Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

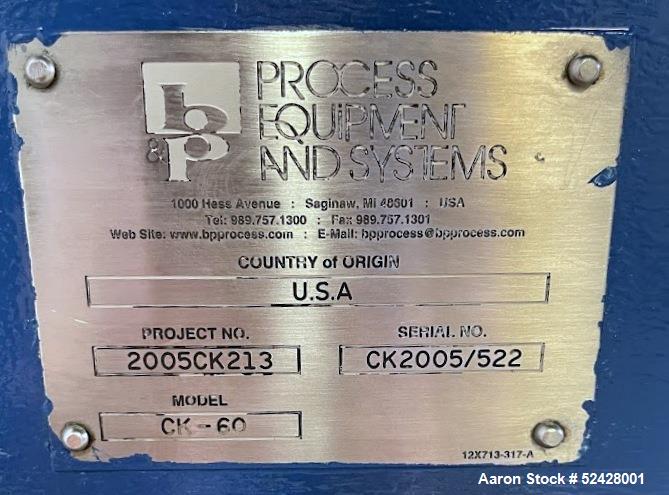

B&P Process Equipment Ko-Kneader System

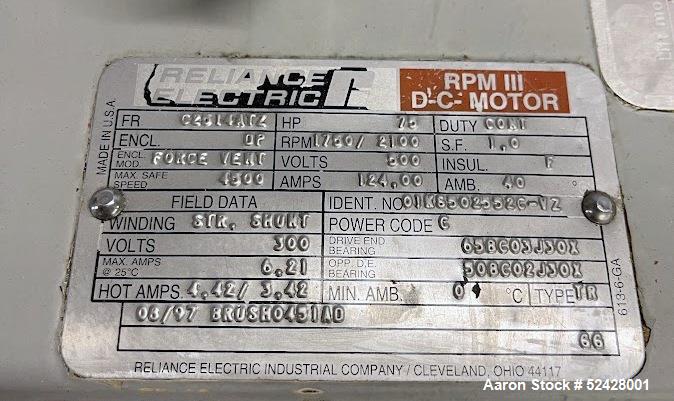

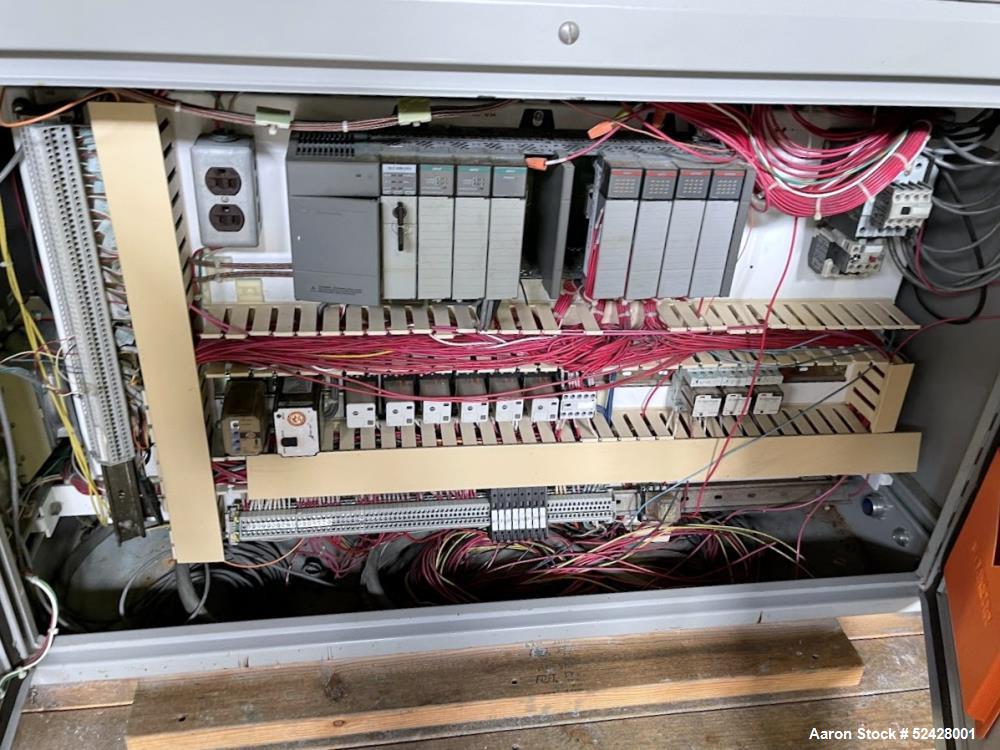

Used B&P Process Equipment Ko-Kneader System, Model CK-60-12D. System consists of: B&P Ko-Kneader, 60mm screw diameter, 12:1 L/D, barrel vertically split. Cored shaft with segmented screw elements and liners, barrels are water heated cooled. 75 HP DC-Motor with drive. Screw speed up to 500 rpm; Brabender type SF-40 side feeder mounted on a turntable. This feeder is feeding the first barrel of the Ko-Kneader; Complete gear pump system including separate controls; Combination pressure / temperature probe up/ and downstream the gear pump; Complete controls, relays logic. Last used in a Soap Pellet application.

| Manufacturer | B & P Process EquipmentB & P Process Equipment |

| Model | CK-60 |

| Serial # | CK2005/522 |

| Category | Extruders - Non PlasticExtruders - Non Plastic |

| Subcategory | Extruders - Non PlasticExtruders - Non Plastic |

Overview

This Used B&P Process Equipment Ko-Kneader System, Model CK-60-12D, is a continuous compounding system designed for high-shear, intensive mixing and kneading applications. The system includes a 60mm screw diameter with a 12:1 L/D barrel, vertically split for easy maintenance and cleaning.

Featuring a cored shaft with segmented screw elements, water-heated and cooled barrels, and a 75 HP DC motor with variable speed control, this kneader offers precise control over shear and temperature, essential for consistent and efficient processing.

The system also includes a Brabender SF-40 side feeder, a complete gear pump system with separate controls, and combination pressure/temperature probes, making it a comprehensive processing solution.

Previously used in soap pellet production, it’s well-suited for plastics, chemicals, pharmaceuticals, and specialty materials.

Key Specifications

- Manufacturer: B&P Process Equipment

- Model: CK-60-12D

- Screw Diameter: 60mm

- L/D Ratio: 12:1

- Barrel Type: Vertically Split Barrel (Water Heated/Cooled)

- Shaft & Screws:

- Cored Shaft

- Segmented Screw Elements

- Segmented Liners

- Motor:

- 75 HP DC Motor

- Drive System Included

- Variable Screw Speed (Up to 500 RPM)

- Side Feeder:

- Brabender SF-40 Feeder

- Mounted on a Turntable

- Feeds First Barrel Section

- Gear Pump System:

- Complete with Separate Controls

- Combination Pressure/Temperature Probes (Upstream & Downstream)

- Control Panel:

- Includes Relays and Logic Controls

- Complete Control System

- Previous Application: Soap Pellet Production

Features & Benefits

- High Shear Ko-Kneader Technology – Provides excellent distributive and dispersive mixing for demanding compounding processes

- Segmented Screws & Liners – Easy maintenance and replacement for reduced downtime and extended life

- Vertically Split Barrel – Simplifies cleaning and inspection, ideal for multi-product facilities

- Integrated Gear Pump System – Ensures consistent pressure and output flow, enhancing product quality

- Brabender Side Feeder – Flexible feeding of additives, fillers, and pigments, improving formulation control

- Complete Control Package – Full operational control with temperature and pressure monitoring for process stability

- Proven in Soap Pellet Production – Suitable for a wide range of materials, including plastics, elastomers, chemicals, and food products

Applications

- Soap Pellets & Detergent Processing

- Plastic Compounding (Fillers, Masterbatch)

- Rubber & Elastomer Blending

- Chemical Processing (Catalysts, Additives)

- Pharmaceutical Granulation & Pelletizing

- Food & Nutraceuticals (if non-contact with soaps)

Industries Served

- Personal Care & Soaps

- Plastics & Polymers

- Chemicals & Catalysts

- Pharmaceuticals

- Food Processing

- Masterbatch & Additive Compounding

- Ko-Kneader, B&P kneader, twin screw compounding

- Used B&P Ko-Kneader CK-60-12D, soap pellet processing equipment, 60mm kneader extruder

- Used B&P Process Equipment CK-60-12D Ko-Kneader system with 60mm screw and 75 HP motor, high-shear compounding system for soap pellet production with gear pump and Brabender feeder, used industrial kneader with 12:1 L/D and vertically split water-cooled barrels

Used B&P Process Equipment Ko-Kneader System, Model CK-60-12D. System consists of: B&P Ko-Kneader, 60mm screw diameter, 12:1 L/D, barrel vertically split. Cored shaft with segmented screw elements and liners, barrels are water heated cooled. 75 HP DC-Motor with drive. Screw speed up to 500 rpm; Brabender type SF-40 side feeder mounted on a turntable. This feeder is feeding the first barrel of the Ko-Kneader; Complete gear pump system including separate controls; Combination pressure / temperature probe up/ and downstream the gear pump; Complete controls, relays logic. Last used in a Soap Pellet application.

Overview

This Used B&P Process Equipment Ko-Kneader System, Model CK-60-12D, is a continuous compounding system designed for high-shear, intensive mixing and kneading applications. The system includes a 60mm screw diameter with a 12:1 L/D barrel, vertically split for easy maintenance and cleaning.

Featuring a cored shaft with segmented screw elements, water-heated and cooled barrels, and a 75 HP DC motor with variable speed control, this kneader offers precise control over shear and temperature, essential for consistent and efficient processing.

The system also includes a Brabender SF-40 side feeder, a complete gear pump system with separate controls, and combination pressure/temperature probes, making it a comprehensive processing solution.

Previously used in soap pellet production, it’s well-suited for plastics, chemicals, pharmaceuticals, and specialty materials.

Key Specifications

- Manufacturer: B&P Process Equipment

- Model: CK-60-12D

- Screw Diameter: 60mm

- L/D Ratio: 12:1

- Barrel Type: Vertically Split Barrel (Water Heated/Cooled)

- Shaft & Screws:

- Cored Shaft

- Segmented Screw Elements

- Segmented Liners

- Motor:

- 75 HP DC Motor

- Drive System Included

- Variable Screw Speed (Up to 500 RPM)

- Side Feeder:

- Brabender SF-40 Feeder

- Mounted on a Turntable

- Feeds First Barrel Section

- Gear Pump System:

- Complete with Separate Controls

- Combination Pressure/Temperature Probes (Upstream & Downstream)

- Control Panel:

- Includes Relays and Logic Controls

- Complete Control System

- Previous Application: Soap Pellet Production

Features & Benefits

- High Shear Ko-Kneader Technology – Provides excellent distributive and dispersive mixing for demanding compounding processes

- Segmented Screws & Liners – Easy maintenance and replacement for reduced downtime and extended life

- Vertically Split Barrel – Simplifies cleaning and inspection, ideal for multi-product facilities

- Integrated Gear Pump System – Ensures consistent pressure and output flow, enhancing product quality

- Brabender Side Feeder – Flexible feeding of additives, fillers, and pigments, improving formulation control

- Complete Control Package – Full operational control with temperature and pressure monitoring for process stability

- Proven in Soap Pellet Production – Suitable for a wide range of materials, including plastics, elastomers, chemicals, and food products

Applications

- Soap Pellets & Detergent Processing

- Plastic Compounding (Fillers, Masterbatch)

- Rubber & Elastomer Blending

- Chemical Processing (Catalysts, Additives)

- Pharmaceutical Granulation & Pelletizing

- Food & Nutraceuticals (if non-contact with soaps)

Industries Served

- Personal Care & Soaps

- Plastics & Polymers

- Chemicals & Catalysts

- Pharmaceuticals

- Food Processing

- Masterbatch & Additive Compounding

| Manufacturer | B & P Process Equipment |

| Model | CK-60 |

| Serial # | CK2005/522 |

| Category | Extruders - Non Plastic |

| Subcategory | Extruders - Non Plastic |

- Ko-Kneader, B&P kneader, twin screw compounding

- Used B&P Ko-Kneader CK-60-12D, soap pellet processing equipment, 60mm kneader extruder

- Used B&P Process Equipment CK-60-12D Ko-Kneader system with 60mm screw and 75 HP motor, high-shear compounding system for soap pellet production with gear pump and Brabender feeder, used industrial kneader with 12:1 L/D and vertically split water-cooled barrels

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory