Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

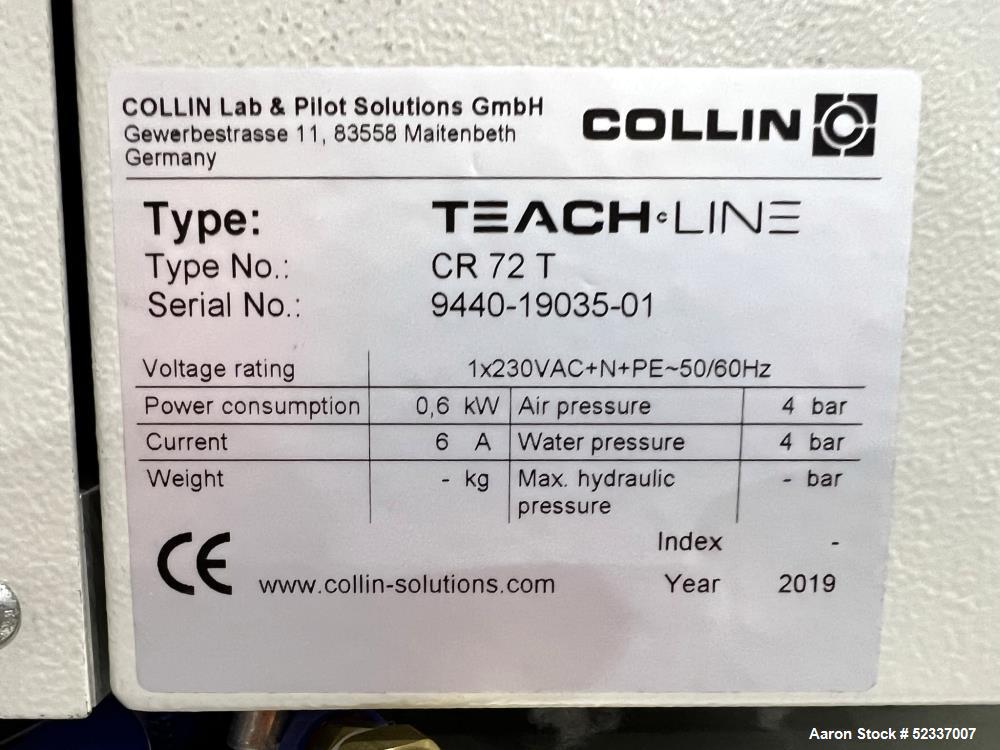

Used 3 Roll Flat Film Line – Collins Solutions CR 72 T, 0.5-14 m/min

Used Collins Solutions 3 Roll Flat Film Line, Model Teach-Line CR 72 T. Take-off speed 0.5 to 14 m/min. Fine setting of gap 0.1 to 2mm. (3) Chrome cored 2-7/8" (72mm) diameter x 7-1/2" (190mm) wide, upper finishing roll, middle chill roll, bottom cooling roll. Maximum roll temperature 90 degrees C (194 F). All three rolls driven via a 100W DC-motor with reducing gearbox. Tensile force max 260 N. Maximum outer die width 200mm. Maximum die working width 100mm. Mounted on modular frame with casters. Serial# 944H2112. Does not have a winder.

Manufacturer Information:

- Brand: Collins Solutions

- Model: Teach-Line CR 72 T

- Serial Number: 944H2112

Description:

The Collins Solutions Teach-Line CR 72 T is a precision 3-roll flat film extrusion line, designed for thin film production, material testing, and laboratory-scale plastic processing.

Equipped with three chrome-cored rolls (upper finishing, middle chill, and bottom cooling roll), this system ensures precise film thickness control and excellent temperature regulation. The gap setting is adjustable from 0.1mm to 2mm, allowing for fine-tuned film thickness adjustments.

The take-off speed ranges from 0.5 to 14 meters per minute, making it ideal for variable-speed production. The rolls are 72mm (2-7/8”) in diameter and 190mm (7-1/2”) wide, providing a maximum die working width of 100mm and an outer die width of 200mm.

Each roll is driven by a 100W DC motor with a reducing gearbox, delivering precise control over film handling. The system supports a maximum roll temperature of 90°C (194°F) and operates with a maximum tensile force of 260N.

Mounted on a modular frame with casters, this unit offers portability and easy integration into laboratory and industrial environments.

Key Features:

- 3-Roll Chrome-Cored System for high-precision flat film extrusion

- Adjustable Gap Range: 0.1mm to 2mm for fine thickness control

- Take-Off Speed: 0.5 to 14 meters per minute

- Three Rolls:

- Upper Finishing Roll

- Middle Chill Roll

- Bottom Cooling Roll

- Roll Dimensions: 72mm (2-7/8”) Diameter x 190mm (7-1/2”) Wide

- Maximum Roll Temperature: 90°C (194°F)

- Tensile Force: Maximum 260N

- Maximum Outer Die Width: 200mm

- Maximum Die Working Width: 100mm

- Drive System: 100W DC Motor with Reducing Gearbox

- Modular Frame with Casters for easy mobility

Specifications:

- Machine Type: 3-Roll Flat Film Line

- Brand: Collins Solutions

- Model: Teach-Line CR 72 T

- Serial Number: 944H2112

- Take-Off Speed: 0.5 - 14 m/min

- Gap Setting: 0.1 - 2mm

- Rolls: 3 Chrome-Cored Rolls

- Roll Dimensions: 72mm (2-7/8”) Diameter x 190mm (7-1/2”) Wide

- Maximum Temperature: 90°C (194°F)

- Maximum Tensile Force: 260N

- Maximum Outer Die Width: 200mm

- Maximum Die Working Width: 100mm

- Drive System: 100W DC Motor with Reducing Gearbox

- Mounting: Modular Frame with Casters

Applications:

- Plastics & Polymer Industry: Flat film extrusion and material testing

- Packaging Industry: Thin plastic film production for flexible packaging

- Laboratory Research: Testing and developing new film formulations

- Medical & Pharmaceutical Industry: Specialty plastic film production

- Electronics Industry: Extrusion of insulating films for electronic components

What Products Would This Be Used For?

- Thermoplastic flat film production

- Plastic sheet and thin film testing

- Research & development of new polymer formulations

- Specialty and high-performance film manufacturing

- Coating and laminating film processing

Calendering, Casting Film, Coating, Drawing Film, Laminating, Smoothing Plates

- Collins Solutions 3-roll flat film line

- Used flat film extrusion system

- Industrial thin film extruder

- Plastic film processing line

- Collins Solutions CR 72 T for sale

- Used three-roll film machine

- Adjustable gap film extrusion

- Chrome-cored roll film extruder

- Lab-scale film processing line

- High-precision film extrusion system

- Used Collins Solutions 3-roll flat film line for laboratory testing

- Pre-owned thin film extrusion system with adjustable gap control

- Industrial film processing line with chrome-cored rolls

- Collins Solutions CR 72 T three-roll system for plastic sheet production

- Used film extrusion line with take-off speed of 0.5 to 14 m/min

- Pre-owned plastic film extruder with modular frame and casters

- Thin film extrusion system with 72mm rolls and 90°C max temperature

- Used flat film production machine with DC motor drive

- Collins Solutions flat film line with 100mm working width

- Precision film extrusion equipment for laboratory and industrial applications

- Used Collins Solutions 3-roll flat film line with 72mm diameter rolls and adjustable 0.1-2mm gap

- Buy a pre-owned industrial thin film extrusion system with chrome-cored rolls

- High-performance plastic film processing line for lab-scale and industrial use

- Used thin film extruder with modular frame and precision roll temperature control

- Collins Solutions CR 72 T flat film line for sale – 100mm max working width

- Cost-effective used film extrusion machine with take-off speed control

- Pre-owned three-roll flat film system for flexible packaging and material testing

- Used industrial film processing system with adjustable gap and temperature settings

- High-precision flat film extruder for research and production applications

- Buy a used Collins Solutions thin film extrusion system with 100W DC motor

- Used Collins Solutions flat film line for sale

- Buy used 3-roll thin film extruder

- Industrial thin film extrusion system pricing

- Affordable used plastic sheet processing equipment

- Pre-owned three-roll extrusion line for plastics

- High-performance film extruder for sale

- Used industrial film processing line with adjustable gap control

- Collins Solutions CR 72 T availability

- Reliable used thin film extrusion machine

- Used plastic film production line with modular frame

- Used Plastics Equipment

- Used Industrial Equipment

- Three Roll Mill

- Used Mill

- Process Equipment

- Used Equipment

- Right of Return

Used Collins Solutions 3 Roll Flat Film Line, Model Teach-Line CR 72 T. Take-off speed 0.5 to 14 m/min. Fine setting of gap 0.1 to 2mm. (3) Chrome cored 2-7/8" (72mm) diameter x 7-1/2" (190mm) wide, upper finishing roll, middle chill roll, bottom cooling roll. Maximum roll temperature 90 degrees C (194 F). All three rolls driven via a 100W DC-motor with reducing gearbox. Tensile force max 260 N. Maximum outer die width 200mm. Maximum die working width 100mm. Mounted on modular frame with casters. Serial# 944H2112. Does not have a winder.

Manufacturer Information:

- Brand: Collins Solutions

- Model: Teach-Line CR 72 T

- Serial Number: 944H2112

Description:

The Collins Solutions Teach-Line CR 72 T is a precision 3-roll flat film extrusion line, designed for thin film production, material testing, and laboratory-scale plastic processing.

Equipped with three chrome-cored rolls (upper finishing, middle chill, and bottom cooling roll), this system ensures precise film thickness control and excellent temperature regulation. The gap setting is adjustable from 0.1mm to 2mm, allowing for fine-tuned film thickness adjustments.

The take-off speed ranges from 0.5 to 14 meters per minute, making it ideal for variable-speed production. The rolls are 72mm (2-7/8”) in diameter and 190mm (7-1/2”) wide, providing a maximum die working width of 100mm and an outer die width of 200mm.

Each roll is driven by a 100W DC motor with a reducing gearbox, delivering precise control over film handling. The system supports a maximum roll temperature of 90°C (194°F) and operates with a maximum tensile force of 260N.

Mounted on a modular frame with casters, this unit offers portability and easy integration into laboratory and industrial environments.

Key Features:

- 3-Roll Chrome-Cored System for high-precision flat film extrusion

- Adjustable Gap Range: 0.1mm to 2mm for fine thickness control

- Take-Off Speed: 0.5 to 14 meters per minute

- Three Rolls:

- Upper Finishing Roll

- Middle Chill Roll

- Bottom Cooling Roll

- Roll Dimensions: 72mm (2-7/8”) Diameter x 190mm (7-1/2”) Wide

- Maximum Roll Temperature: 90°C (194°F)

- Tensile Force: Maximum 260N

- Maximum Outer Die Width: 200mm

- Maximum Die Working Width: 100mm

- Drive System: 100W DC Motor with Reducing Gearbox

- Modular Frame with Casters for easy mobility

Specifications:

- Machine Type: 3-Roll Flat Film Line

- Brand: Collins Solutions

- Model: Teach-Line CR 72 T

- Serial Number: 944H2112

- Take-Off Speed: 0.5 - 14 m/min

- Gap Setting: 0.1 - 2mm

- Rolls: 3 Chrome-Cored Rolls

- Roll Dimensions: 72mm (2-7/8”) Diameter x 190mm (7-1/2”) Wide

- Maximum Temperature: 90°C (194°F)

- Maximum Tensile Force: 260N

- Maximum Outer Die Width: 200mm

- Maximum Die Working Width: 100mm

- Drive System: 100W DC Motor with Reducing Gearbox

- Mounting: Modular Frame with Casters

Applications:

- Plastics & Polymer Industry: Flat film extrusion and material testing

- Packaging Industry: Thin plastic film production for flexible packaging

- Laboratory Research: Testing and developing new film formulations

- Medical & Pharmaceutical Industry: Specialty plastic film production

- Electronics Industry: Extrusion of insulating films for electronic components

What Products Would This Be Used For?

- Thermoplastic flat film production

- Plastic sheet and thin film testing

- Research & development of new polymer formulations

- Specialty and high-performance film manufacturing

- Coating and laminating film processing

Calendering, Casting Film, Coating, Drawing Film, Laminating, Smoothing Plates

- Collins Solutions 3-roll flat film line

- Used flat film extrusion system

- Industrial thin film extruder

- Plastic film processing line

- Collins Solutions CR 72 T for sale

- Used three-roll film machine

- Adjustable gap film extrusion

- Chrome-cored roll film extruder

- Lab-scale film processing line

- High-precision film extrusion system

- Used Collins Solutions 3-roll flat film line for laboratory testing

- Pre-owned thin film extrusion system with adjustable gap control

- Industrial film processing line with chrome-cored rolls

- Collins Solutions CR 72 T three-roll system for plastic sheet production

- Used film extrusion line with take-off speed of 0.5 to 14 m/min

- Pre-owned plastic film extruder with modular frame and casters

- Thin film extrusion system with 72mm rolls and 90°C max temperature

- Used flat film production machine with DC motor drive

- Collins Solutions flat film line with 100mm working width

- Precision film extrusion equipment for laboratory and industrial applications

- Used Collins Solutions 3-roll flat film line with 72mm diameter rolls and adjustable 0.1-2mm gap

- Buy a pre-owned industrial thin film extrusion system with chrome-cored rolls

- High-performance plastic film processing line for lab-scale and industrial use

- Used thin film extruder with modular frame and precision roll temperature control

- Collins Solutions CR 72 T flat film line for sale – 100mm max working width

- Cost-effective used film extrusion machine with take-off speed control

- Pre-owned three-roll flat film system for flexible packaging and material testing

- Used industrial film processing system with adjustable gap and temperature settings

- High-precision flat film extruder for research and production applications

- Buy a used Collins Solutions thin film extrusion system with 100W DC motor

- Used Collins Solutions flat film line for sale

- Buy used 3-roll thin film extruder

- Industrial thin film extrusion system pricing

- Affordable used plastic sheet processing equipment

- Pre-owned three-roll extrusion line for plastics

- High-performance film extruder for sale

- Used industrial film processing line with adjustable gap control

- Collins Solutions CR 72 T availability

- Reliable used thin film extrusion machine

- Used plastic film production line with modular frame

- Used Plastics Equipment

- Used Industrial Equipment

- Three Roll Mill

- Used Mill

- Process Equipment

- Used Equipment

- Right of Return

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory