Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

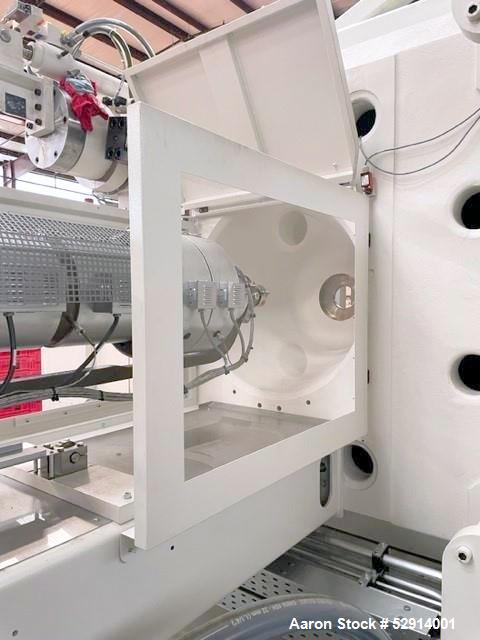

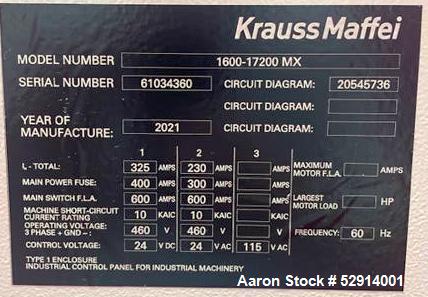

Unused - Krauss Maffei Horizontal Injection Molding Machine

Unused - Krauss Maffei Horizontal Injection Molding Machine, 1760 Tons, Model 1600-17200 MX. 1760 Ton Clamp Force. 17200 plasticizing size. Approximate 241.97 oz. (6.86 kg) shot size. Platens approximate 100.3937" x 82.67717", Distance between tie bars 73.6" x 55.9", Mold opening stroke 13.39", Maximum daylight 133.85", 7 heating zones, 135mm screw diameter, 10mm nozzle radius, 4mm nozzle bore, 460 volt/60Hz . Includes: MC6 Control, PV-closed loop control for injection unit, hydraulic-mechanical 2 platen clamping system. (4) locking devices and (4) pressure pads. Wedge type anti-vibration pads; Shim plates; Horizontal stops for fixing machine; Electric screw motor; Blue Power-Servo pump drive; Steel hopper; Cylindrical valve type shut-off nozzle HSVS; Pneumatic valves on moving and fixed platens for blow function; Pneumatic cascade control; Maintenance unit for treatment of oil-free compressed air; Hydraulic cascade control; Electric interface on fixed platen; Mold fixing platens; Mechanical robot interface; Mechanical preparation for future retrofitting of a mechanical progressive drop-in bar; Hydraulically actuated ejector plate; Hydraulic operated safety gate; Tie bar retraction system; Internal oil filtration; Level sensor for oil drip tray; Increased oil cooler; Pressure gauge; Pressure accumulator; Hydraulic core pull system on moving and fixed platens; Hydraulic ejector and cores on moving platen; Twin pressure check valves for hydraulic core pulls; Extended parallel movements of injection unit; Cooling water connections; 2 Additional circles; Cold slug ejection; Control cabinet cooling fan; TN-C/TN-C-S/TN-S power supply capability; Separate heat and power circuit connections; Additional temperature zone for nozzle heater; Data logbook; Stabilized power supply unit; Quality monitoring package; Cycle time recording/analysis; TFT color screen; Graph displays; Automatic maintenance alerts; PV-closed loop control; 110 and 220V outlets; Electronic coding

Automotive, Consumer Goods, Consumer Products, Logistics, Packaging

Unused - Krauss Maffei Horizontal Injection Molding Machine, 1760 Tons, Model 1600-17200 MX. 1760 Ton Clamp Force. 17200 plasticizing size. Approximate 241.97 oz. (6.86 kg) shot size. Platens approximate 100.3937" x 82.67717", Distance between tie bars 73.6" x 55.9", Mold opening stroke 13.39", Maximum daylight 133.85", 7 heating zones, 135mm screw diameter, 10mm nozzle radius, 4mm nozzle bore, 460 volt/60Hz . Includes: MC6 Control, PV-closed loop control for injection unit, hydraulic-mechanical 2 platen clamping system. (4) locking devices and (4) pressure pads. Wedge type anti-vibration pads; Shim plates; Horizontal stops for fixing machine; Electric screw motor; Blue Power-Servo pump drive; Steel hopper; Cylindrical valve type shut-off nozzle HSVS; Pneumatic valves on moving and fixed platens for blow function; Pneumatic cascade control; Maintenance unit for treatment of oil-free compressed air; Hydraulic cascade control; Electric interface on fixed platen; Mold fixing platens; Mechanical robot interface; Mechanical preparation for future retrofitting of a mechanical progressive drop-in bar; Hydraulically actuated ejector plate; Hydraulic operated safety gate; Tie bar retraction system; Internal oil filtration; Level sensor for oil drip tray; Increased oil cooler; Pressure gauge; Pressure accumulator; Hydraulic core pull system on moving and fixed platens; Hydraulic ejector and cores on moving platen; Twin pressure check valves for hydraulic core pulls; Extended parallel movements of injection unit; Cooling water connections; 2 Additional circles; Cold slug ejection; Control cabinet cooling fan; TN-C/TN-C-S/TN-S power supply capability; Separate heat and power circuit connections; Additional temperature zone for nozzle heater; Data logbook; Stabilized power supply unit; Quality monitoring package; Cycle time recording/analysis; TFT color screen; Graph displays; Automatic maintenance alerts; PV-closed loop control; 110 and 220V outlets; Electronic coding

Automotive, Consumer Goods, Consumer Products, Logistics, Packaging

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory