Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Sano Blown Film Co-Extrusion Line

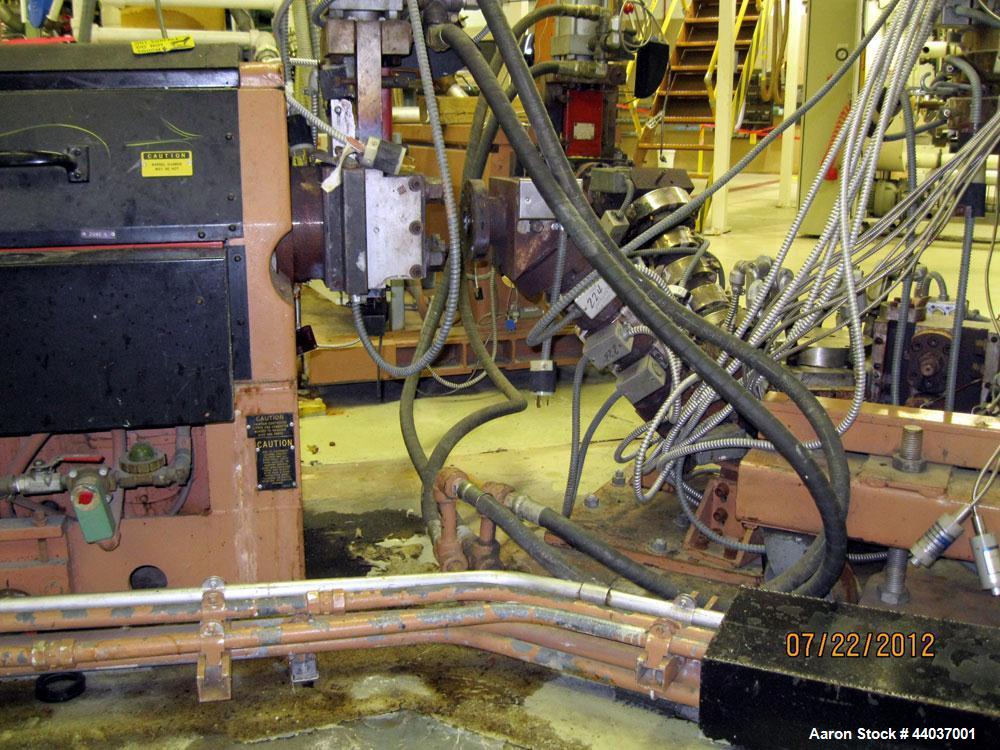

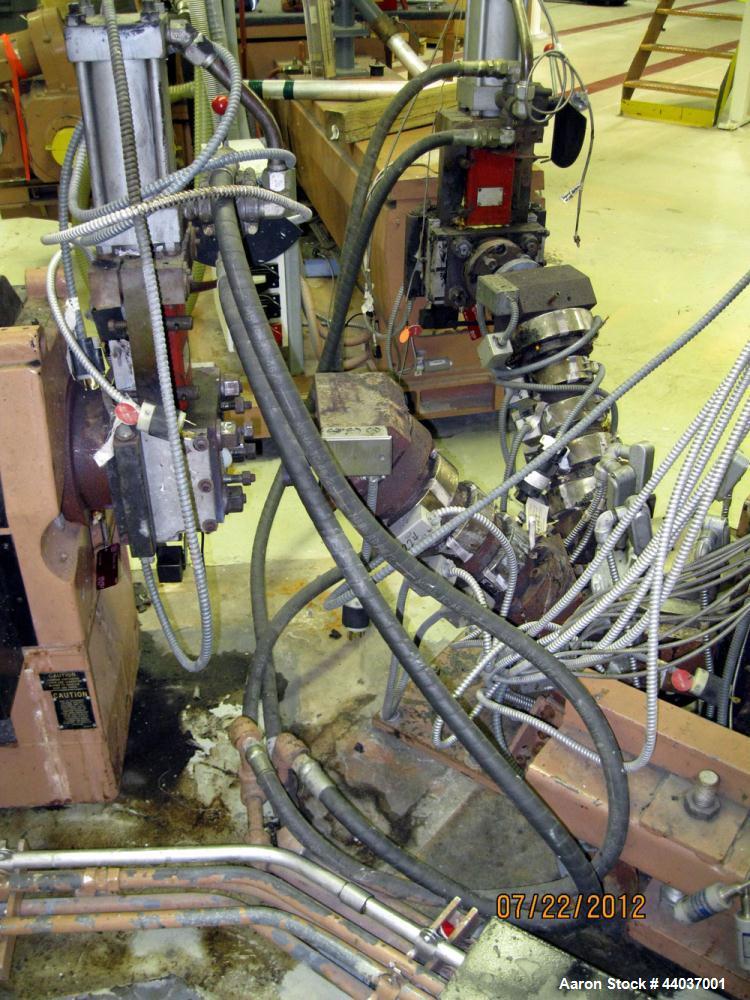

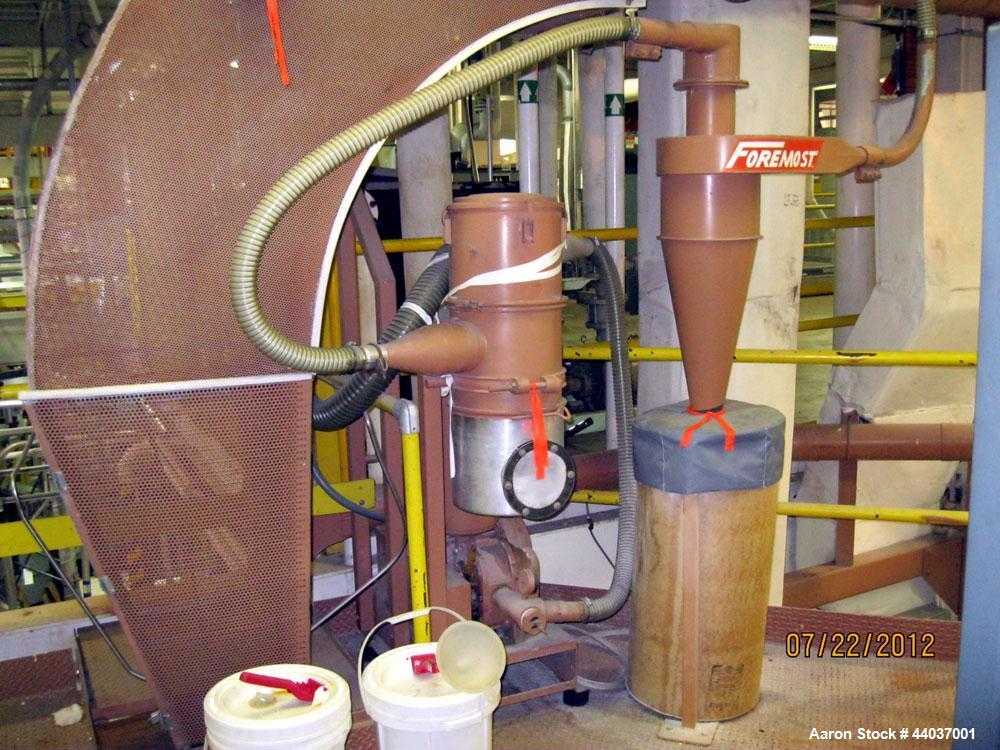

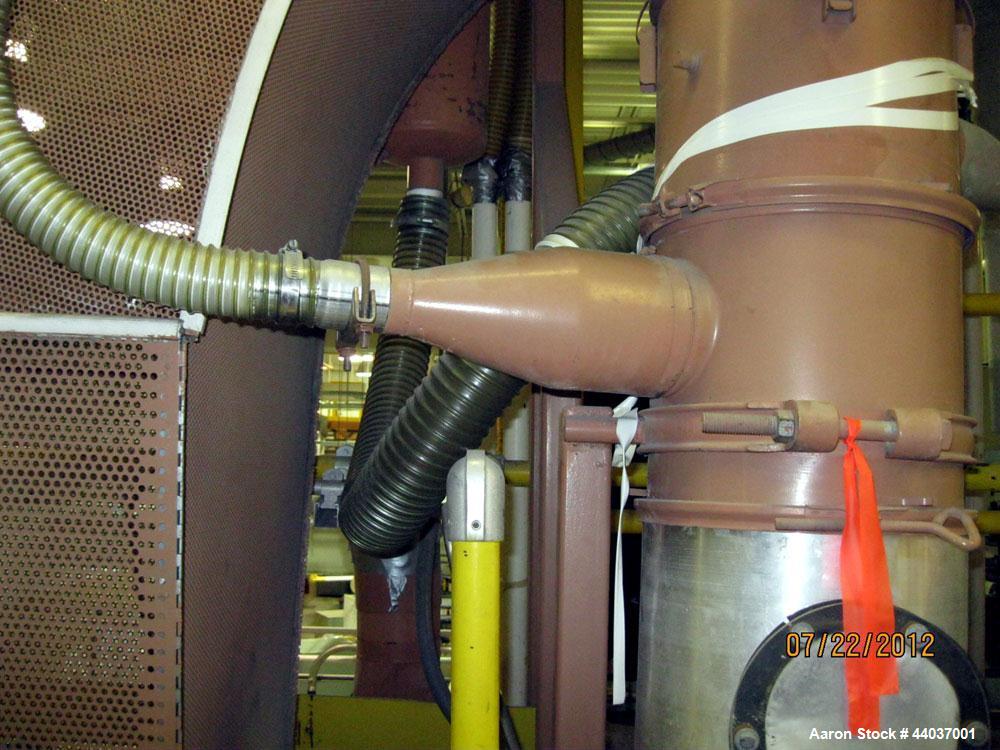

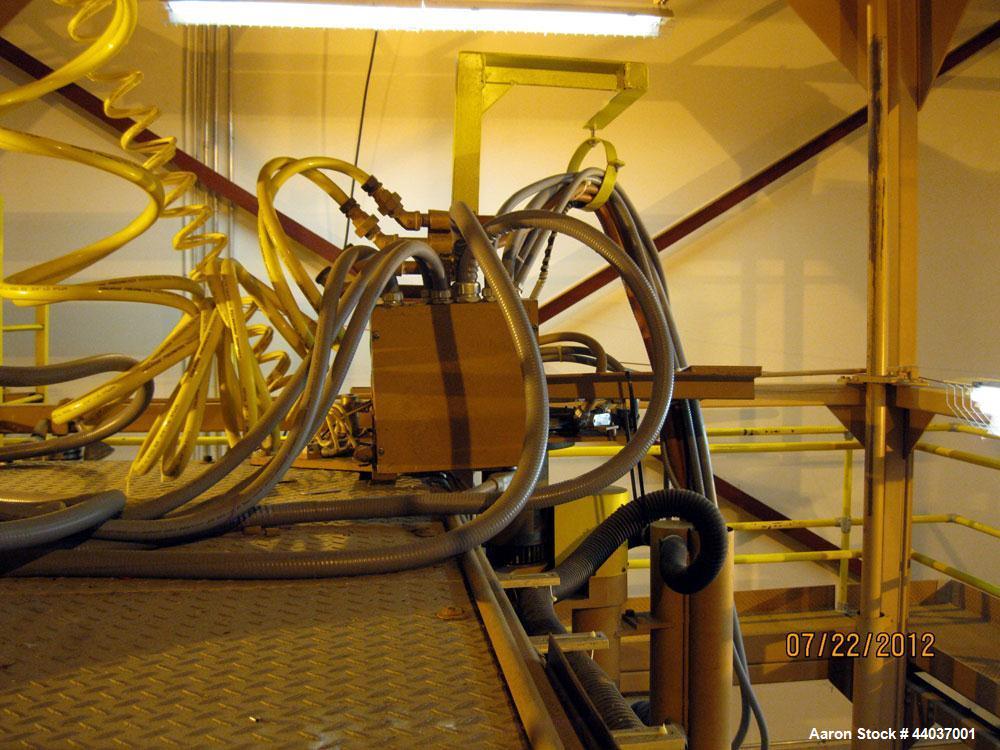

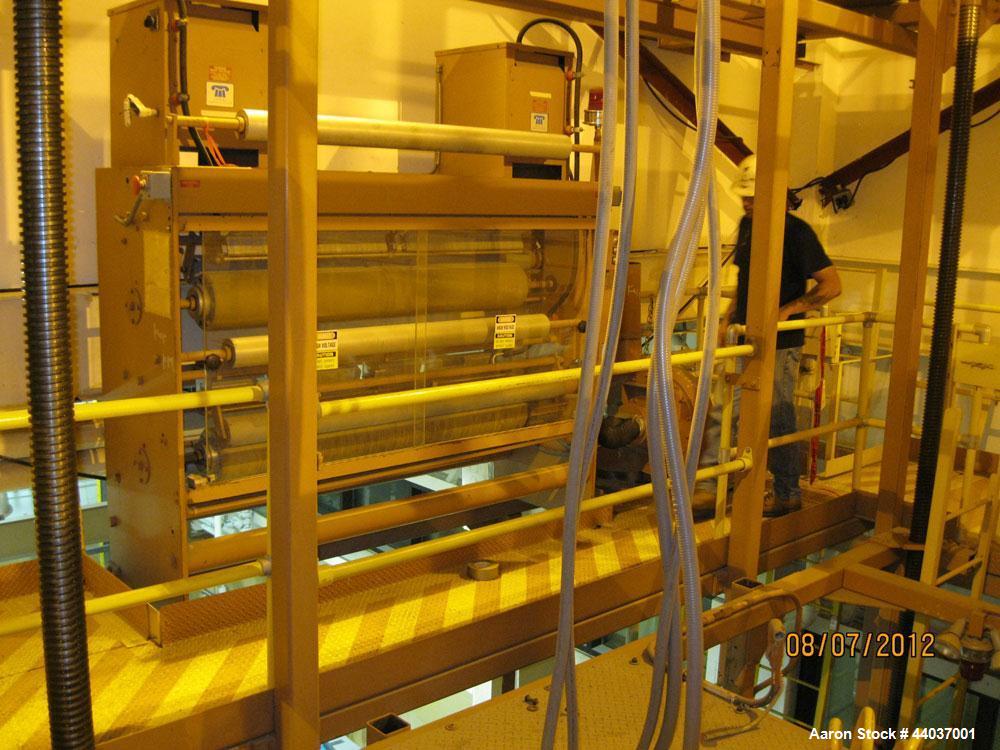

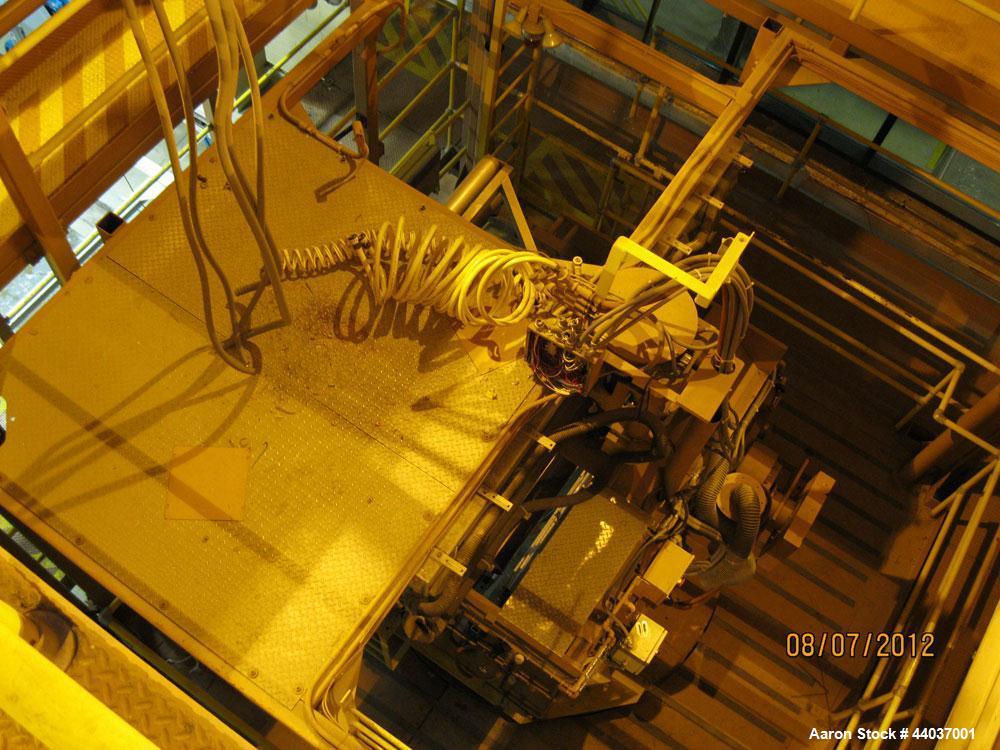

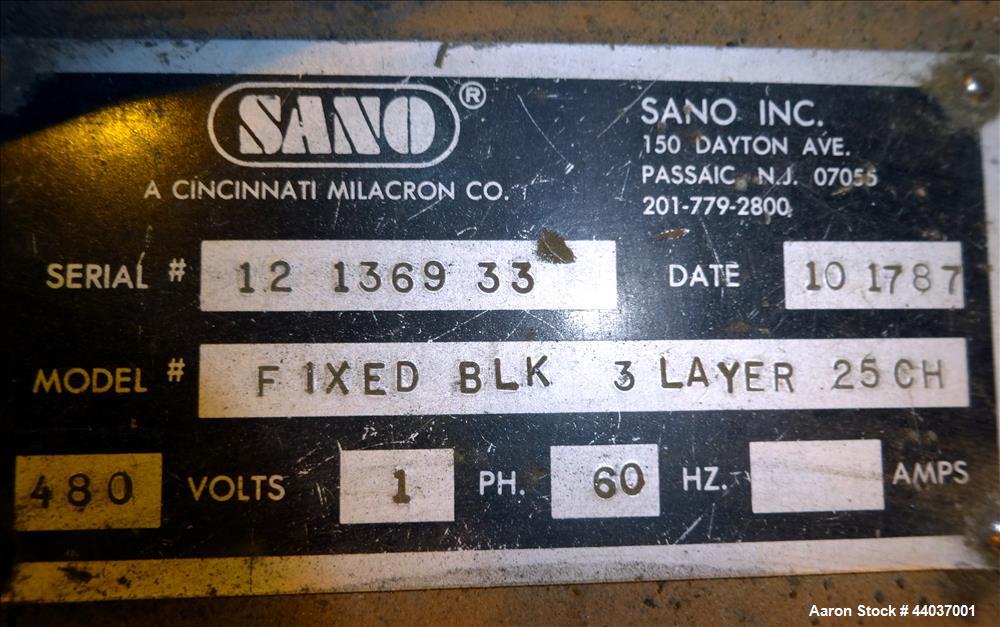

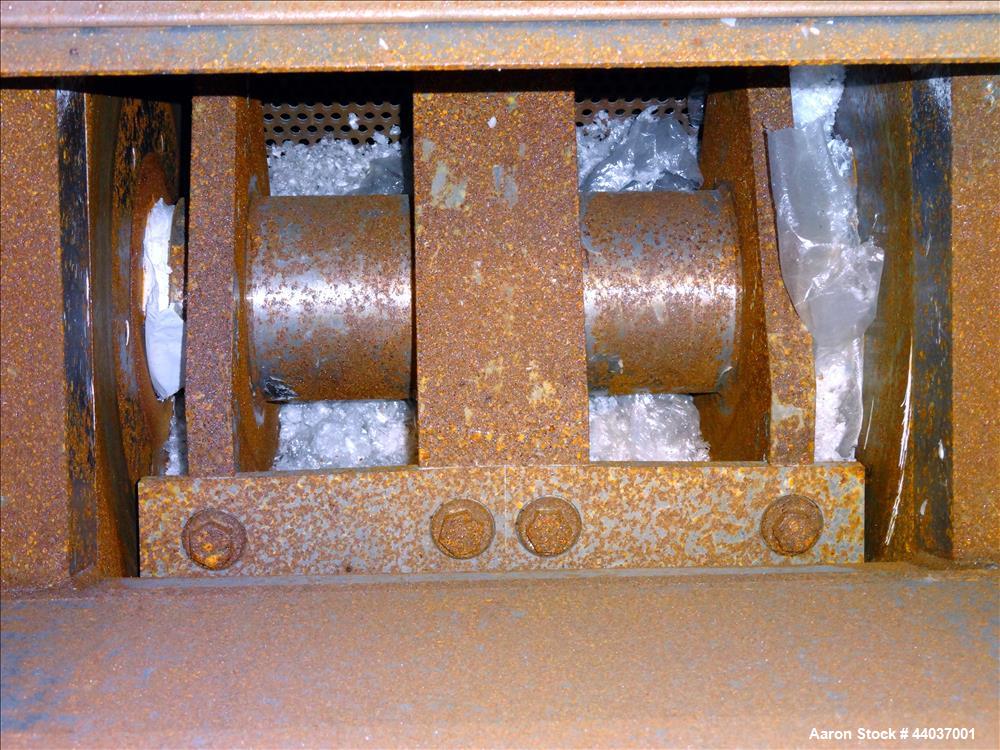

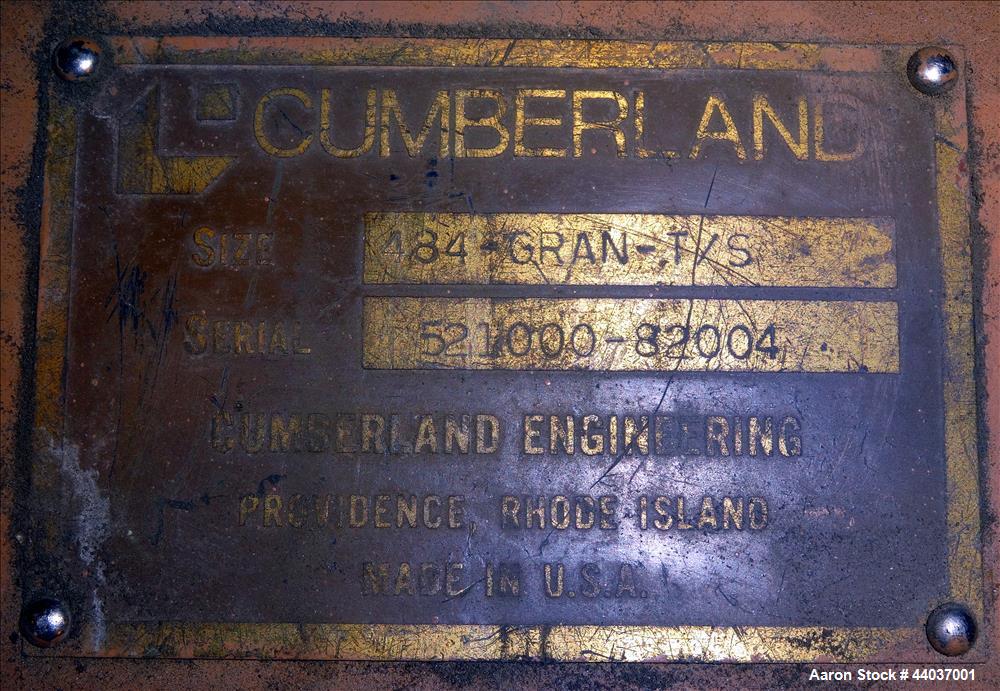

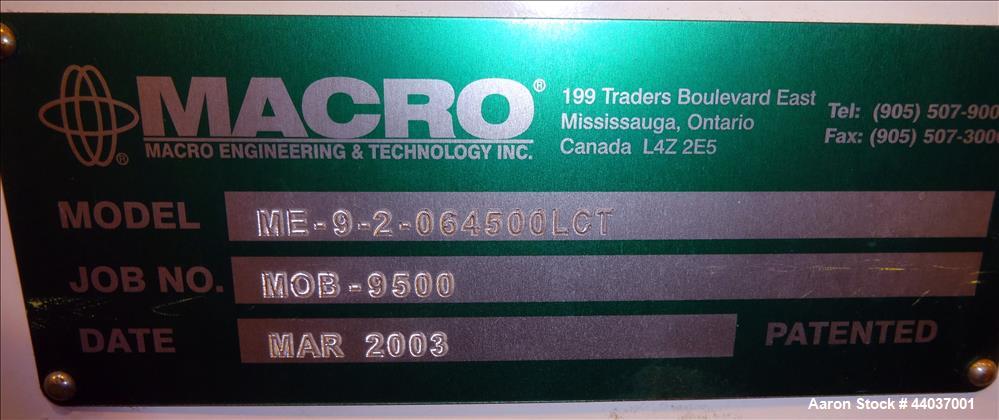

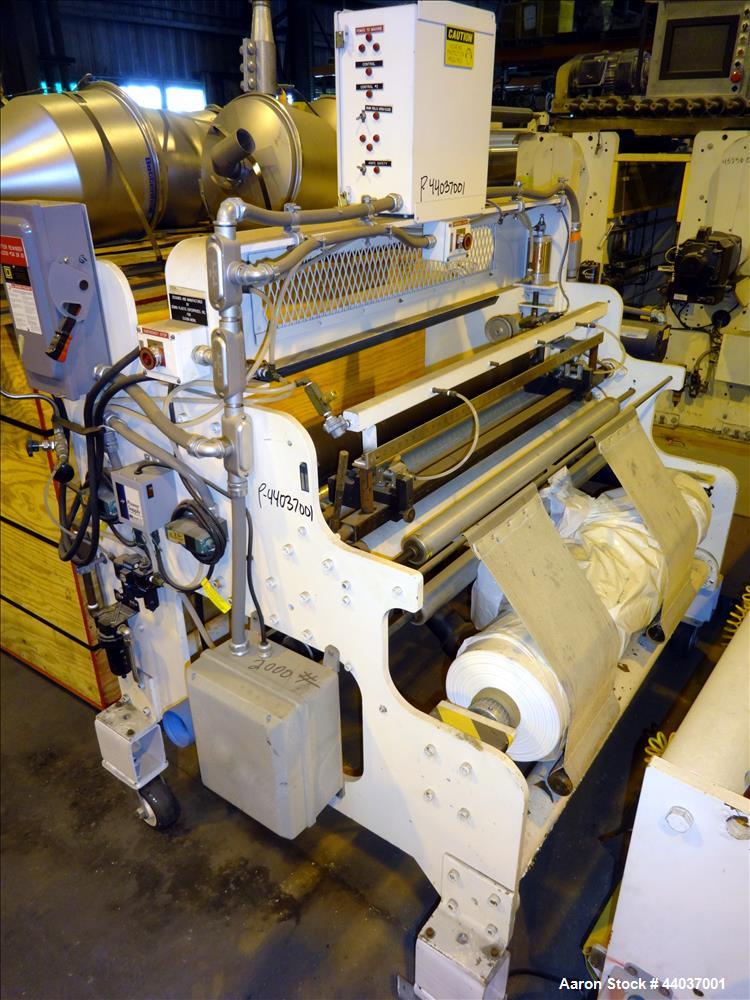

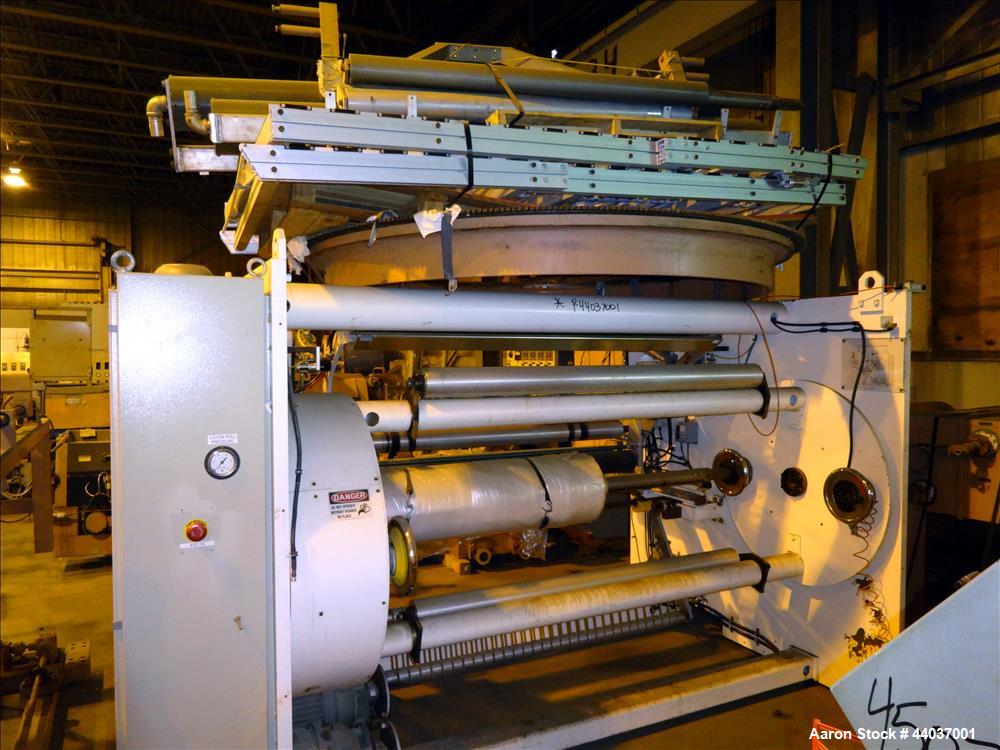

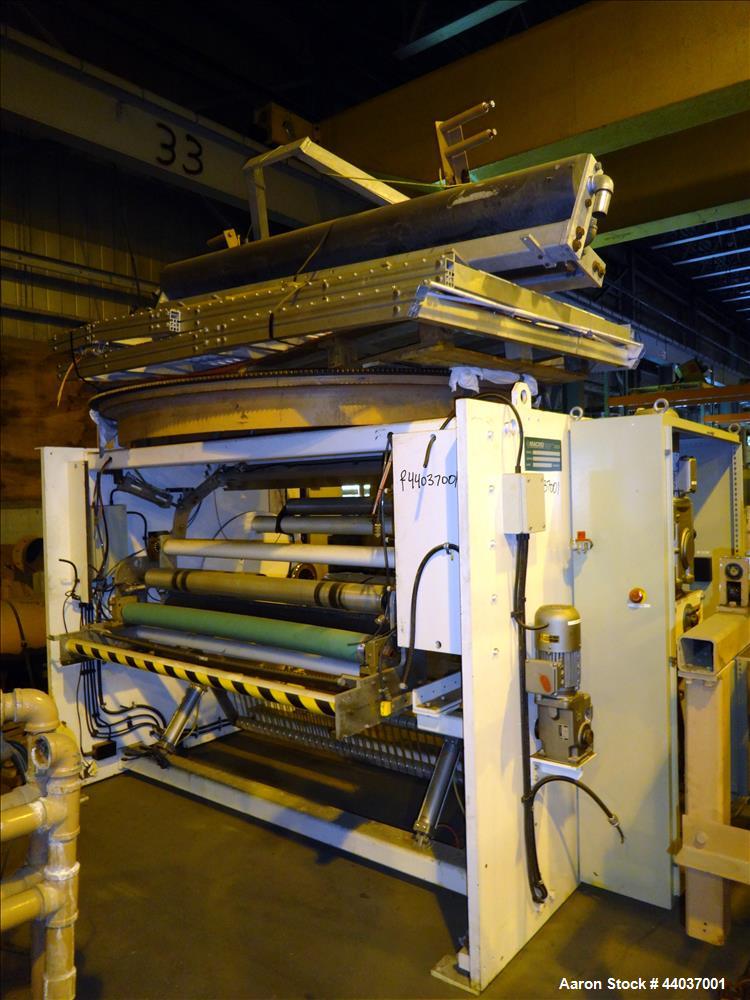

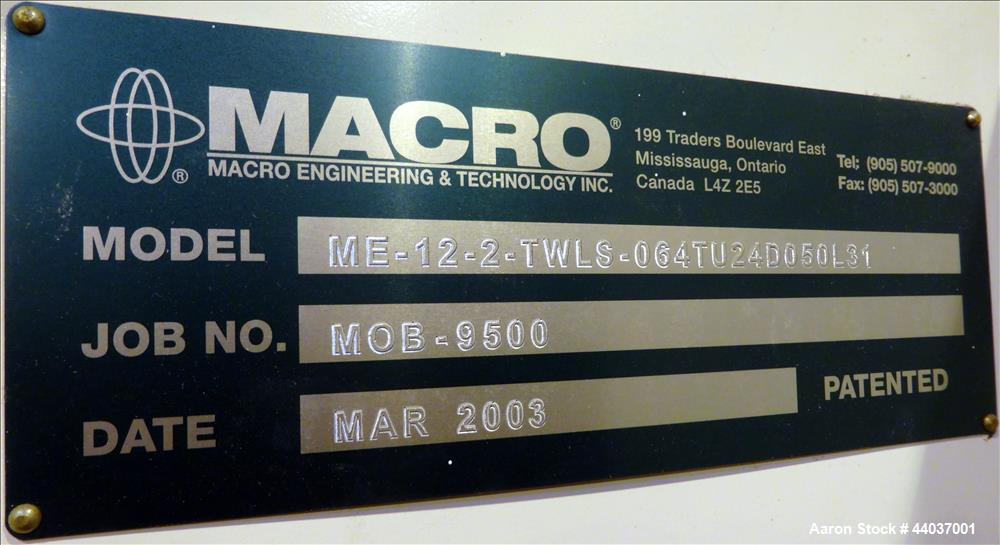

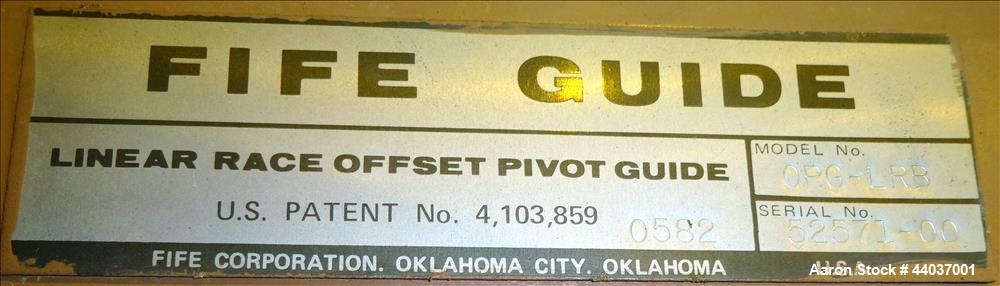

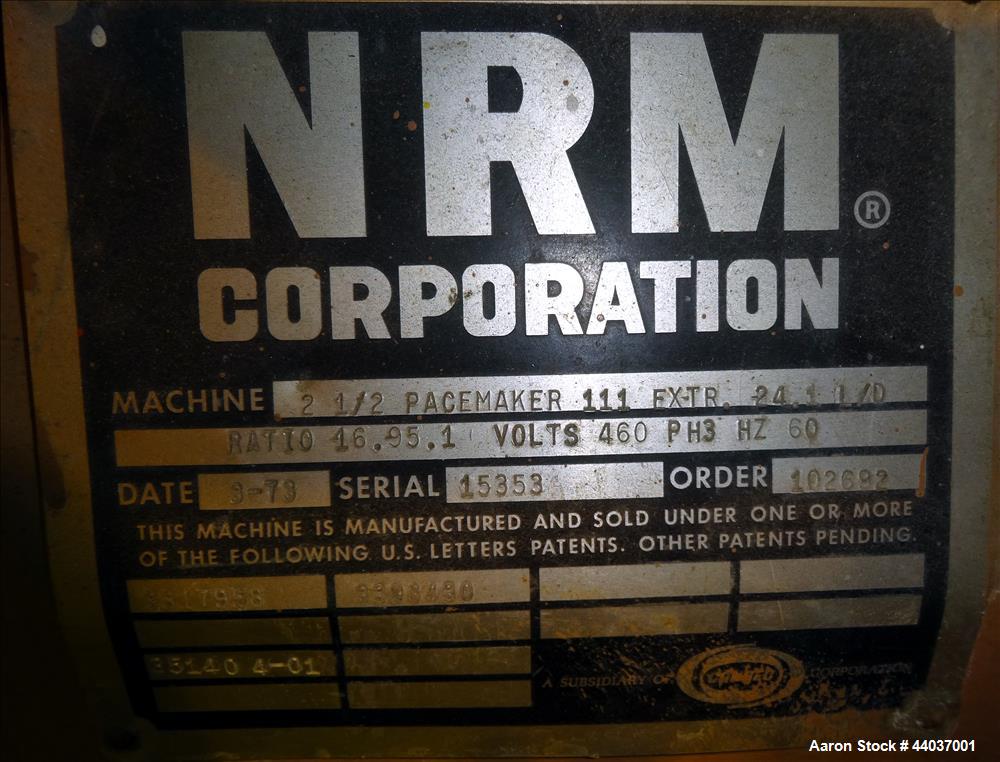

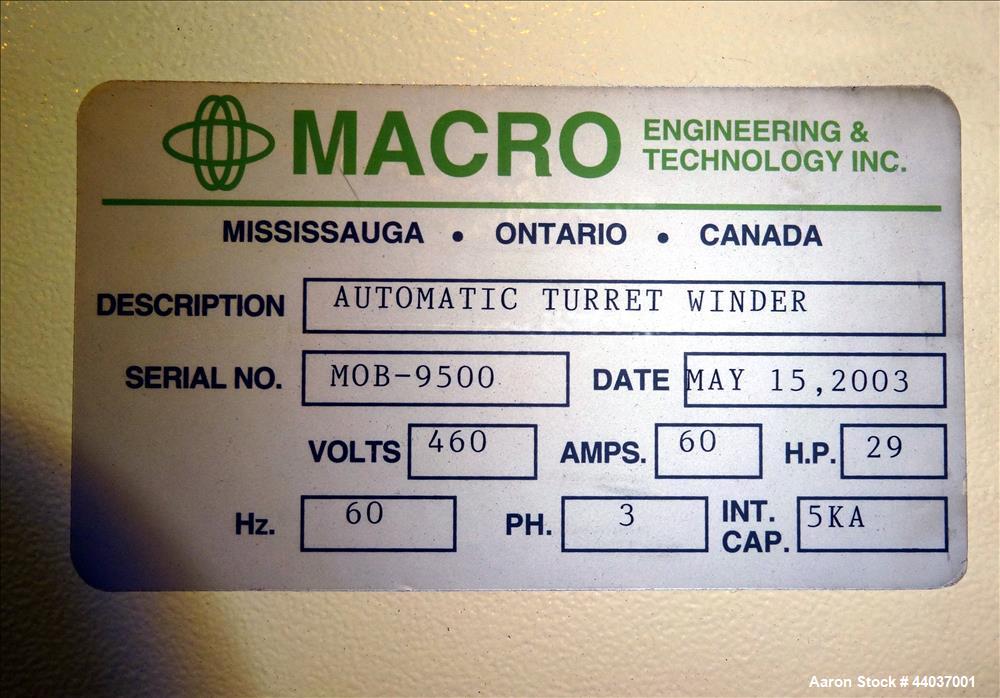

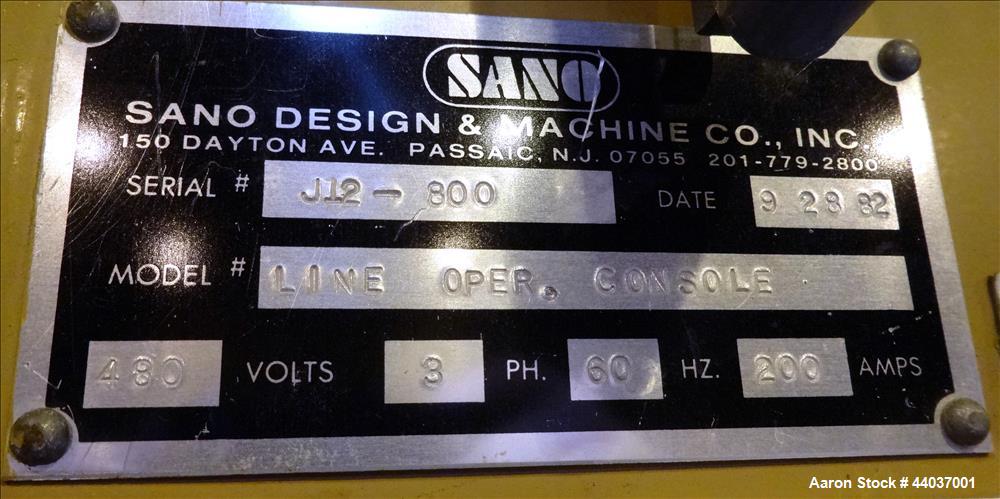

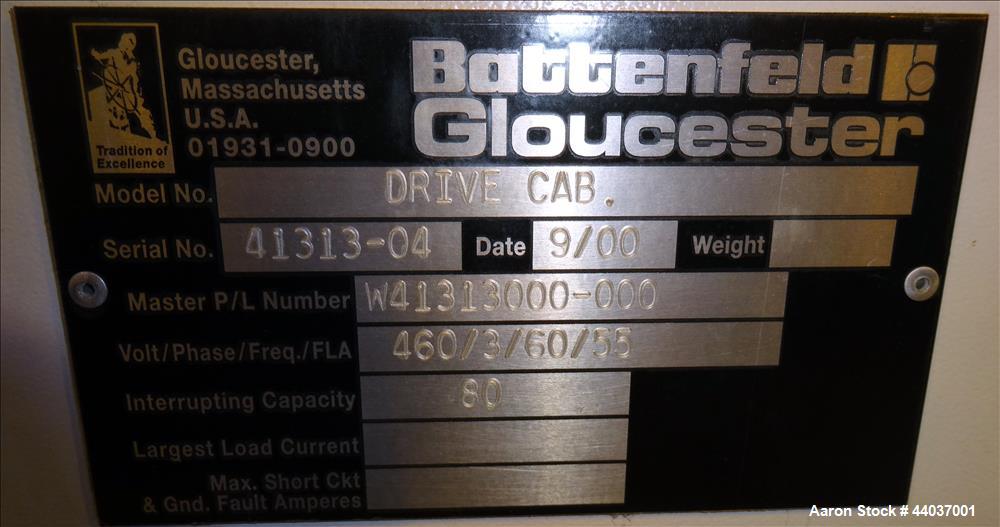

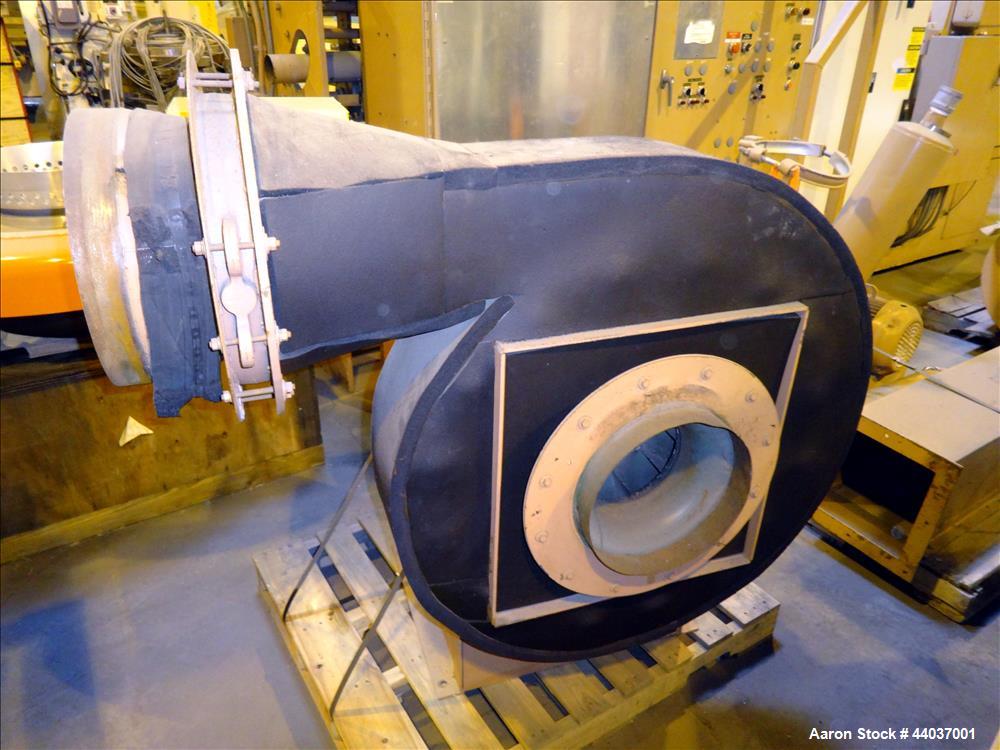

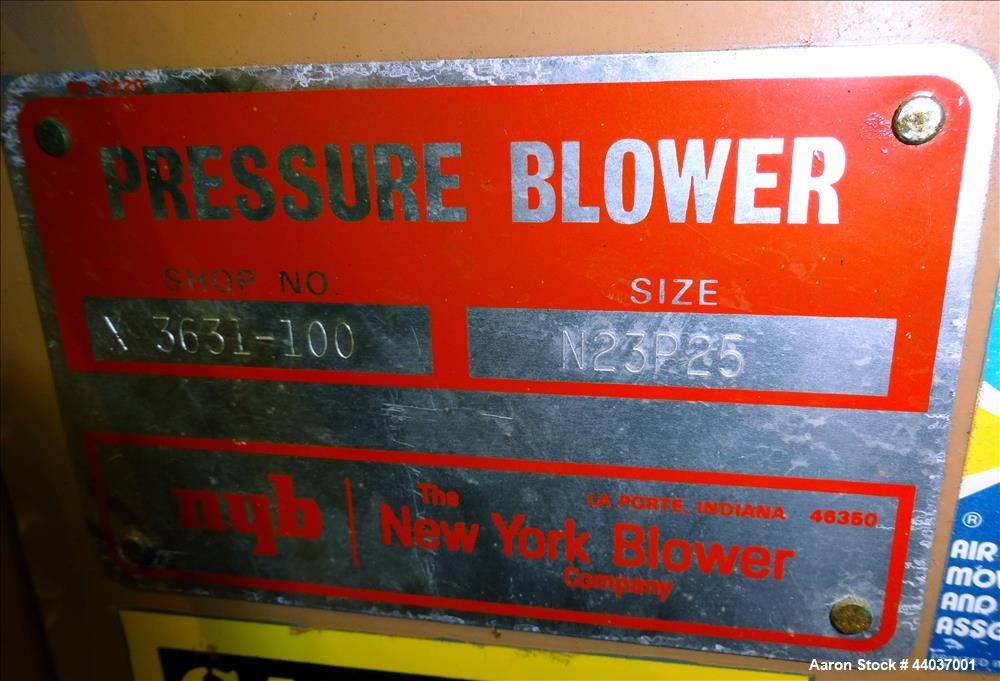

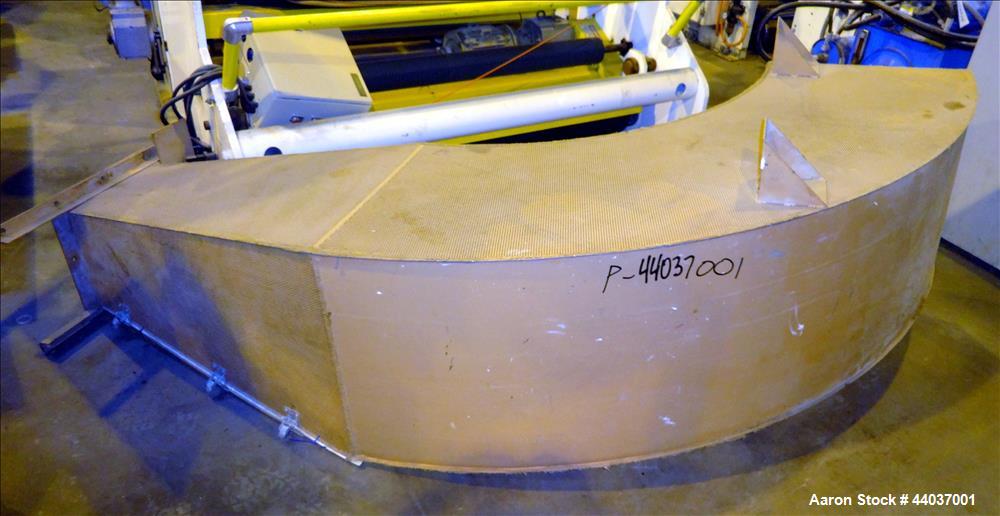

Used Sano Blown Film Co-Extrusion Line. Designed to make multi-layer thin film less than 10 mils thick, and 60" wide. Line consisting of: (1) Davis Standard System 201 Thematic II 3-1/2" single screw extruder, model 35IN35DSPA/W24, SO# 95620, serial# H8888, built 1982. 5 Zone non-vented barrel electrically heated, water cooled, approximate 24 to 1 L/D ratio, with a hydraulic screen changer. Driven by an approximate 124 hp DC motor thru a gearbox, ratio 17.39 to 1. (1) NRM Pacemaker III 2-1/2" single screw extruder, serial#15353, built 1973. 4 Zone non-vented barrel electrically heated, water cooled, approximate 24 to 1 L/D ratio, with hydraulic screen changer. Driven by a 40 hp DC motor thru a gearbox, ratio 16.95 to 1. (2) Battenfeld 4 color feeders for the extruders, (1) hydraulic power pack for the screen changers. (1) diverter block assembly, (1) Sano 10-14" combination 3 layer co-extrusion blown film die, model FAIXED Block 3 Layer 24CH, serial# 12-1369-33, built 1987. (1) Macro air ring, (1) Future Design air ring, model SAT-11-1001, serial# 98-4638-1001 MP. (1) Sano 10" to 40" bubble sizing cage, serial# J12-800, built 1982. (2) Sections of cooling conveyor. (2) Macro nip assemblies. (1) Sano 64" dual treater station, serial# J12-800, built 1982. (1) Macro winder, model ME-12-2-TWLS-064TU24D050L31, 64" wide, Max diameter Roll is 24" or 610mm limited by air shaft capacity (3" Composite Air Shafts -Carbon Fiber), serial# MOB-9500, built 2003. (1) Gemini Plastics slitter/rewind. (1) Cumberland granulator, model 454-GRAN-T/S, serial# 521000-82004. (2) AEC blown film coolers, model BFC-1000H, serial# 82D013, (5) blowers, miscellaneous control panels, die pins, transformers, and parts.

Used Sano Blown Film Co-Extrusion Line. Designed to make multi-layer thin film less than 10 mils thick, and 60" wide. Line consisting of: (1) Davis Standard System 201 Thematic II 3-1/2" single screw extruder, model 35IN35DSPA/W24, SO# 95620, serial# H8888, built 1982. 5 Zone non-vented barrel electrically heated, water cooled, approximate 24 to 1 L/D ratio, with a hydraulic screen changer. Driven by an approximate 124 hp DC motor thru a gearbox, ratio 17.39 to 1. (1) NRM Pacemaker III 2-1/2" single screw extruder, serial#15353, built 1973. 4 Zone non-vented barrel electrically heated, water cooled, approximate 24 to 1 L/D ratio, with hydraulic screen changer. Driven by a 40 hp DC motor thru a gearbox, ratio 16.95 to 1. (2) Battenfeld 4 color feeders for the extruders, (1) hydraulic power pack for the screen changers. (1) diverter block assembly, (1) Sano 10-14" combination 3 layer co-extrusion blown film die, model FAIXED Block 3 Layer 24CH, serial# 12-1369-33, built 1987. (1) Macro air ring, (1) Future Design air ring, model SAT-11-1001, serial# 98-4638-1001 MP. (1) Sano 10" to 40" bubble sizing cage, serial# J12-800, built 1982. (2) Sections of cooling conveyor. (2) Macro nip assemblies. (1) Sano 64" dual treater station, serial# J12-800, built 1982. (1) Macro winder, model ME-12-2-TWLS-064TU24D050L31, 64" wide, Max diameter Roll is 24" or 610mm limited by air shaft capacity (3" Composite Air Shafts -Carbon Fiber), serial# MOB-9500, built 2003. (1) Gemini Plastics slitter/rewind. (1) Cumberland granulator, model 454-GRAN-T/S, serial# 521000-82004. (2) AEC blown film coolers, model BFC-1000H, serial# 82D013, (5) blowers, miscellaneous control panels, die pins, transformers, and parts.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory