Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

USED 120" HPM SHEET EXTRUSION LINE(1984) CONSISTING OF THE FOLLOWING:A) (1) USED CONAIR FRANKLIN AUTOWEIGH GRAVIMETRIC BLENDING SYSTEM RATED 3000 LBS. PER HOUR. INCLUDES WEIGHT SCALE HOPPER, MOTORIZE...

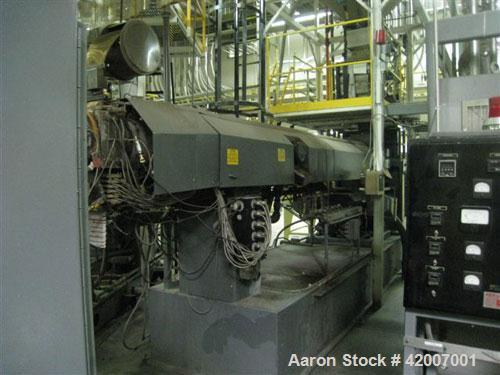

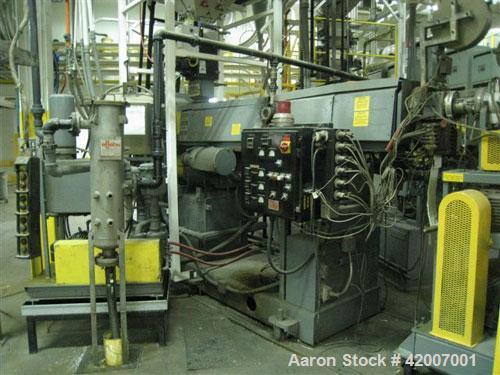

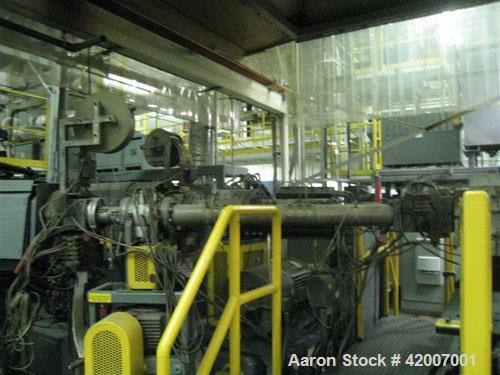

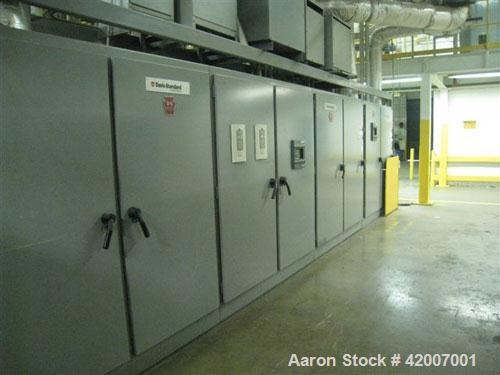

USED 120" HPM SHEET EXTRUSION LINE(1984) CONSISTING OF THE FOLLOWING:A) (1) USED CONAIR FRANKLIN AUTOWEIGH GRAVIMETRIC BLENDING SYSTEM RATED 3000 LBS. PER HOUR. INCLUDES WEIGHT SCALE HOPPER, MOTORIZED SHAFT BLENDER AND GP SERIES PROGRAMMABLE CONTROL. LAST USED OVER 6" EXTRUDER.B) (1) USED 6" 32:1 HPM EXTRUDER HAVING AN ELECTRICALLY HEATED, WATER COOLED, (CLOSED LOOP) AND VENTED BARREL WITH APPROXIMATELY A 52" CENTERLINE HEIGHT. GEARBOX IS A LUFKIN SIZE D262-911C CHANGE GEAR TYPE BOX, AND HAS14.0:1 GEARS INSTALLED. GEARBOX IS DIRECT DRIVEN IN A TUCK UNDER MANNER BY A 400 HP DC MOTOR WITH SCR CONTROL. MOUNTED ON THE EXTRUDER DISCHARGE IS A KEY FILTERS MODEL KCN CONTINUOUS SCREEN CHANGER WITH CONTROLS. SCREEN CHANGER WAS MANUFACTURED IN 1998.C) (1) USED MAAG MODEL EXTREX 90/80 MELT PUMP, SERIAL #815-835/15 HAVING A 40 HP DRIVE SYSTEM.D) (1) MAGUIRE MODEL SGBD-500-4 BLENDER SERIAL #30AG1203, RATED AT 500 LBS.PER HOUR, ABLE TO HANDLE UP TO (4) COMPONENTS. UNIT FEEDS 3.5" HPM EXTRUDER.E) (1) USED 3.5" 32:1 HPM MODEL 3.5TM III EXTRUDER HAVING AN ELECTRICALLY HEATED, WATER COOLED(CLOSED LOOP)AND VENTED BARREL AT APPROXIMATELY A 52"CENTERLINE HEIGHT. GEARBOX IS A LUFKIN SIZE D104-6110 CHANGE GEAR TYPE BOX. PRESENTLY HAS 11.67:1 GEARS INSTALLED AND IS DIRECT DRIVEN IN A TUCK UNDER MANNER BY A 100 HP DC MOTOR WITH SCR CONTROL. MOUNTED ON EXTRUDER DISCHARGE IS A KEY FILTERS MODEL KNC 3.5 CONTINUOUS SCREEN CHANGER WITHCONTROLS. SERIAL #980011. MANUFACTURED IN 1998.F) TWO APPROXIMATELY 10 HP WATER CENTRIFUGAL VACUUM PUMPS FOR DRAWING VACUUM ON THE VENTS ON THE TWO EXTRUDERS.G) ONE (1) USED MELT PUMP ON 3.5" EXTRUDER IS A MAAG TYPE EXTREX 45/45 WITH 10 HP DRIVE SYSTEM. SERIAL #818828/24.H) ONE(1) USED 114" PRODUCTION COMPONENTS SHEET DIE HAVING A 45 DEGREE RESTRICTOR BAR AND REMOVABLE LOWER LIP. INCLUDES TWO SPARE LIPS.I) ONE (1) USED HPM SHEET TAKE-OFF HAVING (3) 120" FACE CHROME PLATED ROLLS MOUNTED IN A VERTICAL ARRANGEMENT FOR DOWNSTACK OPERATION AT APPROXIMATELY A 62" CENTERLINE HEIGHT. TOP ROLL MEASURES 18" IN DIAMETER WHILE MIDDLE AND BOTTOM ROLLS MEASURE 24" IN DIAMETER. ROLLS ARE DRIVEN BY A DC MOTOR THROUGH A GEAR REDUCER VIA SILENT CHAIN AND SPROCKETS. DOWNSTREAM INCLUDES THREE(3)CORE TECHNOLOGY MODEL TC2-5-18 WATER TEMPERATURE UNITS AND PULL ROLL STAND WITH GEAR REDUCER ANS DC DRIVE SYSTEMJ) ONE(1) WYSONG MODEL 10-RD ELECTRO MECHANICAL SHEAR HAVING A 120" WIDE CAPACITY CAPACITY. SERIAL #P32-2117X. UNIT RATED TO 1/2" THICK IN ABS.INCLUDES 110" WIDE POWERED BELT RUN OFF TABLE.

USED 120" HPM SHEET EXTRUSION LINE(1984) CONSISTING OF THE FOLLOWING:A) (1) USED CONAIR FRANKLIN AUTOWEIGH GRAVIMETRIC BLENDING SYSTEM RATED 3000 LBS. PER HOUR. INCLUDES WEIGHT SCALE HOPPER, MOTORIZED SHAFT BLENDER AND GP SERIES PROGRAMMABLE CONTROL. LAST USED OVER 6" EXTRUDER.B) (1) USED 6" 32:1 HPM EXTRUDER HAVING AN ELECTRICALLY HEATED, WATER COOLED, (CLOSED LOOP) AND VENTED BARREL WITH APPROXIMATELY A 52" CENTERLINE HEIGHT. GEARBOX IS A LUFKIN SIZE D262-911C CHANGE GEAR TYPE BOX, AND HAS14.0:1 GEARS INSTALLED. GEARBOX IS DIRECT DRIVEN IN A TUCK UNDER MANNER BY A 400 HP DC MOTOR WITH SCR CONTROL. MOUNTED ON THE EXTRUDER DISCHARGE IS A KEY FILTERS MODEL KCN CONTINUOUS SCREEN CHANGER WITH CONTROLS. SCREEN CHANGER WAS MANUFACTURED IN 1998.C) (1) USED MAAG MODEL EXTREX 90/80 MELT PUMP, SERIAL #815-835/15 HAVING A 40 HP DRIVE SYSTEM.D) (1) MAGUIRE MODEL SGBD-500-4 BLENDER SERIAL #30AG1203, RATED AT 500 LBS.PER HOUR, ABLE TO HANDLE UP TO (4) COMPONENTS. UNIT FEEDS 3.5" HPM EXTRUDER.E) (1) USED 3.5" 32:1 HPM MODEL 3.5TM III EXTRUDER HAVING AN ELECTRICALLY HEATED, WATER COOLED(CLOSED LOOP)AND VENTED BARREL AT APPROXIMATELY A 52"CENTERLINE HEIGHT. GEARBOX IS A LUFKIN SIZE D104-6110 CHANGE GEAR TYPE BOX. PRESENTLY HAS 11.67:1 GEARS INSTALLED AND IS DIRECT DRIVEN IN A TUCK UNDER MANNER BY A 100 HP DC MOTOR WITH SCR CONTROL. MOUNTED ON EXTRUDER DISCHARGE IS A KEY FILTERS MODEL KNC 3.5 CONTINUOUS SCREEN CHANGER WITHCONTROLS. SERIAL #980011. MANUFACTURED IN 1998.F) TWO APPROXIMATELY 10 HP WATER CENTRIFUGAL VACUUM PUMPS FOR DRAWING VACUUM ON THE VENTS ON THE TWO EXTRUDERS.G) ONE (1) USED MELT PUMP ON 3.5" EXTRUDER IS A MAAG TYPE EXTREX 45/45 WITH 10 HP DRIVE SYSTEM. SERIAL #818828/24.H) ONE(1) USED 114" PRODUCTION COMPONENTS SHEET DIE HAVING A 45 DEGREE RESTRICTOR BAR AND REMOVABLE LOWER LIP. INCLUDES TWO SPARE LIPS.I) ONE (1) USED HPM SHEET TAKE-OFF HAVING (3) 120" FACE CHROME PLATED ROLLS MOUNTED IN A VERTICAL ARRANGEMENT FOR DOWNSTACK OPERATION AT APPROXIMATELY A 62" CENTERLINE HEIGHT. TOP ROLL MEASURES 18" IN DIAMETER WHILE MIDDLE AND BOTTOM ROLLS MEASURE 24" IN DIAMETER. ROLLS ARE DRIVEN BY A DC MOTOR THROUGH A GEAR REDUCER VIA SILENT CHAIN AND SPROCKETS. DOWNSTREAM INCLUDES THREE(3)CORE TECHNOLOGY MODEL TC2-5-18 WATER TEMPERATURE UNITS AND PULL ROLL STAND WITH GEAR REDUCER ANS DC DRIVE SYSTEMJ) ONE(1) WYSONG MODEL 10-RD ELECTRO MECHANICAL SHEAR HAVING A 120" WIDE CAPACITY CAPACITY. SERIAL #P32-2117X. UNIT RATED TO 1/2" THICK IN ABS.INCLUDES 110" WIDE POWERED BELT RUN OFF TABLE.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory