Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used PTI/Welex Co-Extrusion Sheet Line.

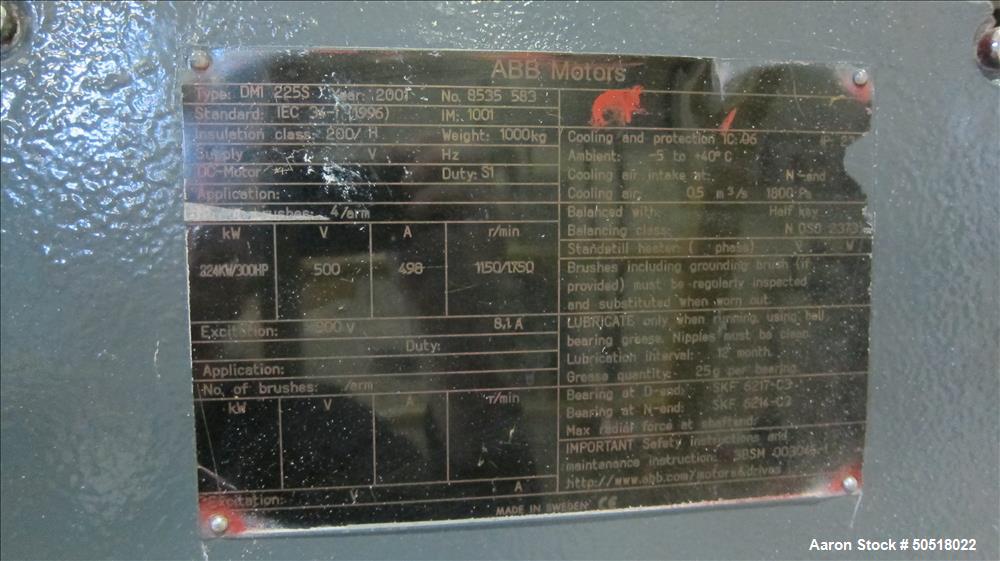

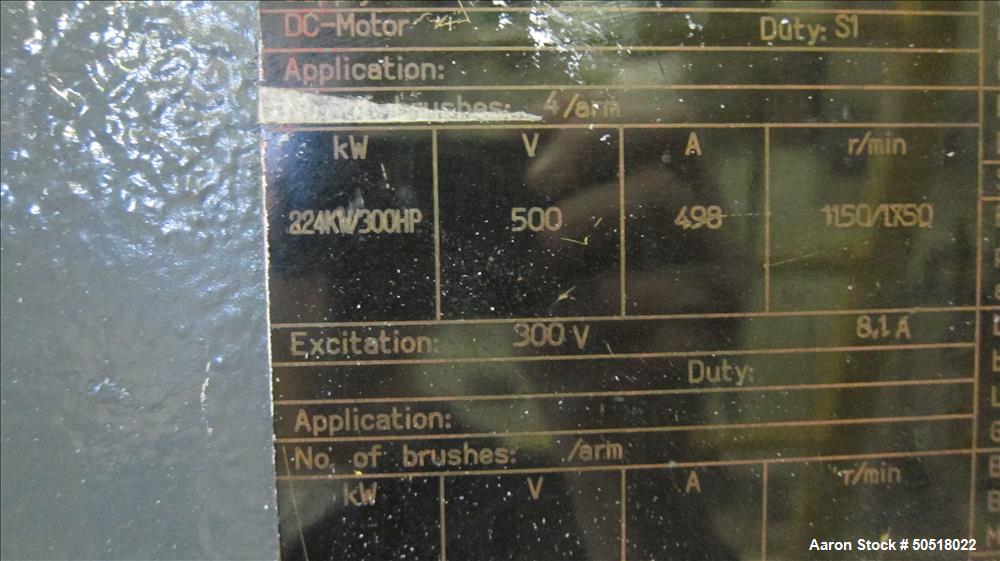

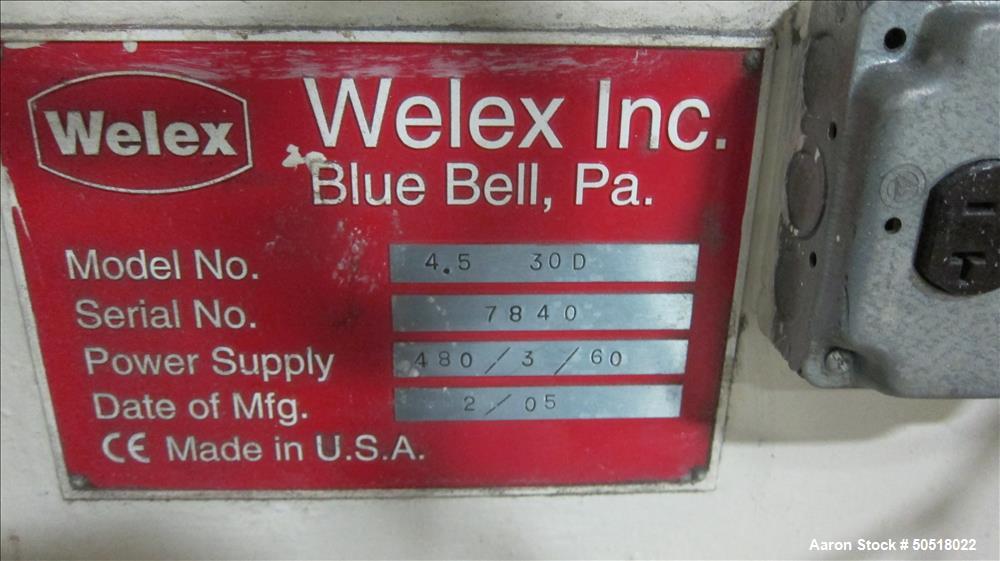

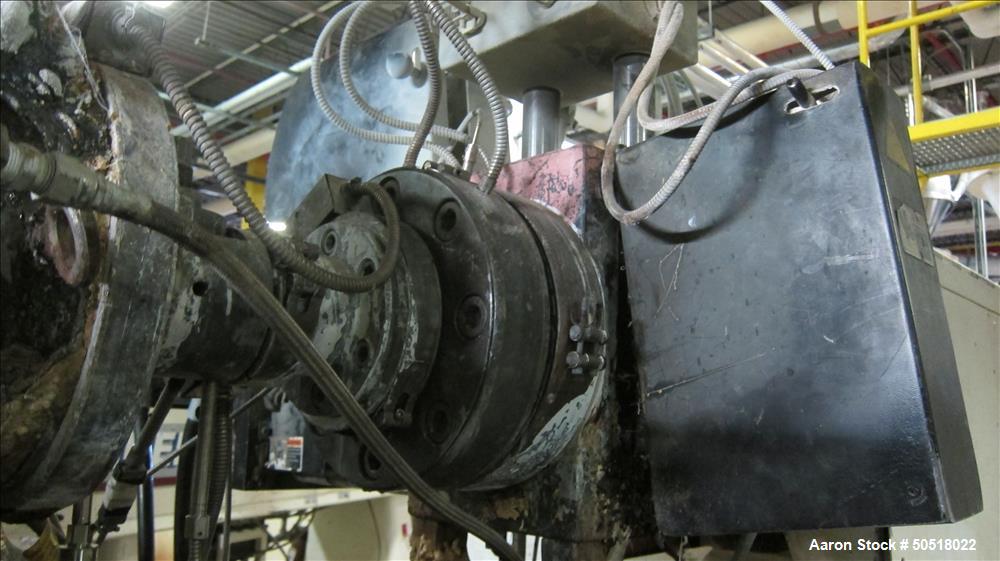

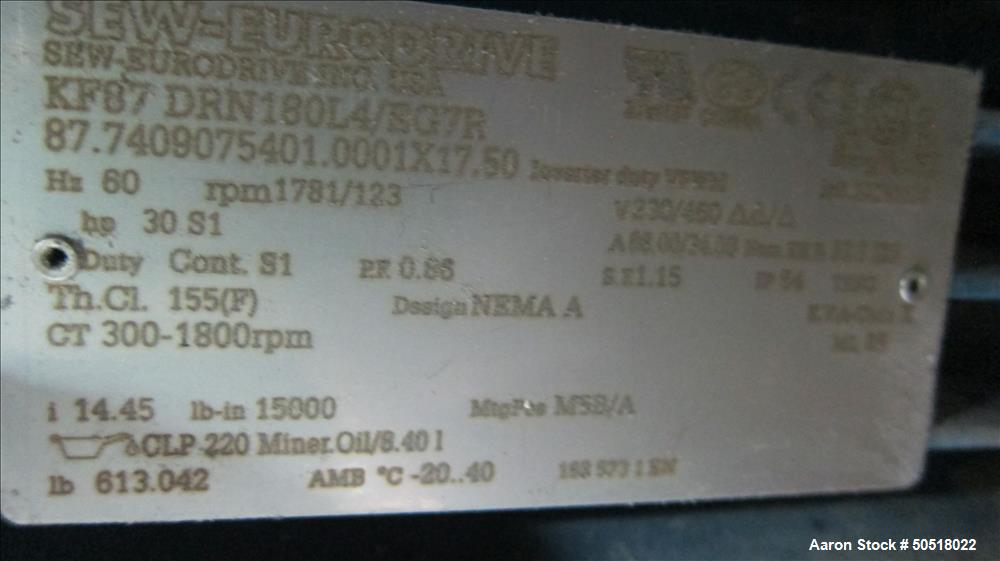

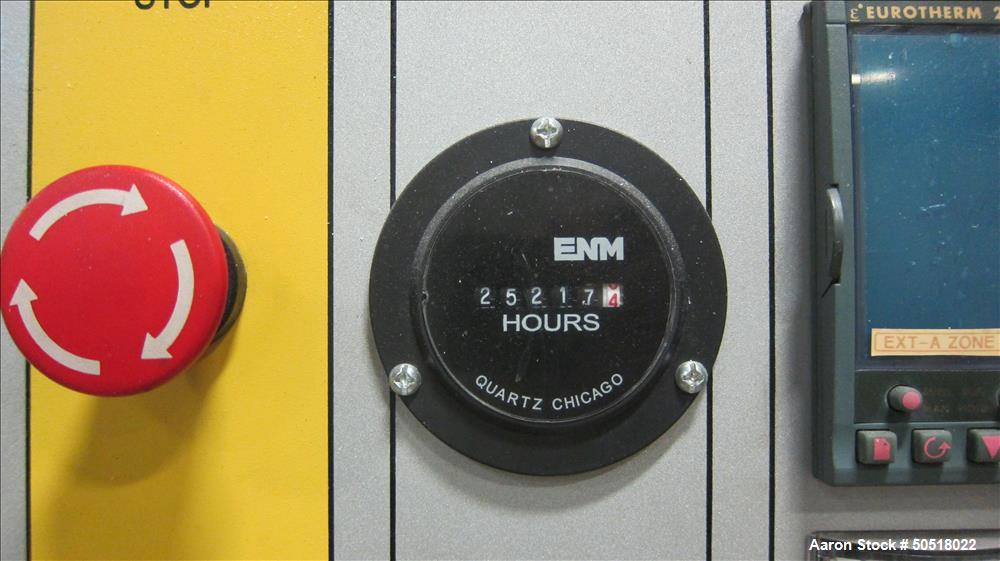

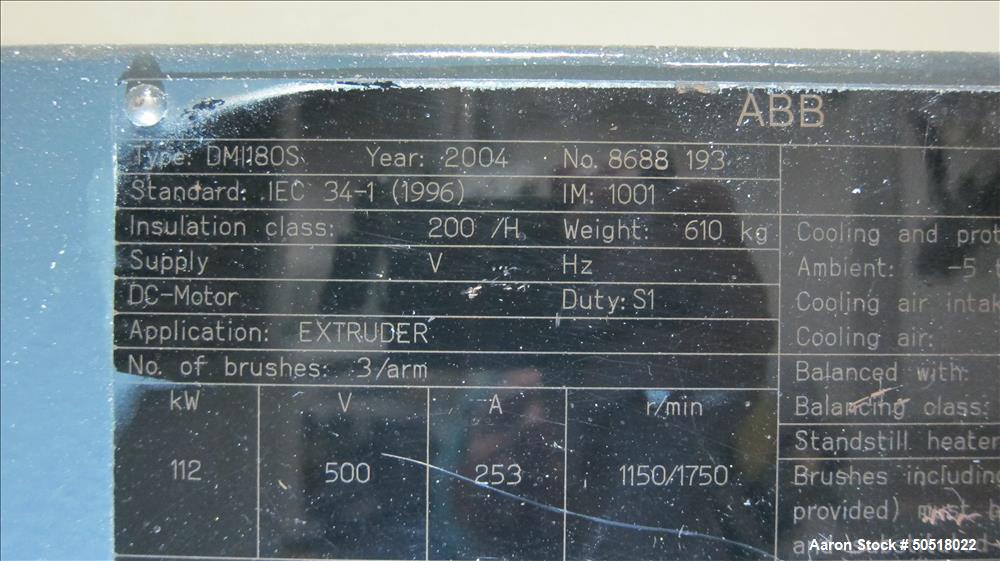

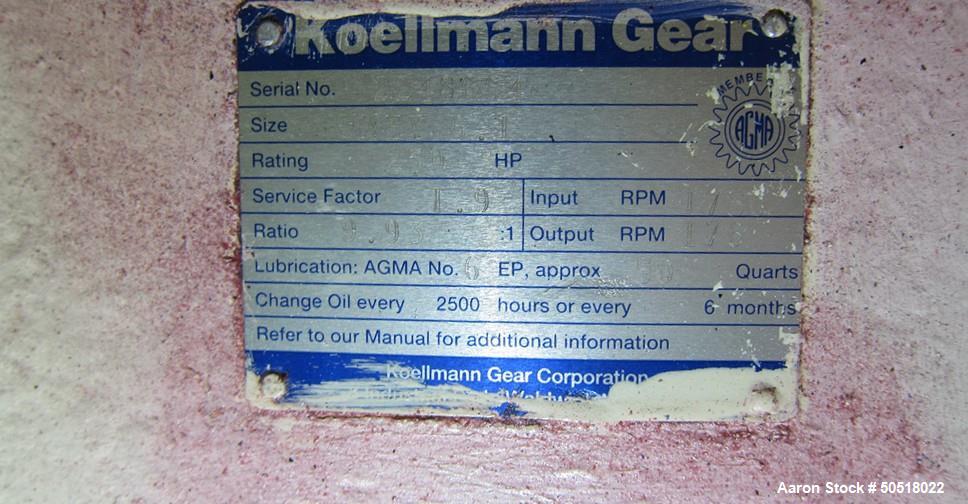

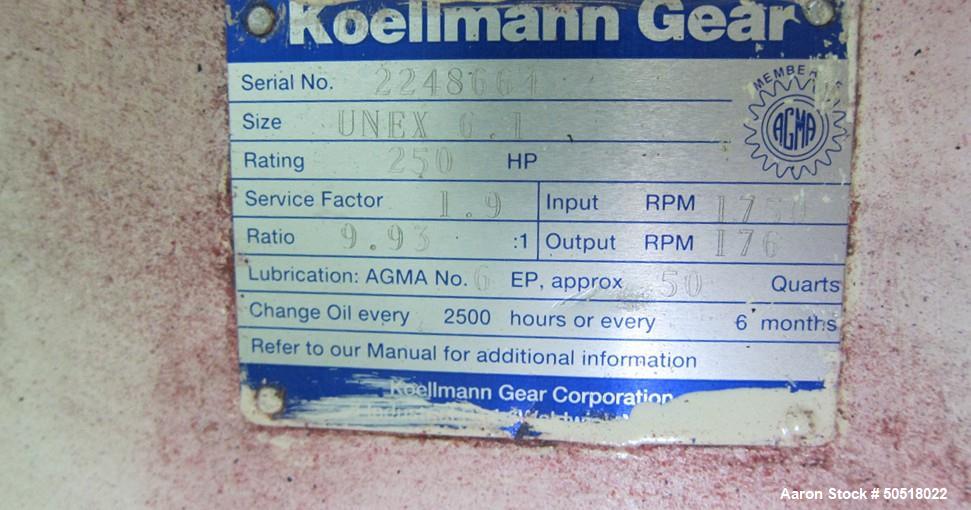

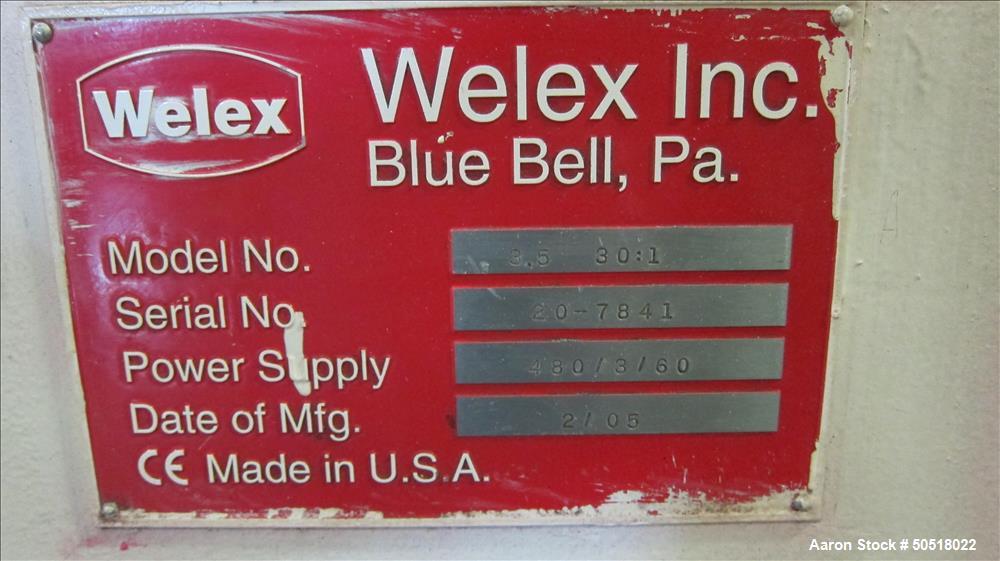

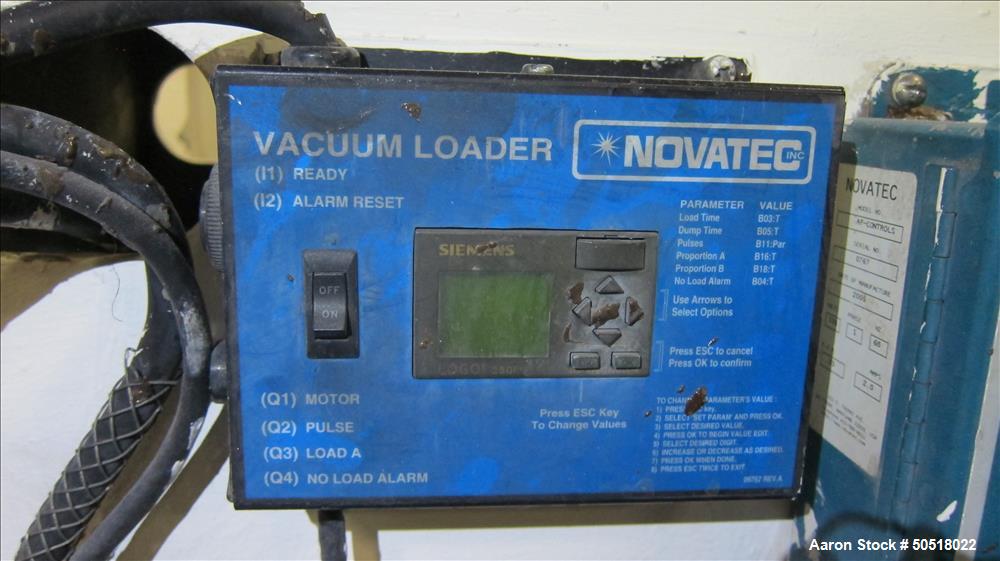

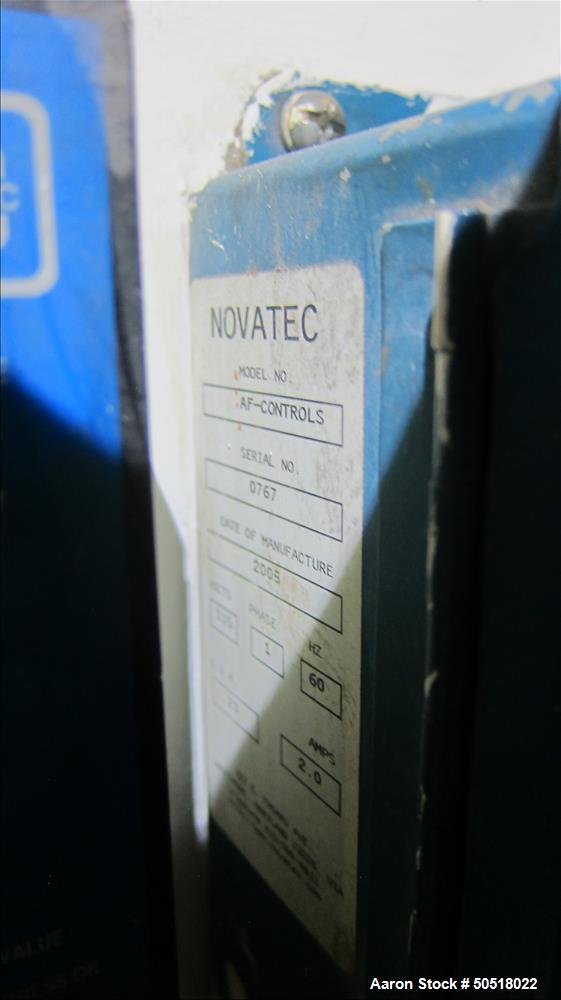

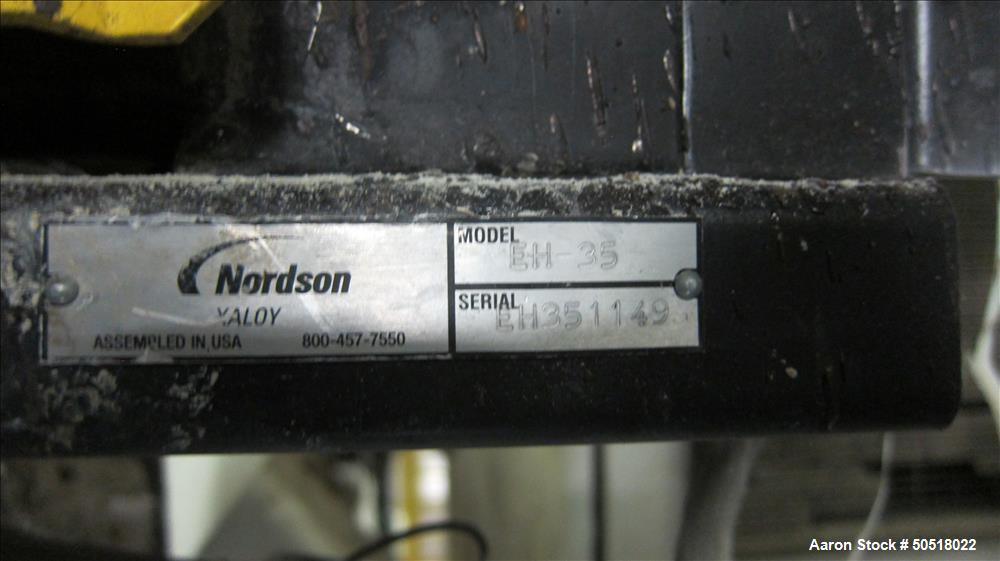

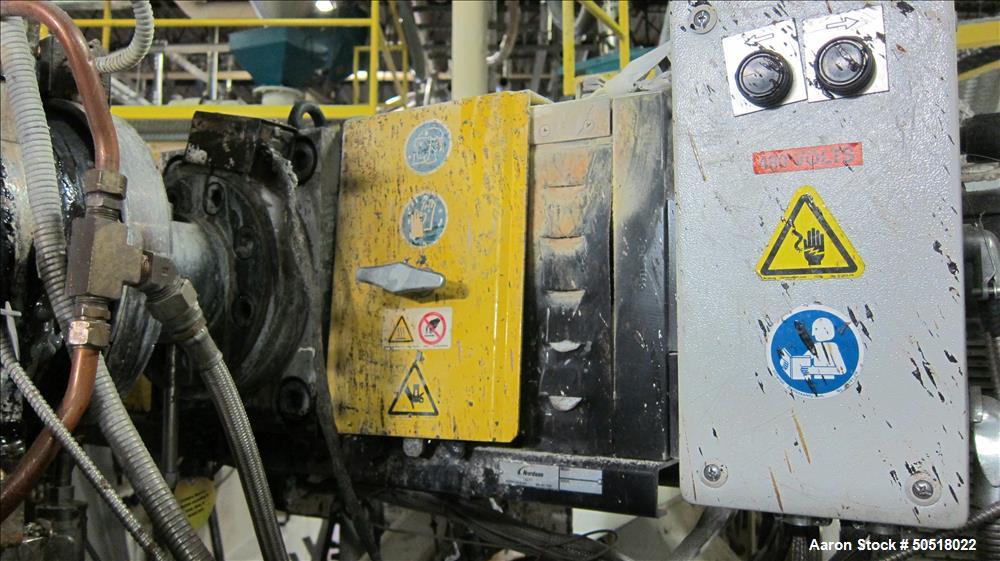

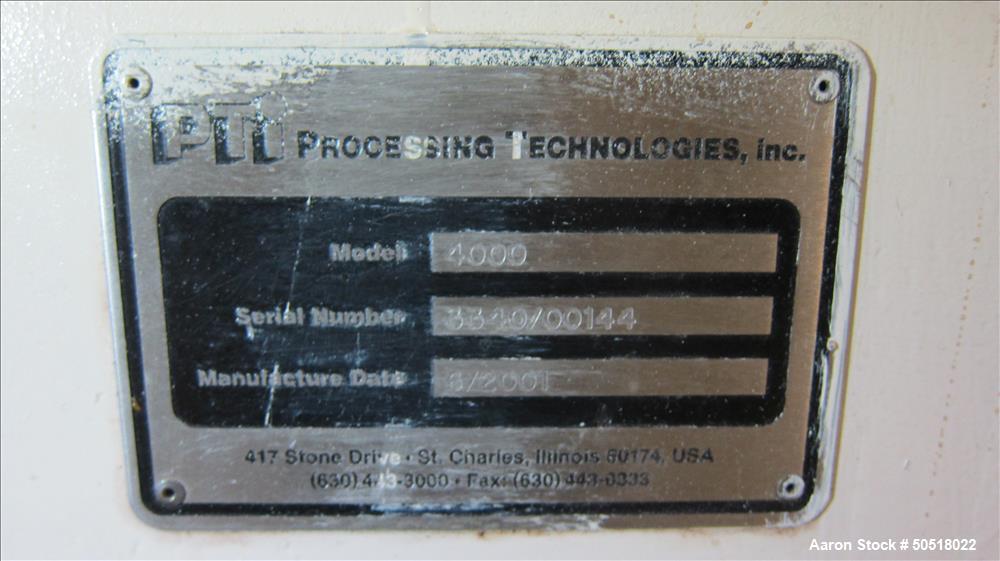

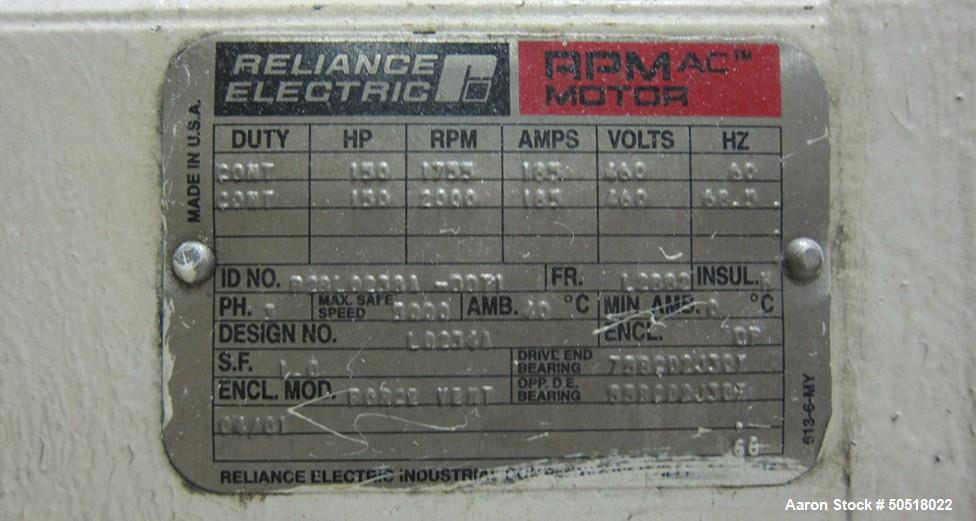

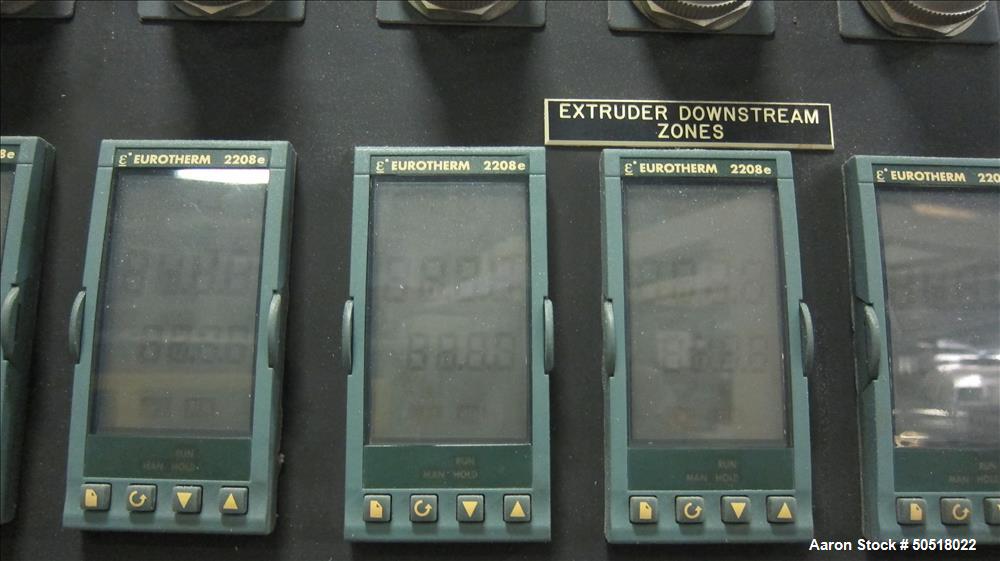

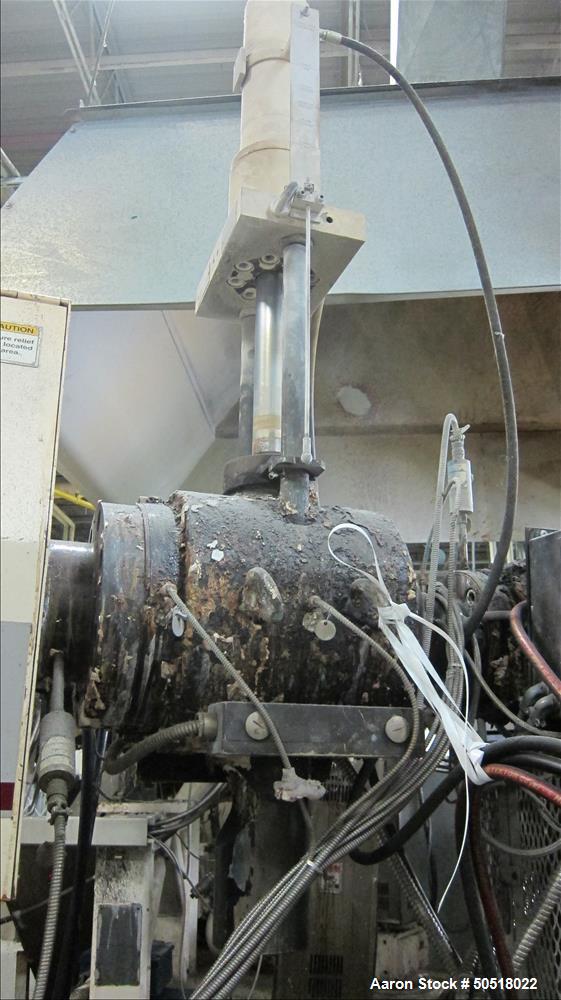

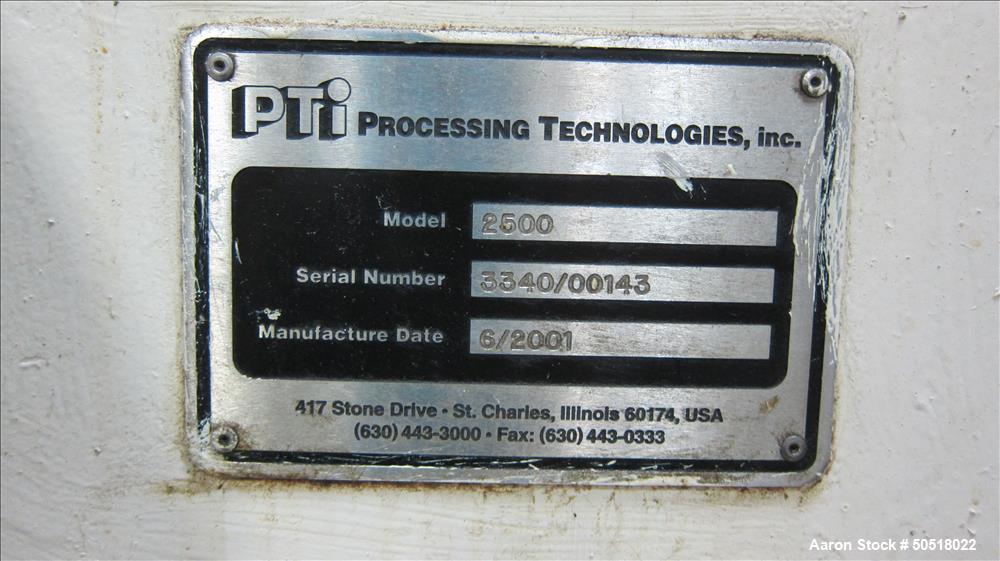

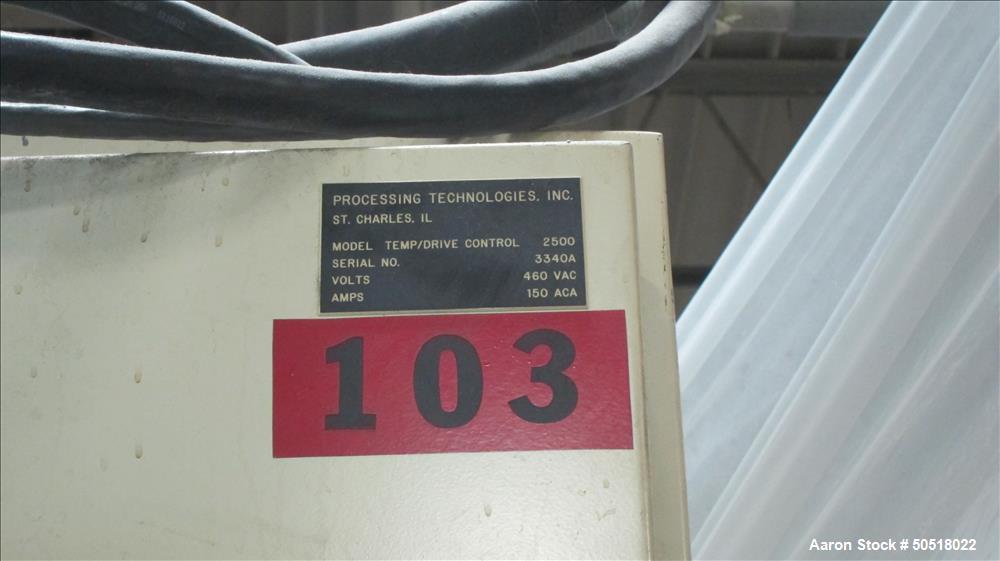

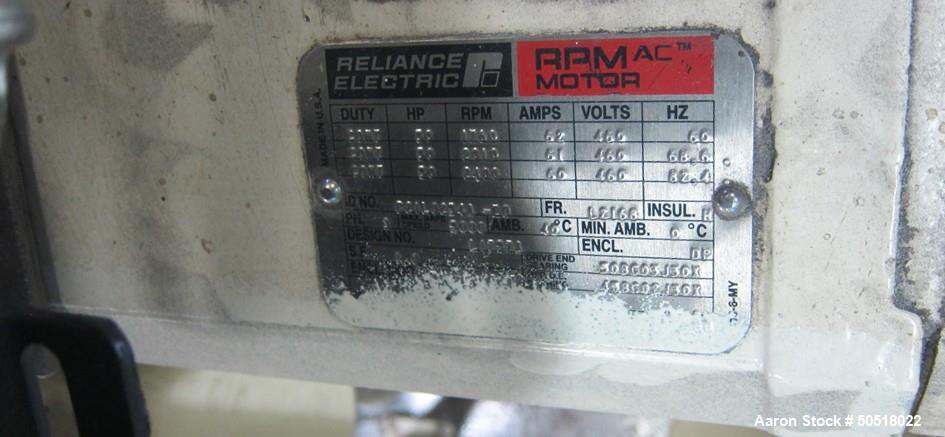

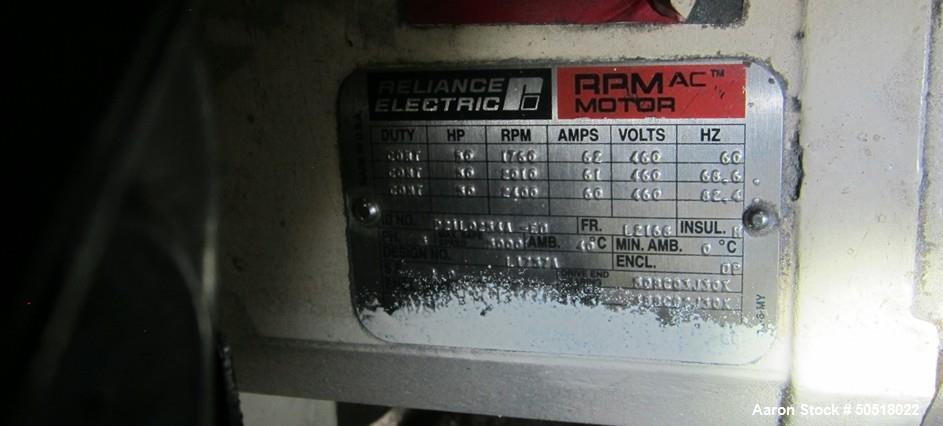

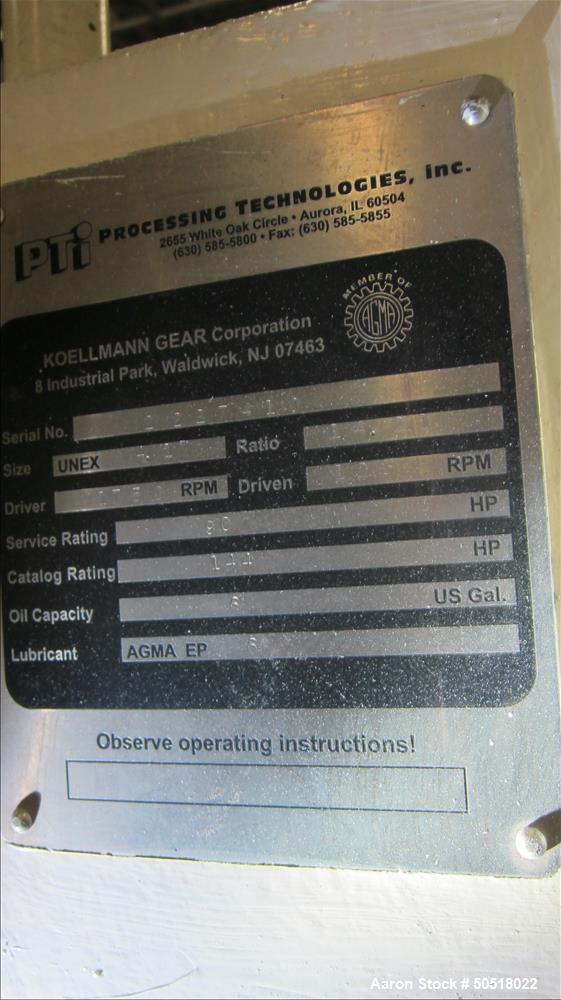

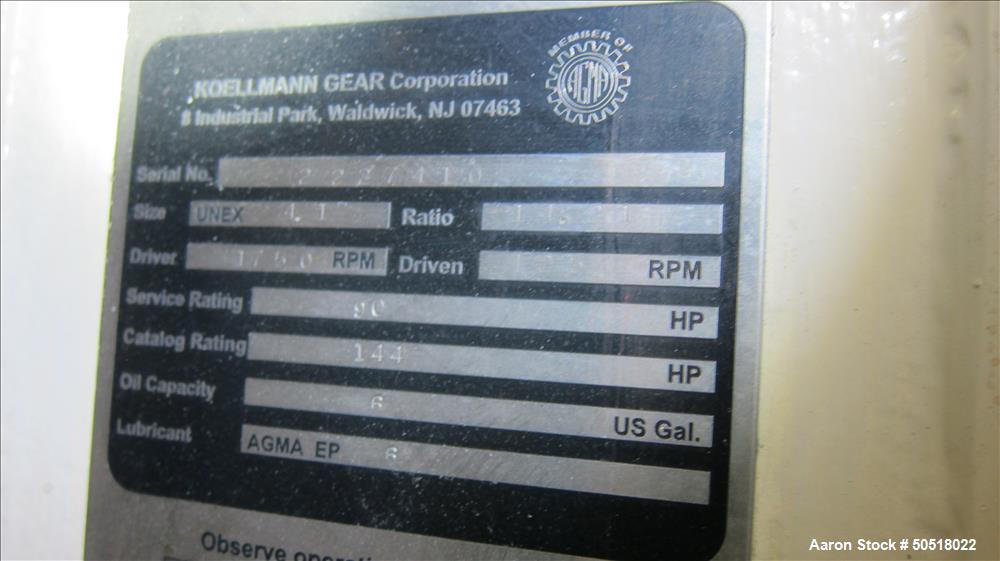

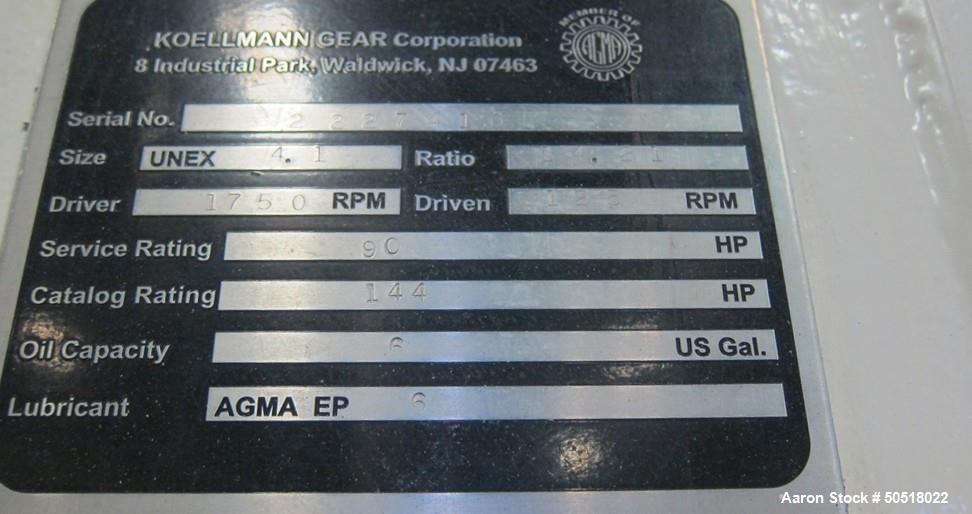

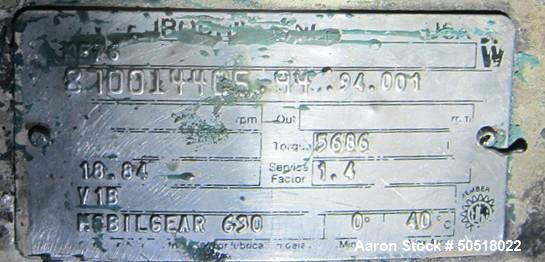

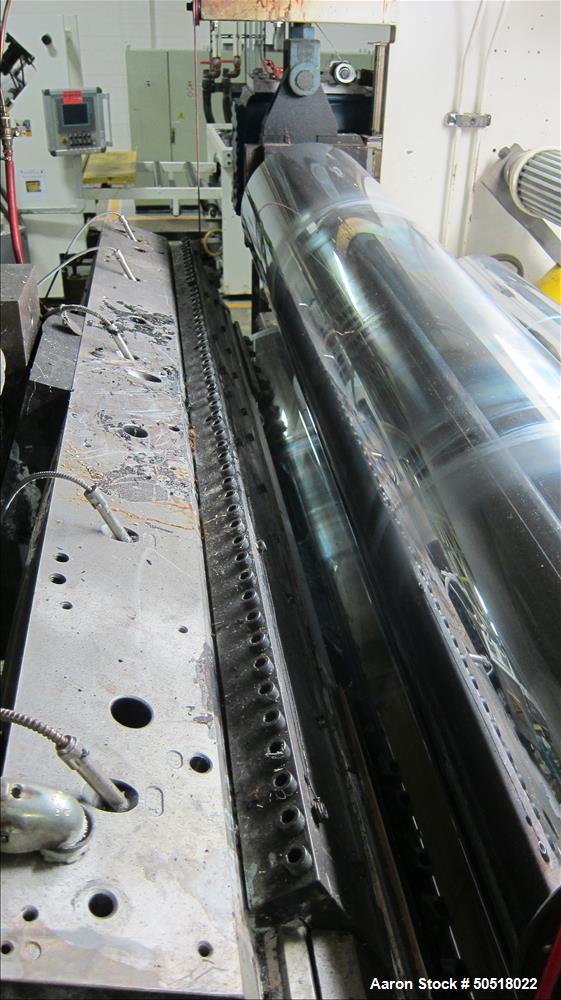

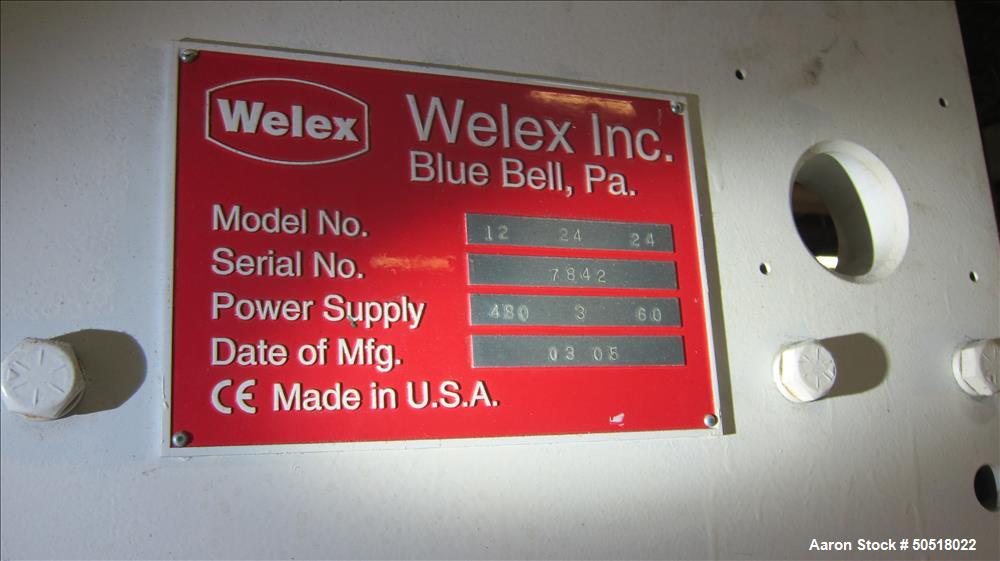

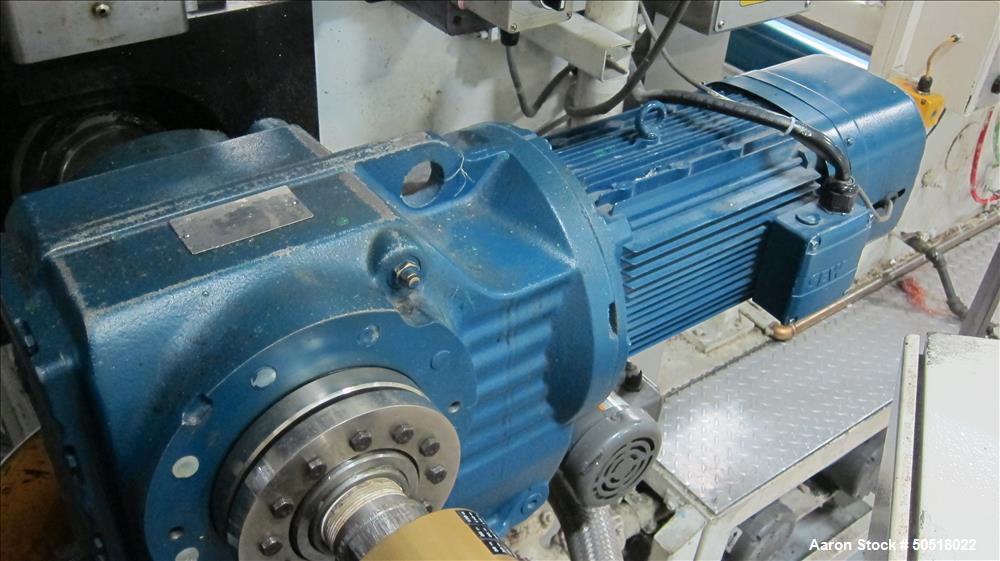

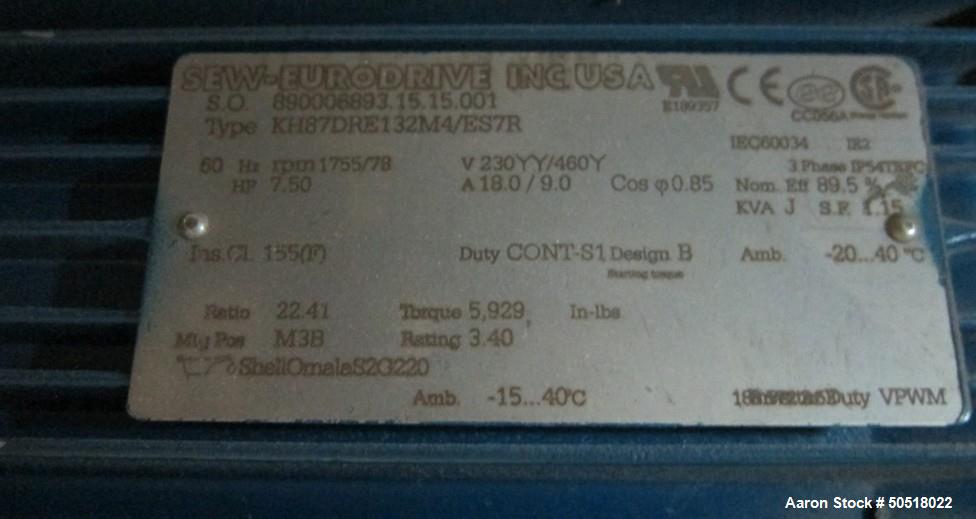

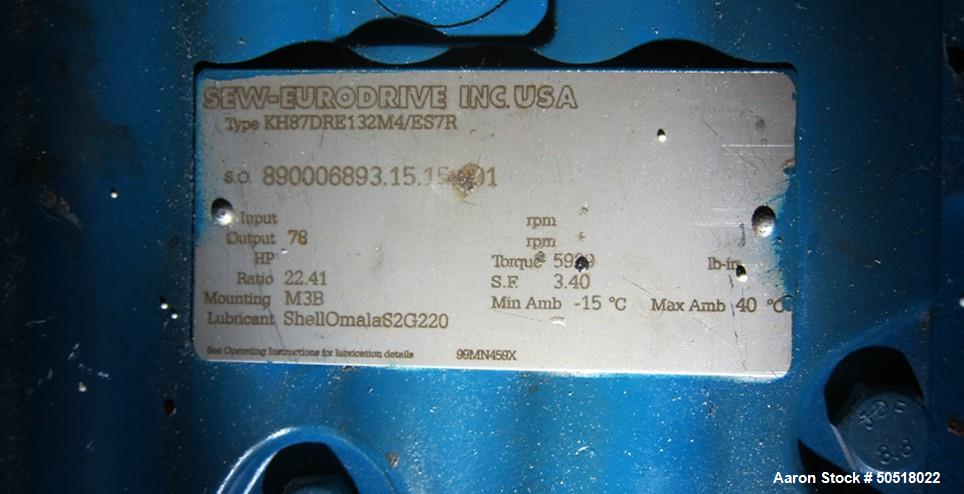

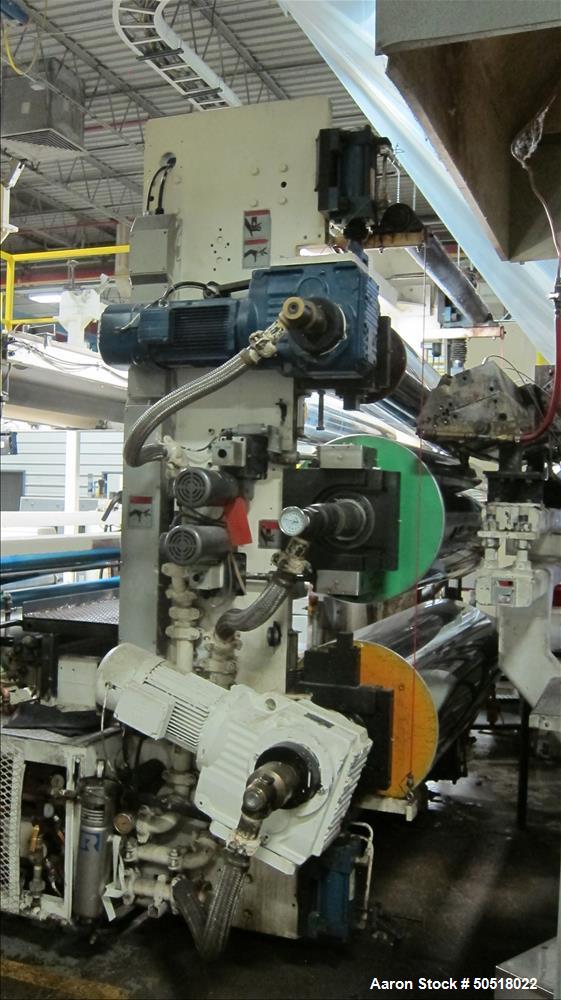

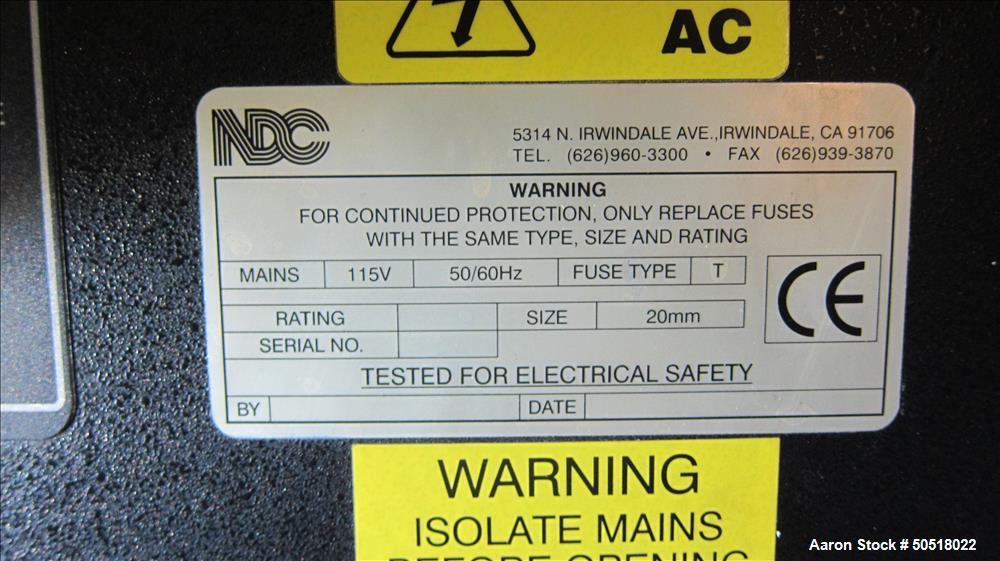

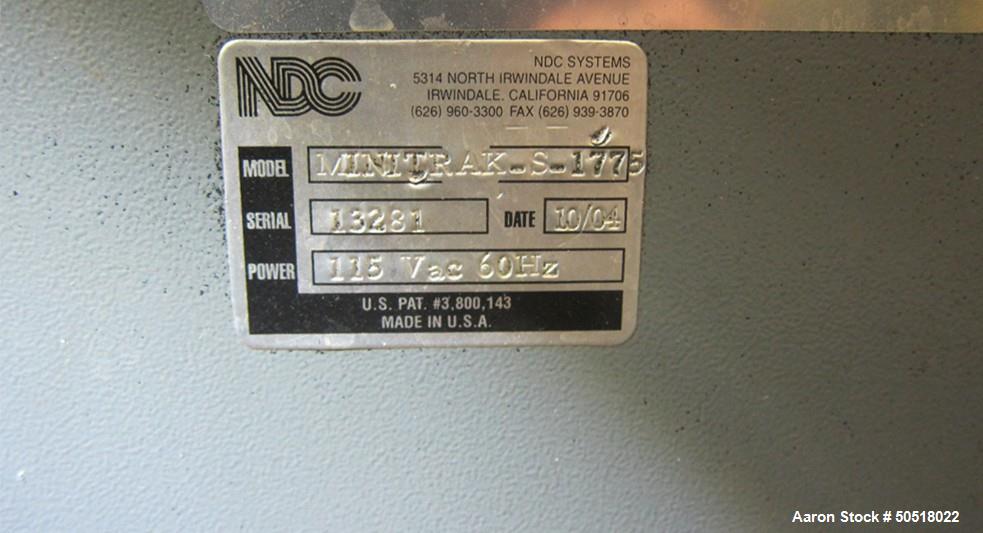

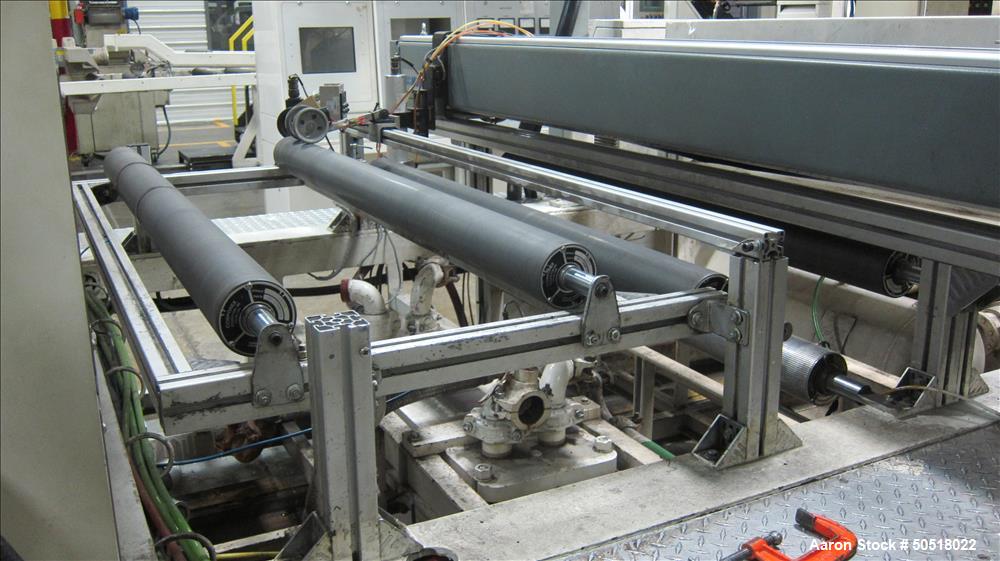

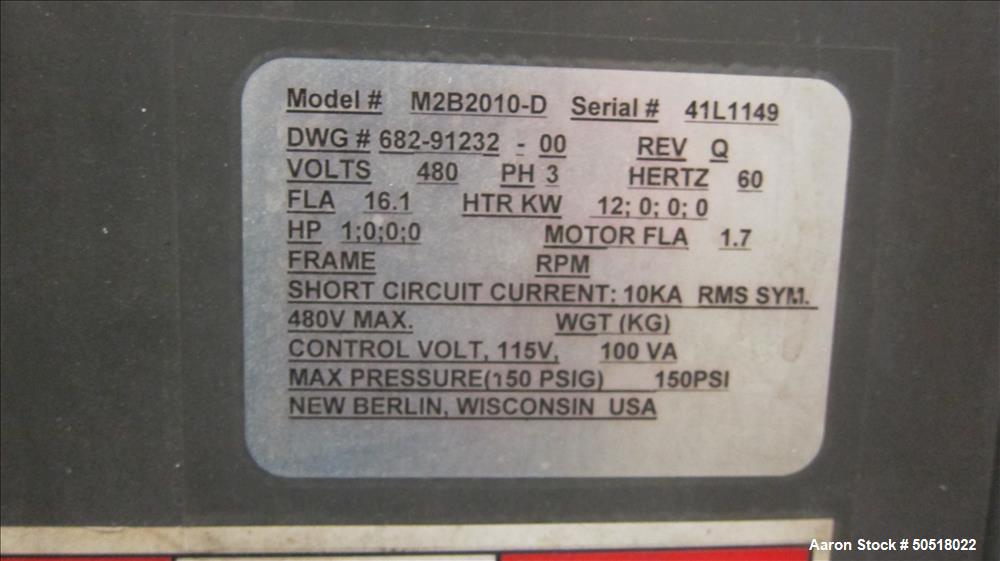

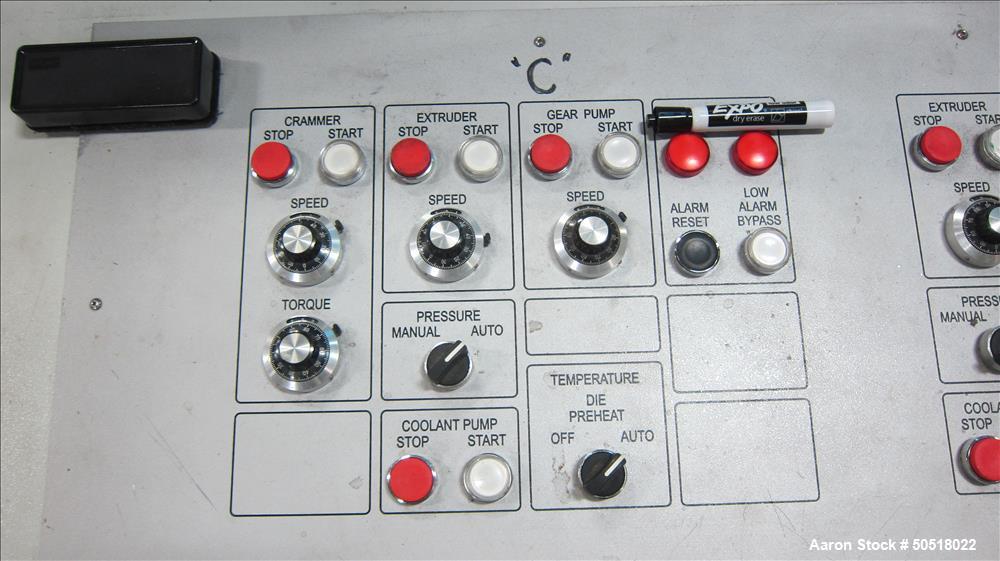

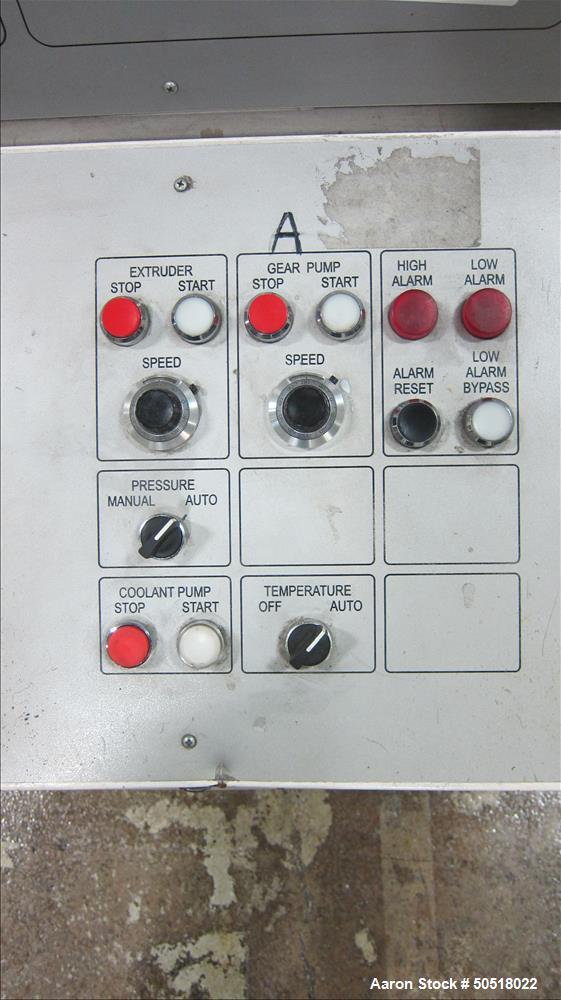

Used PTI/Welex Co-Extrusion Sheet Line. Main Extruder: 4.5" Welex Single Screw Extruder. Model 4.5 30D, Serial # 7840, 30:1 L/D Ratio. ABB 300 hp DC motor, vented barrel. Electrically heated barrel and water cooled. Mfg 2005. HYD screen changer. Gear pump. Welex 3.5" single screw extruder, Model 3.5 30:1 Serial # 20-7841, ABB 112 kW DC motor, Koellmann gear box size UNEX 6.1 Serial # 2248664, rated 250 hp service factor 1.9 input rpm 1750 ratio 9.93:1, output rpm 176, 30:1 L/D ratio. Vented barrel. Novatec vacuum loader. Mfg 2005. Nordson Xaloy hydraulic screen changer Model EH-35 Serial # EH351149 and gear pump. 4.5" PTI single screw extruder. Model 4000 Serial # 3340/00144. 150 hp Reliance electric AC motor Koellmann gear box UNEX 6.1 Serial # 22166077, ratio 13.894, rated 1750 rpm. Eurotherm 2208E temperature controllers, vented barrel. 5 zones electrically heated, water cooled, hydraulic screen changer and gear pump. PTI 2.5: single screw extruder. Model 2500 Serial # 3340/00143 5 zones electrically heated, water cooled, Reliance electric 50 hp motor rated 1760 rpm, Koellmann gear box UNEX 4.1 Serial # 2227410 ratio 14.2:1, driver 1750 rpm, driven 125 rpm Eurotherm and Barber-Colman temperature controllers, Mfg 2001. Hydraulic screen changer and gear pump. Approximate 60" Nordson sheet die. 2005 3 roll Welex sheet stack downstack. Model 12" x 24" x 24" diameter 65" wide individually driven rolls by 7.5 hp motors. NDC Beta thickness gauge (radioactive material removed) Model MINITRAK-S-1775 Serial # 13281 Year 2004, slitter station including Sterling thermolater Model M2B2010-D Serial # 41l1149, NIP roll/tension section and 4 position turret winder, turret driven by Emerson M700 drive controller and NIDEC 10 hp motor.

Used PTI/Welex Co-Extrusion Sheet Line. Main Extruder: 4.5" Welex Single Screw Extruder. Model 4.5 30D, Serial # 7840, 30:1 L/D Ratio. ABB 300 hp DC motor, vented barrel. Electrically heated barrel and water cooled. Mfg 2005. HYD screen changer. Gear pump. Welex 3.5" single screw extruder, Model 3.5 30:1 Serial # 20-7841, ABB 112 kW DC motor, Koellmann gear box size UNEX 6.1 Serial # 2248664, rated 250 hp service factor 1.9 input rpm 1750 ratio 9.93:1, output rpm 176, 30:1 L/D ratio. Vented barrel. Novatec vacuum loader. Mfg 2005. Nordson Xaloy hydraulic screen changer Model EH-35 Serial # EH351149 and gear pump. 4.5" PTI single screw extruder. Model 4000 Serial # 3340/00144. 150 hp Reliance electric AC motor Koellmann gear box UNEX 6.1 Serial # 22166077, ratio 13.894, rated 1750 rpm. Eurotherm 2208E temperature controllers, vented barrel. 5 zones electrically heated, water cooled, hydraulic screen changer and gear pump. PTI 2.5: single screw extruder. Model 2500 Serial # 3340/00143 5 zones electrically heated, water cooled, Reliance electric 50 hp motor rated 1760 rpm, Koellmann gear box UNEX 4.1 Serial # 2227410 ratio 14.2:1, driver 1750 rpm, driven 125 rpm Eurotherm and Barber-Colman temperature controllers, Mfg 2001. Hydraulic screen changer and gear pump. Approximate 60" Nordson sheet die. 2005 3 roll Welex sheet stack downstack. Model 12" x 24" x 24" diameter 65" wide individually driven rolls by 7.5 hp motors. NDC Beta thickness gauge (radioactive material removed) Model MINITRAK-S-1775 Serial # 13281 Year 2004, slitter station including Sterling thermolater Model M2B2010-D Serial # 41l1149, NIP roll/tension section and 4 position turret winder, turret driven by Emerson M700 drive controller and NIDEC 10 hp motor.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory