Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: [email protected]

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

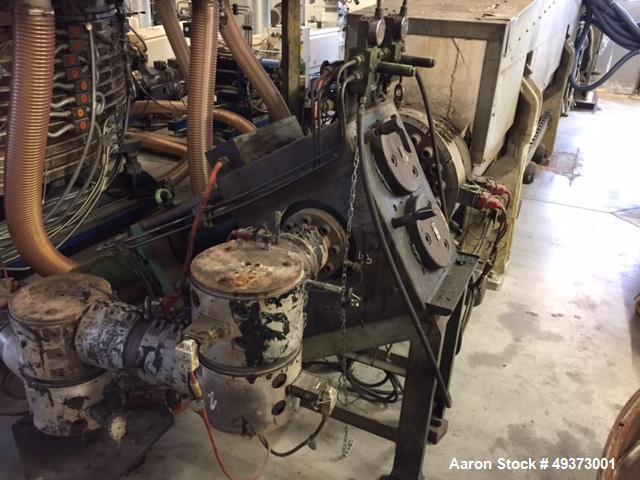

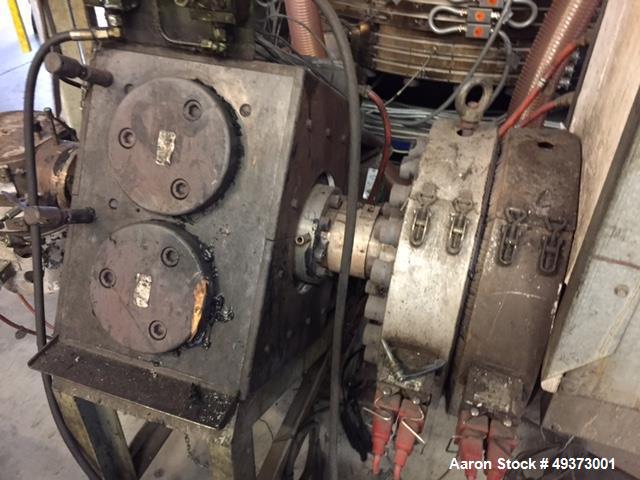

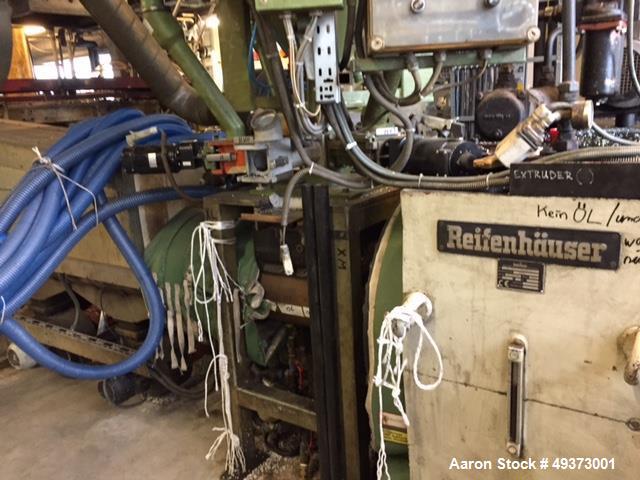

Used Reifenhäuser Gloucester 3 Layer Co-Extrusion Blown Film Line.

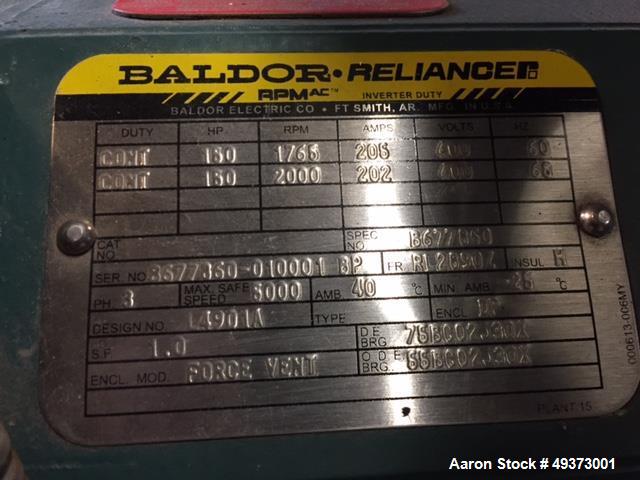

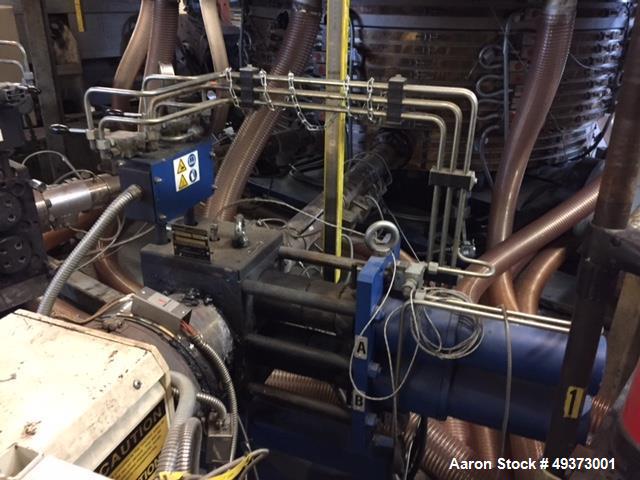

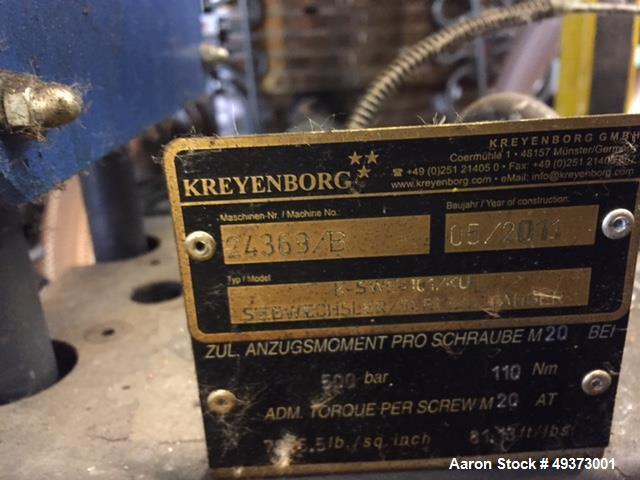

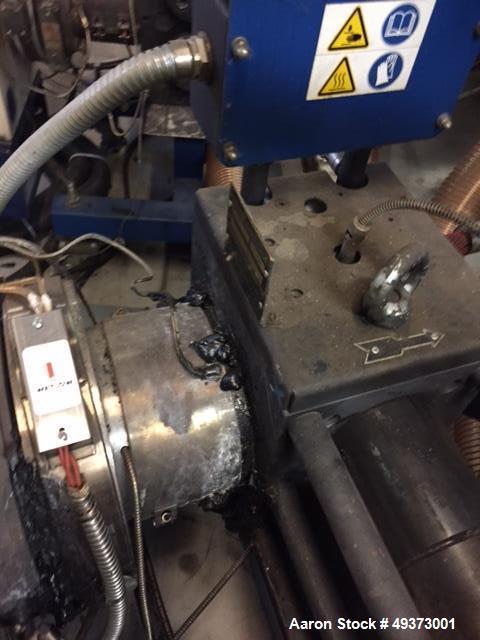

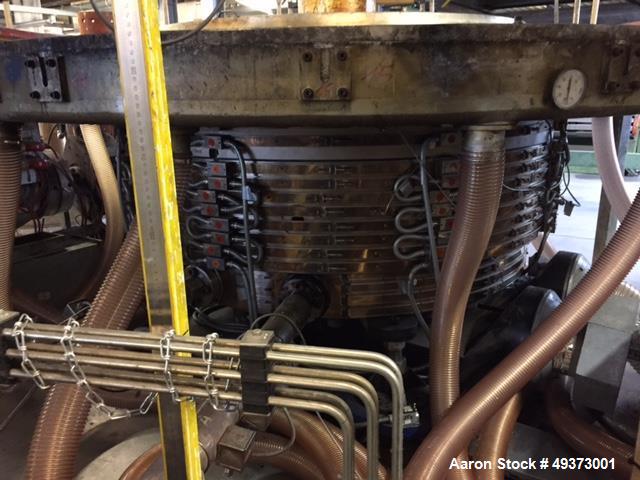

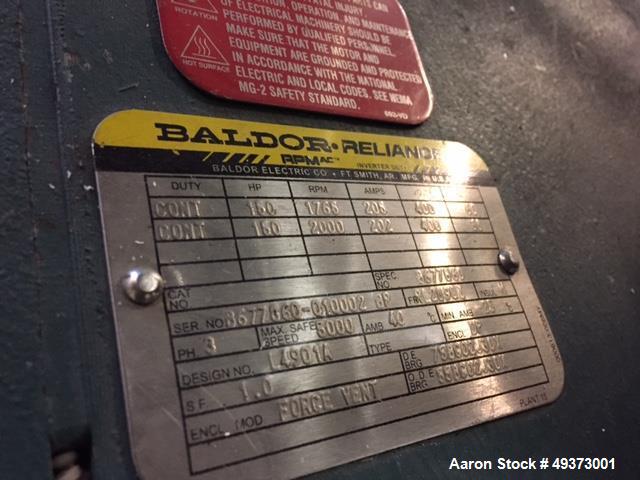

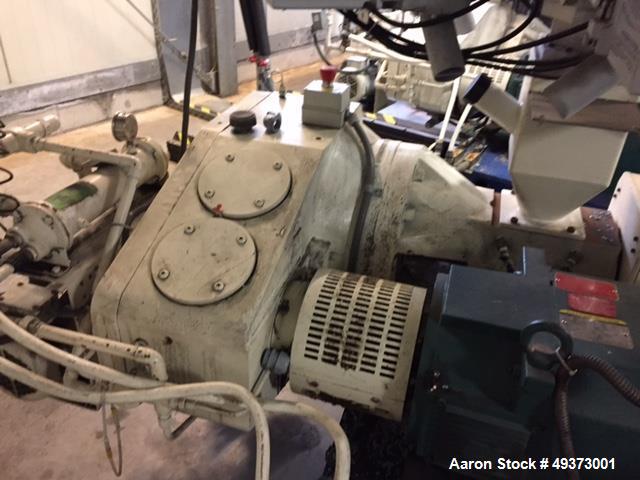

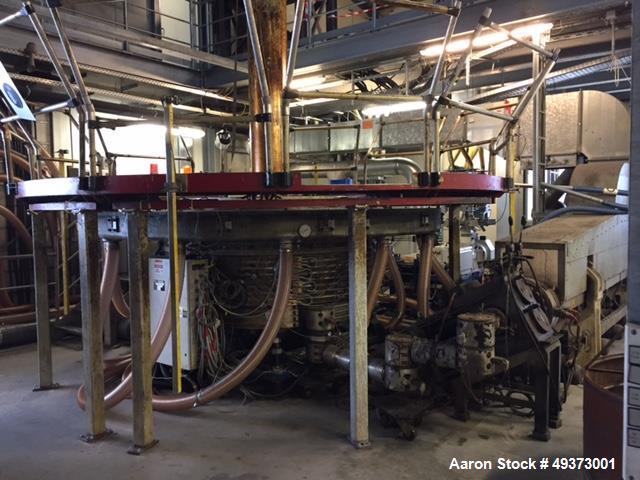

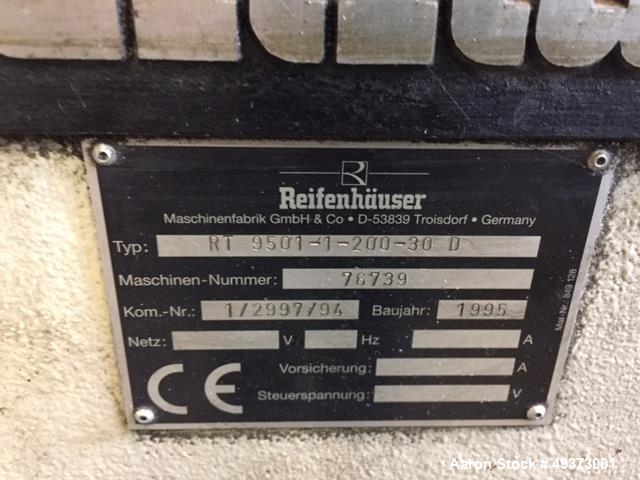

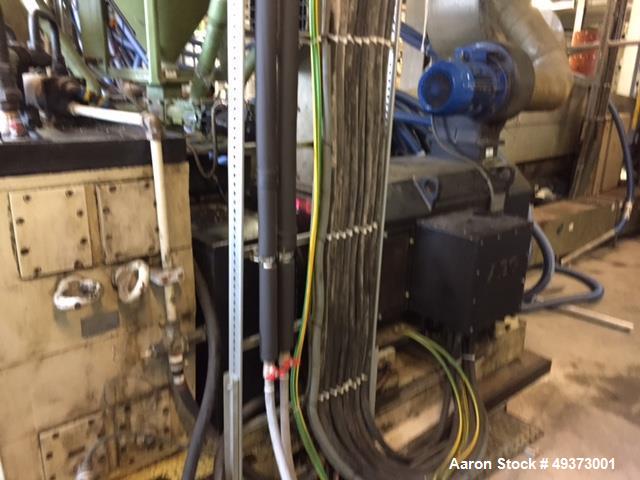

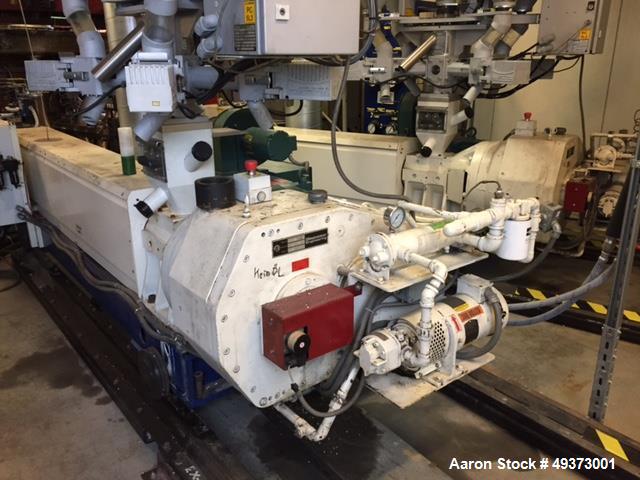

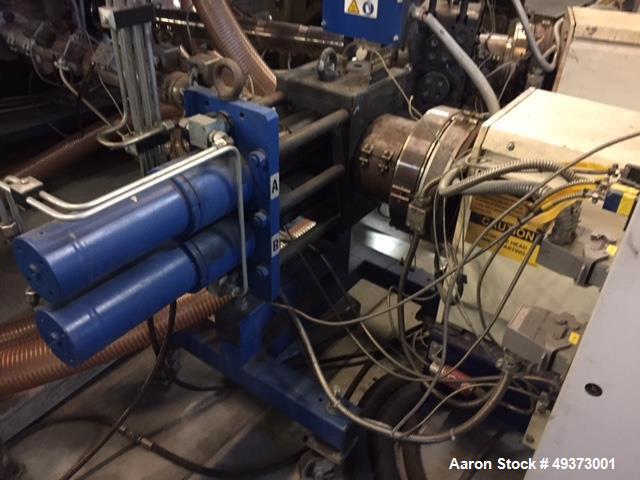

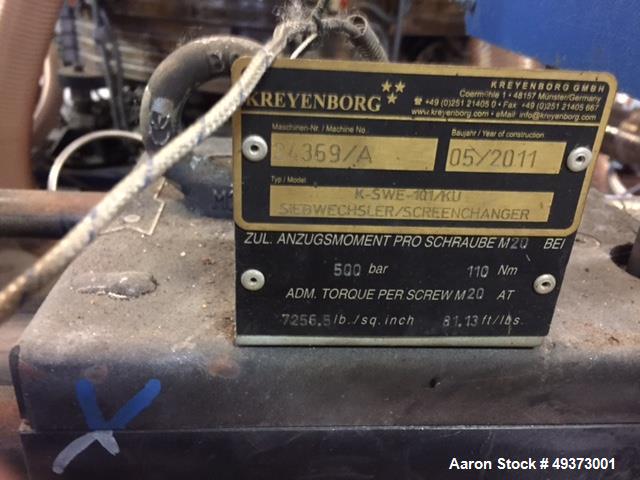

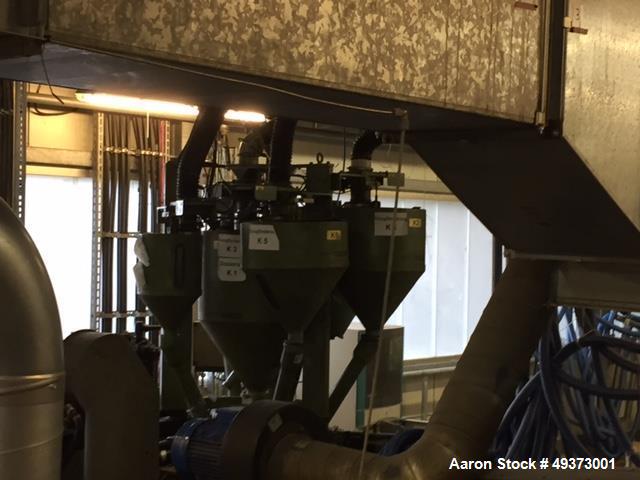

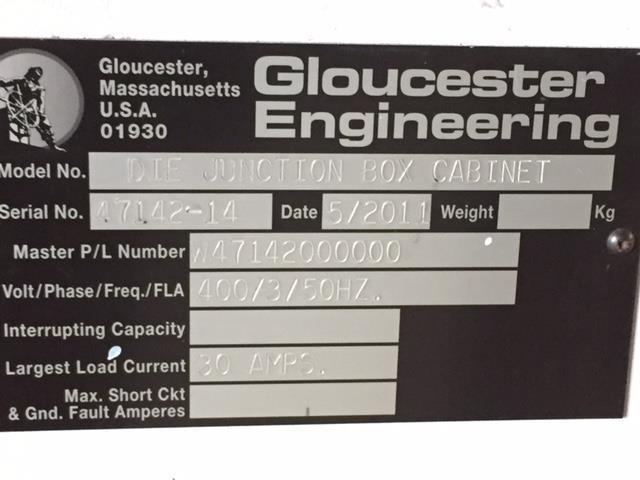

Used Reifenhäuser Gloucester 3 Layer Co-Extrusion Blown Film Line. Designed for Geomembranes with a capacity of 1980-2640 pounds. (900-1200 kgs) per hour consisting of: (2) Gloucester 90 mm (3.5") single screw extruders, Type 90250.R2. 30:1 L/D ratio. non-vented barrel electrically heated, air cooled. Driven via a gearbox by a 180 hp 50/60 cycle motor. (1) Kreyenborg double screen changer, Type K-SWE 101 KV, on wheels. Includes: Plastcontrol feeding system. (1) Reifenhäuser 200 mm (7.8") single screw extruder, type RT 9501-1-200-30D. 30:1 L/D ratio. Non-vented barrel electrically heated, air cooled. Driven via a gearbox/motor. (1) Kreyenborg double screen changer, on wheels. Including: feeding system. (1) 3 Layer extrusion blown film die head designed for structured Geomembranes includes air ring with blower, on wheels. (1) Menzel 156" (4000 mm) width x 31.2" (800 mm) diameter take off winding station. For winding side-gusseted film tubes up to 156" (4000 mm) winding width. 3" (76.9 mm) and 6" (152 mm) cores. Maximum roll weight is 2475 pounds (1125 kgs). (1) Menzel 234" (6000 mm) width x 31.2" (800 mm) diameter take off winding. Core diameter 6" (152 mm). For all flat laying membrane products up to 234" (6000 mm) width. Center cut available for e.g. 2 x 117" (2 x 3000 mm) width or 78" + 156" (2000 + 4000 mm) width Maximum roll weight is 5940 pounds (2700 kgs). Includes (1) Flexoprint 1 color printer, (1) EBS black and white ink jet, Inside and outside film cooling. Includes control panels and further infrastructure. New year 1980/2011/2012.

"Dealing with Aaron is an easy and enjoyable process"

"Aaron Equipment is always my first call for used process equipment. Their inventory and customer service has ensured successful project results every time. Thanks y’all!"

"I have purchased all different types of equipment from Aaron Equipment over the last 10 years and have always been 100% happy with not only the equipment but with their customer service!"

"Working with Aaron Equipment Company was as easy as it gets."

"It is a pleasure to work with AEK and I would recommend them as an equipment supplier."

"The partnership we enjoy with Aaron has helped our business to be what it is today – thank you guys!”

"I will definitely use Aaron Equipment in the future."

"Aaron’s customer service indicates that they want long term partnerships and that is something we especially appreciate."

"I really value shopping for used equipment from Aaron Equipment Company because the information they present is accurate, their prices fair and their customer service is the best…Highly recommend."

"This is my first time using Aaron Equipment to purchase equipment. They were easy to work with and things were done quickly and efficiently. I will be a repeat customer when the need arises. This is a trustworthy company that delivers what they advertise."

"I have purchased multiple pieces of equipment through Aaron equipment over the past 15 years. The staff has been very knowledgeable on every request & have spent countless hours ensuring that the equipment I was purchasing met my expectations."

"I have been doing business with Aaron equipment for many years. This year I had the need for some used equipment in a new business Venture. I got in touch with Ryan Davies. I could not be happier with the response and honesty exhibited by him. Dealing with them was a pleasure and everything was as represented. Fair an Honest is how I would describe them."

“Aaron Equipment was very easy to get into contact with and get a price on a un-used chiller they were selling. The process was seamless and very easy on our end and we had the equipment much faster than going out for bid on it to multiple vendors and we able to come in under budget on the project.”

"Aaron Equipment is always my first call for used process equipment. Their inventory and customer service has ensured successful project results every time. Thanks y’all!"

"I have purchased all different types of equipment from Aaron Equipment over the last 10 years and have always been 100% happy with not only the equipment but with their customer service!"

"Working with Aaron Equipment Company was as easy as it gets."

"It is a pleasure to work with AEK and I would recommend them as an equipment supplier."

"The partnership we enjoy with Aaron has helped our business to be what it is today – thank you guys!”

"I will definitely use Aaron Equipment in the future."

"Aaron’s customer service indicates that they want long term partnerships and that is something we especially appreciate."

"I really value shopping for used equipment from Aaron Equipment Company because the information they present is accurate, their prices fair and their customer service is the best…Highly recommend."

Used Reifenhäuser Gloucester 3 Layer Co-Extrusion Blown Film Line. Designed for Geomembranes with a capacity of 1980-2640 pounds. (900-1200 kgs) per hour consisting of: (2) Gloucester 90 mm (3.5") single screw extruders, Type 90250.R2. 30:1 L/D ratio. non-vented barrel electrically heated, air cooled. Driven via a gearbox by a 180 hp 50/60 cycle motor. (1) Kreyenborg double screen changer, Type K-SWE 101 KV, on wheels. Includes: Plastcontrol feeding system. (1) Reifenhäuser 200 mm (7.8") single screw extruder, type RT 9501-1-200-30D. 30:1 L/D ratio. Non-vented barrel electrically heated, air cooled. Driven via a gearbox/motor. (1) Kreyenborg double screen changer, on wheels. Including: feeding system. (1) 3 Layer extrusion blown film die head designed for structured Geomembranes includes air ring with blower, on wheels. (1) Menzel 156" (4000 mm) width x 31.2" (800 mm) diameter take off winding station. For winding side-gusseted film tubes up to 156" (4000 mm) winding width. 3" (76.9 mm) and 6" (152 mm) cores. Maximum roll weight is 2475 pounds (1125 kgs). (1) Menzel 234" (6000 mm) width x 31.2" (800 mm) diameter take off winding. Core diameter 6" (152 mm). For all flat laying membrane products up to 234" (6000 mm) width. Center cut available for e.g. 2 x 117" (2 x 3000 mm) width or 78" + 156" (2000 + 4000 mm) width Maximum roll weight is 5940 pounds (2700 kgs). Includes (1) Flexoprint 1 color printer, (1) EBS black and white ink jet, Inside and outside film cooling. Includes control panels and further infrastructure. New year 1980/2011/2012.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory