Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Dolci Extrusion/Nextrom Technologies Blown Film Line

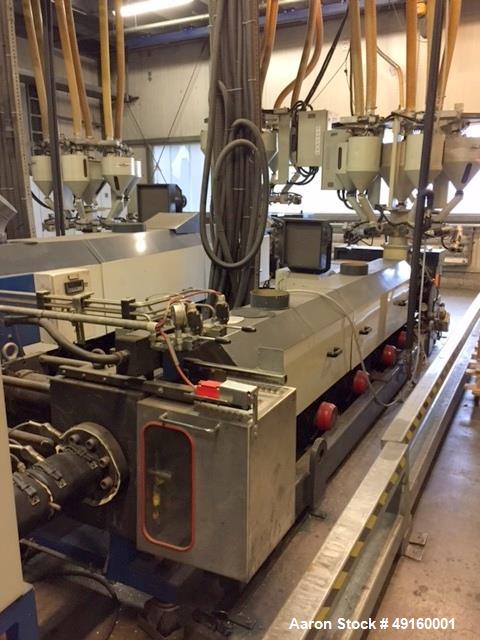

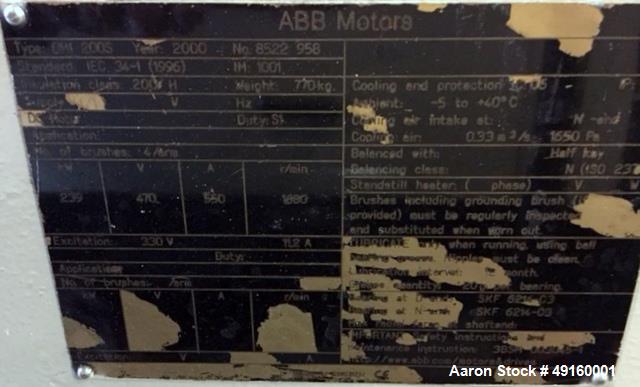

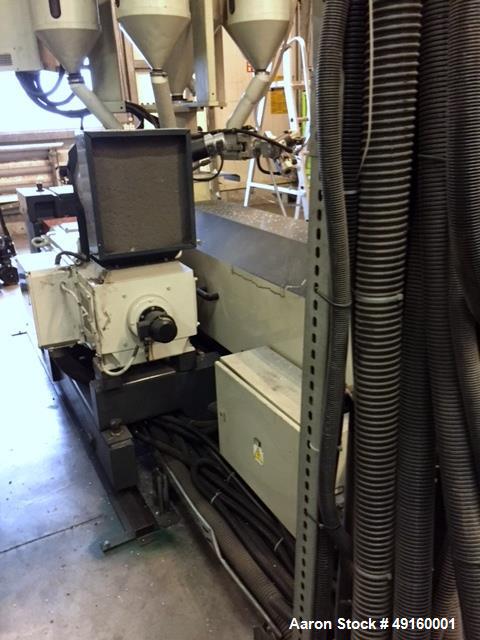

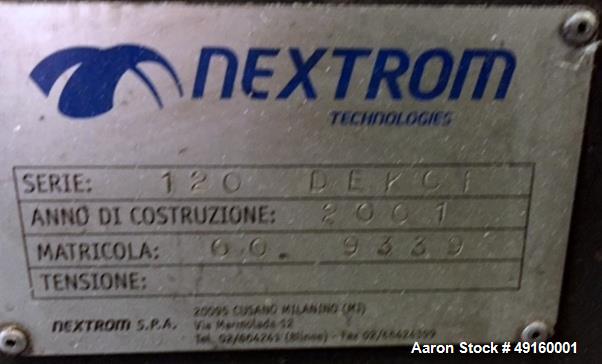

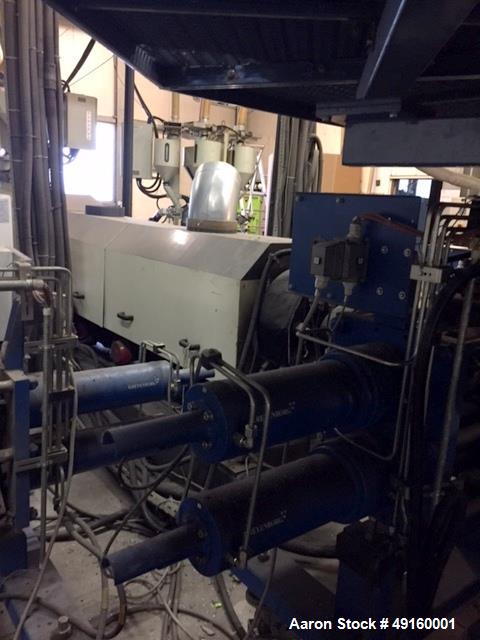

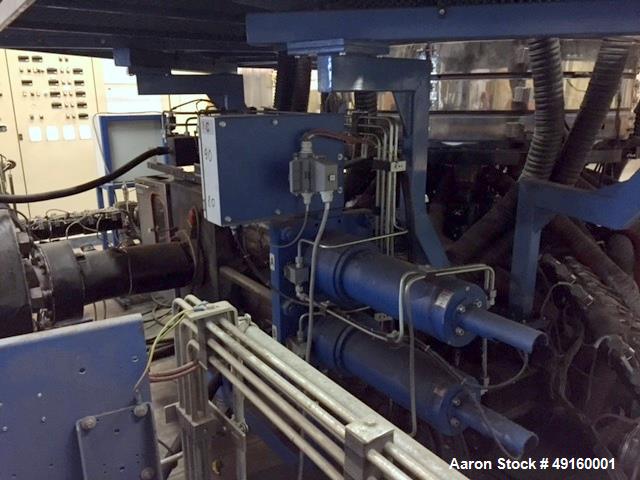

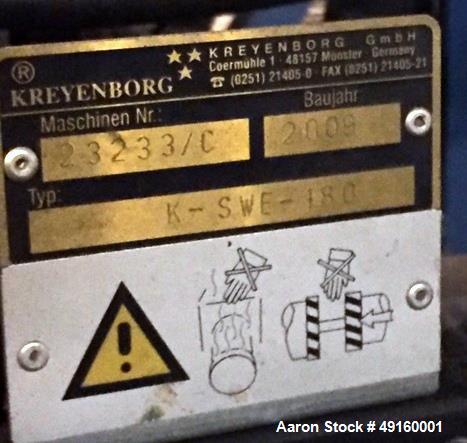

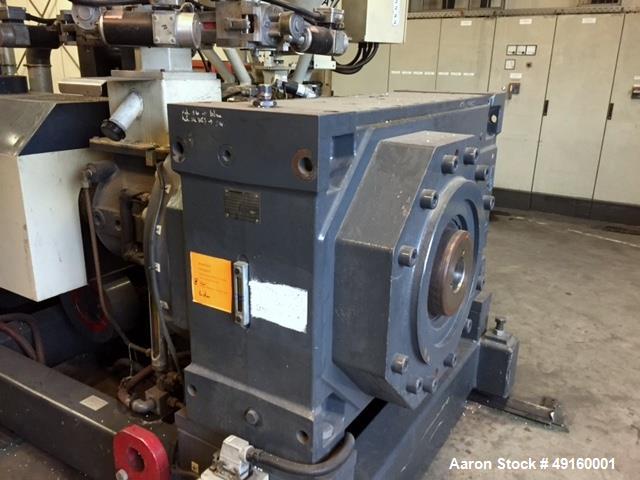

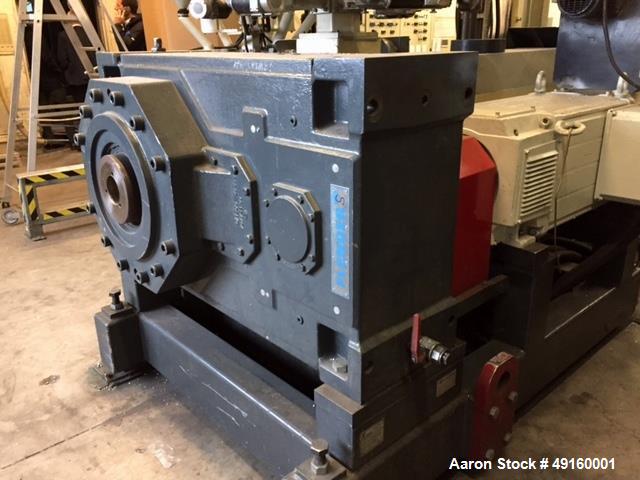

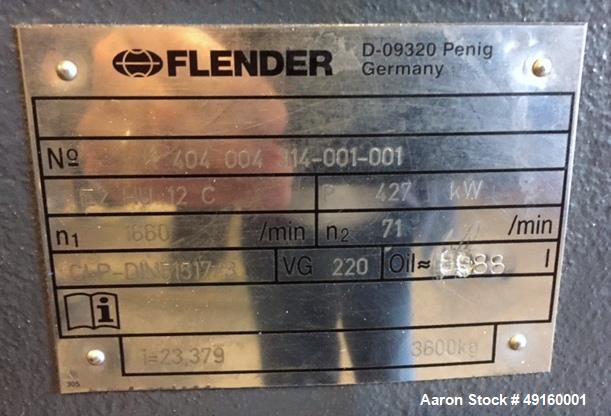

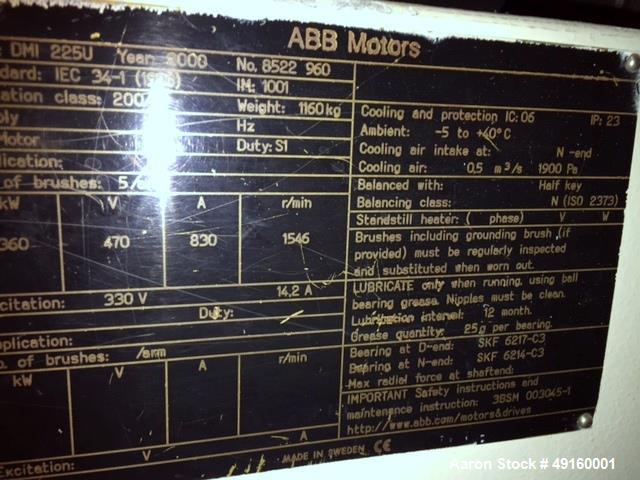

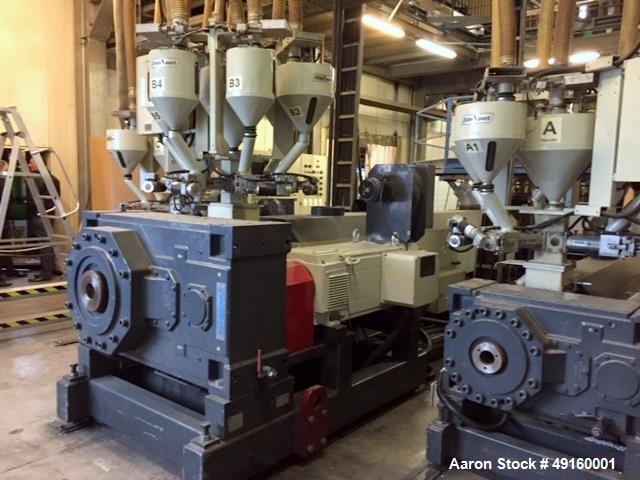

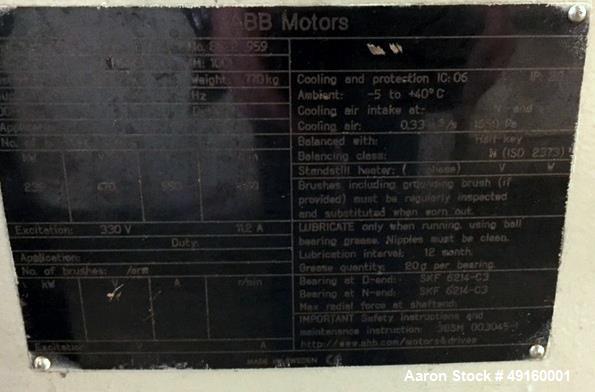

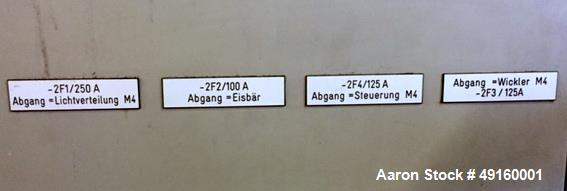

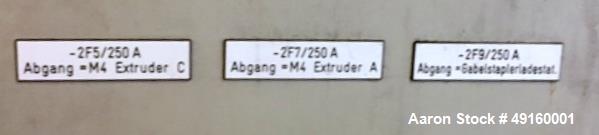

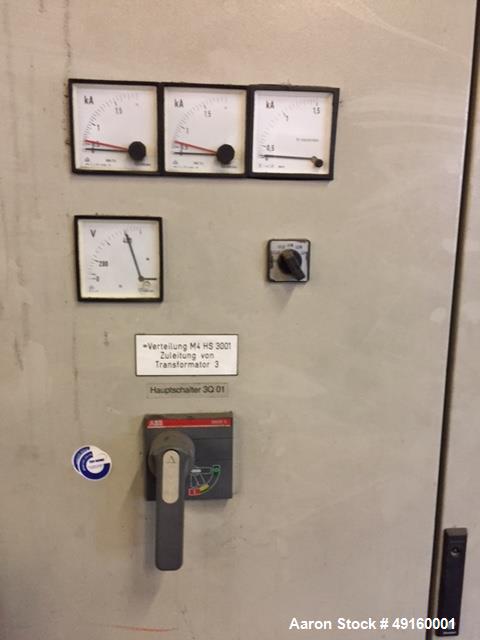

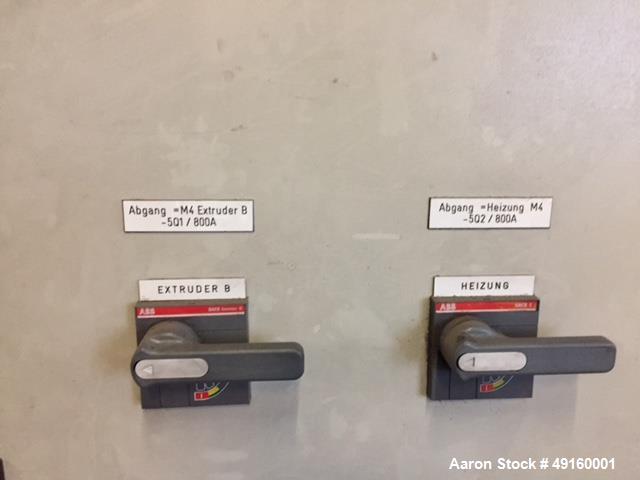

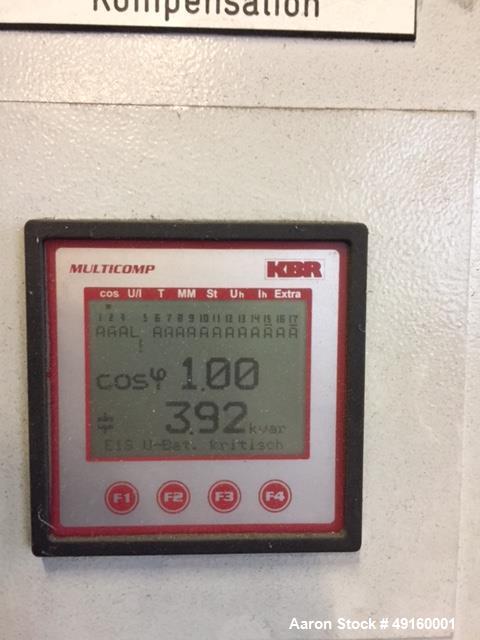

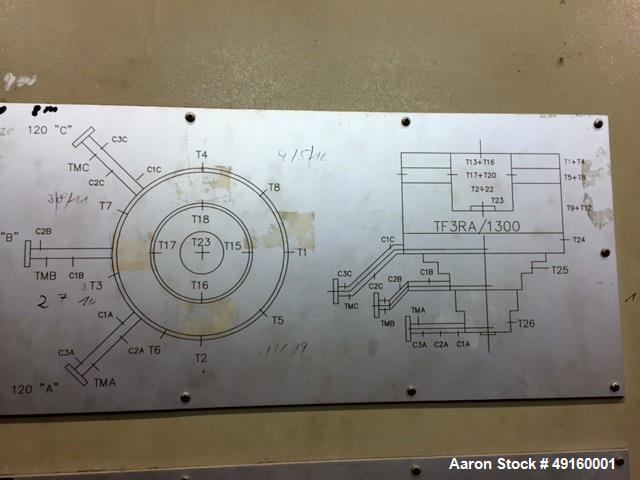

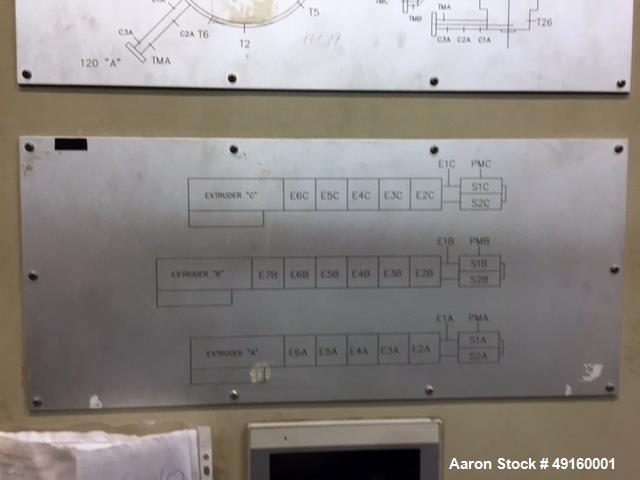

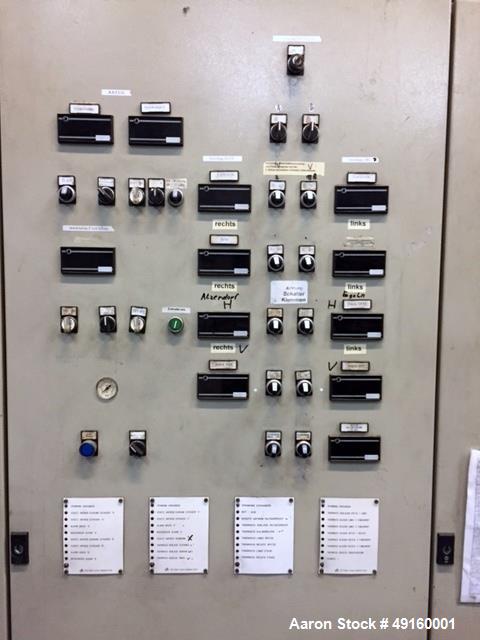

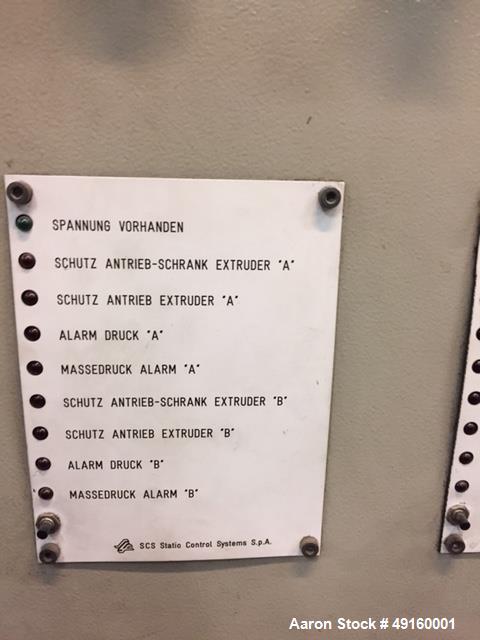

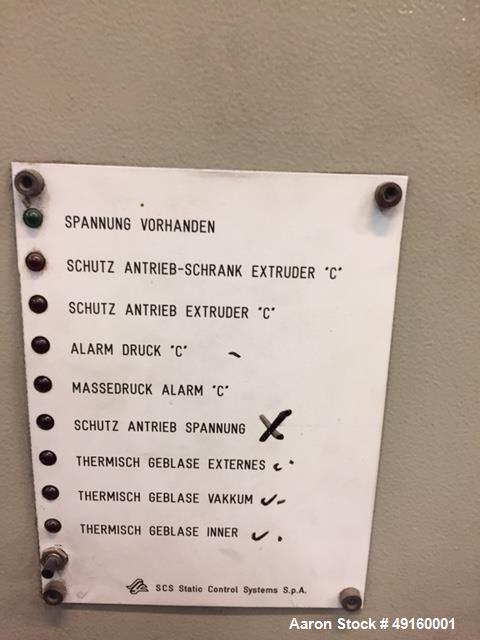

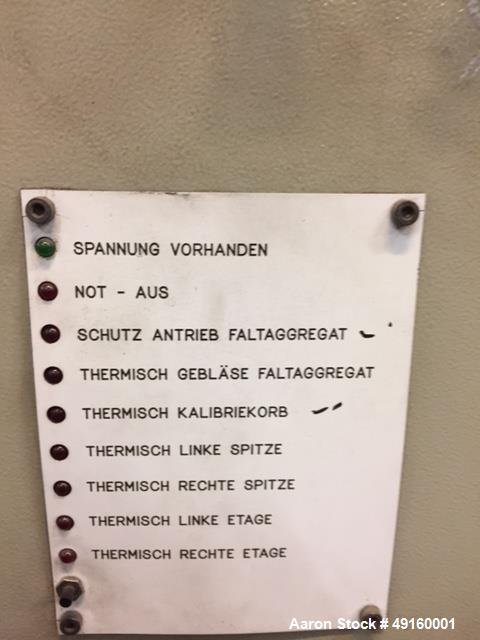

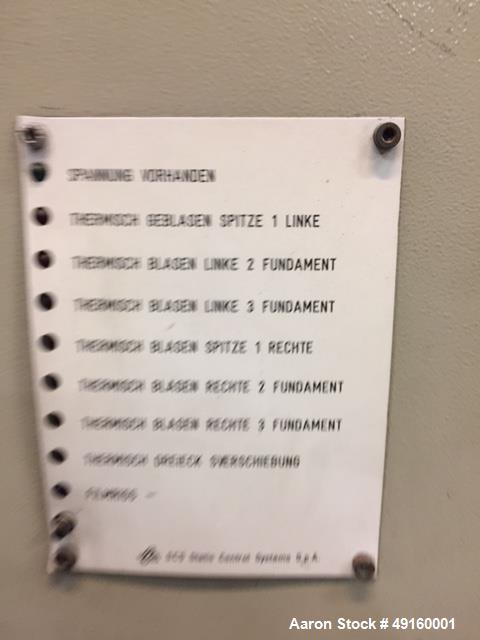

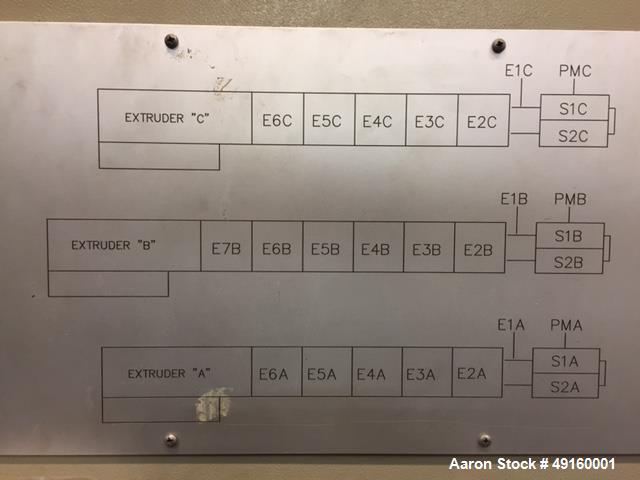

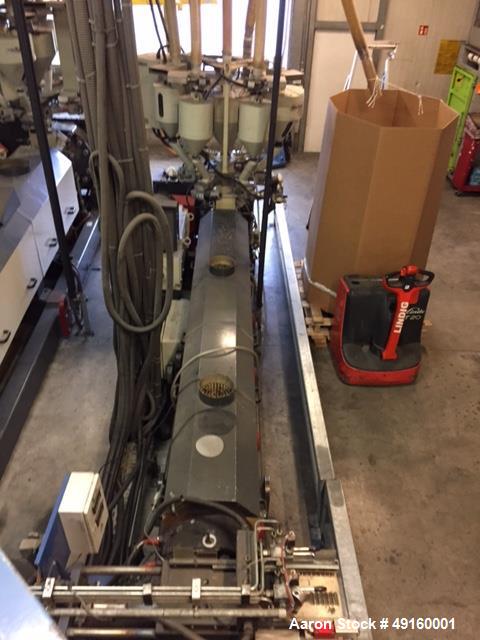

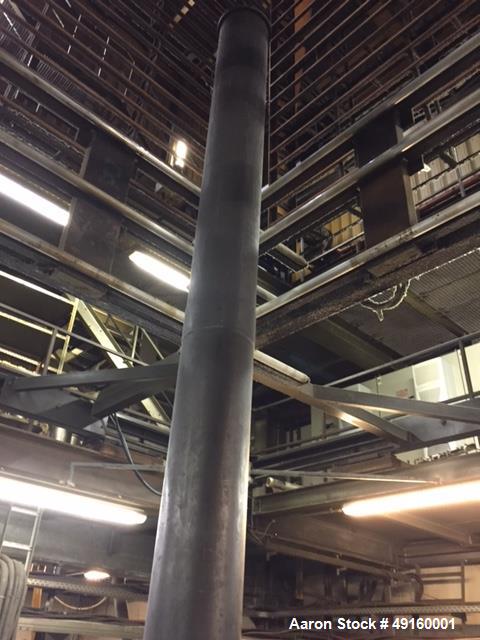

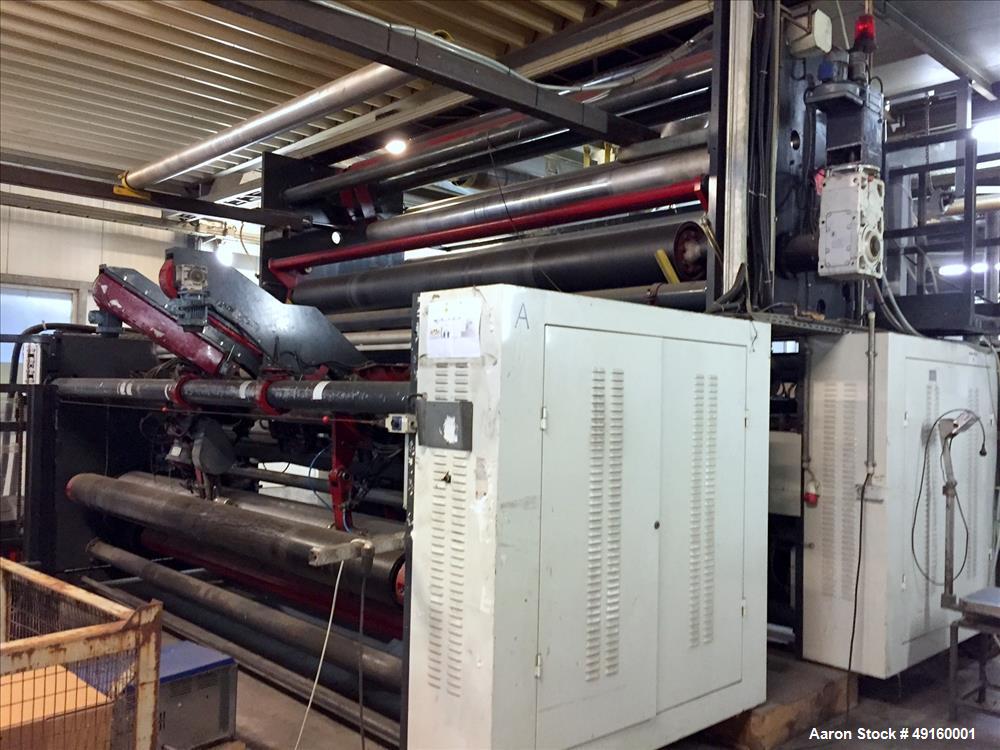

Used Dolci Extrusion/Nextrom Technologies Blown Film Line with a capacity of 2420 lbs. (1100 kgs) per hour consisting of: (2) Dolci Extrusion/Nextrom Technologies 120 mm (4.68") single screw extruders, type 120 DEKCI. 30:1 L/D ratio. 5 Zone non-vented barrel electrically heated, air cooled. Driven via a gearbox by a 239 Kw/358.5 HP, 3/50/470 volt motor. (1) Kreyenborg double screen changer type K-SWE-180, on wheels. (1) AZO-Inno Plast/Film Pert 6 component resin blending feeding system. (1) Dolci Extrusion/Nextrom Technologies 160 mm (6.24") single screw extruder, type 160 DEKCI. D. 30:1 L/D ratio. 6 Zone non-vented barrel electrically heated, air cooled. Driven via a 427 Kw gearbox by a 360 Kw, 3/50/470 volt motor. (1) Kreyenborg double screen changer type K-SWE-180, on wheels. (1) AZO-Inno Plast/Film Pert 6 component resin blending feeding system. (1) Dolci Extrusion blown film die 46.8"/35." (1200 mm/900 mm) diameter, internal double cooling. Includes interchangeable inserts. On wheels (rails),(1) Air ring with blower, (1) manually adjustable iris bubble support ring, (1) height adjustable collapsible frames with nip roll station with a nip width at 159" (4076 mm). (1)Dolci Extrusion/Nextrom Technologies 136.5" (3500 mm) wide take off winding station, 11.7" (300 mm) diameter rolls. Core diameter 2.9" (76 mm). Includes (1) Flexoprint 1 color printer, (1) EBS black and white ink jet, control panels and further infrastructure. New year 2001/2009/2015.

Used Dolci Extrusion/Nextrom Technologies Blown Film Line with a capacity of 2420 lbs. (1100 kgs) per hour consisting of: (2) Dolci Extrusion/Nextrom Technologies 120 mm (4.68") single screw extruders, type 120 DEKCI. 30:1 L/D ratio. 5 Zone non-vented barrel electrically heated, air cooled. Driven via a gearbox by a 239 Kw/358.5 HP, 3/50/470 volt motor. (1) Kreyenborg double screen changer type K-SWE-180, on wheels. (1) AZO-Inno Plast/Film Pert 6 component resin blending feeding system. (1) Dolci Extrusion/Nextrom Technologies 160 mm (6.24") single screw extruder, type 160 DEKCI. D. 30:1 L/D ratio. 6 Zone non-vented barrel electrically heated, air cooled. Driven via a 427 Kw gearbox by a 360 Kw, 3/50/470 volt motor. (1) Kreyenborg double screen changer type K-SWE-180, on wheels. (1) AZO-Inno Plast/Film Pert 6 component resin blending feeding system. (1) Dolci Extrusion blown film die 46.8"/35." (1200 mm/900 mm) diameter, internal double cooling. Includes interchangeable inserts. On wheels (rails),(1) Air ring with blower, (1) manually adjustable iris bubble support ring, (1) height adjustable collapsible frames with nip roll station with a nip width at 159" (4076 mm). (1)Dolci Extrusion/Nextrom Technologies 136.5" (3500 mm) wide take off winding station, 11.7" (300 mm) diameter rolls. Core diameter 2.9" (76 mm). Includes (1) Flexoprint 1 color printer, (1) EBS black and white ink jet, control panels and further infrastructure. New year 2001/2009/2015.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory