Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Johnson Plastics Machinery Co-Extrusion Sheet Line

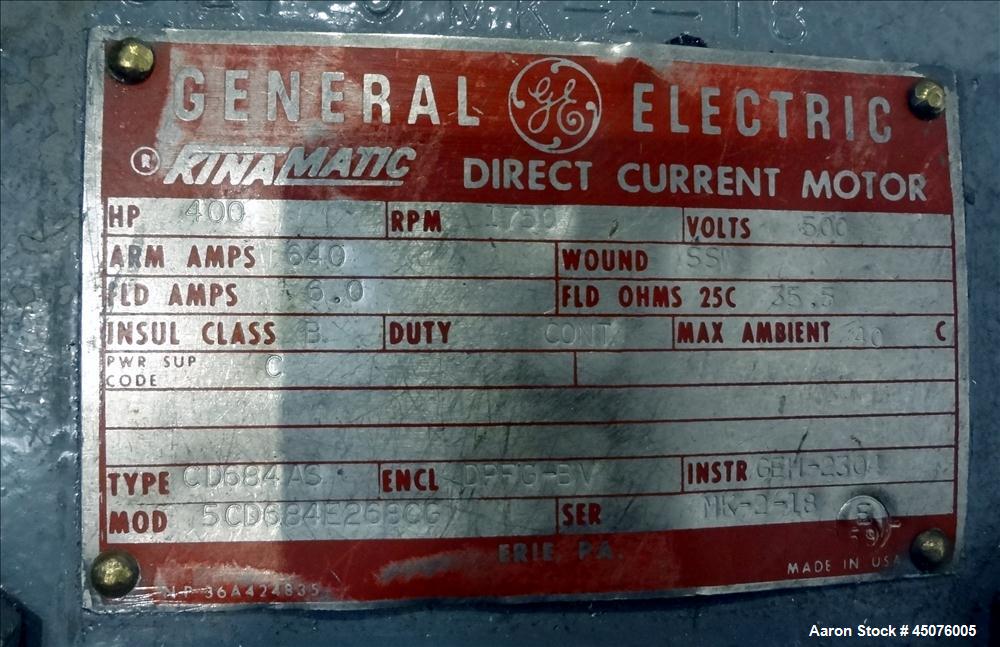

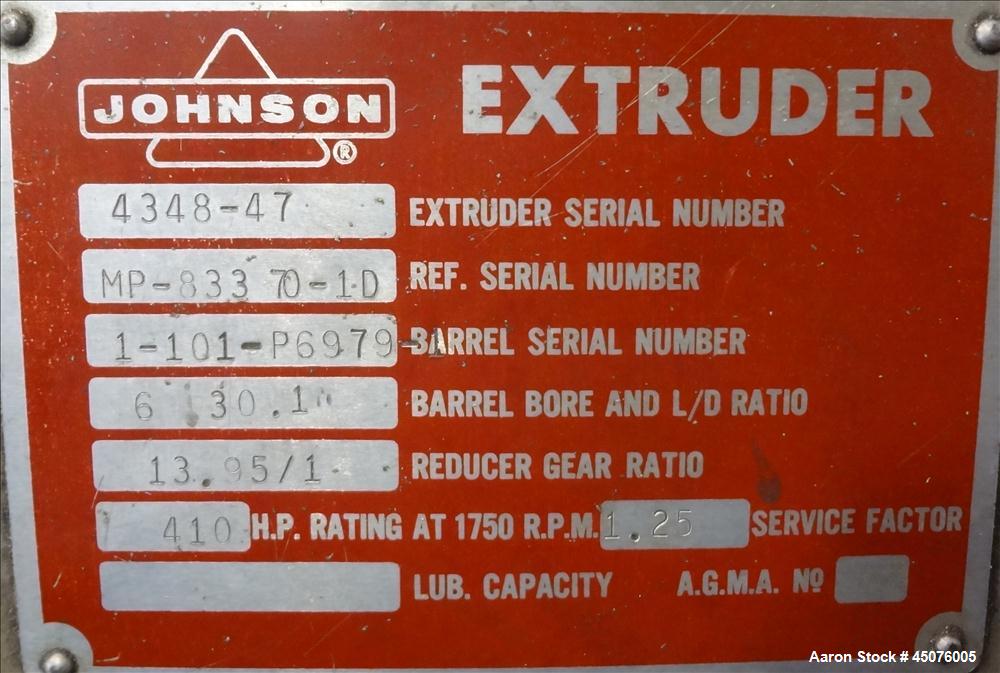

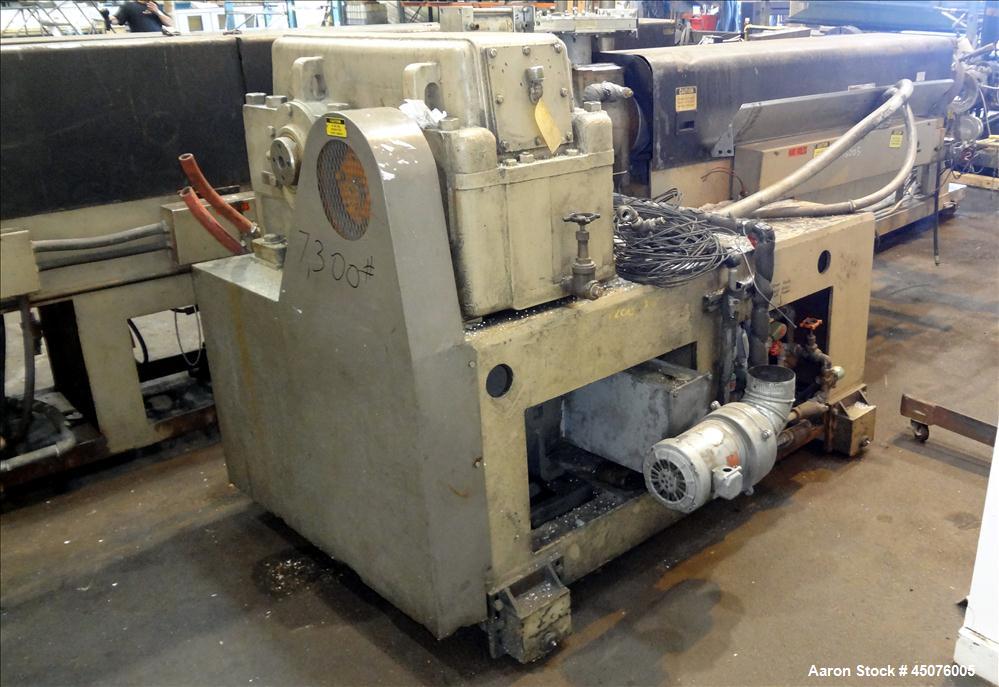

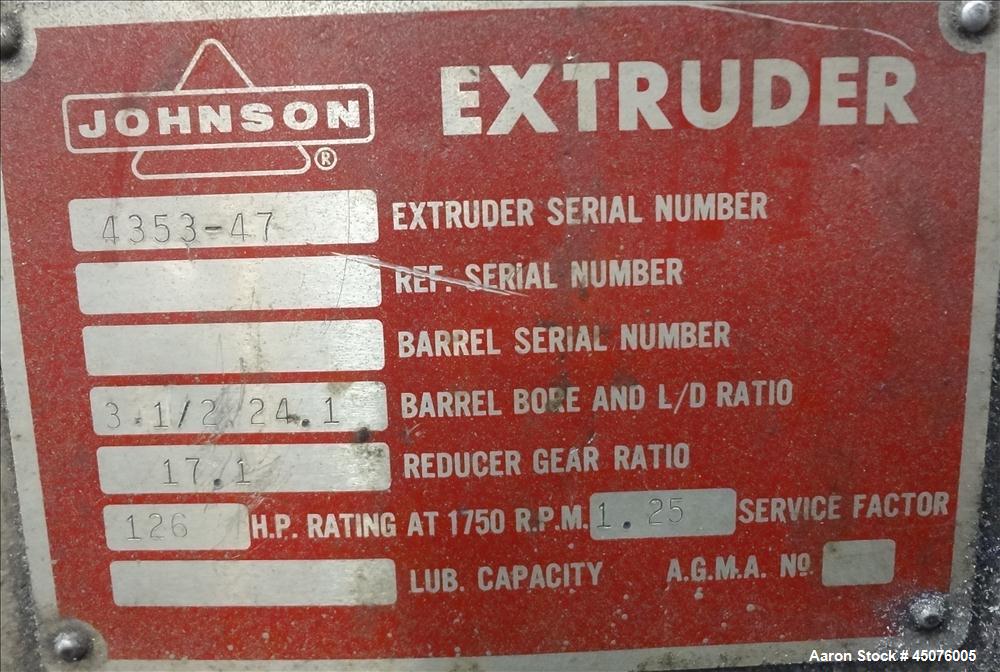

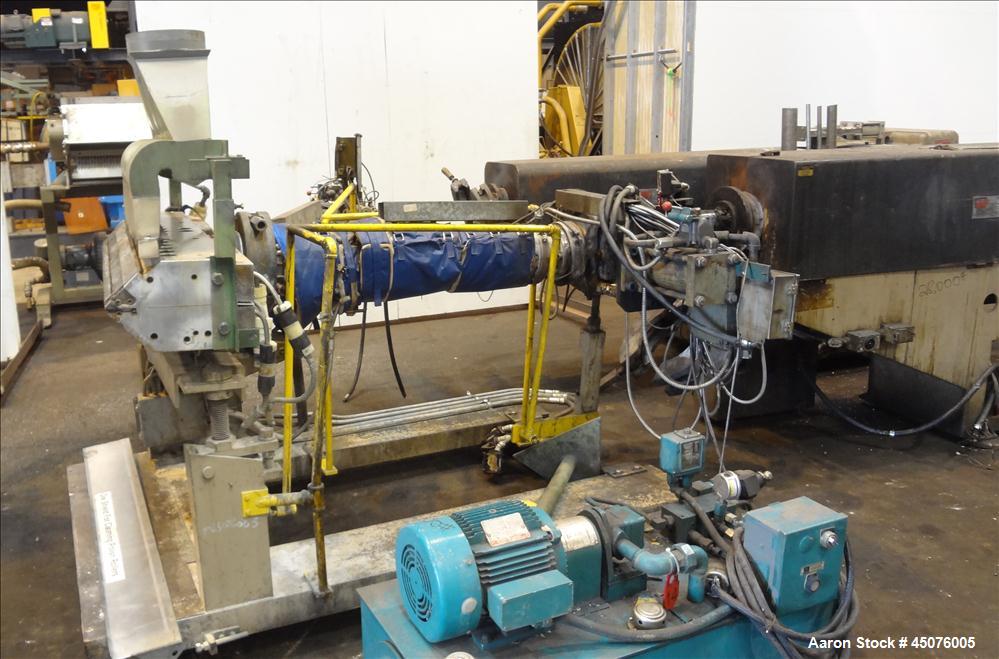

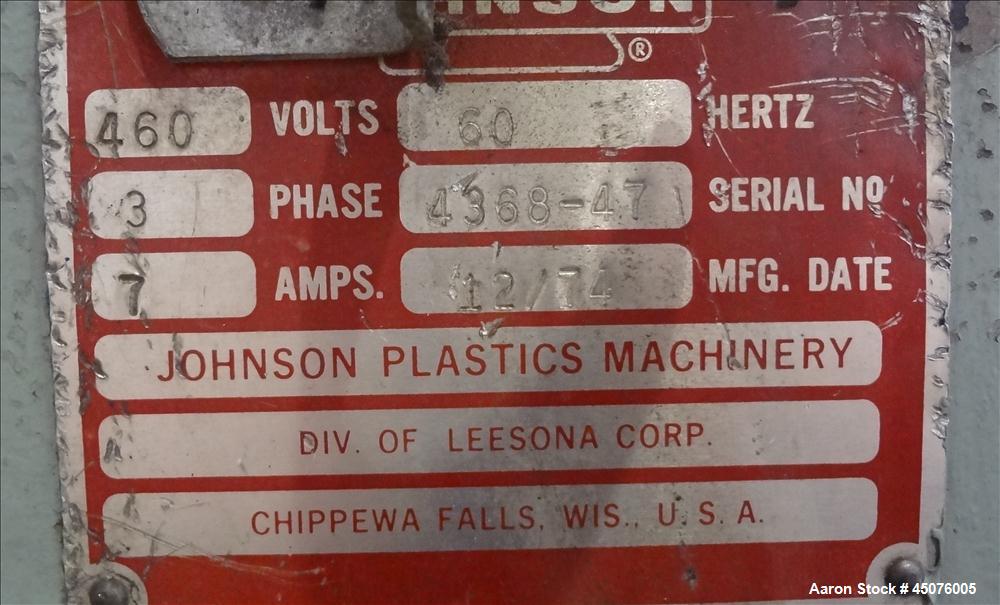

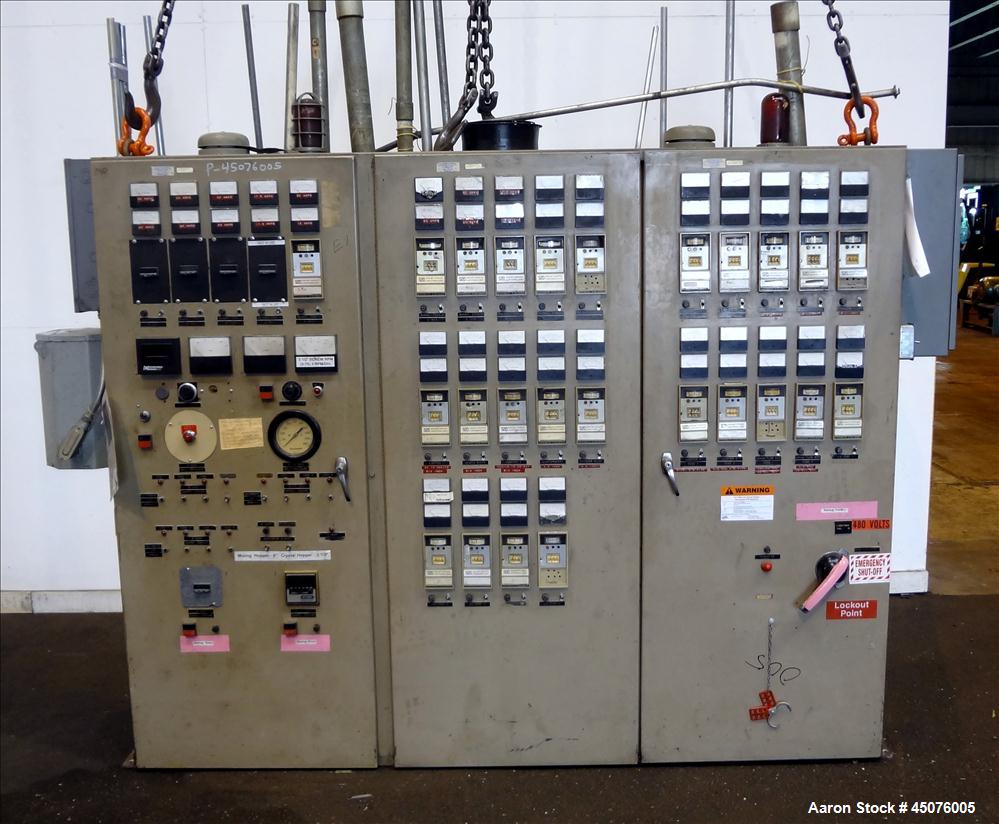

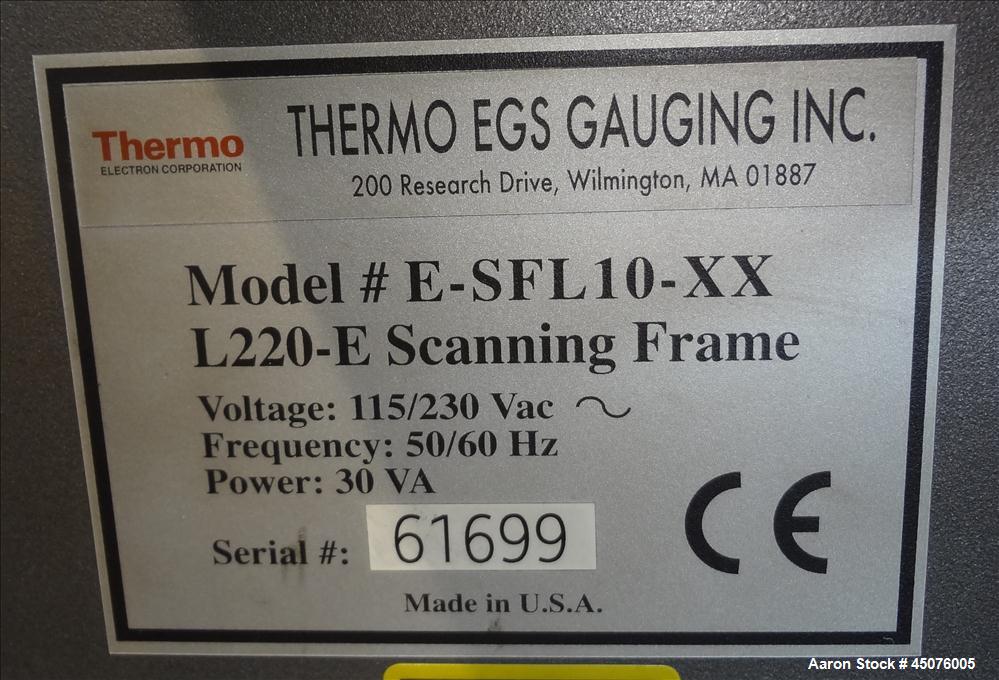

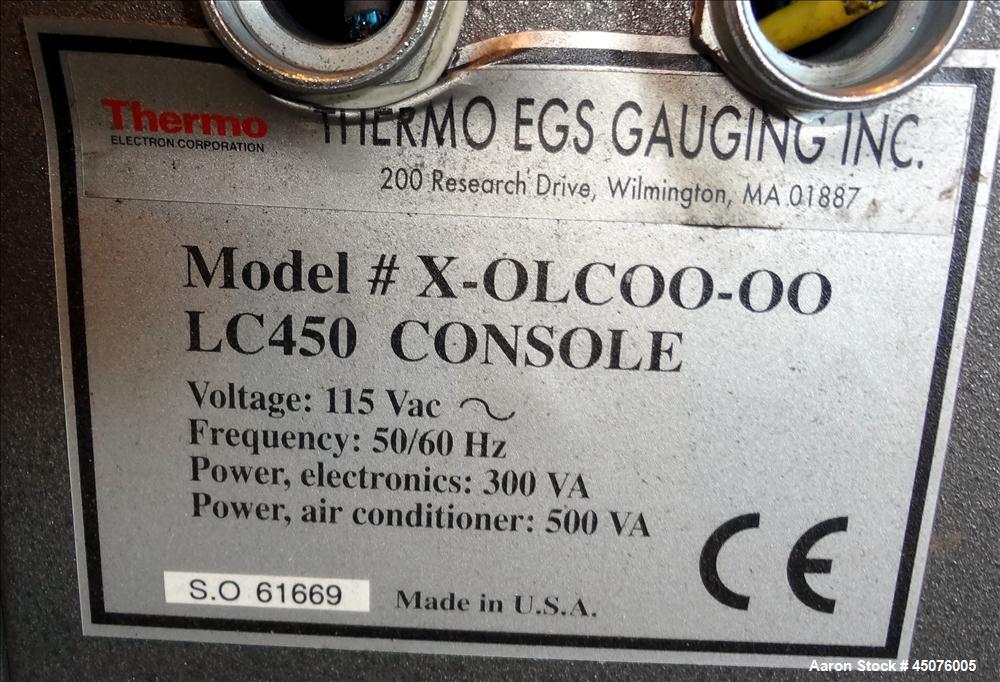

Used Johnson Plastics Machinery Co-Extrusion Sheet Line Consisting of: (1) Johnson 6" Single Screw Extruder, 30 to 1 L/D ratio. Electrically heated, water cooled 8 zone side vented (plugged) barrel with a closed loop system with a pump, tank, and heat exchanger. Water cooled feed throat with a feeding system, approximate 43-3/4" center line height, and die clamp. Driven by a 400 hp, 500 volt, 1750 rpm DC motor thru a gearbox, ratio 13.95 to 1. Serial# 4348-47. (1) Johnson 3.5" Single Screw Extruder, 24 to 1 L/D ratio. Electrically heated, water cooled 4 zone side vented (plugged) barrel with a closed loop system with a pump, tank, and heat exchanger. Water cooled feed throat with hopper, approximate 43-3/4" center line height, and die clamp. Driven by a 75 hp, 550 volt, 1750 rpm DC motor thru a gearbox, ratio 17.1 to 1. Serial# 4353-47. (1) Beringer 2.5" Screen Changer, Model 4, serial# 2818, (1) Beringer 4.5" Screen Changer, both with (1) 3 hp power pack. (2) Static Mixers, (1) EDI 56" wide flex lip sheet die on a cart. (1) Johnson Upstack 3 roll sheet stack. (3) 54" wide x 16" diameter chrome plated cored rolls, fixed middle, hydraulically adjustable top, and bottom, driven by a 5 hp motor with reducer, approximate 102" long cooling conveyor section, serial# 4367-47, built 1974. (1) Johnson nip roll, (2) 8" diameter x 54" wide rubber rolls, (1) Thermo thickness gauge, Model E-SFL10-XX, Serial# 61699 with control panel. (1) Johnson dual turret winder, approximate 54" wide x 24" diameter rolls. Serial# 4368-47, built 1974.

Used Johnson Plastics Machinery Co-Extrusion Sheet Line Consisting of: (1) Johnson 6" Single Screw Extruder, 30 to 1 L/D ratio. Electrically heated, water cooled 8 zone side vented (plugged) barrel with a closed loop system with a pump, tank, and heat exchanger. Water cooled feed throat with a feeding system, approximate 43-3/4" center line height, and die clamp. Driven by a 400 hp, 500 volt, 1750 rpm DC motor thru a gearbox, ratio 13.95 to 1. Serial# 4348-47. (1) Johnson 3.5" Single Screw Extruder, 24 to 1 L/D ratio. Electrically heated, water cooled 4 zone side vented (plugged) barrel with a closed loop system with a pump, tank, and heat exchanger. Water cooled feed throat with hopper, approximate 43-3/4" center line height, and die clamp. Driven by a 75 hp, 550 volt, 1750 rpm DC motor thru a gearbox, ratio 17.1 to 1. Serial# 4353-47. (1) Beringer 2.5" Screen Changer, Model 4, serial# 2818, (1) Beringer 4.5" Screen Changer, both with (1) 3 hp power pack. (2) Static Mixers, (1) EDI 56" wide flex lip sheet die on a cart. (1) Johnson Upstack 3 roll sheet stack. (3) 54" wide x 16" diameter chrome plated cored rolls, fixed middle, hydraulically adjustable top, and bottom, driven by a 5 hp motor with reducer, approximate 102" long cooling conveyor section, serial# 4367-47, built 1974. (1) Johnson nip roll, (2) 8" diameter x 54" wide rubber rolls, (1) Thermo thickness gauge, Model E-SFL10-XX, Serial# 61699 with control panel. (1) Johnson dual turret winder, approximate 54" wide x 24" diameter rolls. Serial# 4368-47, built 1974.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory