Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Welex/Johnson 30" Wide Co-Ex Sheet Extrusion Line

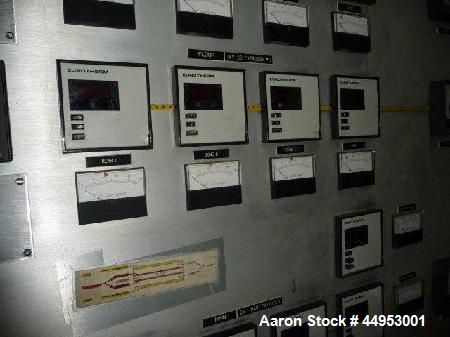

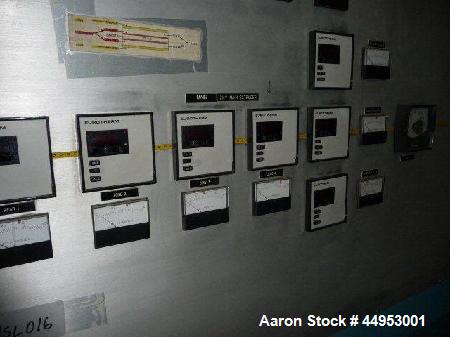

Used Welex/Johnson 30" Wide Co-Ex Sheet Extrusion Line consisting of: (2) 1.25" Welex 24/1 Co-Extruders, each with 10 hp DC motors and SCR controls, electrically heated and air cooled, non- vented barrels. New approximately 1986. Primary extruder is a 2.5" Welex, 30:1 L/D vented (plugged) electrically heated, water cooled barrel with automatic screen changer and hydraulic pump. Primary extruder is driven by a 60 hp DC motor and SCR control. The system includes a main control panel which includes the temperature controls and Compac motor drives. The downstream for the line consists of EDI flex lip die with restrictor and (3) replaceable bottom lips supplying 12-250 mil die thickness, mounted on die cart. Co-ex block for extruder integration, approximately 40" wide NDC thickness gauge, 18" x 30" Johnson 3 roll chill roll stack, chain driven, air actuated and including the necessary pumps and heat exchangers for roll cooling, 32" wide x 42" outside dimension, Johnson (2) position winder.

Used Welex/Johnson 30" Wide Co-Ex Sheet Extrusion Line consisting of: (2) 1.25" Welex 24/1 Co-Extruders, each with 10 hp DC motors and SCR controls, electrically heated and air cooled, non- vented barrels. New approximately 1986. Primary extruder is a 2.5" Welex, 30:1 L/D vented (plugged) electrically heated, water cooled barrel with automatic screen changer and hydraulic pump. Primary extruder is driven by a 60 hp DC motor and SCR control. The system includes a main control panel which includes the temperature controls and Compac motor drives. The downstream for the line consists of EDI flex lip die with restrictor and (3) replaceable bottom lips supplying 12-250 mil die thickness, mounted on die cart. Co-ex block for extruder integration, approximately 40" wide NDC thickness gauge, 18" x 30" Johnson 3 roll chill roll stack, chain driven, air actuated and including the necessary pumps and heat exchangers for roll cooling, 32" wide x 42" outside dimension, Johnson (2) position winder.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory