Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Douglas Contour Model M-75 Multi-Pack Shrink Bundler capable of speeds up to 75 cycles per minute. Now configured for print registered film, unsupported 8 oz and 11 oz bottles in multiple lanes,...

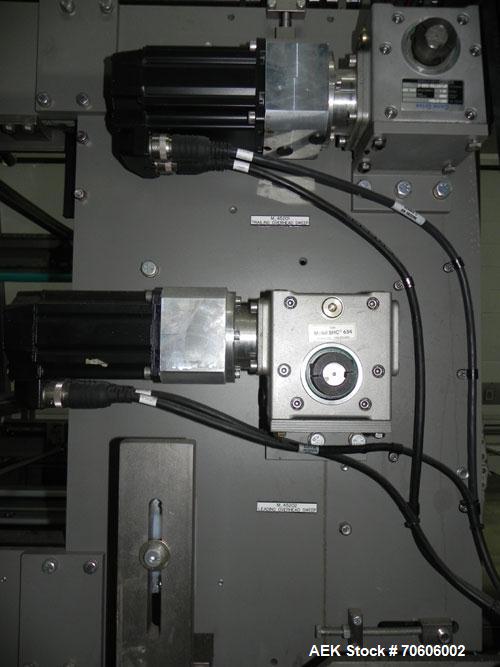

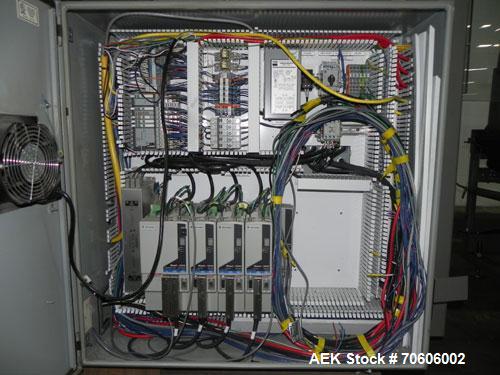

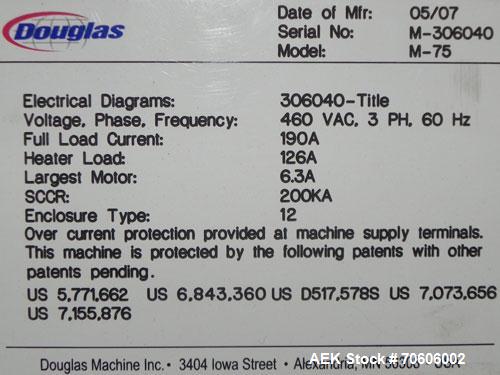

Used Douglas Contour Model M-75 Multi-Pack Shrink Bundler capable of speeds up to 75 cycles per minute. Now configured for print registered film, unsupported 8 oz and 11 oz bottles in multiple lanes, in 2 x 2, 2 x 3, 2 x 4, 3 x 4 and 3 x 5 multi-packs. Machine includes 6 long bottle line infeed transfer to 23 long x 41" wide accumulation and lane separation section (60" overall width), 5 long x 41" wide servo driven metering conveyor, 21 long, 27" belt wide multi-pack grouping section using multiple stage servo driven flight bars and shrink film wrap section (88"overall width), and 21 long x 36" wide belt width, dual zone bottom heat shrink tunnel (81" overall width). System utilizes single roll film application, with inline rotary cutter for multiple bundle lanes, and servo cross cutter. Film roll stand is side mounted and includes two (2) arbors for in-use and spare film rolls plus a powered splice station. Film is print registered, 1.5 3.5 mil, 30" max width. System utilizes Allen Bradley PLC, HMI and Servo drives. 3/60/460V, 90 psi compressed air. 42" (+/- 5" with leveling legs) elevation for infeed and discharge. 71 overall Length, 95" overall width, 100" overall height. Built May of 2007.

- Douglas Contour Model M-75 Multi-Pack Shrink Bundler

- Douglas Contour M-75 Multi-Pack Shrink Bundler

- Douglas Model M-75 Multi-Pack Shrink Bundler

- Douglas Contour Multi-Pack Shrink Bundler

- Douglas M-75 Multi-Pack Shrink Bundler

- Douglas Contour M-75 Shrink Bundler

- Douglas Multi-Pack Shrink Bundler

- Used Packaging Equipment

- Used Packaging Machinery

- Douglas Shrink Bundler

- Douglas Multi-Pack

- Douglas Bundler

- Shrink Bundler

- Douglas M-75

- Douglas

- M-75

Used Douglas Contour Model M-75 Multi-Pack Shrink Bundler capable of speeds up to 75 cycles per minute. Now configured for print registered film, unsupported 8 oz and 11 oz bottles in multiple lanes, in 2 x 2, 2 x 3, 2 x 4, 3 x 4 and 3 x 5 multi-packs. Machine includes 6 long bottle line infeed transfer to 23 long x 41" wide accumulation and lane separation section (60" overall width), 5 long x 41" wide servo driven metering conveyor, 21 long, 27" belt wide multi-pack grouping section using multiple stage servo driven flight bars and shrink film wrap section (88"overall width), and 21 long x 36" wide belt width, dual zone bottom heat shrink tunnel (81" overall width). System utilizes single roll film application, with inline rotary cutter for multiple bundle lanes, and servo cross cutter. Film roll stand is side mounted and includes two (2) arbors for in-use and spare film rolls plus a powered splice station. Film is print registered, 1.5 3.5 mil, 30" max width. System utilizes Allen Bradley PLC, HMI and Servo drives. 3/60/460V, 90 psi compressed air. 42" (+/- 5" with leveling legs) elevation for infeed and discharge. 71 overall Length, 95" overall width, 100" overall height. Built May of 2007.

- Douglas Contour Model M-75 Multi-Pack Shrink Bundler

- Douglas Contour M-75 Multi-Pack Shrink Bundler

- Douglas Model M-75 Multi-Pack Shrink Bundler

- Douglas Contour Multi-Pack Shrink Bundler

- Douglas M-75 Multi-Pack Shrink Bundler

- Douglas Contour M-75 Shrink Bundler

- Douglas Multi-Pack Shrink Bundler

- Used Packaging Equipment

- Used Packaging Machinery

- Douglas Shrink Bundler

- Douglas Multi-Pack

- Douglas Bundler

- Shrink Bundler

- Douglas M-75

- Douglas

- M-75

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory