Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Coperion 72" Sheet Extrusion Line

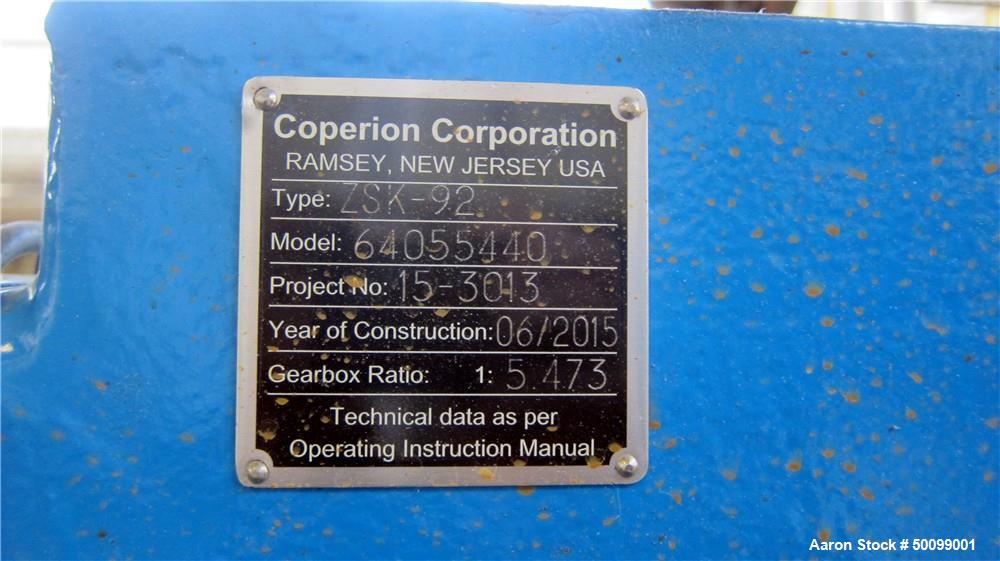

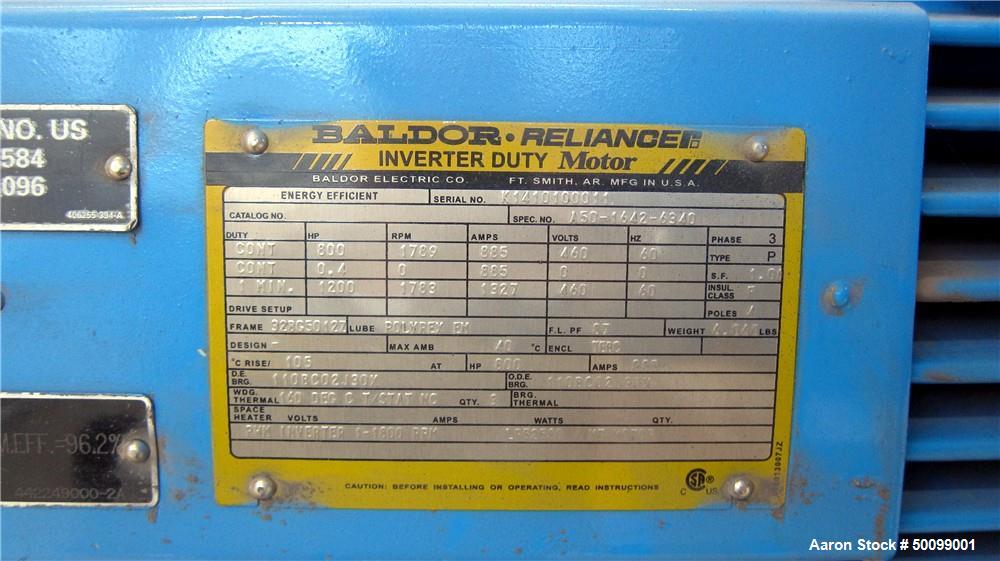

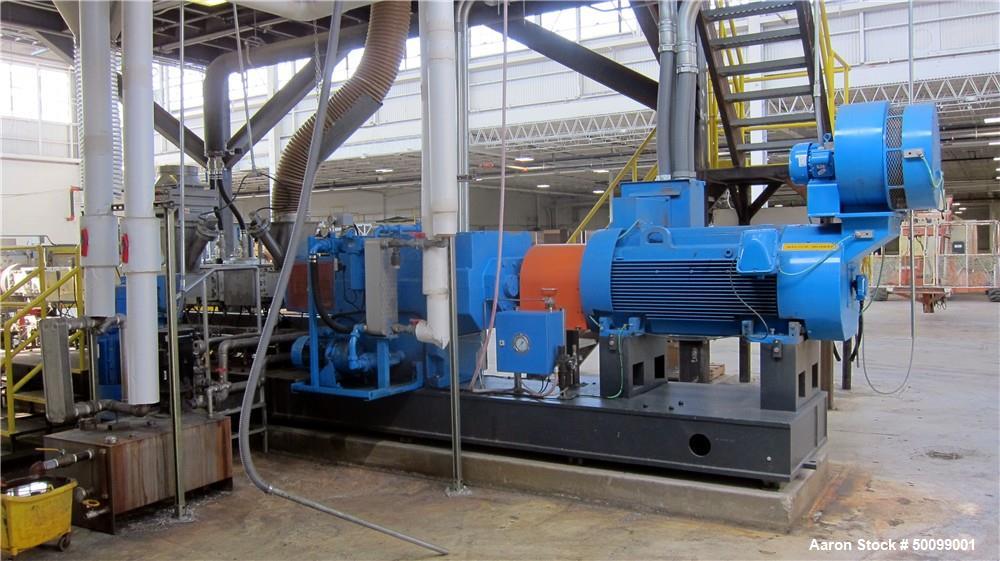

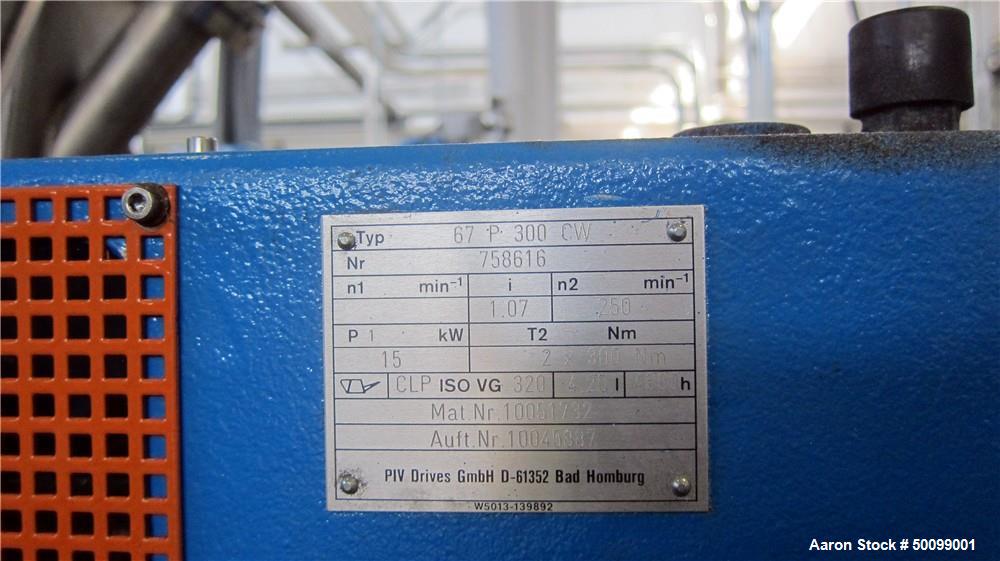

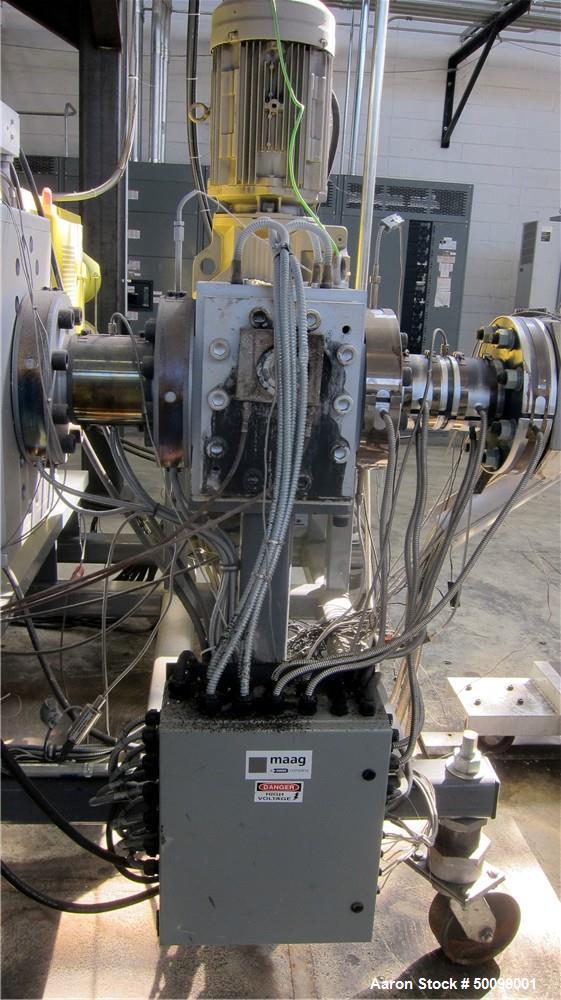

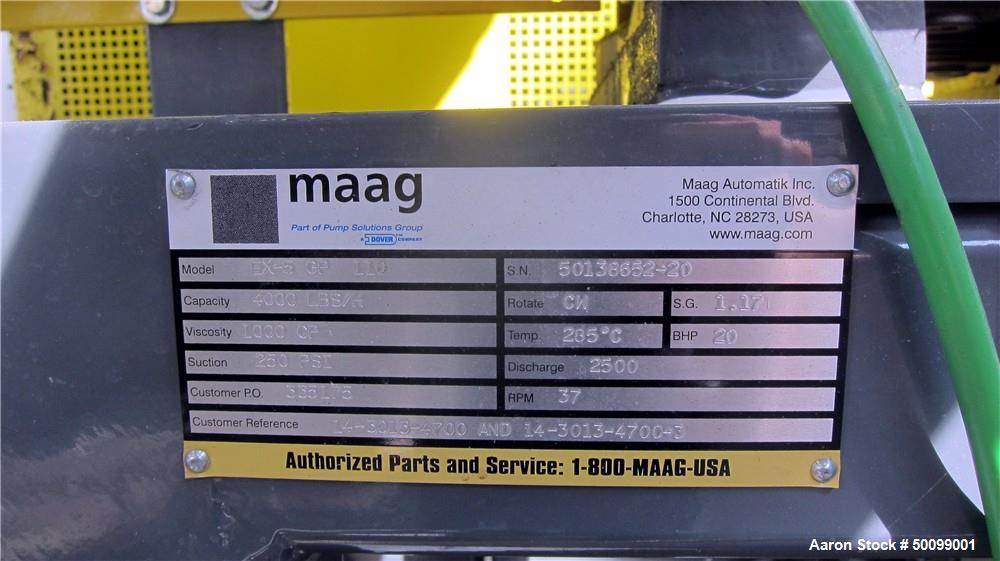

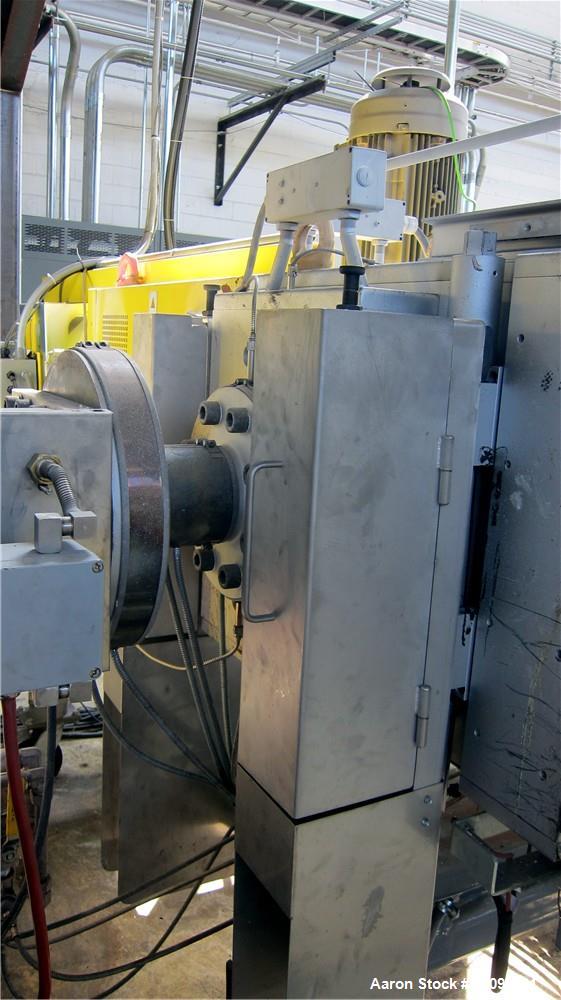

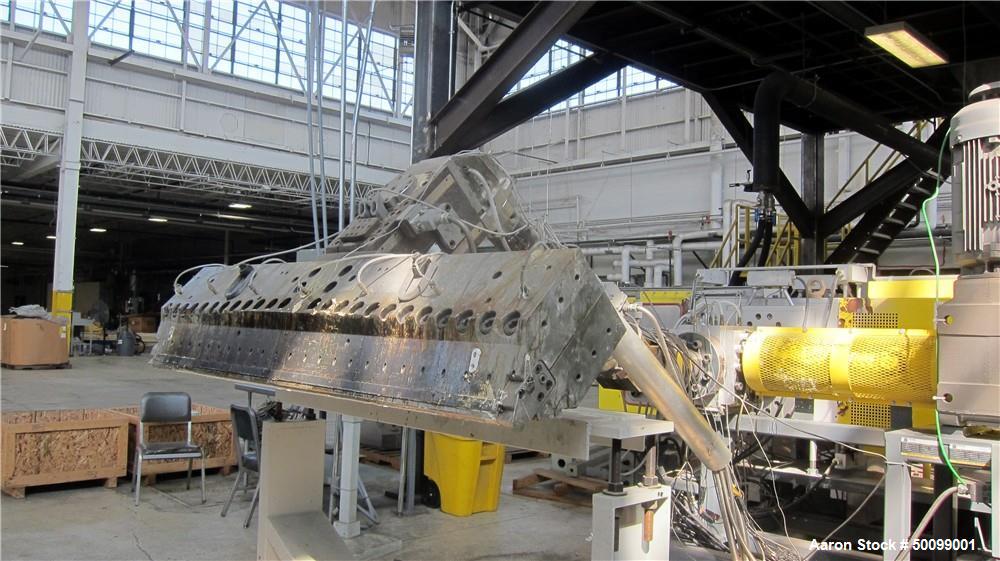

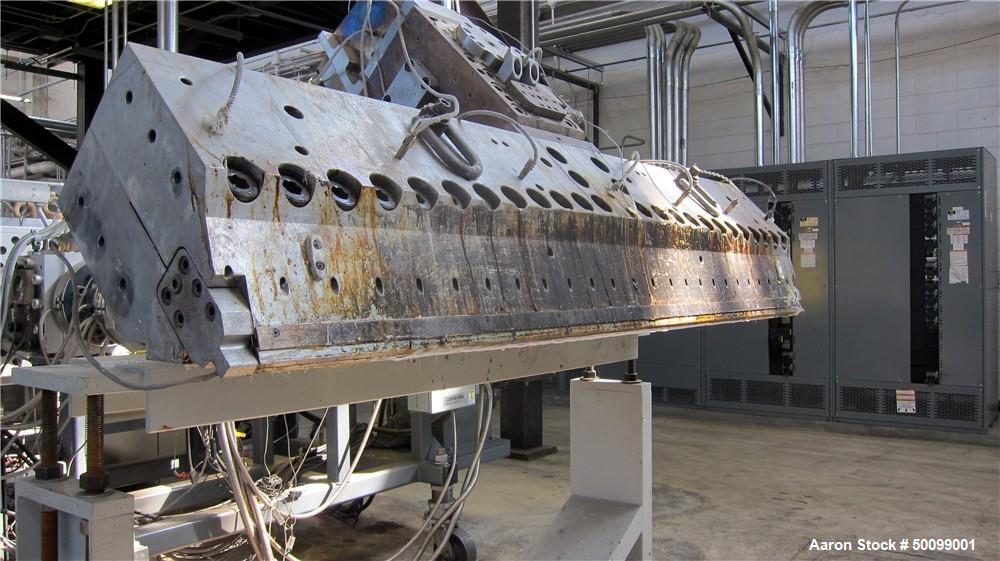

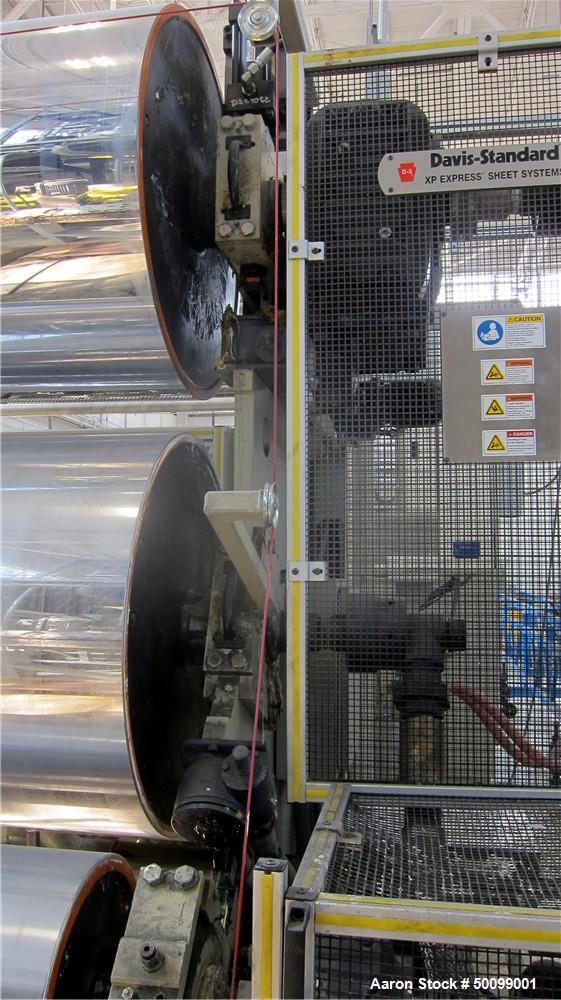

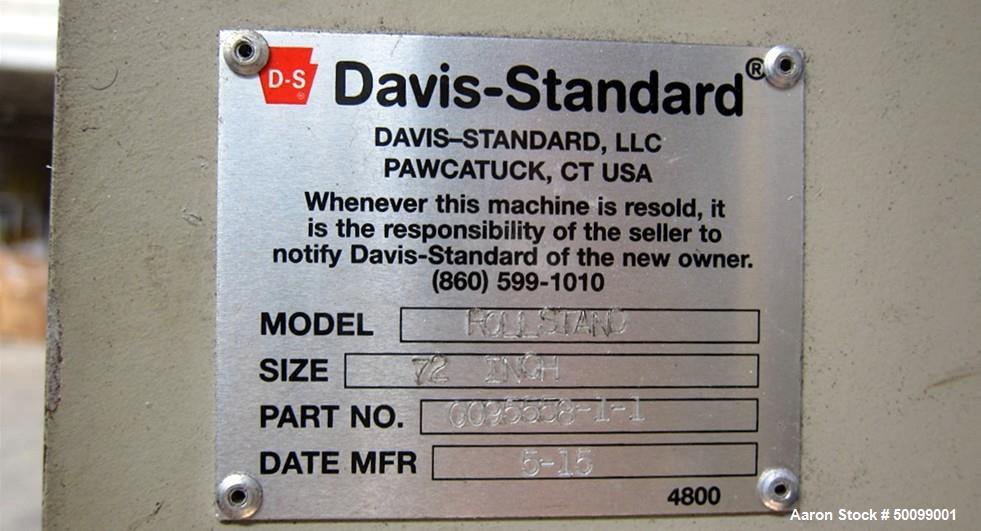

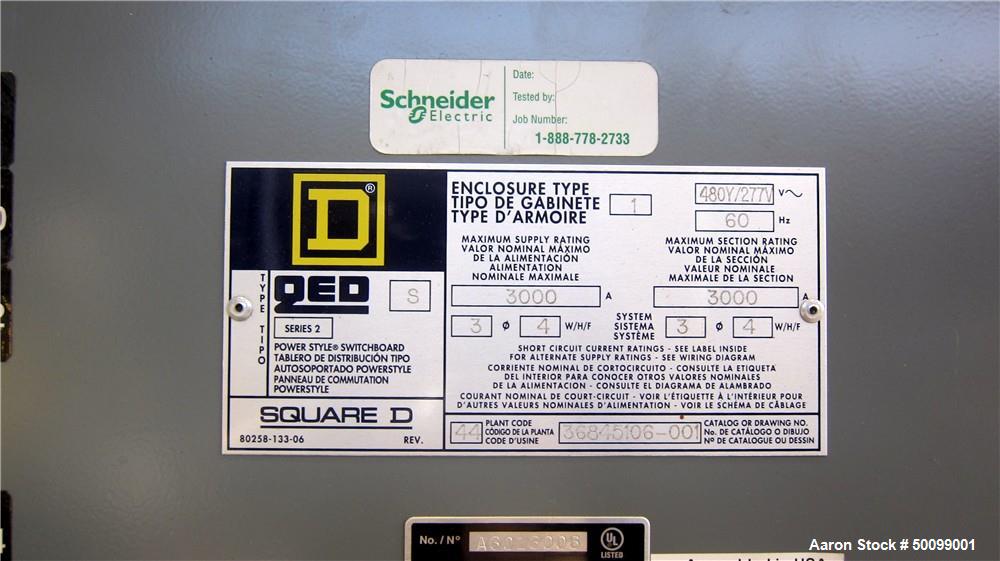

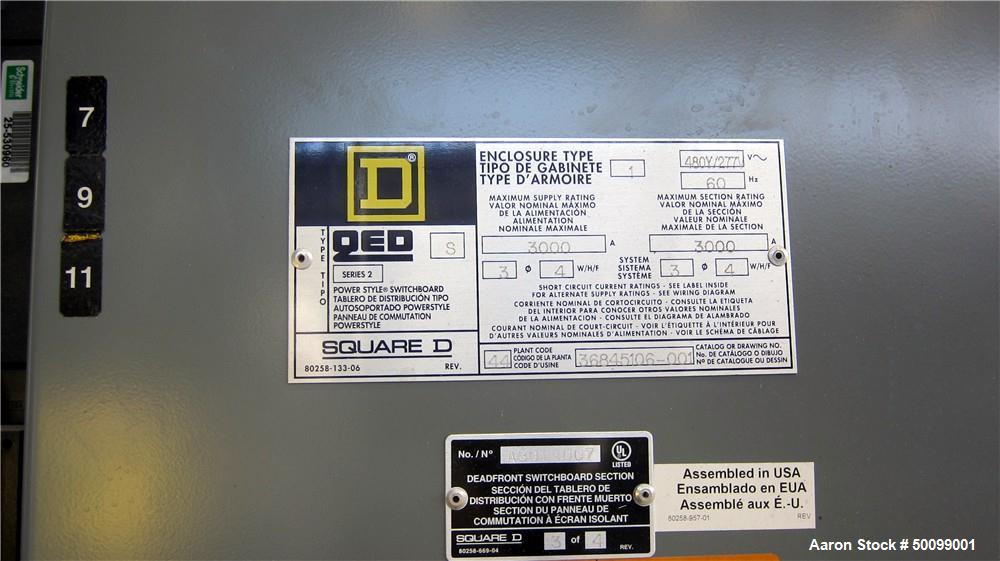

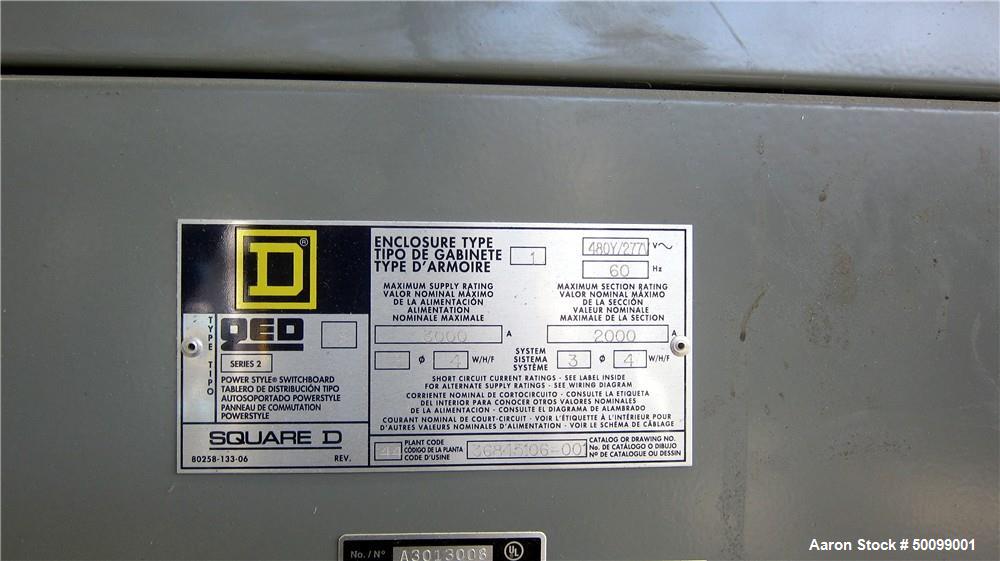

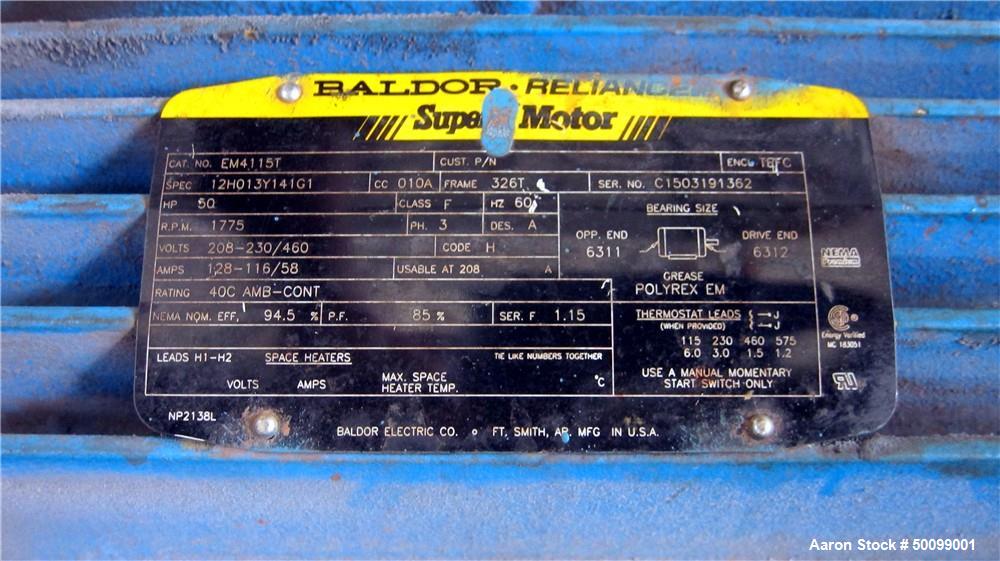

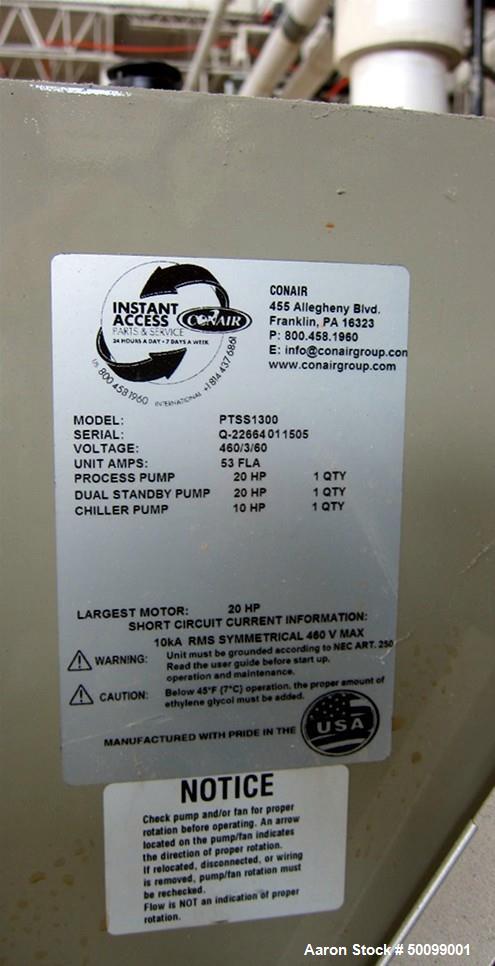

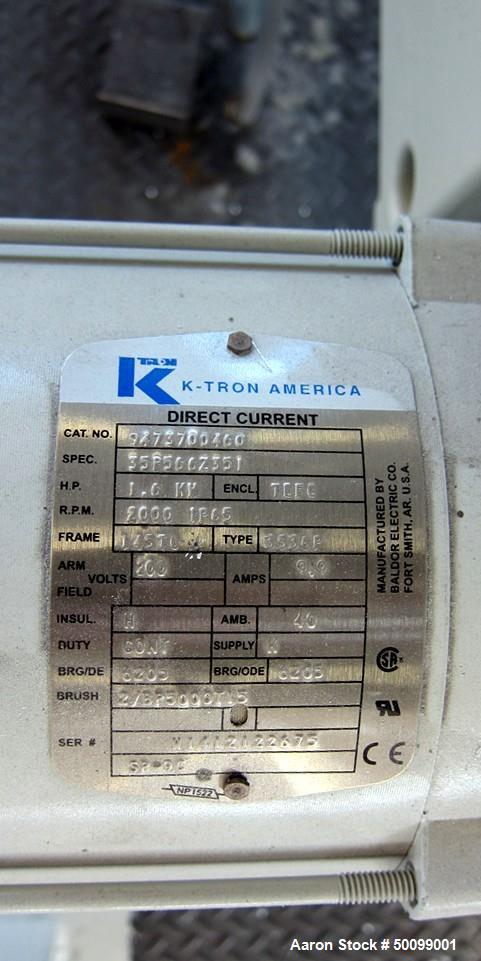

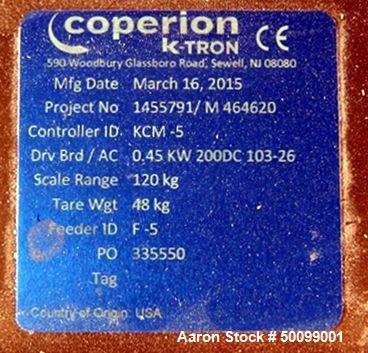

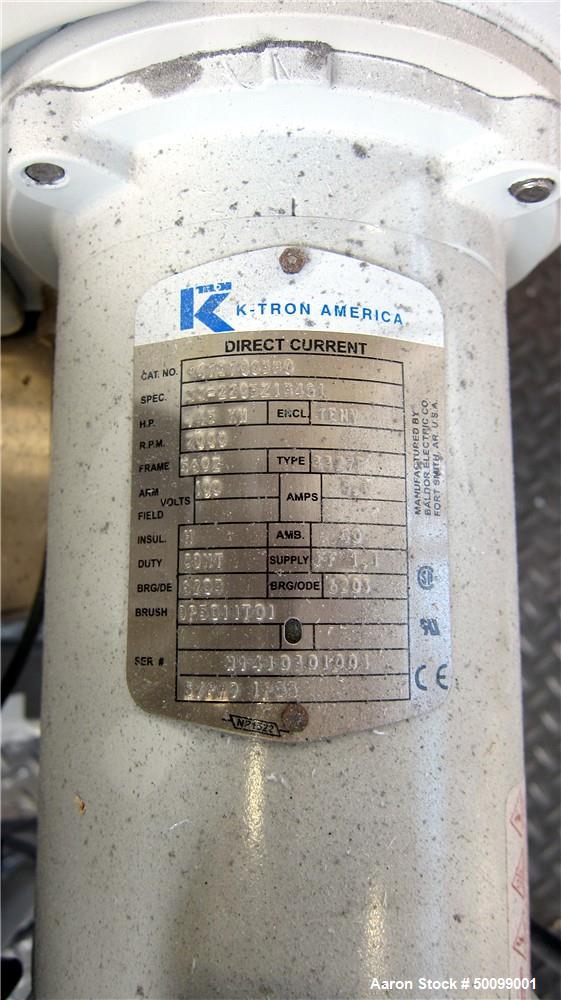

Used Coperion Sheet Extrusion Line. Includes the following: Ktron Feeding system, Model k2-ML-S100, KCM-5 & KCM-4 feeders; KCM Touchscreen Controller; Coperion Extruder Type ZSK-92 MC18 Model 64055440 Serial 20524240; 92mm screw diameter co rotating design 48:1 L/D ratio. Gearbox: Ratio 1:5.473, Maximum Torque 7500 Nm, Maximum motor Speed 1800 RPM, Maximum Screw Speed 328 RPM, Maximum Allowable Horsepower 690; Extruder Driven by Baldor Electric 800 HP Motor Spec A50-1642-6340, S/N K1410100011m 1789 RPM, 885 Amps, 460 Volt, 60 Hz; Allen Bradley PowerFlex 755 Variable Speed Controller; Extruder has 12 Barrel Sections 360mm each, (1 Feed Barrel, 3 Vent Barrels, 8 Closed Barrels), Shaft Centerline Height 76mm; Coperion ZS-B 92 Side Feeder S/N 205242241, Year 2015, Driven by Stober 15Kw Electric motor 480V 60 Hz, 25 Amps, 1780 RPM. Extruder is Electrically Heated, Water Cooled; Maag Dual Piston Screen Changer Back Flushing Type; 7.8" Screens, Year 2015, including Hydraulic Unit; Maag Gear Pump Model EX-5 GP 110 SN 50138652-20, Capacity 4000 LBS/Hr; Allied (ADI) 72" Flex Lip Sheet Die job# AD2763; Davis Standard 3-Up Sheet Stack, Bottom Roll is 18" Diameter x 72" Wide Top Rolls are 36" Diameter x 72" Wide. Rolls are individually driven by AC motors, With Touchscreen Controller and Cooling System; Scantech X-Ray Gauge Frame LF1-2000 S/N 001REPL.0001-001DASD.0021-000, Year 11/2014. Dual Rubber Pull Roll Stand, Approximate 17' Long cooling section with Dual Edge Trim Section and Vacuum system for regrind; Winding Accumulation tower; (4) Turret Shuttle type Winder; Includes Unicarriers Turret Shuttle. All Controls are Allen Bradley PLC. Mfg. 2014.

Used Coperion Sheet Extrusion Line. Includes the following: Ktron Feeding system, Model k2-ML-S100, KCM-5 & KCM-4 feeders; KCM Touchscreen Controller; Coperion Extruder Type ZSK-92 MC18 Model 64055440 Serial 20524240; 92mm screw diameter co rotating design 48:1 L/D ratio. Gearbox: Ratio 1:5.473, Maximum Torque 7500 Nm, Maximum motor Speed 1800 RPM, Maximum Screw Speed 328 RPM, Maximum Allowable Horsepower 690; Extruder Driven by Baldor Electric 800 HP Motor Spec A50-1642-6340, S/N K1410100011m 1789 RPM, 885 Amps, 460 Volt, 60 Hz; Allen Bradley PowerFlex 755 Variable Speed Controller; Extruder has 12 Barrel Sections 360mm each, (1 Feed Barrel, 3 Vent Barrels, 8 Closed Barrels), Shaft Centerline Height 76mm; Coperion ZS-B 92 Side Feeder S/N 205242241, Year 2015, Driven by Stober 15Kw Electric motor 480V 60 Hz, 25 Amps, 1780 RPM. Extruder is Electrically Heated, Water Cooled; Maag Dual Piston Screen Changer Back Flushing Type; 7.8" Screens, Year 2015, including Hydraulic Unit; Maag Gear Pump Model EX-5 GP 110 SN 50138652-20, Capacity 4000 LBS/Hr; Allied (ADI) 72" Flex Lip Sheet Die job# AD2763; Davis Standard 3-Up Sheet Stack, Bottom Roll is 18" Diameter x 72" Wide Top Rolls are 36" Diameter x 72" Wide. Rolls are individually driven by AC motors, With Touchscreen Controller and Cooling System; Scantech X-Ray Gauge Frame LF1-2000 S/N 001REPL.0001-001DASD.0021-000, Year 11/2014. Dual Rubber Pull Roll Stand, Approximate 17' Long cooling section with Dual Edge Trim Section and Vacuum system for regrind; Winding Accumulation tower; (4) Turret Shuttle type Winder; Includes Unicarriers Turret Shuttle. All Controls are Allen Bradley PLC. Mfg. 2014.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory