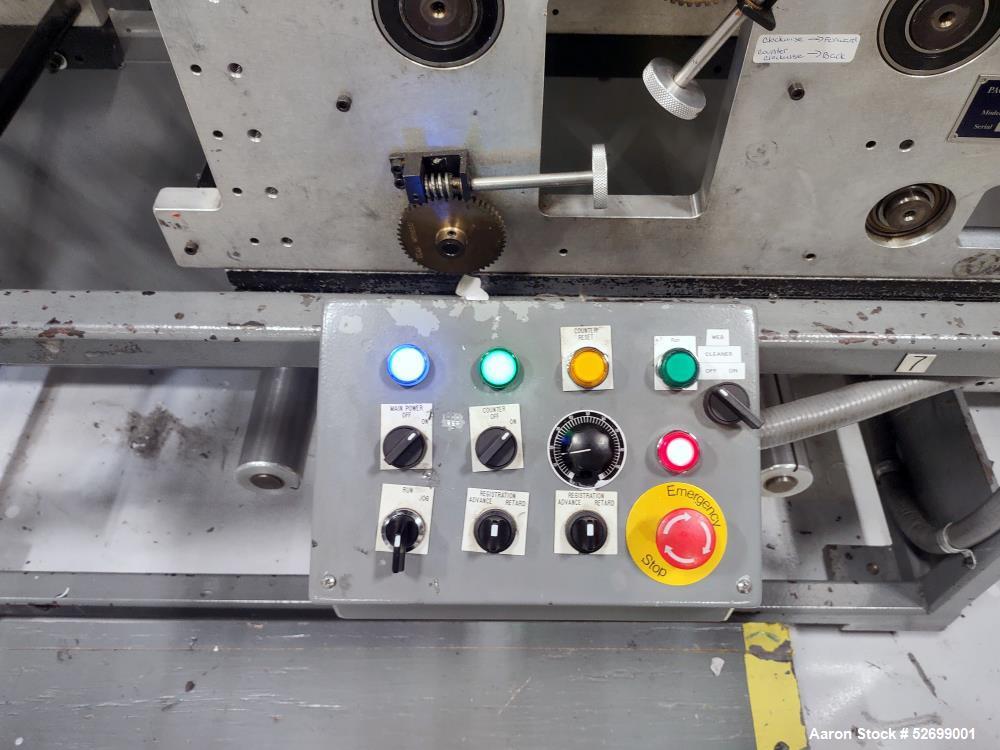

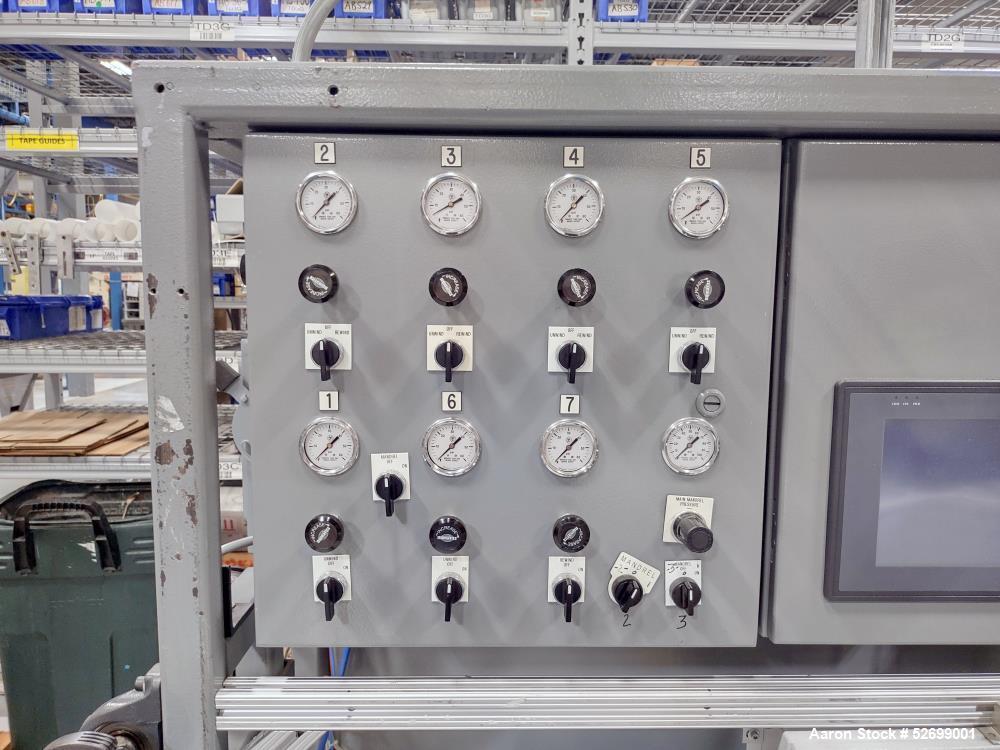

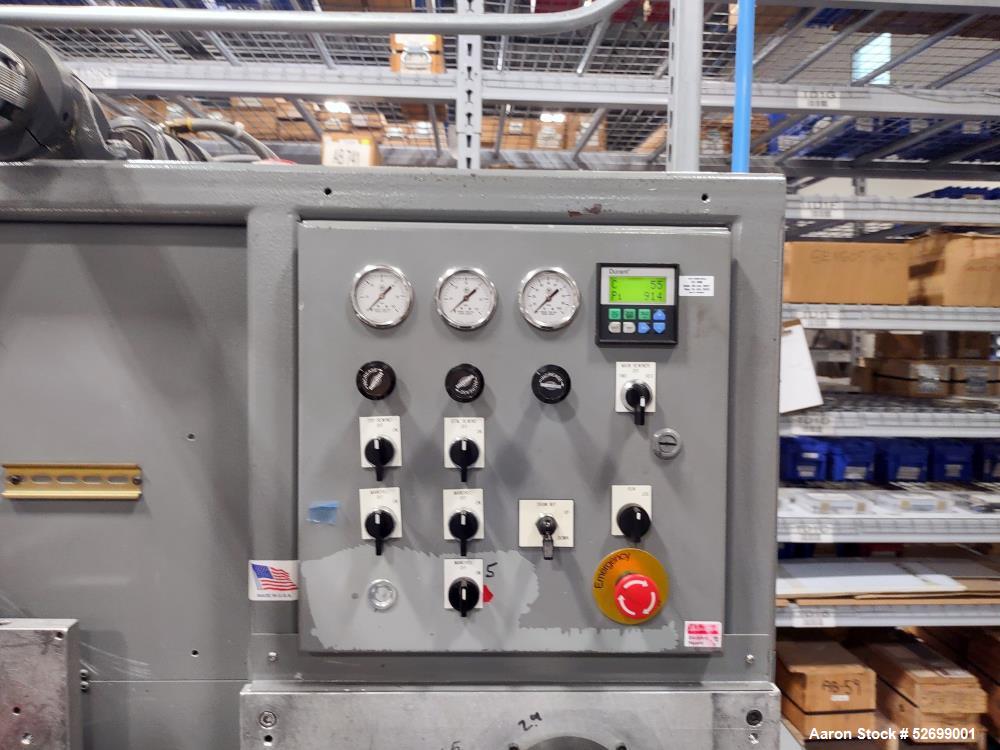

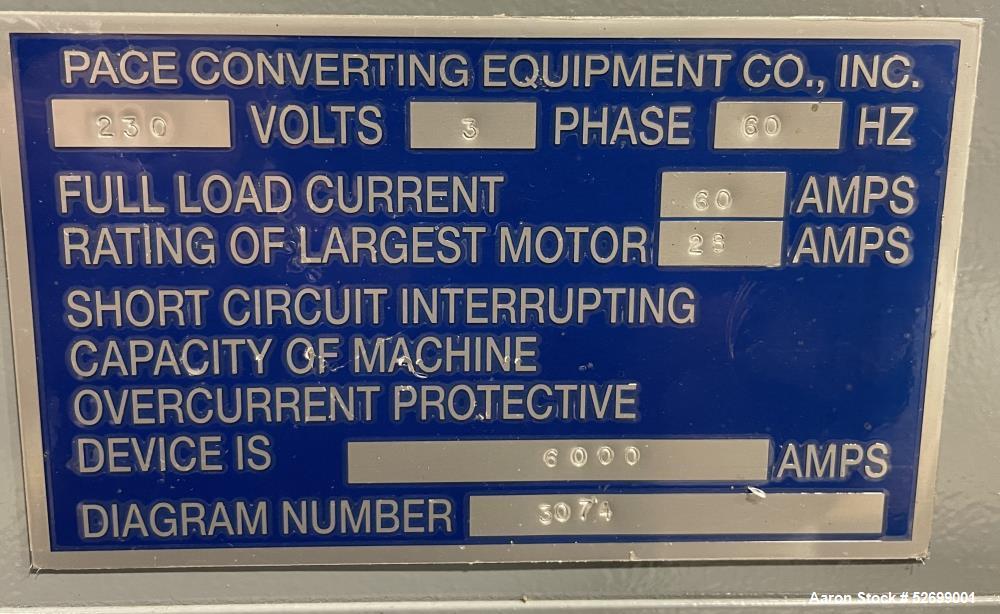

Used Pace Converting Equipment Converting Die Cutter, Model Pacer. 10" Web Width, 1/8" Gearing, Edge Guide, (4) Die Stations, (2) Product Rewinds, (3) Waste Rewinds, 24" Max Rewind Diameter, 40" Max Unwind Diameter. (2) Main unwinds with pneumatic mandrel and brake: max capacity of 40? OD and 200#, Main module: (4 ) die stations with through-hardened anvil rolls, Easy-to-remove anvils with heavy-duty driven support rolls, Dual, reversible rewinds with pneumatic mandrel and clutch, Electronic & switch controlled, Mandrel capacity: 21? OD, 200# finished roll, Pneumatic draw nip assembly, with roller, gauge, regulator and up / down switch, Four overhead, powered rewind / unwind assemblies with 3? OD air mandrel & combination pneumatic brakes / clutches, Two underneath; (1) powered unwind / rewind and (1) unpowered unwind assemblies with 3? OD air mandrel & combination pneumatic brakes / clutches, 1/8" CP gearing, 60 durometer laminating nip, Run speeds up to 240 FPM, Pre-determining, programmable counter, Heavy duty truck assist assembly, Hold-down hardware for die stations, (3) swing register assemblies, One razor slitting assembly with blade holders, 1" thickness machined aluminum side frames, Welded and painted tubular steel subframe. Power and air requirements: 230 Volt/3 Phase/60Hz/60 Amps, Air required: 2 to 3 CFM at 80 PSI.

Used Pace Converting Equipment Converting Die Cutter, Model Pacer. 10" Web Width, 1/8" Gearing, Edge Guide, (4) Die Stations, (2) Product Rewinds, (3) Waste Rewinds, 24" Max Rewind Diameter, 40" Max Unwind Diameter. (2) Main unwinds with pneumatic mandrel and brake: max capacity of 40? OD and 200#, Main module: (4 ) die stations with through-hardened anvil rolls, Easy-to-remove anvils with heavy-duty driven support rolls, Dual, reversible rewinds with pneumatic mandrel and clutch, Electronic & switch controlled, Mandrel capacity: 21? OD, 200# finished roll, Pneumatic draw nip assembly, with roller, gauge, regulator and up / down switch, Four overhead, powered rewind / unwind assemblies with 3? OD air mandrel & combination pneumatic brakes / clutches, Two underneath; (1) powered unwind / rewind and (1) unpowered unwind assemblies with 3? OD air mandrel & combination pneumatic brakes / clutches, 1/8" CP gearing, 60 durometer laminating nip, Run speeds up to 240 FPM, Pre-determining, programmable counter, Heavy duty truck assist assembly, Hold-down hardware for die stations, (3) swing register assemblies, One razor slitting assembly with blade holders, 1" thickness machined aluminum side frames, Welded and painted tubular steel subframe. Power and air requirements: 230 Volt/3 Phase/60Hz/60 Amps, Air required: 2 to 3 CFM at 80 PSI.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory