Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used PTI (2004) multi layer sheet extrusion line including the following: A) (1) Used PTI model 6000 Trident series 6", 28:1 extruder having a 7-zone electrically heated air cooled barrel at an appro...

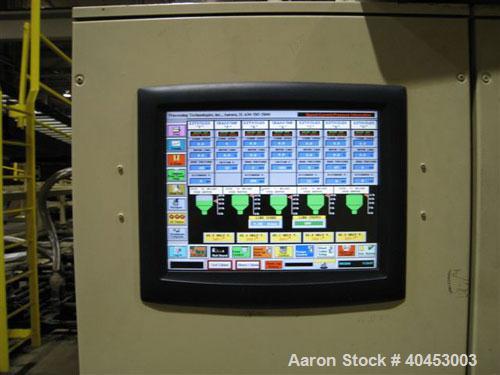

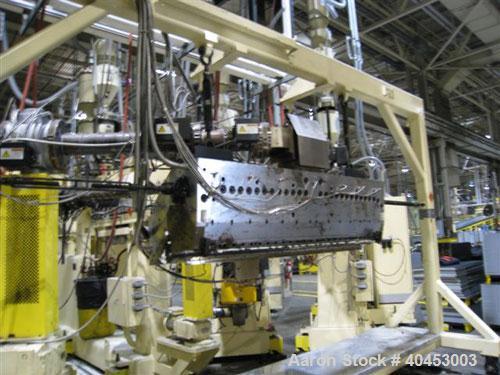

Used PTI (2004) multi layer sheet extrusion line including the following: A) (1) Used PTI model 6000 Trident series 6", 28:1 extruder having a 7-zone electrically heated air cooled barrel at an approximate 94" centerline height. Gearbox is a Flender model SZNS-390, has reduction ratio of 21.756:1, has a service rating of 400 hp and a catalog rating of 701 hp. Gearbox is direct driven by a 400 hp Reliance AC motor, having a base speed of 1791 rpm and a maximum speed of 2685 rpm. Also includes Reliance AC inverter. Mounted on extruder discharge is a 6" PTI/Dynisco hydraulic screen changer. Power pack for screen changer is mounted on extruder base. Extruder has grooved feed throat. Also mounted on extruder discharge is a Mag model EX112/70 melt pump with 40 hp AC drive system. All contactors and AC inverters for extruder and melt pump are mounted in extruder panel. B) (1) Used PTI model 2500 Trident 2-1/2", 32:1 extruder having a 5-zone electrically heated, air cooled barrel at an approximate 89" centerline height. Unit has a Koellman model Unex 4.1 gearbox having a 17.533:1 reduction ratio with a service rating of 75 hp and a catalog rating of 150 hp. Gearbox is driven by a 50 hp Reliance AC motor having 1780 rpm base speed and 2670 rpm maximum speed. Unit has a 2-1/2" Dynisco manual screen changer mounted on the discharge. Also included in the package is a Maag model EX36-4SDE melt pump, which is mounted on the same base as the extruder. Melt pump is driven by a 5 hp Reliance AC motor with inverter. All contactors and AC inverters for extruder and melt pump are mounted in unitized panel. C) (1) Used PTI model 3500 Trident series 3-1/2", 28/1 extruder having a 4-zone electrically heated, air cooled barrel at an approximate 94" centerline height. Gearbox is a Flenders model SZNF270, has a reduction ratio of 22.18:1 with a service rating of 150 hp and a catalog rating of 237 hp. Gearbox is direct driven by a 150 hp Reliance AC motor having 1750 rpm. Extruder has a grooved feed throat. 3-1/2" Dynicso manual screen changer is mounted on extruder discharge. All contactors and AC inverter for extruder are mounted in unitized panel. D) (1) Used PTI model 5000 Trident series 5", 28:1 extruder having a 5-zone electrically heated, air cooled barrel at anapproximate 55" centerline height. Gearbox is a Flenders type SZNF-320, has a reduction ratio of 17.111:1 with a service rating of 300 hp and a catalog rating of 482 hp at an input rpm of 1200. Gearbox is direct driven by a 300 hp Reliance AC motor having 1150/1785 rpm. 6" PTI/Dynisco hydraulic slide plate screen changer is model EH-60 and is mounted on extruder discharge. Screen changer shares hydraulic pack mounted on 6" extruder. All contactors and AC inverter for extruder are mounted in unitized panel. E) (1) Used PTI model 2500 Trident 2-1/2", 32:1 extruder having a 5-zone electrically heated, air cooled barrel at an approximate 89" centerline height. Unit has a Coleman model Unex 4.1 gearbox having a 17.533:1 reduction ratio, has a service rating of 75 hp and a catalog rating of 150 hp. Gearbox is driven by a 50 hp Reliance AC motor having 1780 rpm base speed and 2670 rpm maximum speed. Unit has a 2-1/2" Dynisco manual screen changer mounted on the discharge. All contactors and AC inverter for extruder are mounted in unitized panel. F) (1) Used EDI 3-manifold sheet die having a 78-1/4" slot opening with an upper adjustable lip, fixed removable lower lip and (2) restrictor bars. Presently installed is lower lip for gap range from .345 to 443. Package includes gantry for die support, (2) co-extrusion blocks, various piping to the extruders, and static mixers on each extruder. Also includes stand alone panel with all contactors for die temperature control. Die feeds sheet take-off at an approximate 45 degree angle. G) (1) Used PTI model 842440 sheet take-off unit consisting of (3) 84" face chrome rolls mounted in a "J" arrangement for upstack operation. Bottom roll is 24" diameter while middle and top roll measure nominal 40" in diameter. Top and bottom rolls are hydraulically actuated and have Servo motors for setting gap clearance on rolls. Each roll is driven by a 3 hp AC motor with inverter through a gear reducer. Approximately 4" of clearance between rolls when they are open. Cooling polishing stand discharges into a 65 foot long idler cooling conveyor having approximately (4) fans installed for additional cooling. Water temperature control on rolls is via stand alone four zone unit for the three rolls plus one spare zone. Pull roll stand consists of (2) 80" face x nominal 12" diameter rubber covered rolls driven by a 3 hp AC motor through a gear reducer. Air actuated top roll. Mounted on the idler conveyor system is slitting station for edge trim and center slit. Underneath each edge trim slitter is a Rapid model G-27 granulator which discharges into a bin via a belt conveyor. Also included are two Video Jet model Xl2000 ink jet printers with heads for printing codes on sheet. H) (1) Used 96" Famco model P-1096P 1.5 electro-mechanical shear having a 96" wide opening and is rated to cut up to .5" thickness in abs and 10 gauge in mild steel. When shear blades are open, there is 1-1/2" of clearance. Includes discharge conveyor. I) (1) PTI Titan integrated computer control system with 17" touch screen having thirteen control screens for items such as process overview, pump start/stop, drive start/stop, select recipe, define recipe, equipment overview( ie; extruder, sheet take-off, etc), alarm log, trends, dianostic and temperature control. J) (1) Used material handling system including 15 hp Novatech pneumatic conveyor mounted in an enclosure, with inline filter, multi zone control panel and receiver with process control Gravimetric load hopper on each extruder.

Used PTI (2004) multi layer sheet extrusion line including the following: A) (1) Used PTI model 6000 Trident series 6", 28:1 extruder having a 7-zone electrically heated air cooled barrel at an approximate 94" centerline height. Gearbox is a Flender model SZNS-390, has reduction ratio of 21.756:1, has a service rating of 400 hp and a catalog rating of 701 hp. Gearbox is direct driven by a 400 hp Reliance AC motor, having a base speed of 1791 rpm and a maximum speed of 2685 rpm. Also includes Reliance AC inverter. Mounted on extruder discharge is a 6" PTI/Dynisco hydraulic screen changer. Power pack for screen changer is mounted on extruder base. Extruder has grooved feed throat. Also mounted on extruder discharge is a Mag model EX112/70 melt pump with 40 hp AC drive system. All contactors and AC inverters for extruder and melt pump are mounted in extruder panel. B) (1) Used PTI model 2500 Trident 2-1/2", 32:1 extruder having a 5-zone electrically heated, air cooled barrel at an approximate 89" centerline height. Unit has a Koellman model Unex 4.1 gearbox having a 17.533:1 reduction ratio with a service rating of 75 hp and a catalog rating of 150 hp. Gearbox is driven by a 50 hp Reliance AC motor having 1780 rpm base speed and 2670 rpm maximum speed. Unit has a 2-1/2" Dynisco manual screen changer mounted on the discharge. Also included in the package is a Maag model EX36-4SDE melt pump, which is mounted on the same base as the extruder. Melt pump is driven by a 5 hp Reliance AC motor with inverter. All contactors and AC inverters for extruder and melt pump are mounted in unitized panel. C) (1) Used PTI model 3500 Trident series 3-1/2", 28/1 extruder having a 4-zone electrically heated, air cooled barrel at an approximate 94" centerline height. Gearbox is a Flenders model SZNF270, has a reduction ratio of 22.18:1 with a service rating of 150 hp and a catalog rating of 237 hp. Gearbox is direct driven by a 150 hp Reliance AC motor having 1750 rpm. Extruder has a grooved feed throat. 3-1/2" Dynicso manual screen changer is mounted on extruder discharge. All contactors and AC inverter for extruder are mounted in unitized panel. D) (1) Used PTI model 5000 Trident series 5", 28:1 extruder having a 5-zone electrically heated, air cooled barrel at anapproximate 55" centerline height. Gearbox is a Flenders type SZNF-320, has a reduction ratio of 17.111:1 with a service rating of 300 hp and a catalog rating of 482 hp at an input rpm of 1200. Gearbox is direct driven by a 300 hp Reliance AC motor having 1150/1785 rpm. 6" PTI/Dynisco hydraulic slide plate screen changer is model EH-60 and is mounted on extruder discharge. Screen changer shares hydraulic pack mounted on 6" extruder. All contactors and AC inverter for extruder are mounted in unitized panel. E) (1) Used PTI model 2500 Trident 2-1/2", 32:1 extruder having a 5-zone electrically heated, air cooled barrel at an approximate 89" centerline height. Unit has a Coleman model Unex 4.1 gearbox having a 17.533:1 reduction ratio, has a service rating of 75 hp and a catalog rating of 150 hp. Gearbox is driven by a 50 hp Reliance AC motor having 1780 rpm base speed and 2670 rpm maximum speed. Unit has a 2-1/2" Dynisco manual screen changer mounted on the discharge. All contactors and AC inverter for extruder are mounted in unitized panel. F) (1) Used EDI 3-manifold sheet die having a 78-1/4" slot opening with an upper adjustable lip, fixed removable lower lip and (2) restrictor bars. Presently installed is lower lip for gap range from .345 to 443. Package includes gantry for die support, (2) co-extrusion blocks, various piping to the extruders, and static mixers on each extruder. Also includes stand alone panel with all contactors for die temperature control. Die feeds sheet take-off at an approximate 45 degree angle. G) (1) Used PTI model 842440 sheet take-off unit consisting of (3) 84" face chrome rolls mounted in a "J" arrangement for upstack operation. Bottom roll is 24" diameter while middle and top roll measure nominal 40" in diameter. Top and bottom rolls are hydraulically actuated and have Servo motors for setting gap clearance on rolls. Each roll is driven by a 3 hp AC motor with inverter through a gear reducer. Approximately 4" of clearance between rolls when they are open. Cooling polishing stand discharges into a 65 foot long idler cooling conveyor having approximately (4) fans installed for additional cooling. Water temperature control on rolls is via stand alone four zone unit for the three rolls plus one spare zone. Pull roll stand consists of (2) 80" face x nominal 12" diameter rubber covered rolls driven by a 3 hp AC motor through a gear reducer. Air actuated top roll. Mounted on the idler conveyor system is slitting station for edge trim and center slit. Underneath each edge trim slitter is a Rapid model G-27 granulator which discharges into a bin via a belt conveyor. Also included are two Video Jet model Xl2000 ink jet printers with heads for printing codes on sheet. H) (1) Used 96" Famco model P-1096P 1.5 electro-mechanical shear having a 96" wide opening and is rated to cut up to .5" thickness in abs and 10 gauge in mild steel. When shear blades are open, there is 1-1/2" of clearance. Includes discharge conveyor. I) (1) PTI Titan integrated computer control system with 17" touch screen having thirteen control screens for items such as process overview, pump start/stop, drive start/stop, select recipe, define recipe, equipment overview( ie; extruder, sheet take-off, etc), alarm log, trends, dianostic and temperature control. J) (1) Used material handling system including 15 hp Novatech pneumatic conveyor mounted in an enclosure, with inline filter, multi zone control panel and receiver with process control Gravimetric load hopper on each extruder.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory