Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

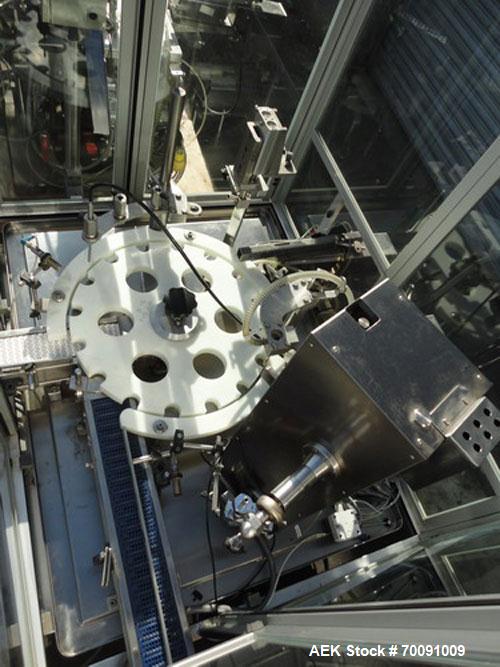

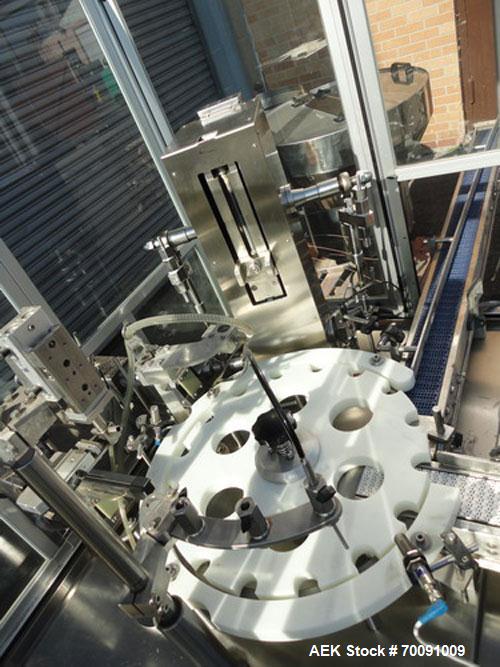

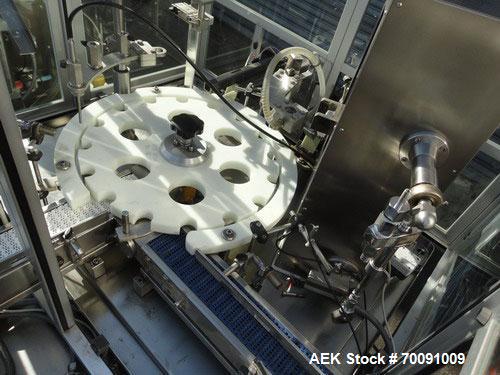

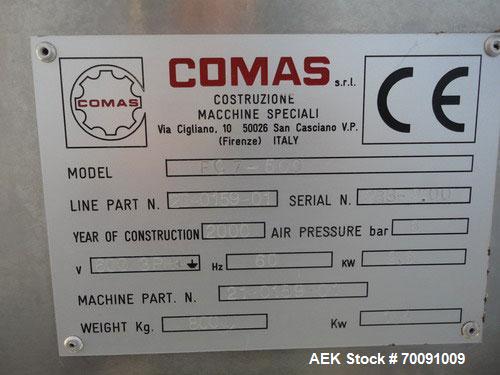

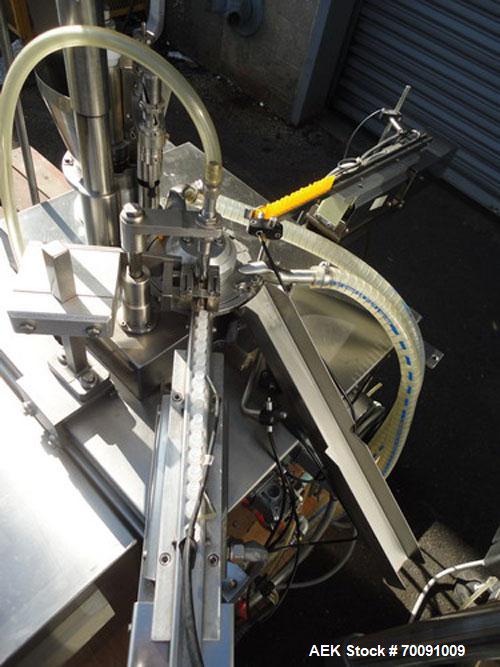

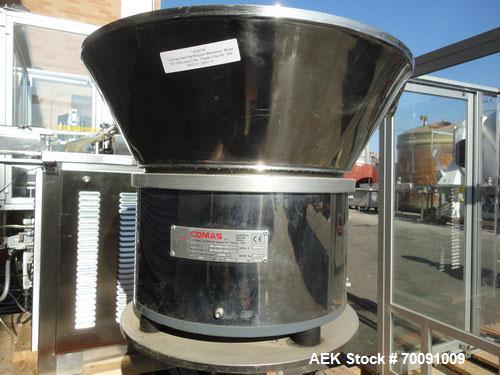

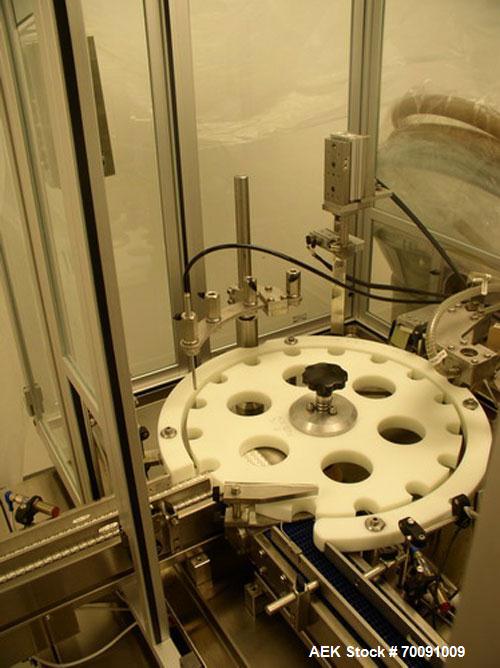

Used Comas Liquid Vial Filler and Capper Monoblock Liquid Filler, Powder Filler RP, Model FC7-50. 3000-4000 parts per hour. This unit has main monoblock with 4 head piston filling mechanism and screw...

Used Comas Liquid Vial Filler and Capper Monoblock Liquid Filler, Powder Filler RP, Model FC7-50. 3000-4000 parts per hour. This unit has main monoblock with 4 head piston filling mechanism and screw capping assembly. Machine is controlled via machine mounted pushbutton control with screen. Bottles are unscrambled via vibratory bowl feeder and enter the main machine via infeed conveyor. A starwheel and guides index bottles to the filling, fitment placing (if used) and finally, the cap placing and tightening station. The caps are fed into the placing head by rotary vibratory feed bowl. The monoblock is equipped with an optional use incoming powder dosing section which was last filling a plastic powder dosing cup which, when fitted with a powder tight cap, can be inverted and placed into the neck of the bottle. When the cap is placed on the bottle, this becomes part of the vial cap asembly. This system is used to separate the powder and the liquid until time to use. To dispense, the cap is tightened which forced plastic powder cup to punch through the bottom of the cap, allowing the powder to fall into the liquid contained in the vial. The system also features an incoming fitment inversion and placement assembly which automatically places the filled plastic powder cup/cap assembly into the filled vial (after liquid filling and prior to capping). Filled vials are carried out of the machine via 4' outfeed conveyor. Control system is PLC based with HMI.

Used Comas Liquid Vial Filler and Capper Monoblock Liquid Filler, Powder Filler RP, Model FC7-50. 3000-4000 parts per hour. This unit has main monoblock with 4 head piston filling mechanism and screw capping assembly. Machine is controlled via machine mounted pushbutton control with screen. Bottles are unscrambled via vibratory bowl feeder and enter the main machine via infeed conveyor. A starwheel and guides index bottles to the filling, fitment placing (if used) and finally, the cap placing and tightening station. The caps are fed into the placing head by rotary vibratory feed bowl. The monoblock is equipped with an optional use incoming powder dosing section which was last filling a plastic powder dosing cup which, when fitted with a powder tight cap, can be inverted and placed into the neck of the bottle. When the cap is placed on the bottle, this becomes part of the vial cap asembly. This system is used to separate the powder and the liquid until time to use. To dispense, the cap is tightened which forced plastic powder cup to punch through the bottom of the cap, allowing the powder to fall into the liquid contained in the vial. The system also features an incoming fitment inversion and placement assembly which automatically places the filled plastic powder cup/cap assembly into the filled vial (after liquid filling and prior to capping). Filled vials are carried out of the machine via 4' outfeed conveyor. Control system is PLC based with HMI.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory