Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

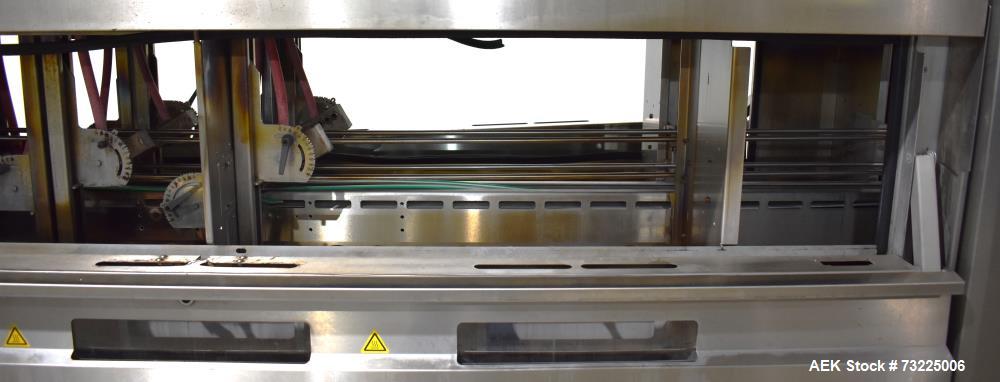

Used Fuji Seal FS400 High-Speed Shrink Sleeve Labeler with Steam Tunnel

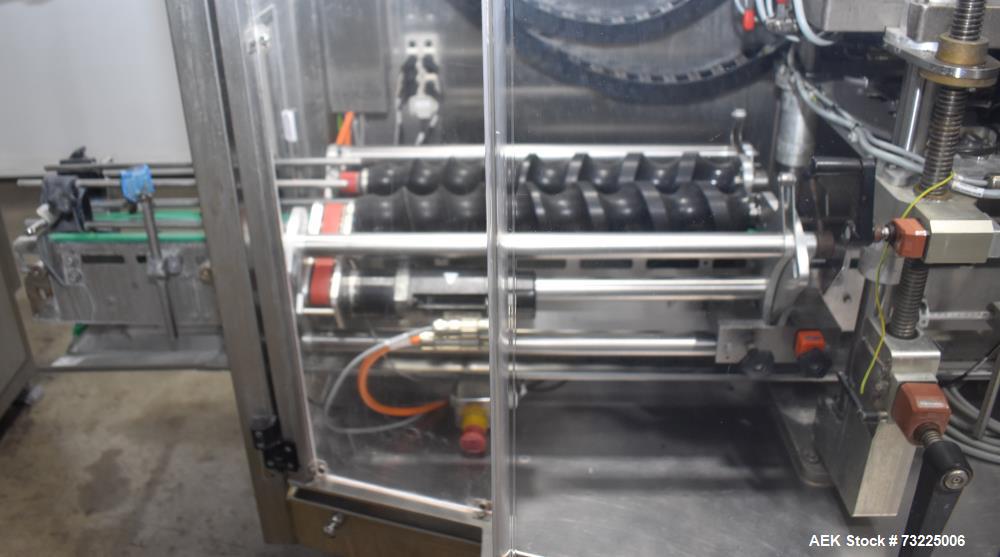

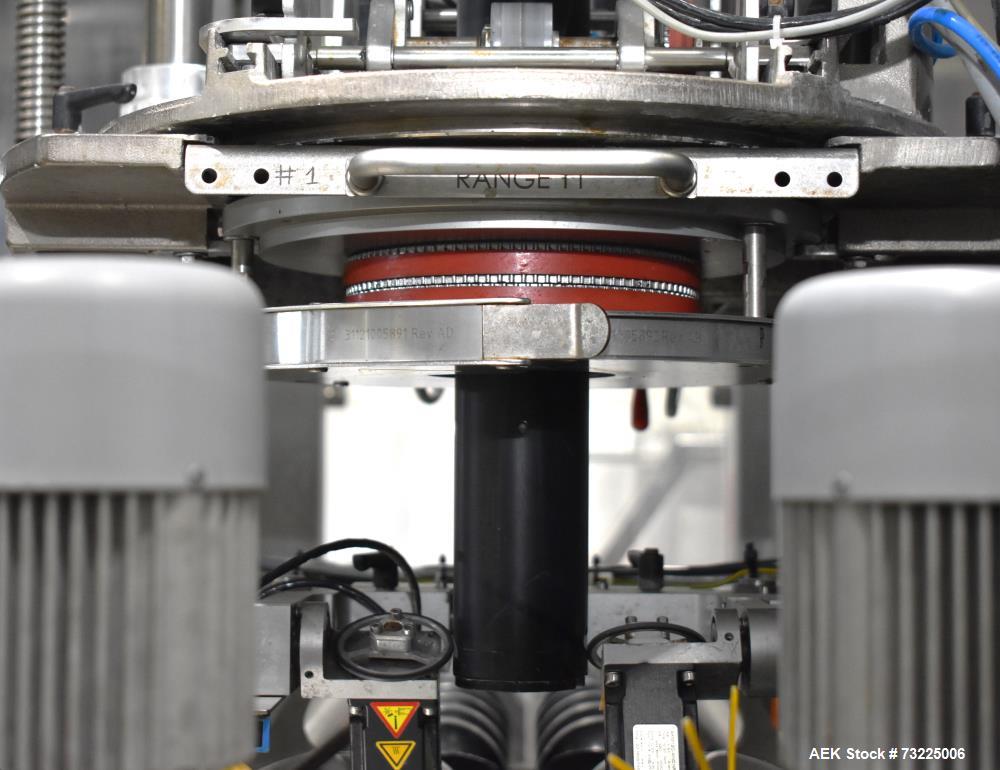

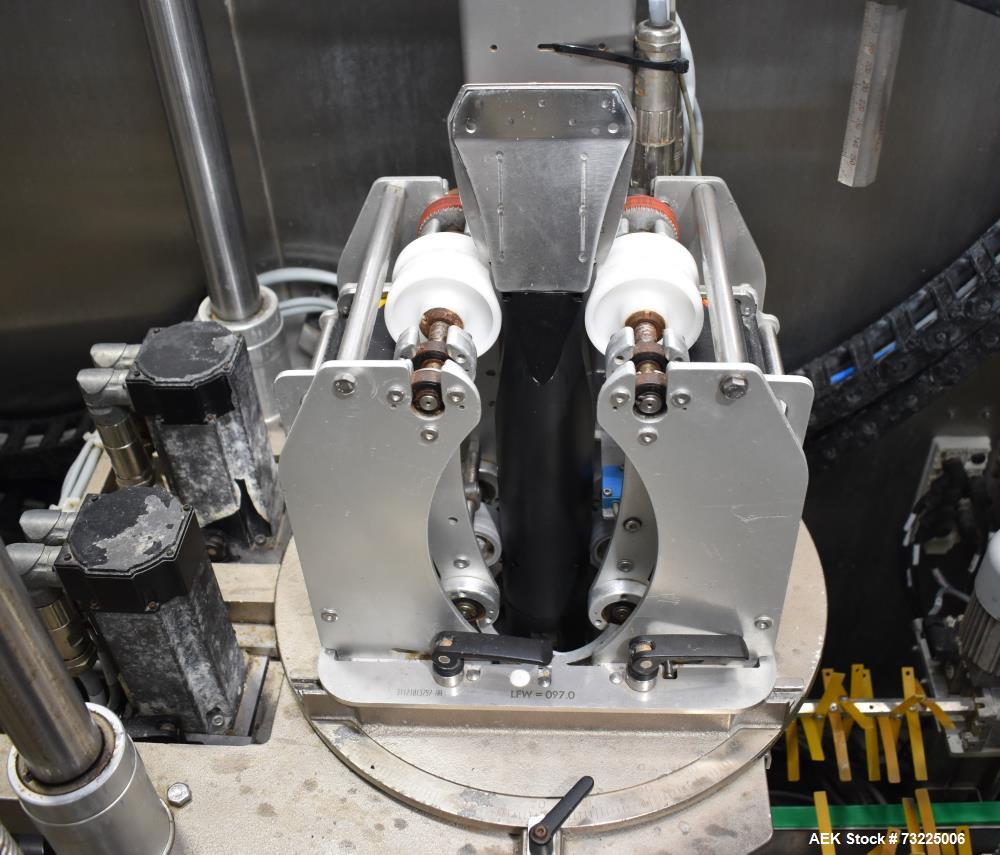

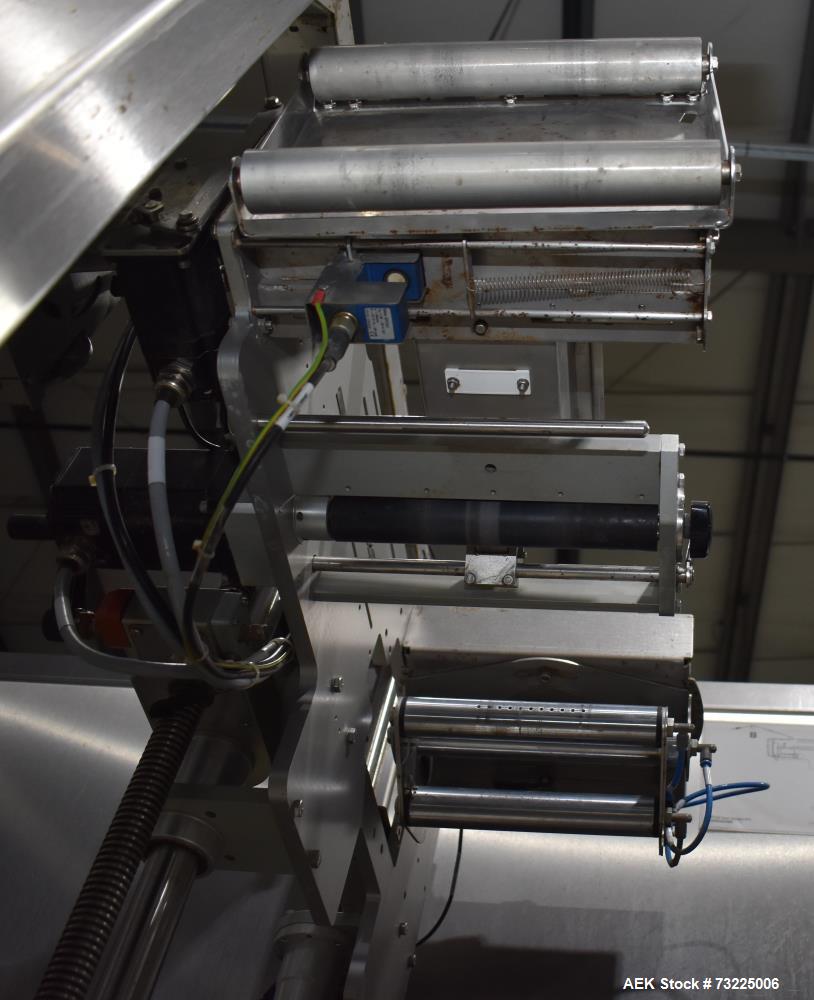

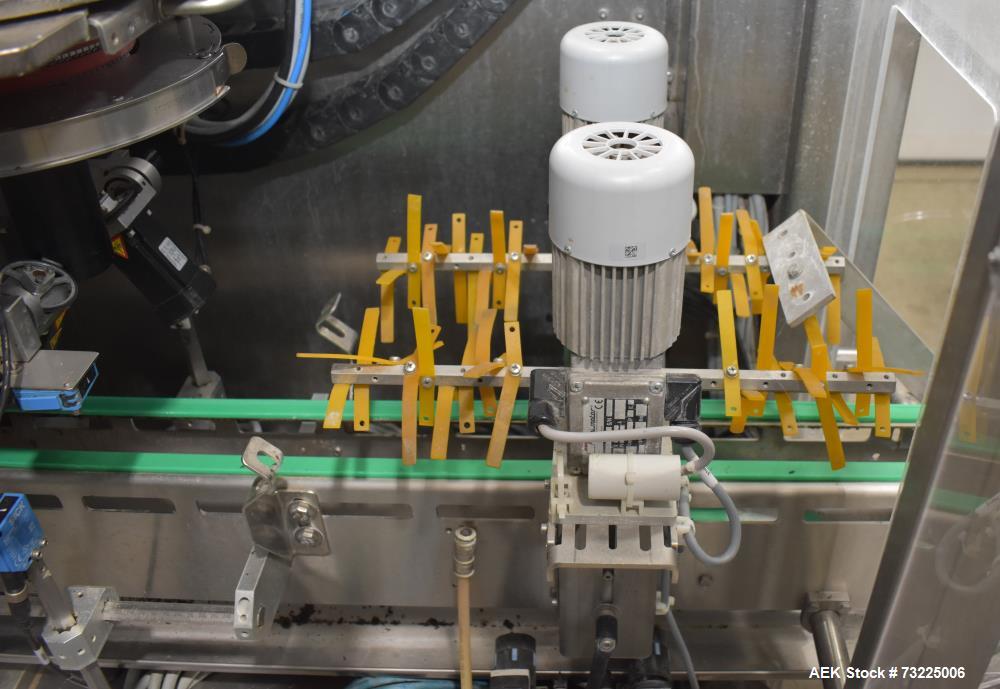

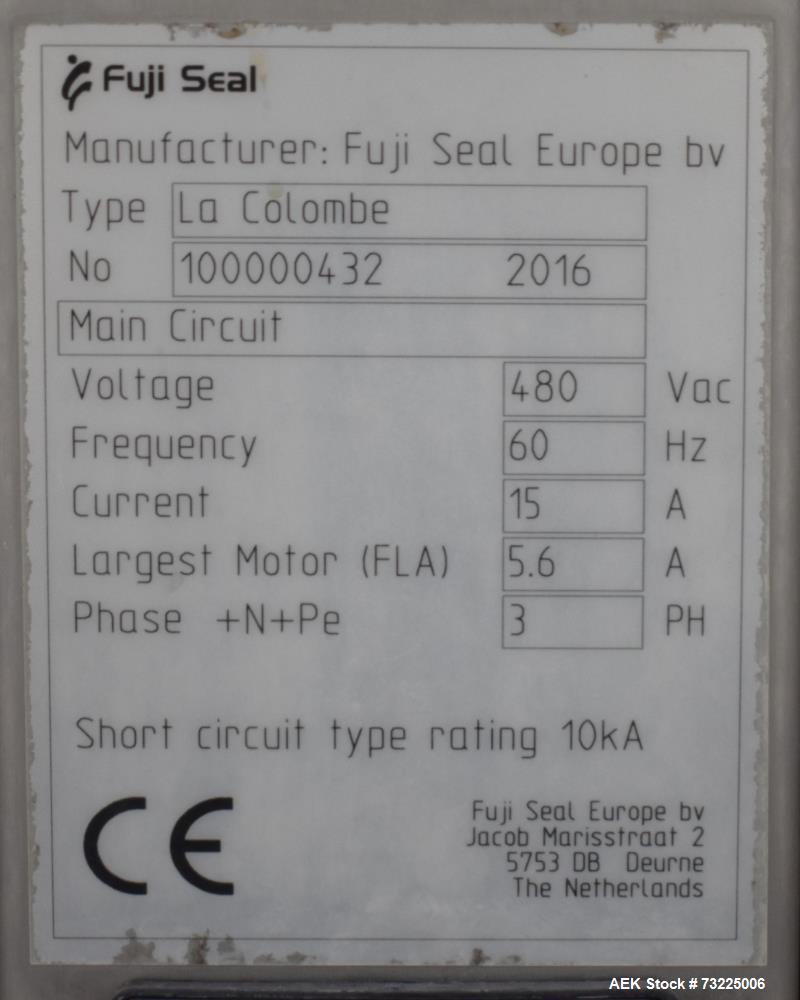

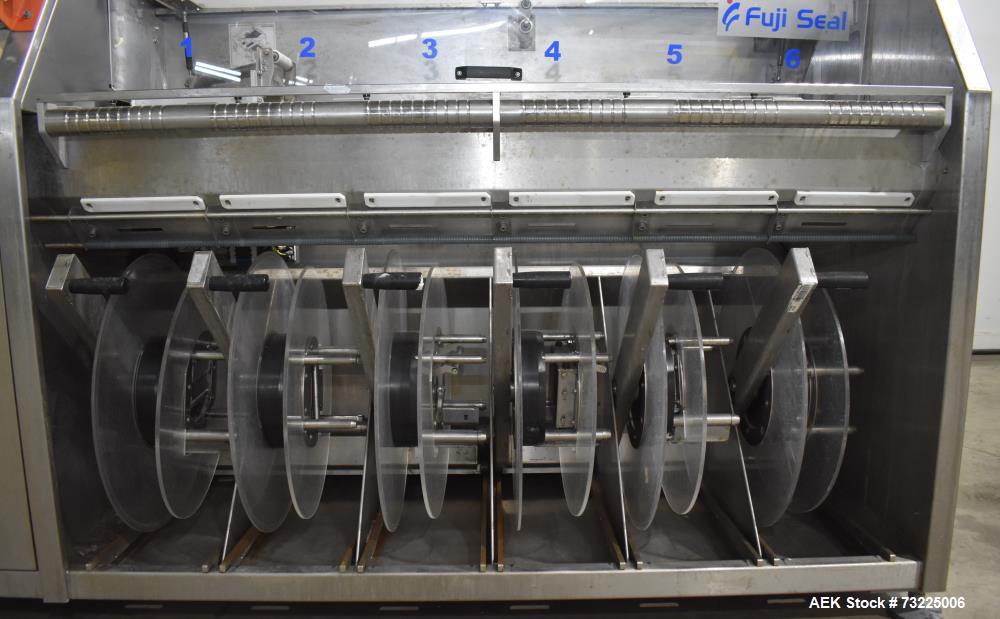

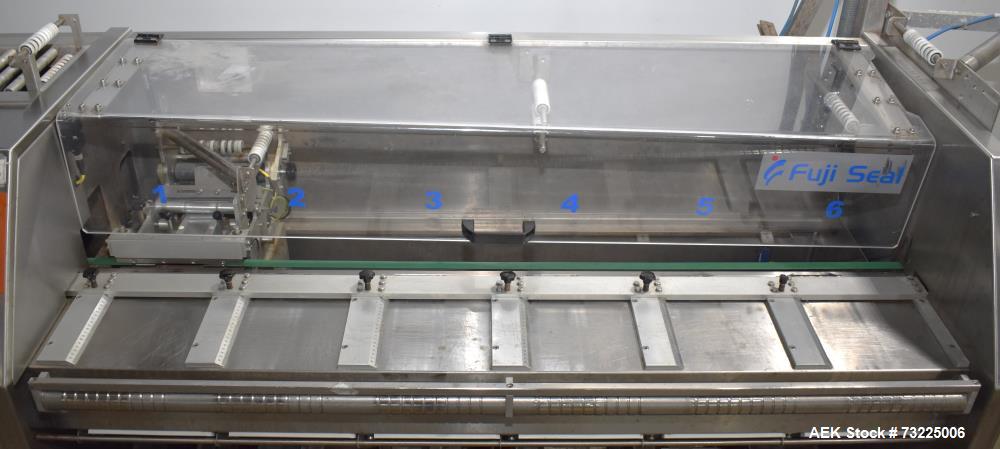

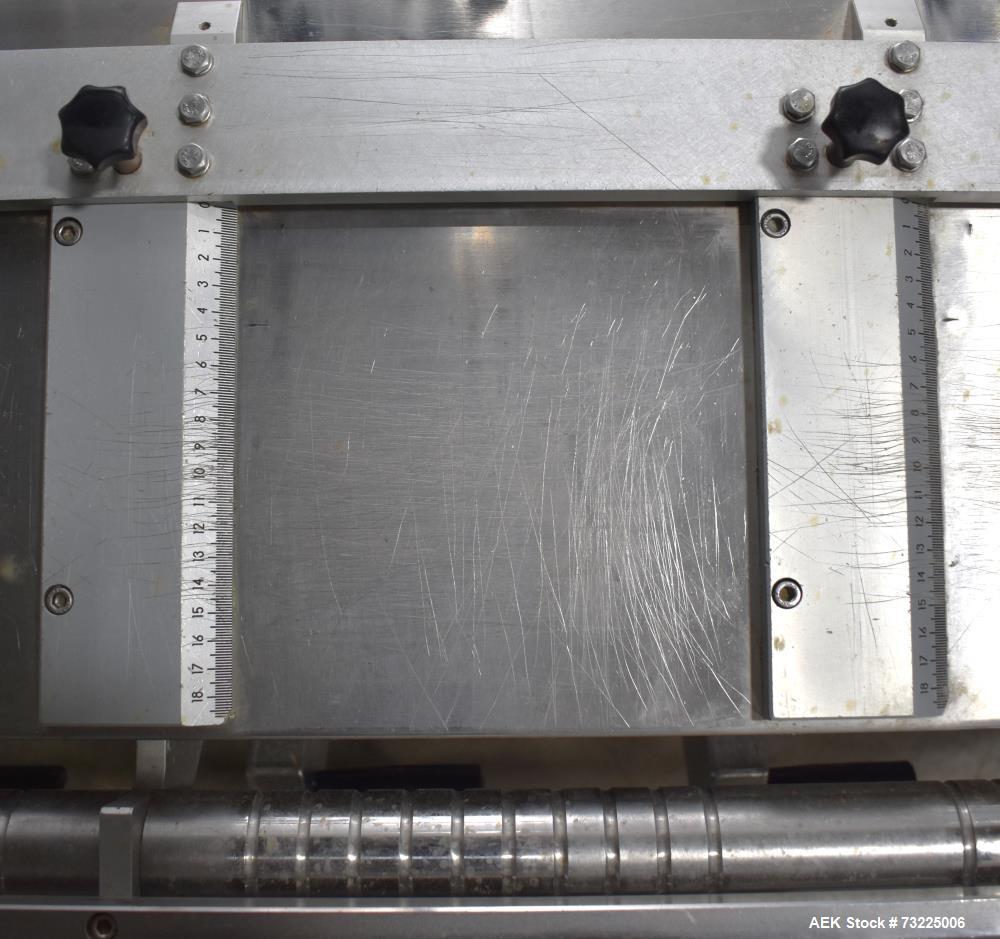

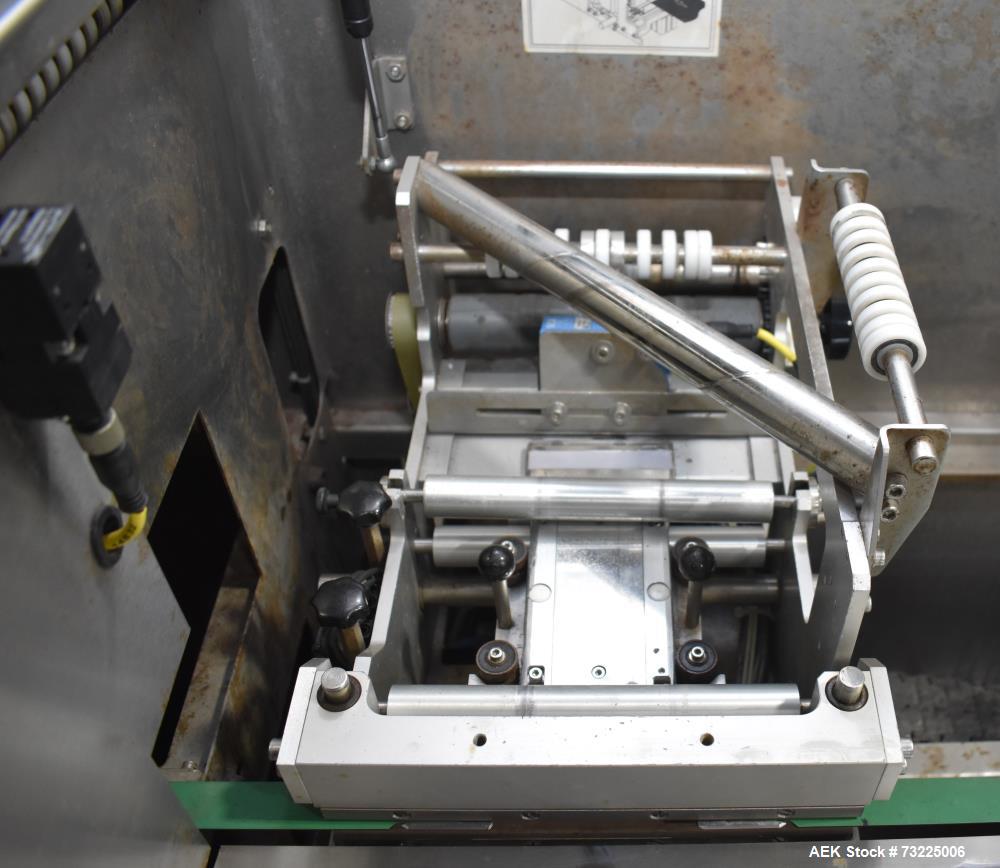

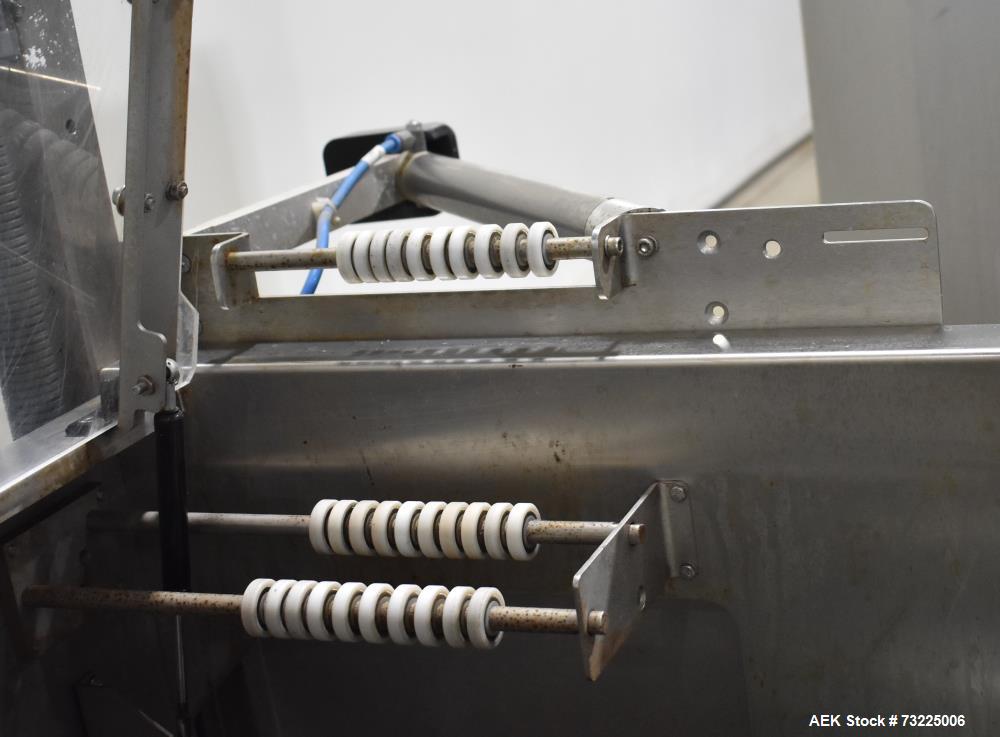

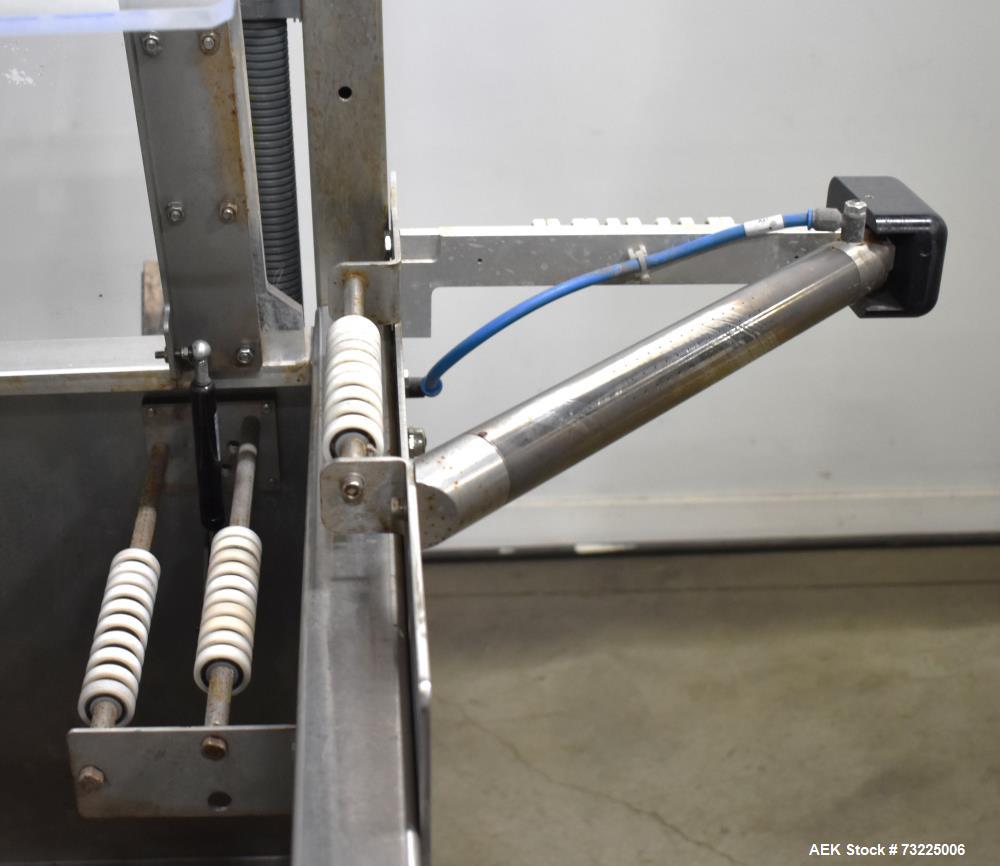

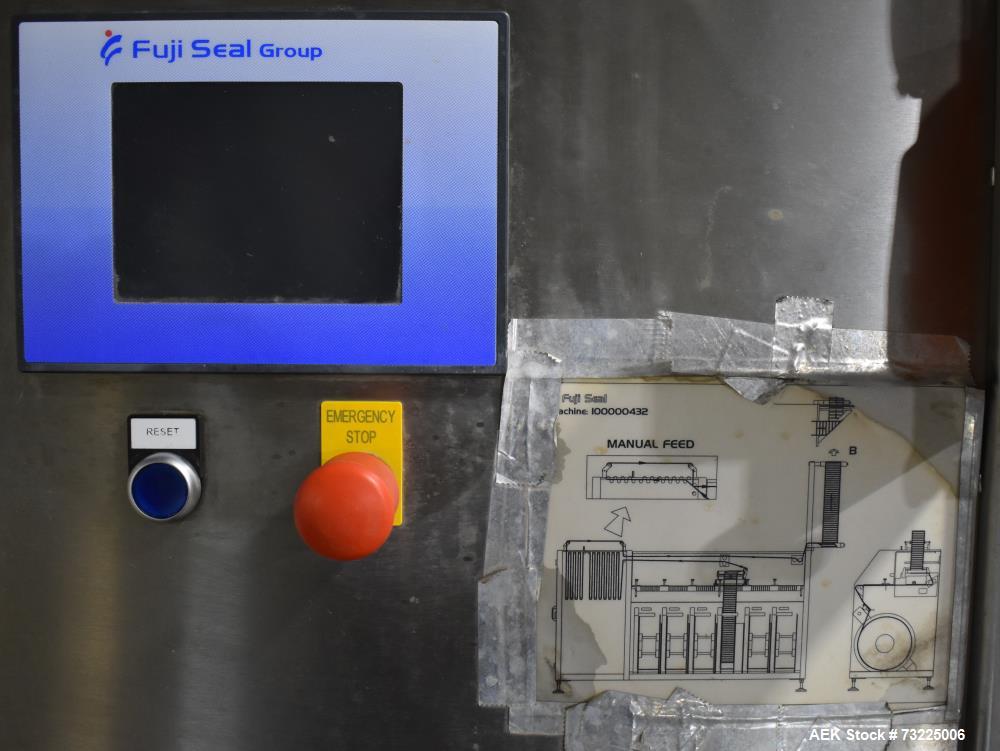

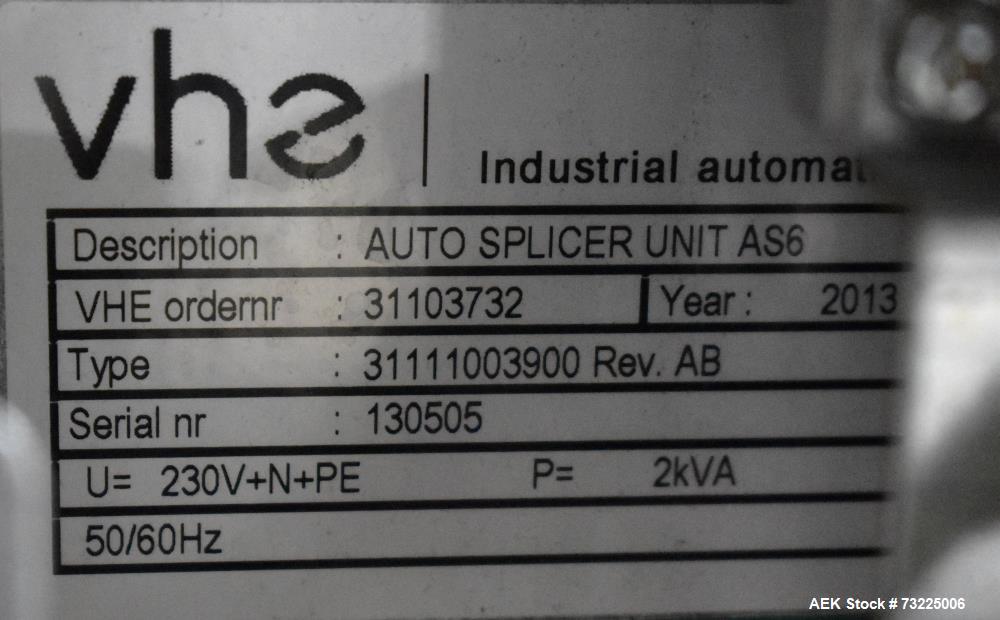

Used Fuji Seal Model FS400 High Speed Shrink Sleeve Labeler. Capable of speeds up to 750 PPM (Depending in application). Sleeve gauge 35-70 micron. Has dual worm screw infeed. Siemens Simatic S7-mEC PLC controls, Siemens HMI, Danfuss VLT drive, Sigmatek drives. 4" Wide conveyor. Approximate 3-3/4" wide cutting knife. Includes Fuji Seal Model ST Steam Tunnel. Fuji Seal automatic splice unit AS6, capable of up to a film web speed of 190 m/min and has 6 reel stations. Last running approximate 202 diameter (neck finish) slim can coffee beverage drink. 3/60/480V CE Certified.

Manufacturer Information:

- Manufacturer: Fuji Seal

- Model: FS400

- Condition: Used

Description:

The Fuji Seal FS400 is a high-speed shrink sleeve labeler designed for precision labeling applications. Capable of speeds up to 750 PPM (depending on application), this system supports sleeve gauges between 35-70 microns and features a dual worm screw infeed for optimized container handling.

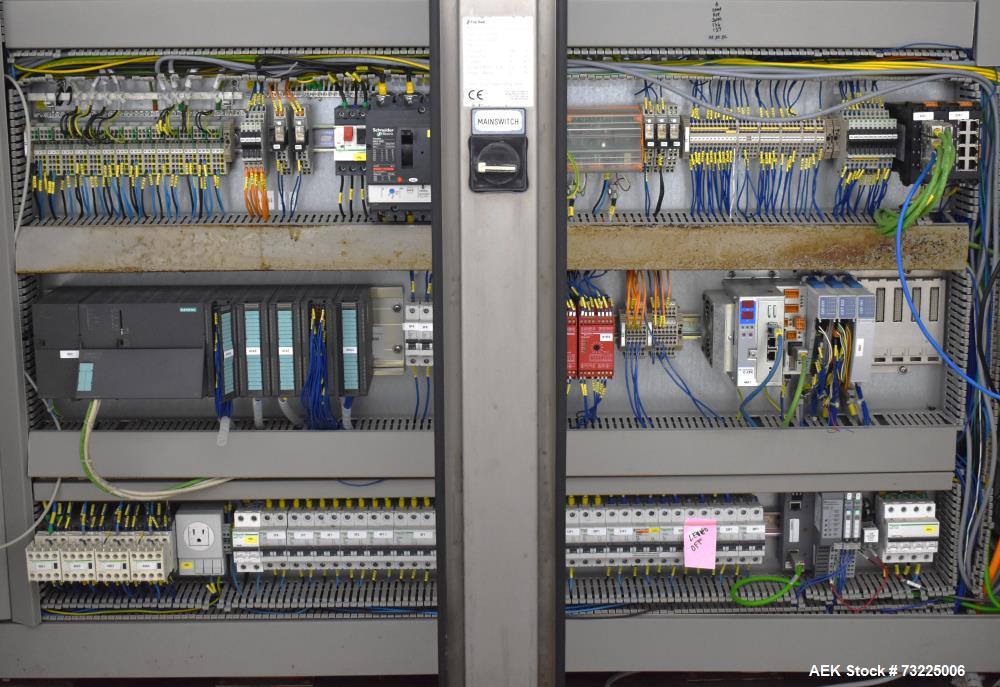

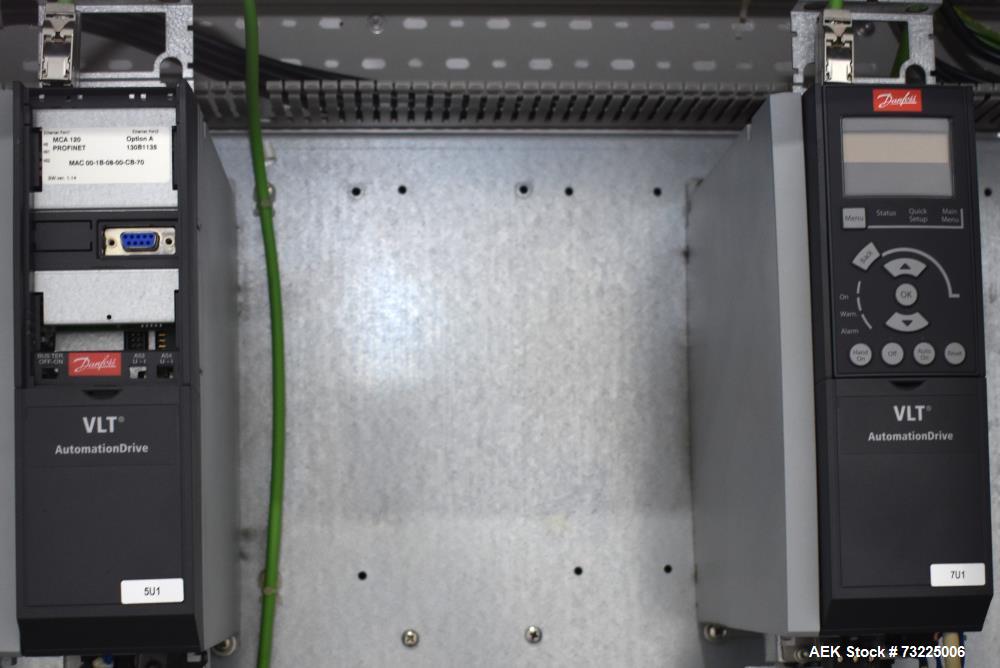

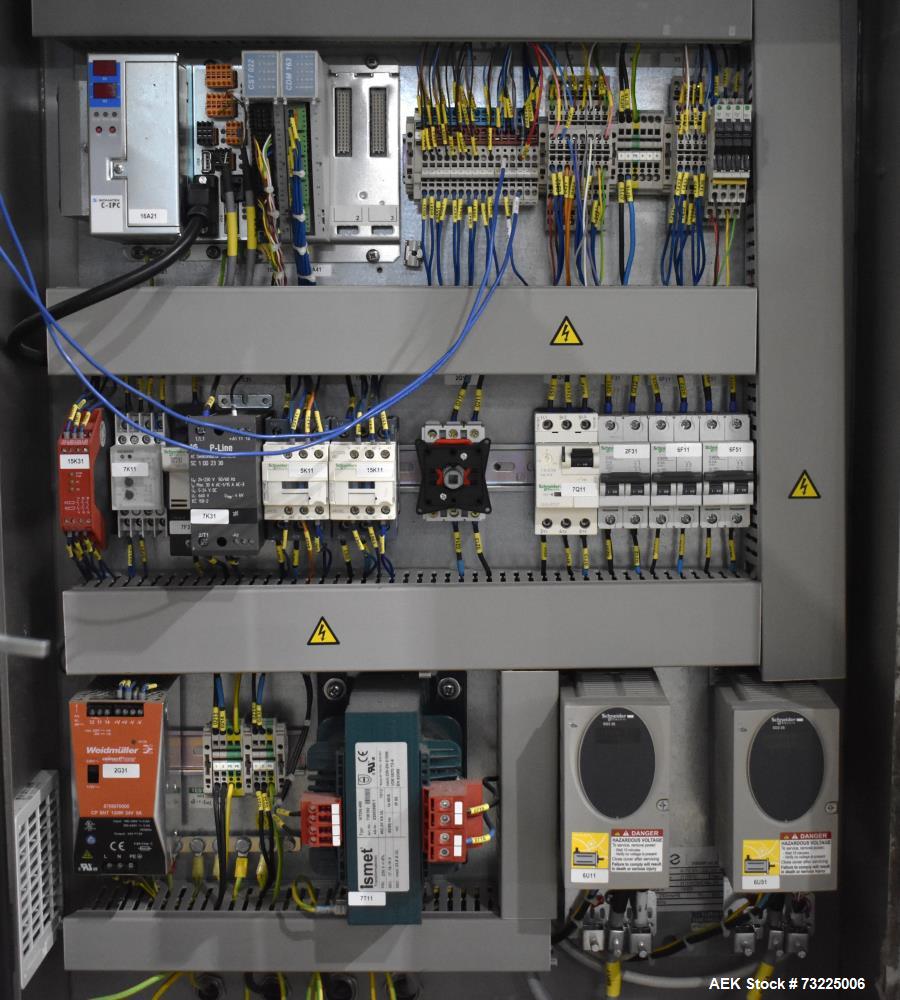

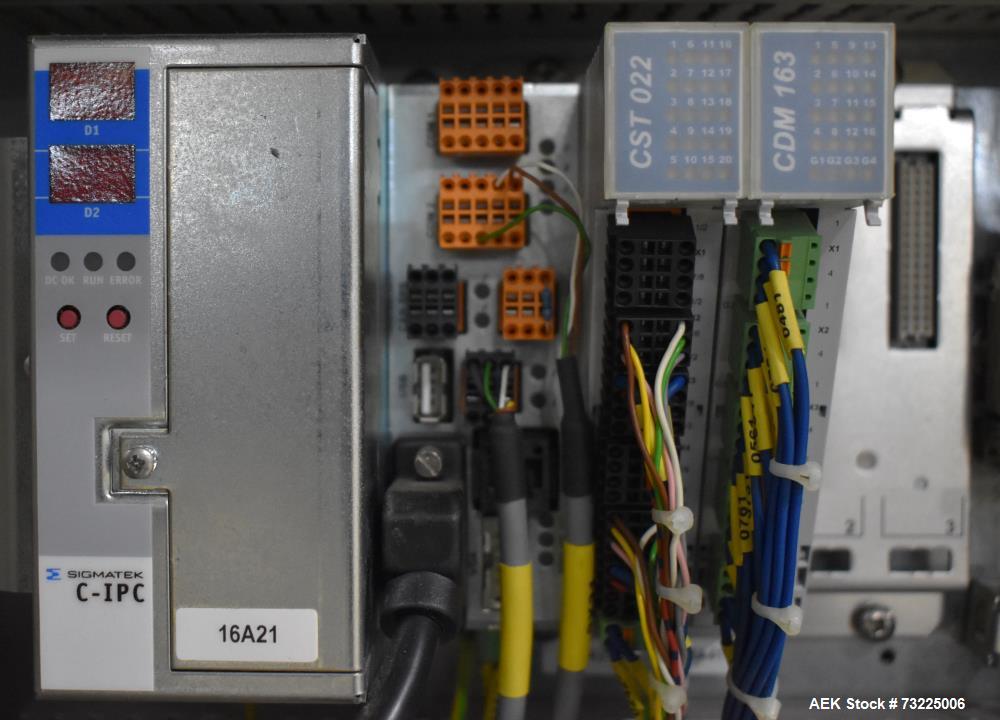

The unit operates with Siemens Simatic S7-mEC PLC controls, Siemens HMI, Danfoss VLT drive, and Sigmatek drives, ensuring high reliability and smooth operation. It includes a 4" wide conveyor and a 3-3/4" wide cutting knife for precise sleeve application.

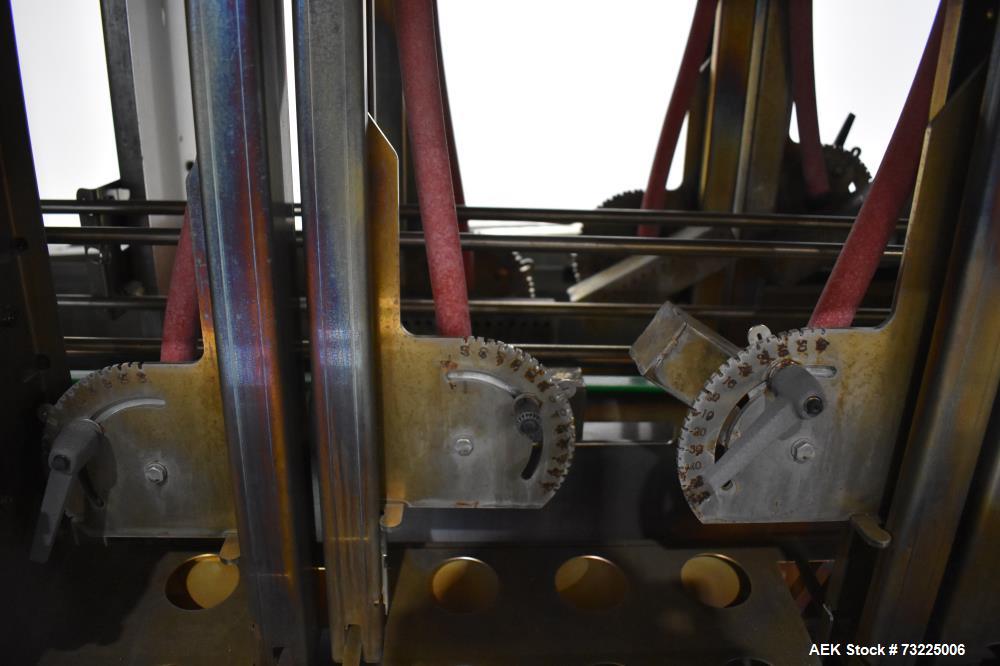

Additionally, this system comes with a Fuji Seal Model ST Steam Tunnel for efficient shrink-sleeving and a Fuji Seal AS6 automatic splice unit, which supports film web speeds of up to 190 m/min and features six reel stations for continuous operation.

Previously used for 202-diameter slim can coffee beverage drinks, the unit is CE certified and operates at 3/60/480V power.

Specifications:

- Machine Type: Shrink Sleeve Labeler

- Speed: Up to 750 PPM (depending on application)

- Sleeve Gauge: 35-70 microns

- Infeed: Dual worm screw

- Controls & Drives:

- Siemens Simatic S7-mEC PLC

- Siemens HMI

- Danfoss VLT drive

- Sigmatek drives

- Conveyor Width: 4"

- Cutting Knife Width: 3-3/4"

- Steam Tunnel: Fuji Seal Model ST

- Automatic Splice Unit: Fuji Seal AS6 (190 m/min film web speed, six reel stations)

- Last Application: 202-diameter slim can coffee beverage drink

- Power Requirements: 3/60/480V

- Certification: CE Certified

Applications:

- Beverage Industry: Coffee drinks, energy drinks, bottled water, soft drinks

- Food Packaging: Condiments, sauces, dairy products, canned goods

- Personal Care & Cosmetics: Shampoo, lotion bottles, body sprays

- Pharmaceuticals: Medical bottles, supplement containers

- Household Products: Cleaning supplies, air fresheners, detergents

Common Product Uses:

- Canned & Bottled Beverages: Slim cans, bottled drinks, energy drinks

- Food Containers: Yogurt cups, juice bottles, spice jars

- Personal Care: Shampoo, conditioners, body wash

- Industrial & Household Goods: Aerosols, cleaning products, chemical bottles

- Fuji Seal FS400 Labeler

- Shrink sleeve applicator

- Automatic splicing unit AS6

- Industrial shrink labeling machine

- High-speed labeling system

- Used packaging equipment

- Beverage shrink labeler

- Sleeve labeling system for sale

- Used Fuji Seal FS400 Labeler

- High-speed shrink sleeve labeling machine

- Fuji Seal FS400 shrink sleeve labeler

- Steam tunnel shrink labeling system

- Automatic sleeve splicing machine

- Used shrink sleeve applicator

- Industrial labeling equipment for sale

- Beverage shrink sleeve labeling system

- Sleeve labeler with steam tunnel

- High-speed shrink sleeve packaging machine

Used Fuji Seal Model FS400 High Speed Shrink Sleeve Labeler. Capable of speeds up to 750 PPM (Depending in application). Sleeve gauge 35-70 micron. Has dual worm screw infeed. Siemens Simatic S7-mEC PLC controls, Siemens HMI, Danfuss VLT drive, Sigmatek drives. 4" Wide conveyor. Approximate 3-3/4" wide cutting knife. Includes Fuji Seal Model ST Steam Tunnel. Fuji Seal automatic splice unit AS6, capable of up to a film web speed of 190 m/min and has 6 reel stations. Last running approximate 202 diameter (neck finish) slim can coffee beverage drink. 3/60/480V CE Certified.

Manufacturer Information:

- Manufacturer: Fuji Seal

- Model: FS400

- Condition: Used

Description:

The Fuji Seal FS400 is a high-speed shrink sleeve labeler designed for precision labeling applications. Capable of speeds up to 750 PPM (depending on application), this system supports sleeve gauges between 35-70 microns and features a dual worm screw infeed for optimized container handling.

The unit operates with Siemens Simatic S7-mEC PLC controls, Siemens HMI, Danfoss VLT drive, and Sigmatek drives, ensuring high reliability and smooth operation. It includes a 4" wide conveyor and a 3-3/4" wide cutting knife for precise sleeve application.

Additionally, this system comes with a Fuji Seal Model ST Steam Tunnel for efficient shrink-sleeving and a Fuji Seal AS6 automatic splice unit, which supports film web speeds of up to 190 m/min and features six reel stations for continuous operation.

Previously used for 202-diameter slim can coffee beverage drinks, the unit is CE certified and operates at 3/60/480V power.

Specifications:

- Machine Type: Shrink Sleeve Labeler

- Speed: Up to 750 PPM (depending on application)

- Sleeve Gauge: 35-70 microns

- Infeed: Dual worm screw

- Controls & Drives:

- Siemens Simatic S7-mEC PLC

- Siemens HMI

- Danfoss VLT drive

- Sigmatek drives

- Conveyor Width: 4"

- Cutting Knife Width: 3-3/4"

- Steam Tunnel: Fuji Seal Model ST

- Automatic Splice Unit: Fuji Seal AS6 (190 m/min film web speed, six reel stations)

- Last Application: 202-diameter slim can coffee beverage drink

- Power Requirements: 3/60/480V

- Certification: CE Certified

Applications:

- Beverage Industry: Coffee drinks, energy drinks, bottled water, soft drinks

- Food Packaging: Condiments, sauces, dairy products, canned goods

- Personal Care & Cosmetics: Shampoo, lotion bottles, body sprays

- Pharmaceuticals: Medical bottles, supplement containers

- Household Products: Cleaning supplies, air fresheners, detergents

Common Product Uses:

- Canned & Bottled Beverages: Slim cans, bottled drinks, energy drinks

- Food Containers: Yogurt cups, juice bottles, spice jars

- Personal Care: Shampoo, conditioners, body wash

- Industrial & Household Goods: Aerosols, cleaning products, chemical bottles

- Fuji Seal FS400 Labeler

- Shrink sleeve applicator

- Automatic splicing unit AS6

- Industrial shrink labeling machine

- High-speed labeling system

- Used packaging equipment

- Beverage shrink labeler

- Sleeve labeling system for sale

- Used Fuji Seal FS400 Labeler

- High-speed shrink sleeve labeling machine

- Fuji Seal FS400 shrink sleeve labeler

- Steam tunnel shrink labeling system

- Automatic sleeve splicing machine

- Used shrink sleeve applicator

- Industrial labeling equipment for sale

- Beverage shrink sleeve labeling system

- Sleeve labeler with steam tunnel

- High-speed shrink sleeve packaging machine

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory