Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Cincinnati Milacron 91" Wide Sheet Line.

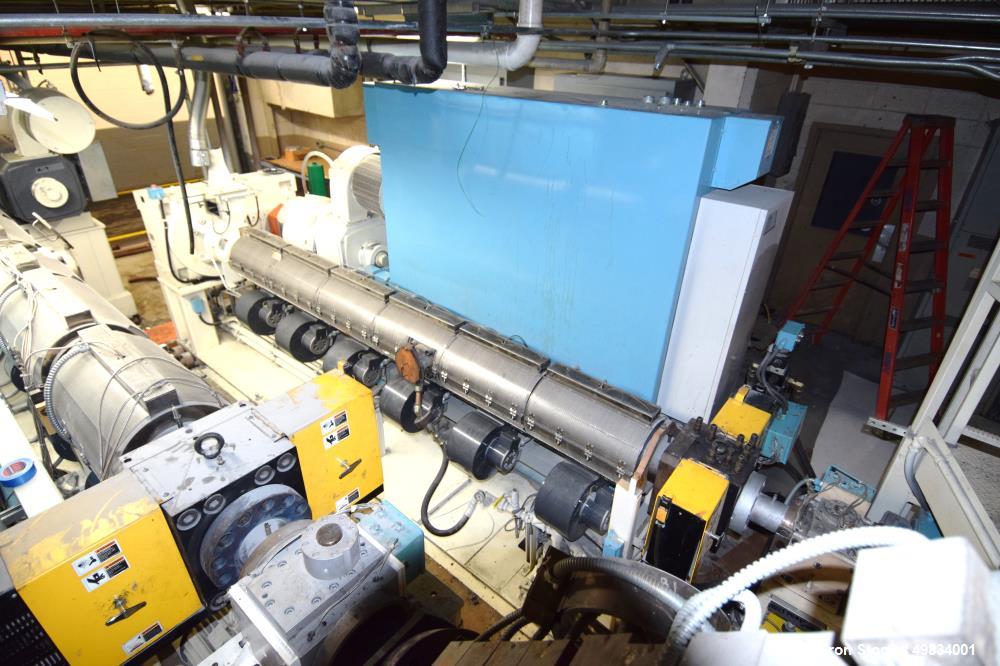

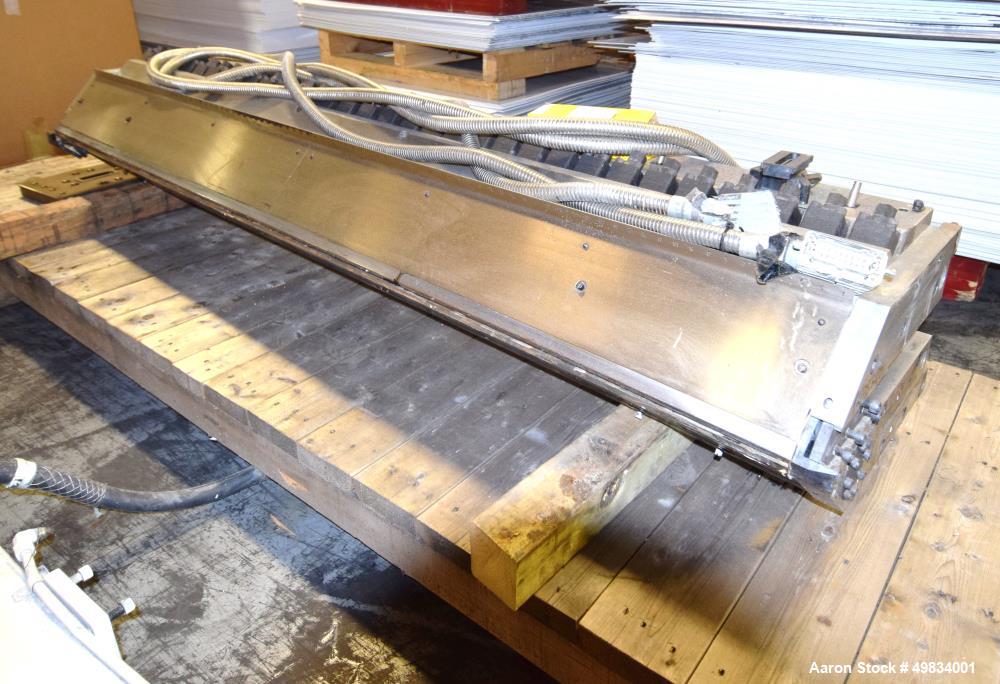

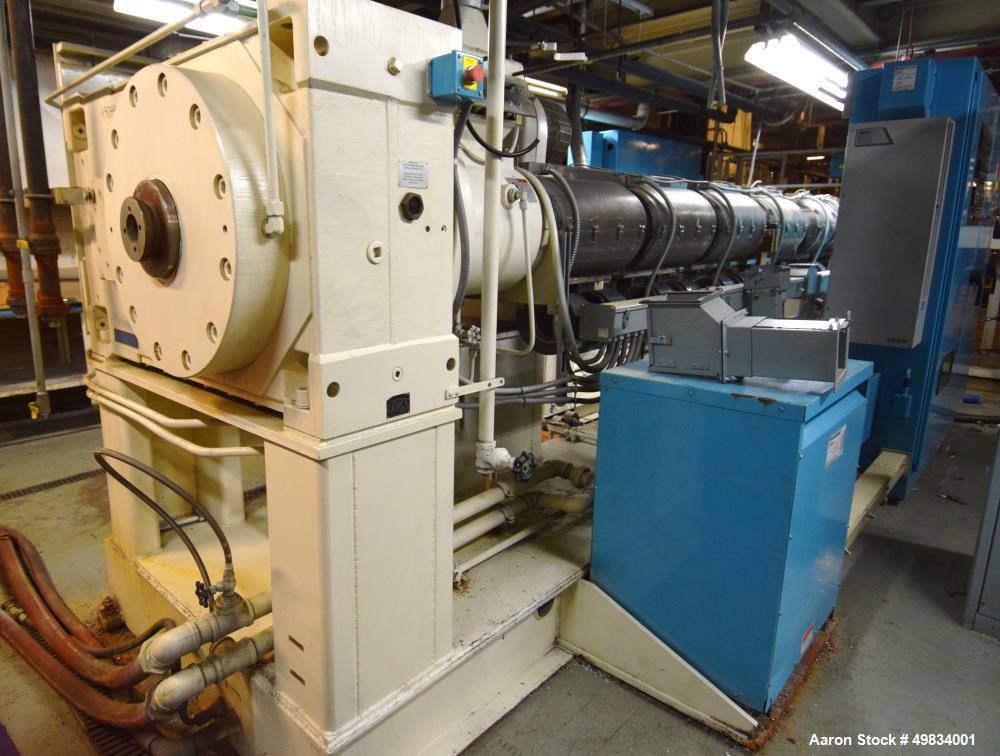

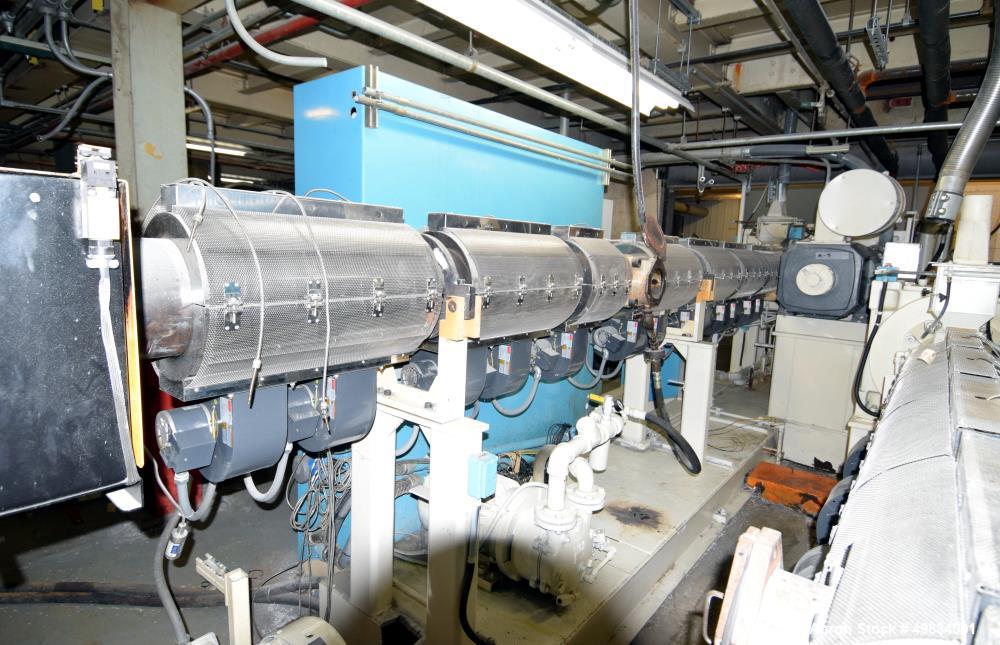

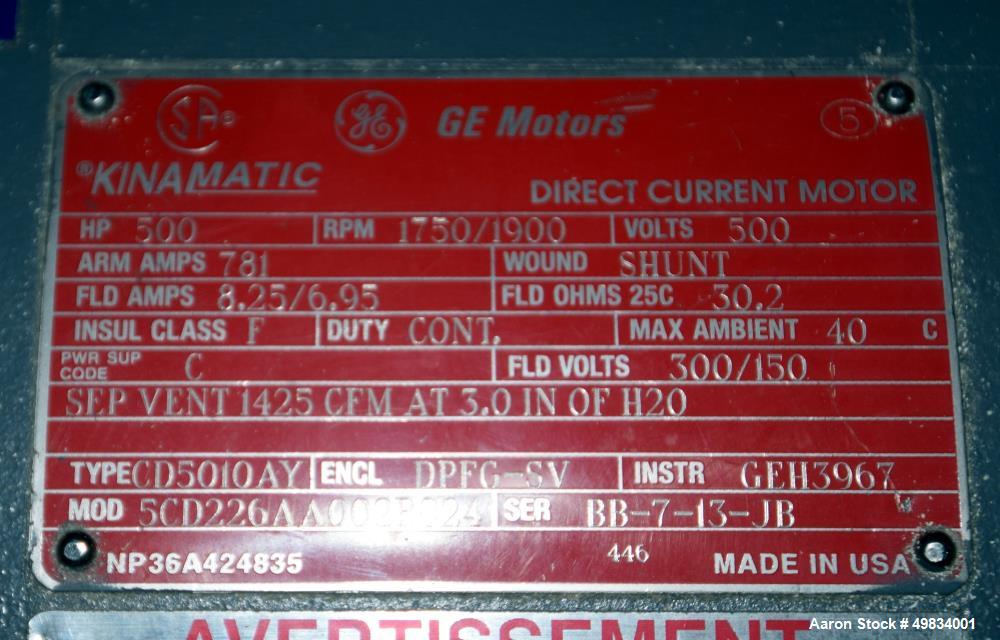

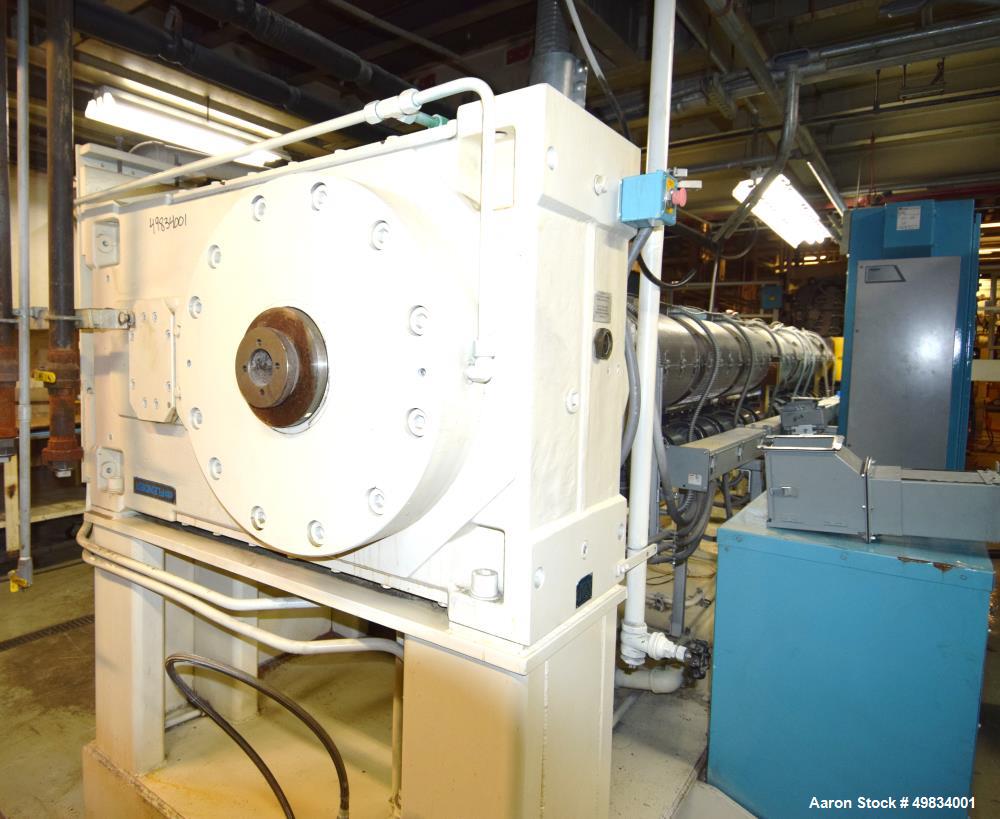

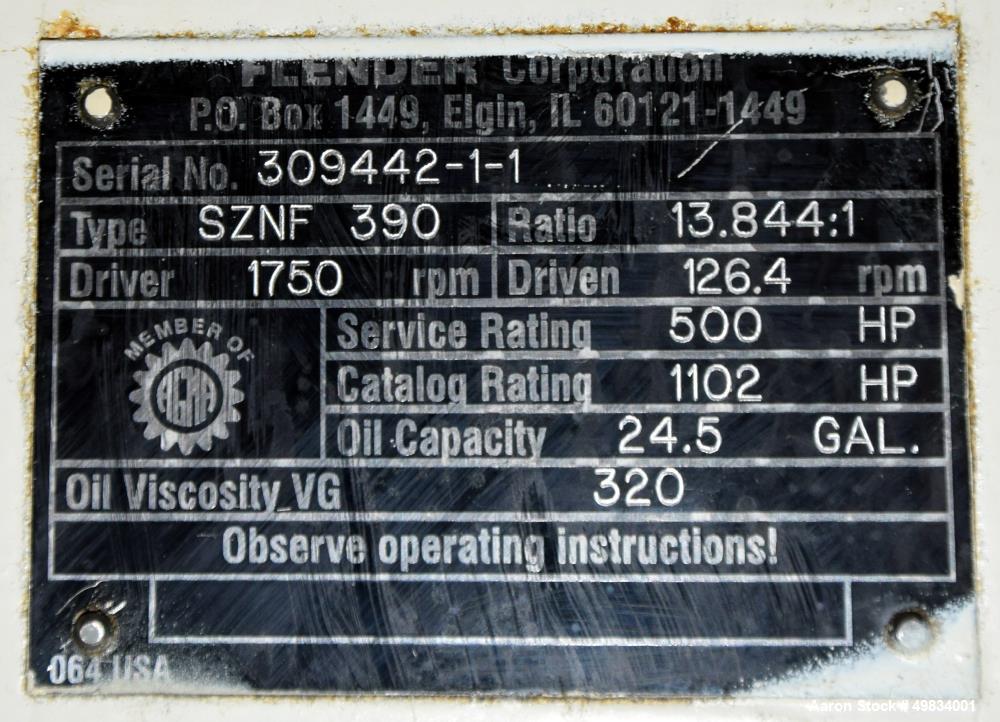

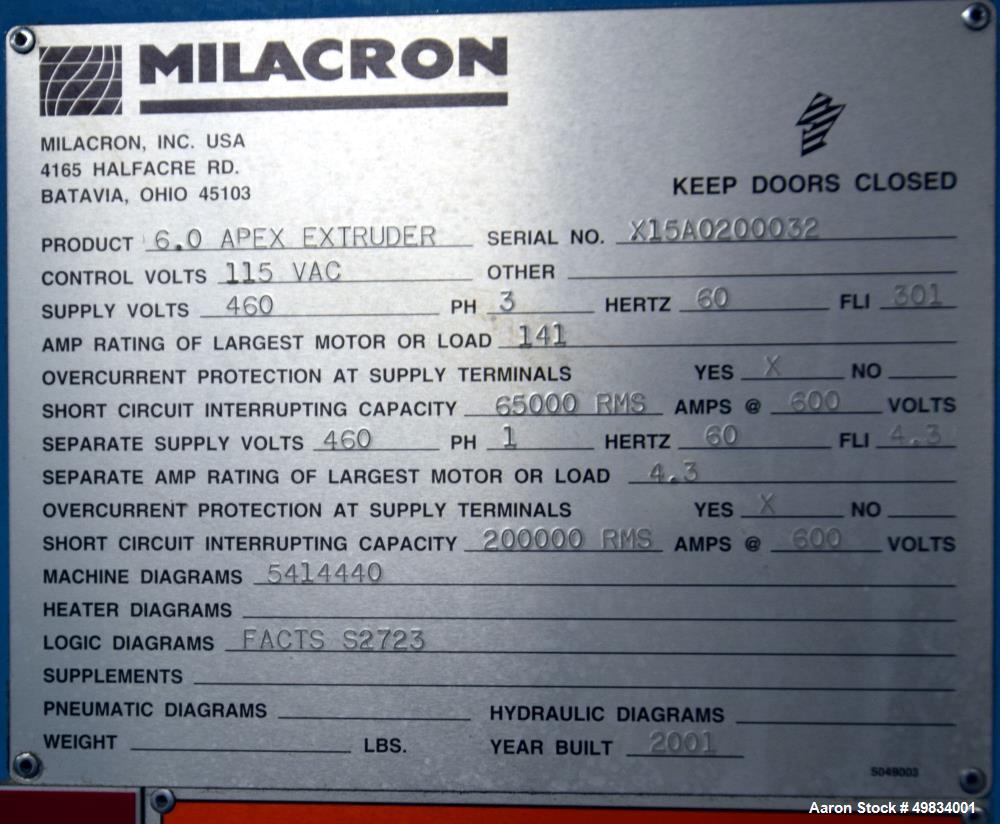

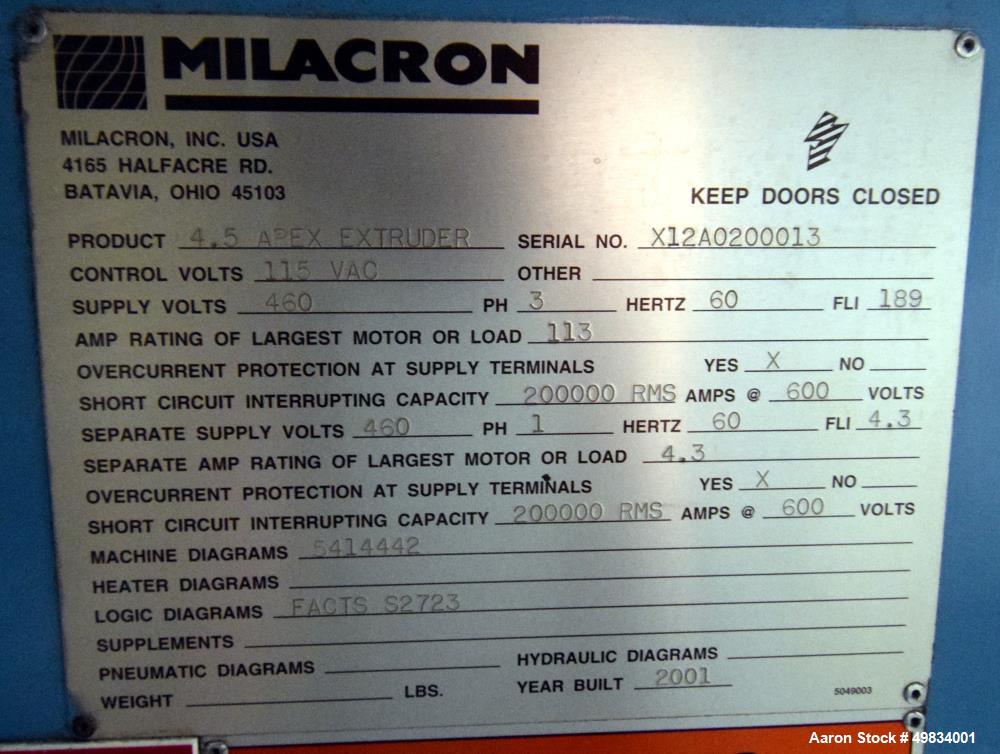

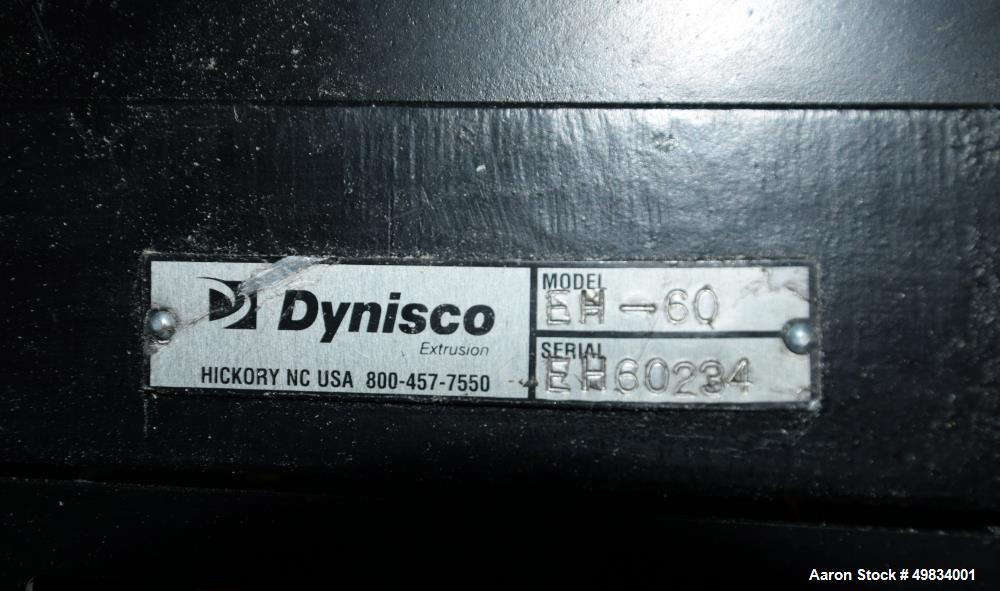

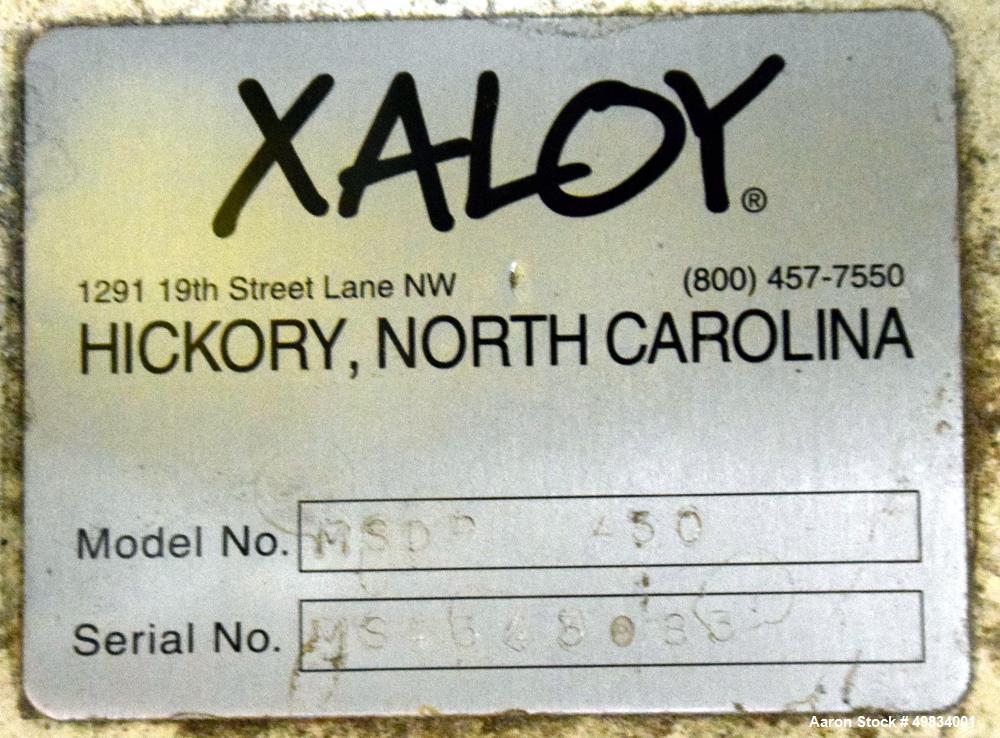

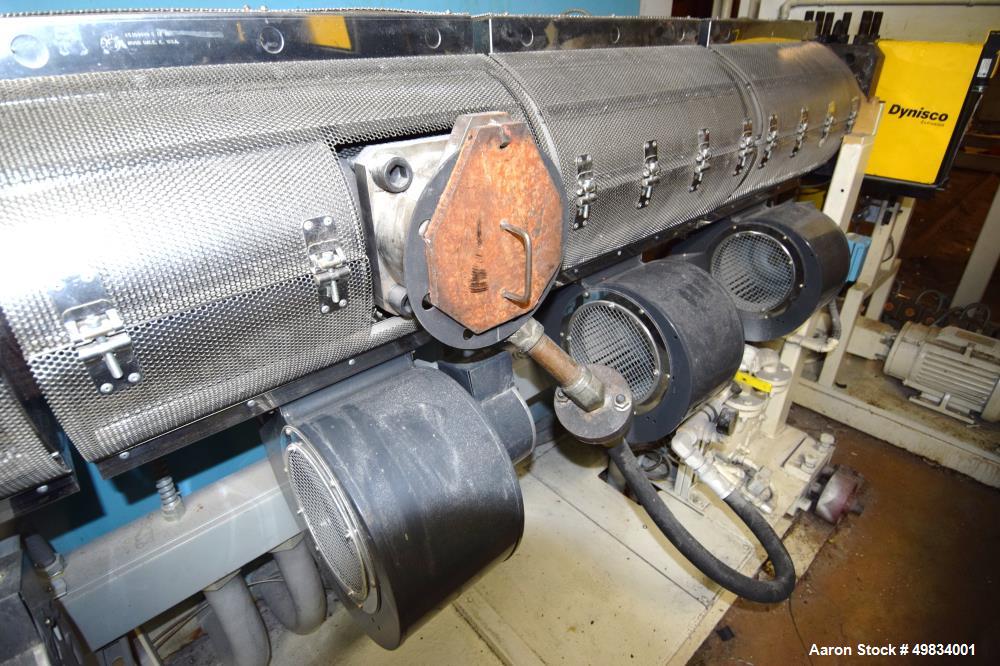

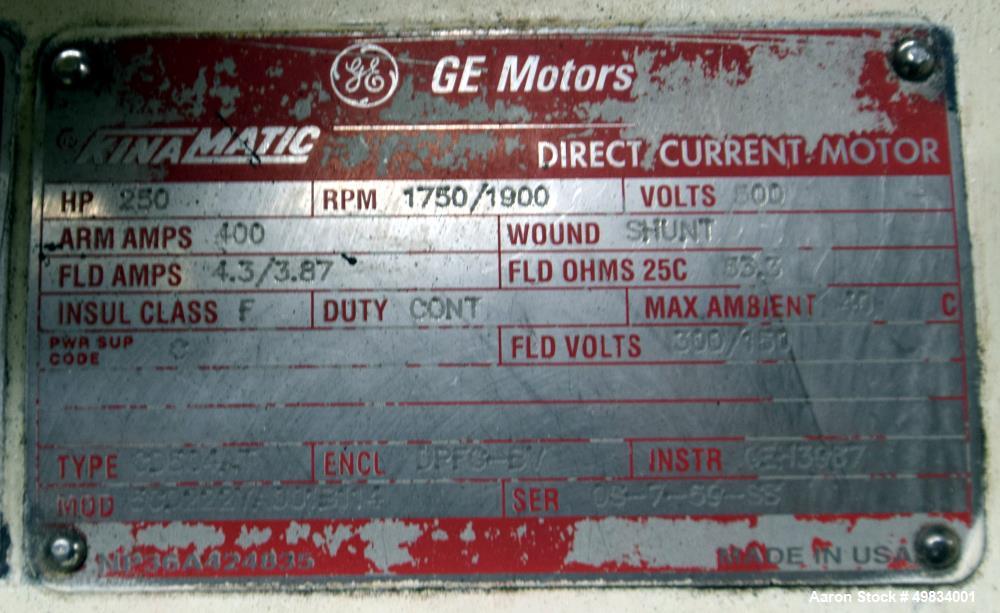

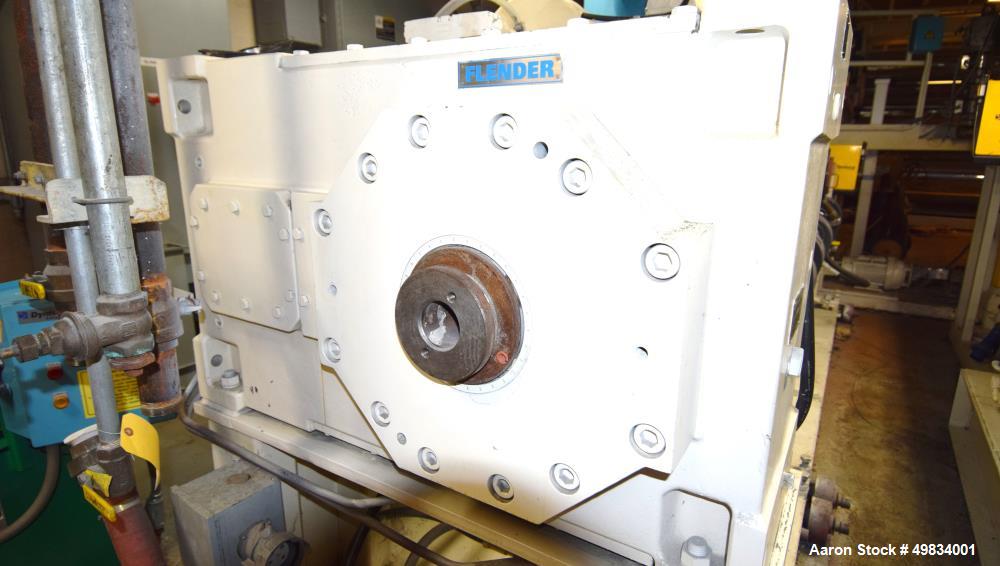

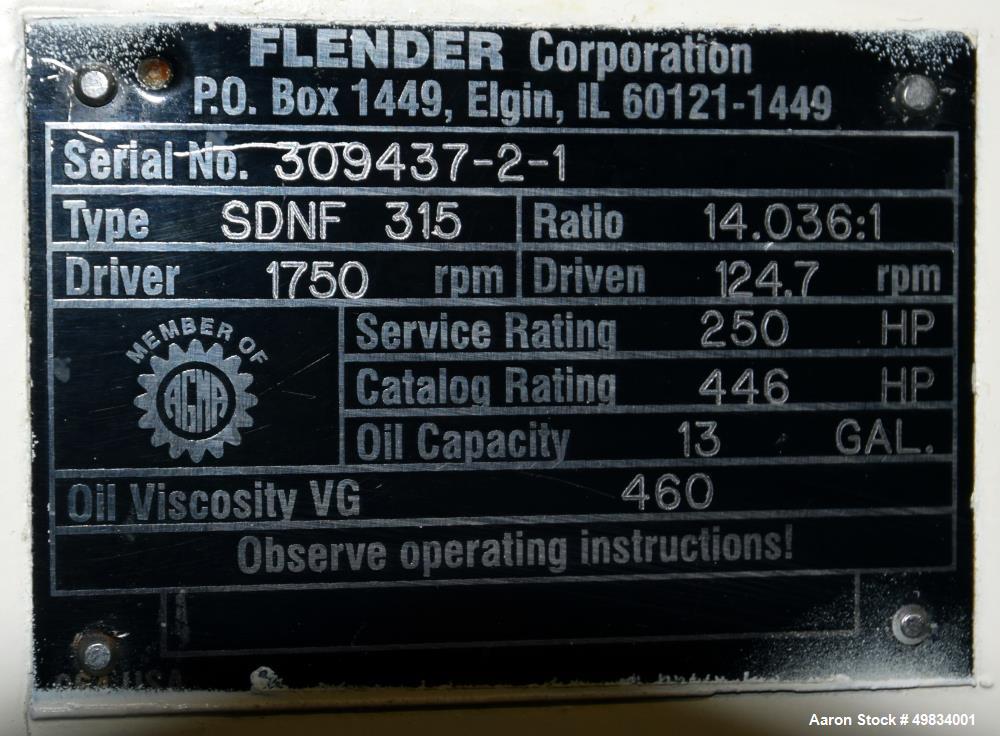

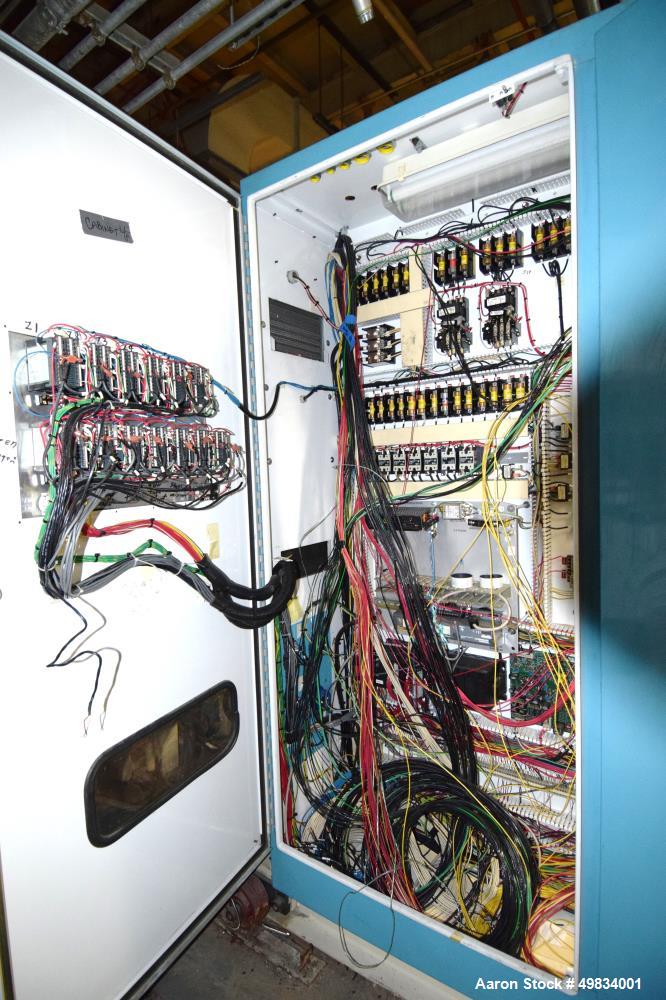

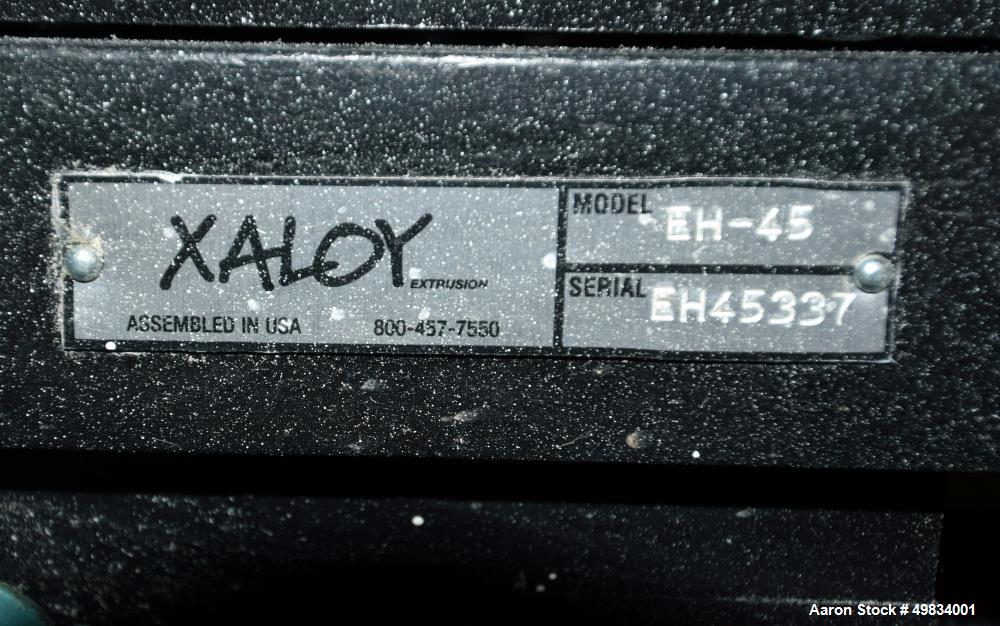

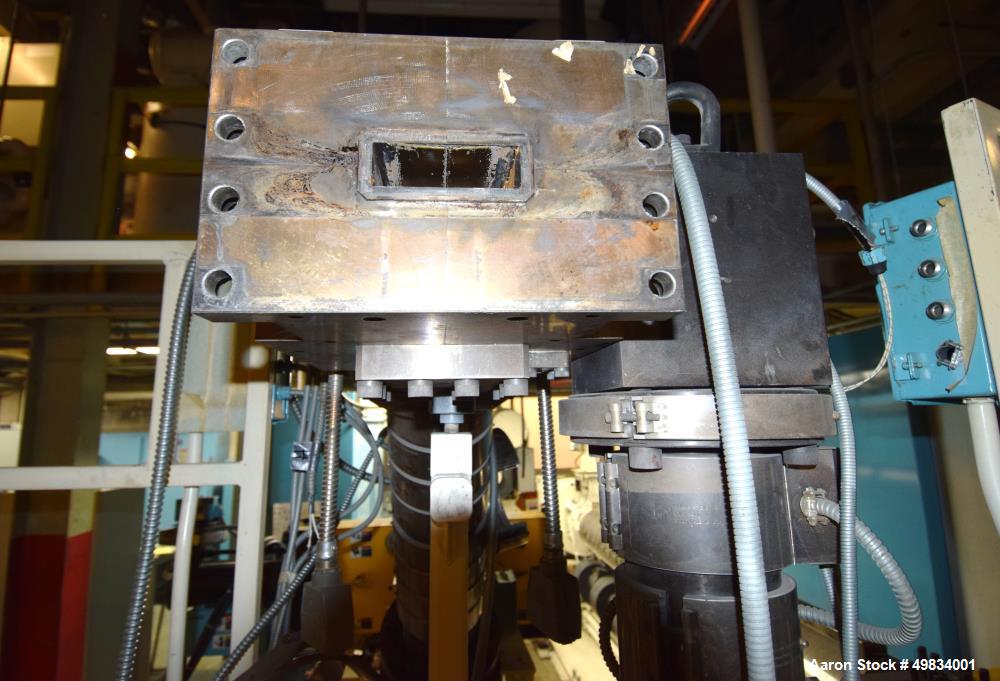

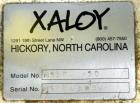

Used Cincinnati Milacron 91" Wide Sheet Line. Consisting of the following components: (1) 6" screw diameter Apex Single screw extruder 38:1 L/D Ratio Side vented including vacuum pump located 88" back from end of barrel. Electrically heated air cooled barrel having 7 barrels zones of heating. Unit is direct connected with a 500 hp DC Motor thru a 13.844:1 ratio, extruder centerline is 61". SCR DC drive and control panel having 7 barrels zones and 13 downstream zones. (1) 4.5" screw diameter Apex Single screw extruder 34:1 L/D ratio side vented including vacuum pump located 55" from end of barrel. Electrically Heated Air Cooled barrel approximate 7 zones for barrels and 7 zones for downstream. Direct connected 250 hp DC motor thru 14.036:1 gearbox ratio. DC drive control. Each extruder is equipped with a hydraulic Dynisco 6" and 4.5" screen changer with hydraulic power unit. Two MAAG gear pumps for each of the extruders. With die stand and die block . 88" wide Model UHRC-200-FG restrictor bar die. Rectangular feed. (1) Cincinnati Milacron Three roll down stack individually driven rolls top roll is 20" diameter x 91" wide Chrome mirror finish, middle and bottom rolls are 36" diameter x 91" wide both rolls are chrome with mirror finish. All rolls driven by a 5 hp motor thru gearbox. Hydraulically operated roll closure and each are cooled by AEC packaged chilling units. Cooling conveyor equipped with a Scan Tech MFG 2011 with controls. Pull Roll stand having 8" diameter x 91" wide. Control system and console. Mfg 2001.

Used Cincinnati Milacron 91" Wide Sheet Line. Consisting of the following components: (1) 6" screw diameter Apex Single screw extruder 38:1 L/D Ratio Side vented including vacuum pump located 88" back from end of barrel. Electrically heated air cooled barrel having 7 barrels zones of heating. Unit is direct connected with a 500 hp DC Motor thru a 13.844:1 ratio, extruder centerline is 61". SCR DC drive and control panel having 7 barrels zones and 13 downstream zones. (1) 4.5" screw diameter Apex Single screw extruder 34:1 L/D ratio side vented including vacuum pump located 55" from end of barrel. Electrically Heated Air Cooled barrel approximate 7 zones for barrels and 7 zones for downstream. Direct connected 250 hp DC motor thru 14.036:1 gearbox ratio. DC drive control. Each extruder is equipped with a hydraulic Dynisco 6" and 4.5" screen changer with hydraulic power unit. Two MAAG gear pumps for each of the extruders. With die stand and die block . 88" wide Model UHRC-200-FG restrictor bar die. Rectangular feed. (1) Cincinnati Milacron Three roll down stack individually driven rolls top roll is 20" diameter x 91" wide Chrome mirror finish, middle and bottom rolls are 36" diameter x 91" wide both rolls are chrome with mirror finish. All rolls driven by a 5 hp motor thru gearbox. Hydraulically operated roll closure and each are cooled by AEC packaged chilling units. Cooling conveyor equipped with a Scan Tech MFG 2011 with controls. Pull Roll stand having 8" diameter x 91" wide. Control system and console. Mfg 2001.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory