Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Lakso 990 (Model93) Complete Solid Dose Packaging line.

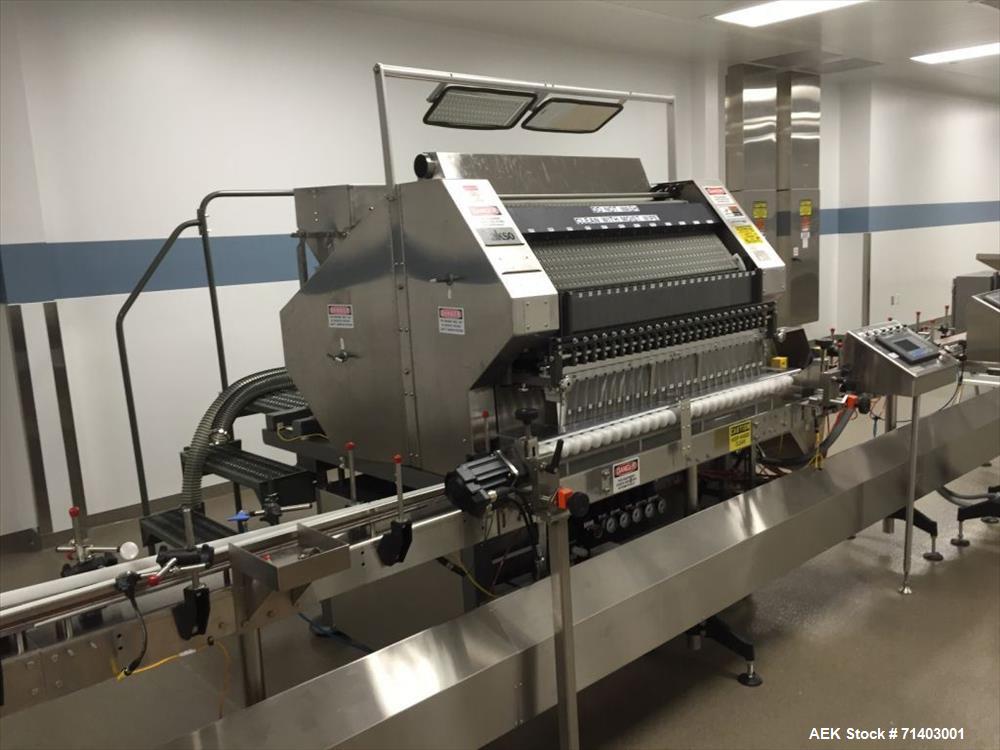

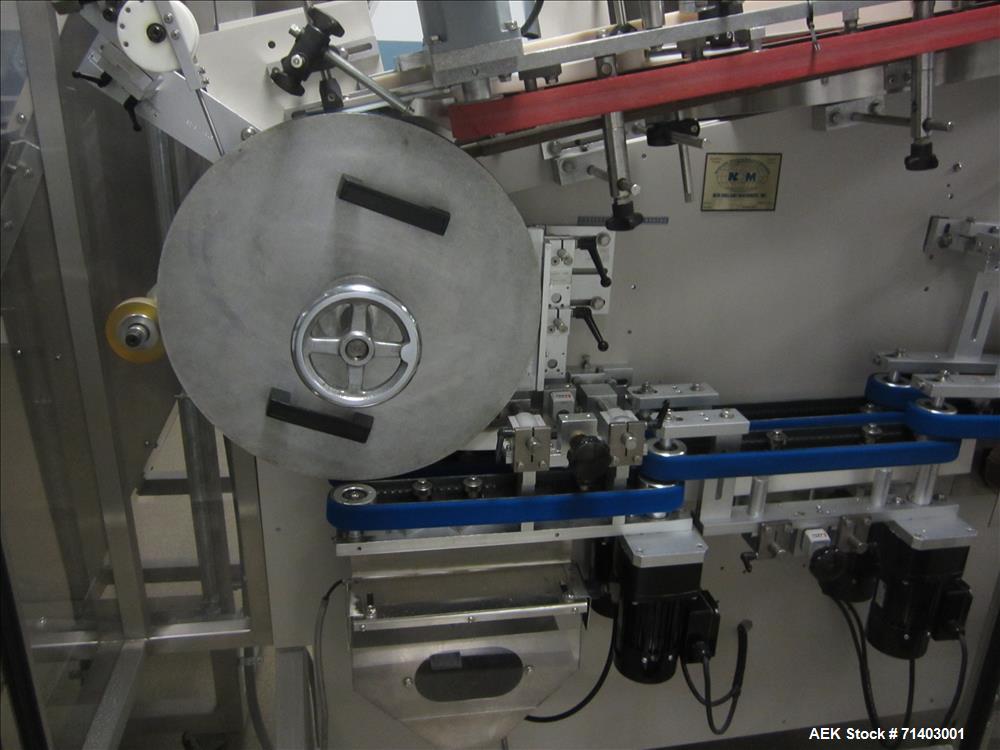

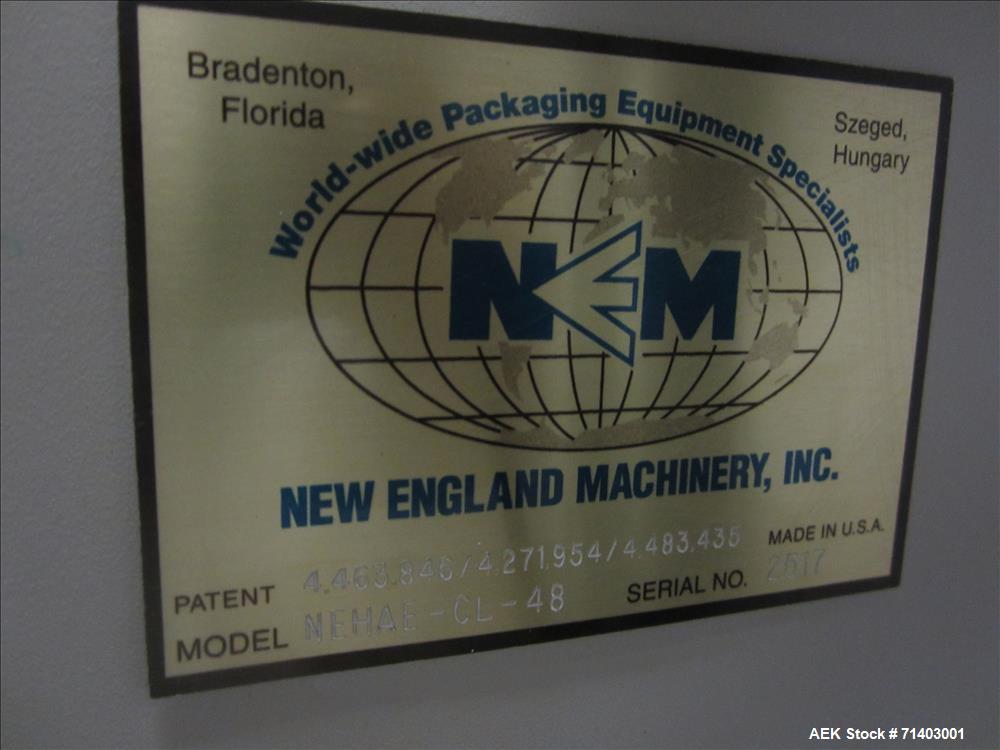

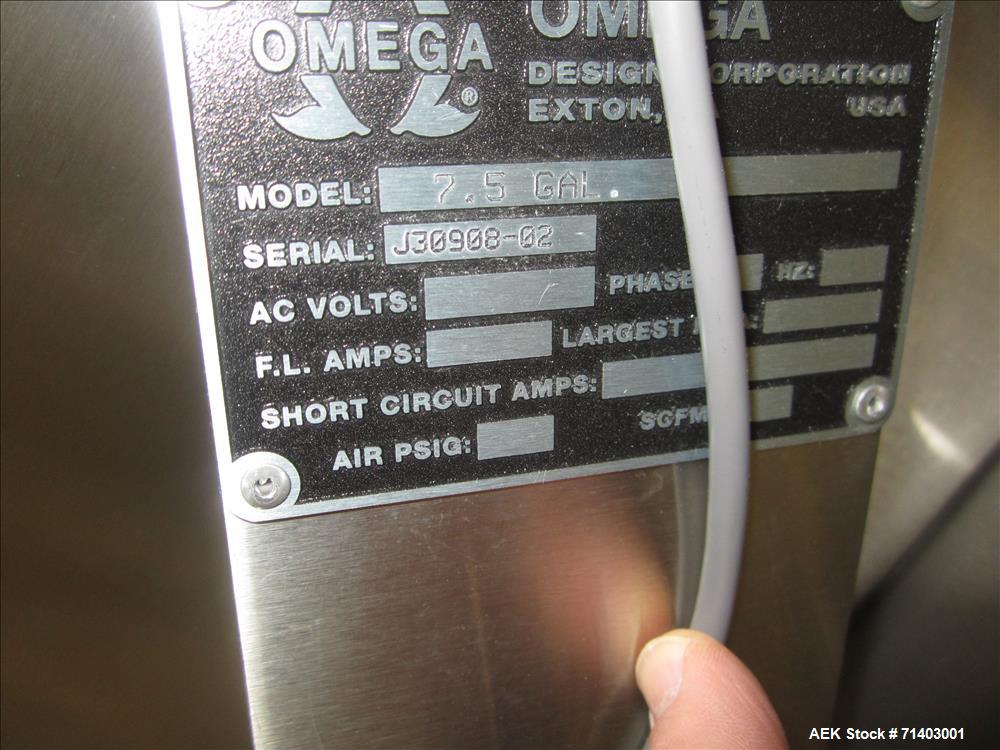

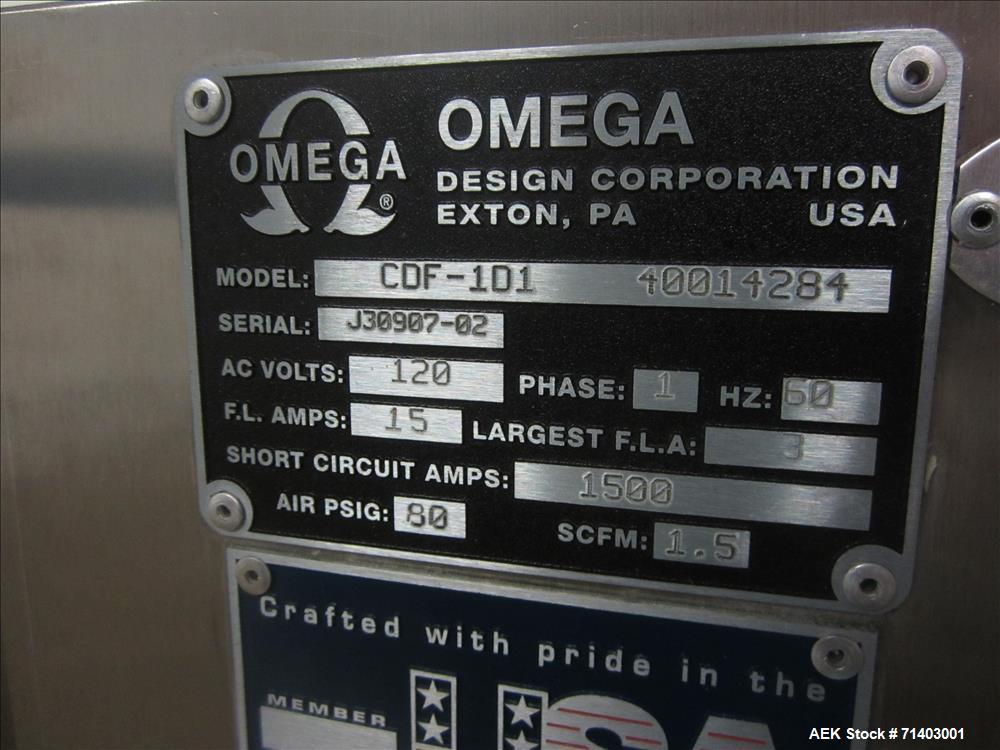

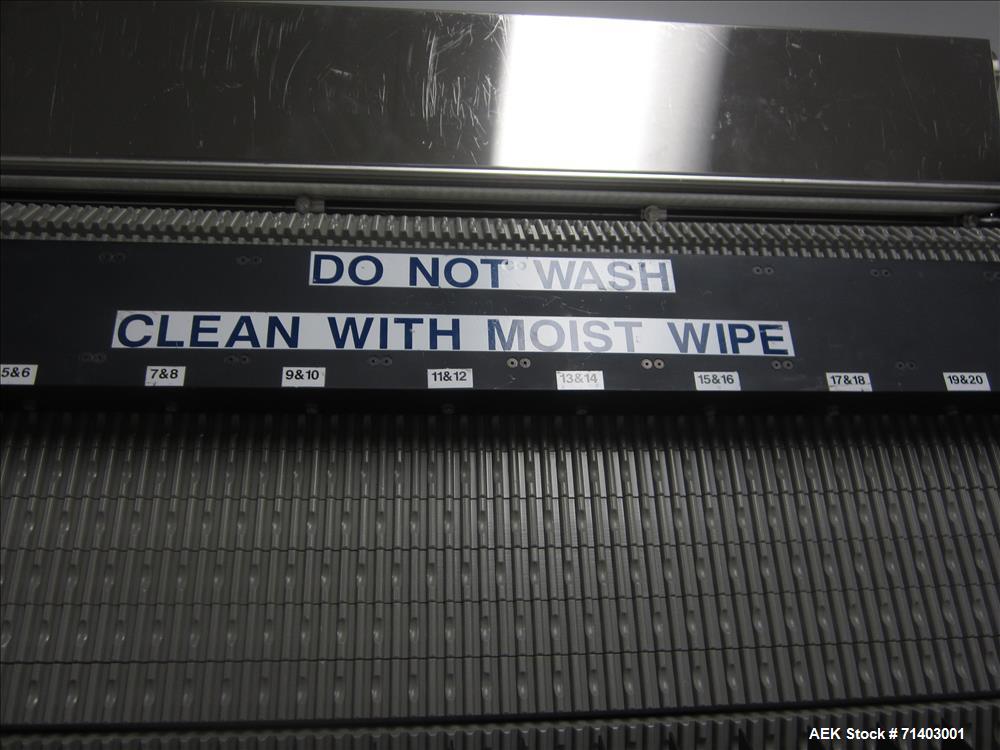

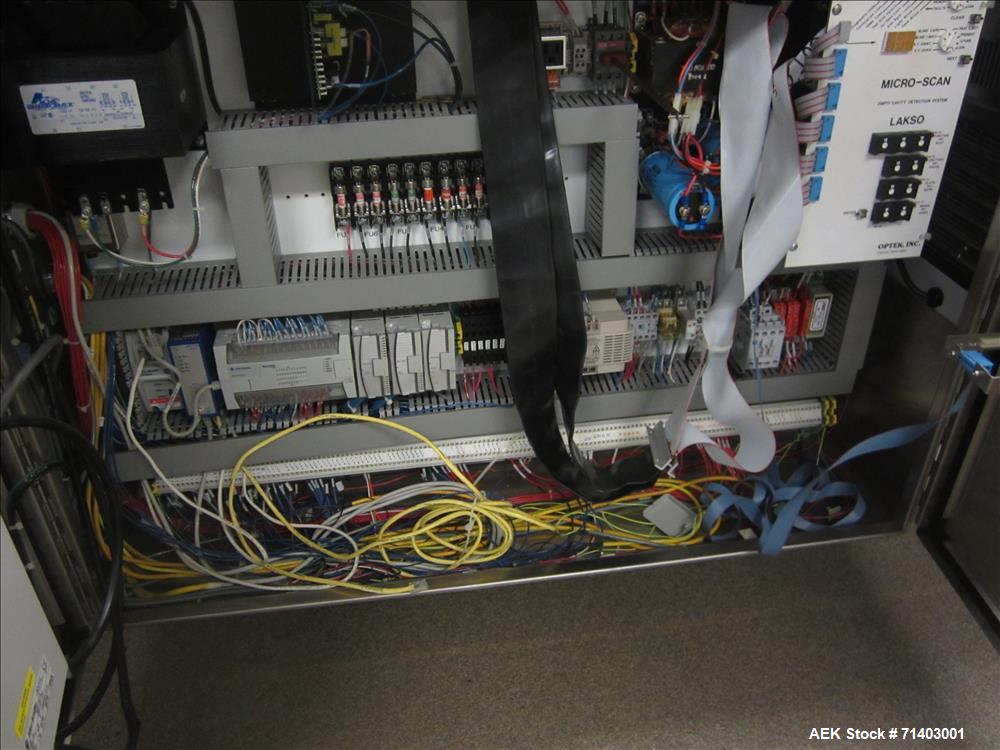

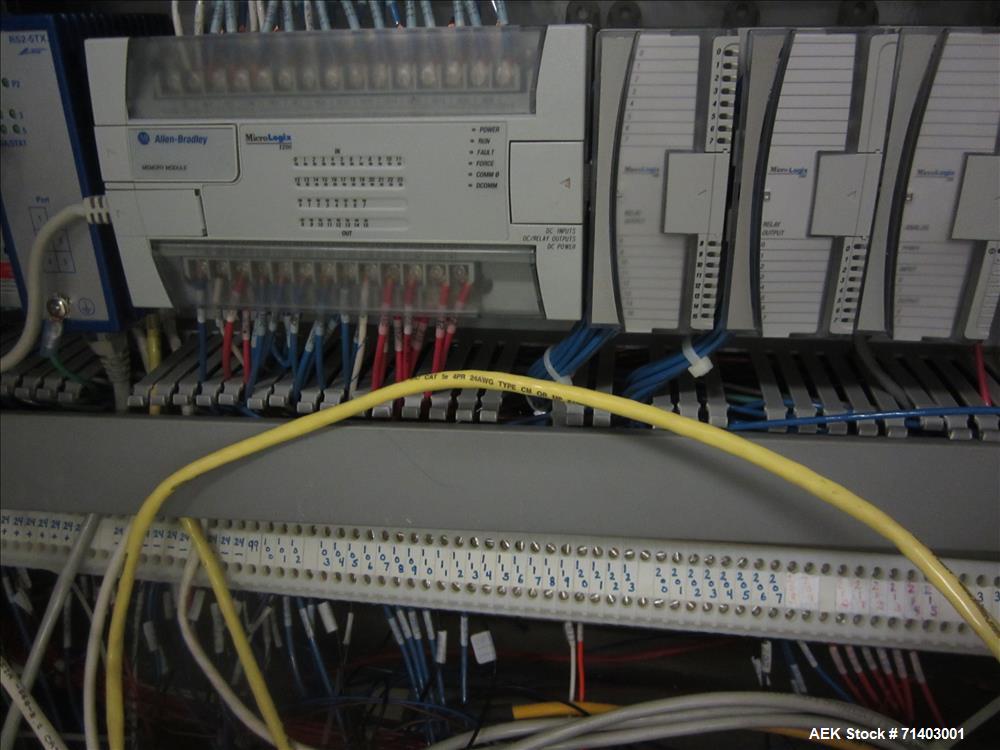

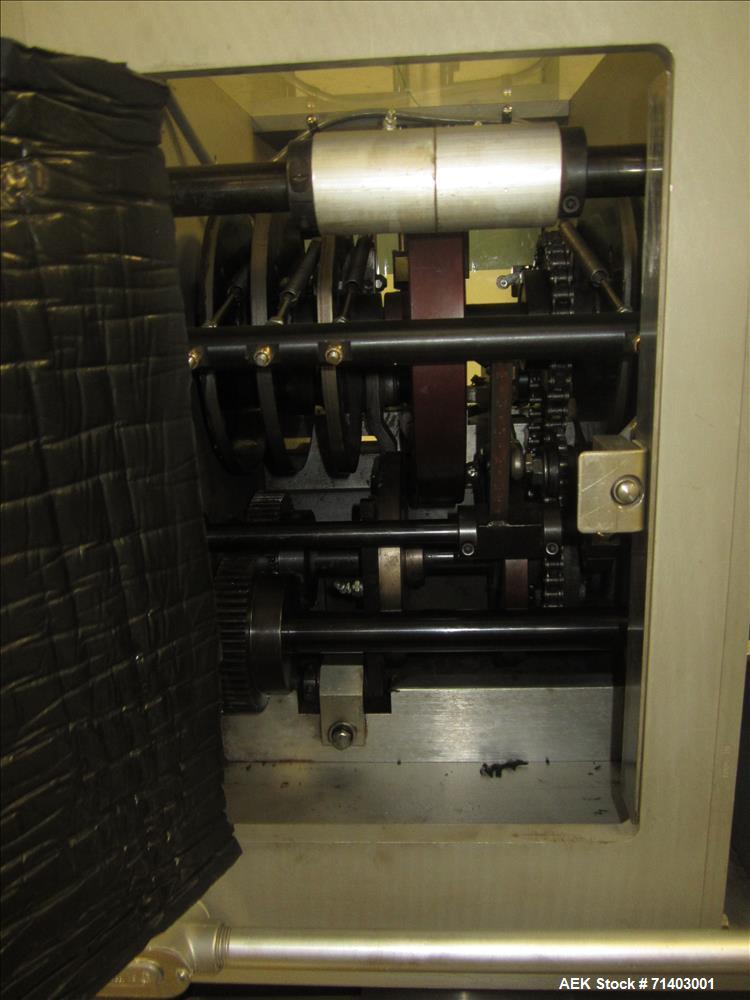

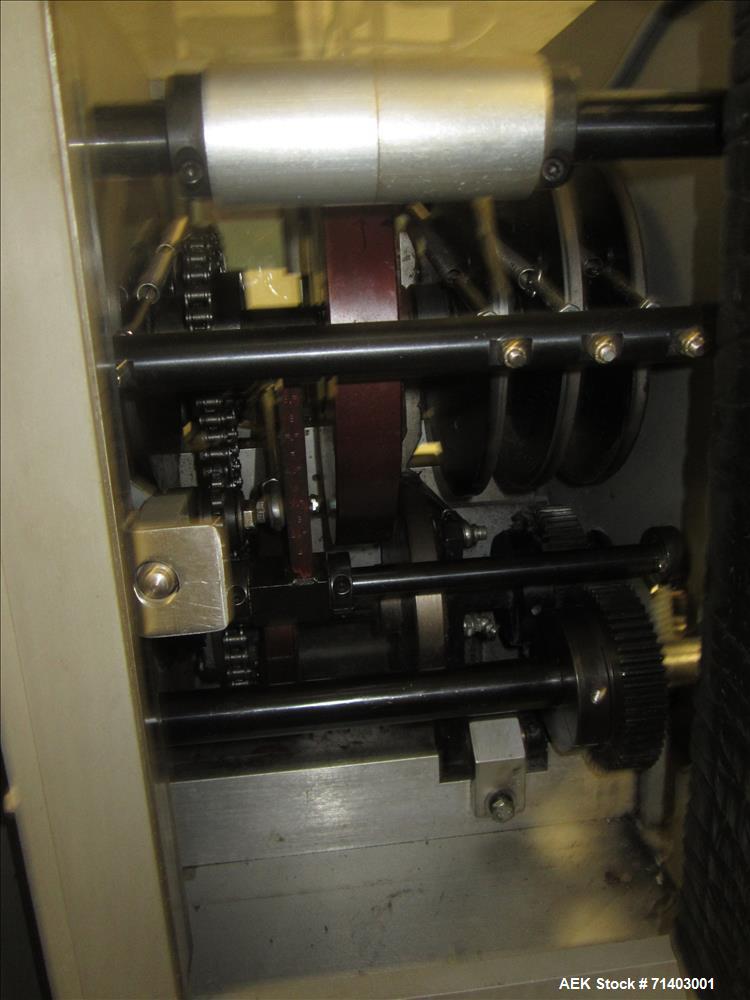

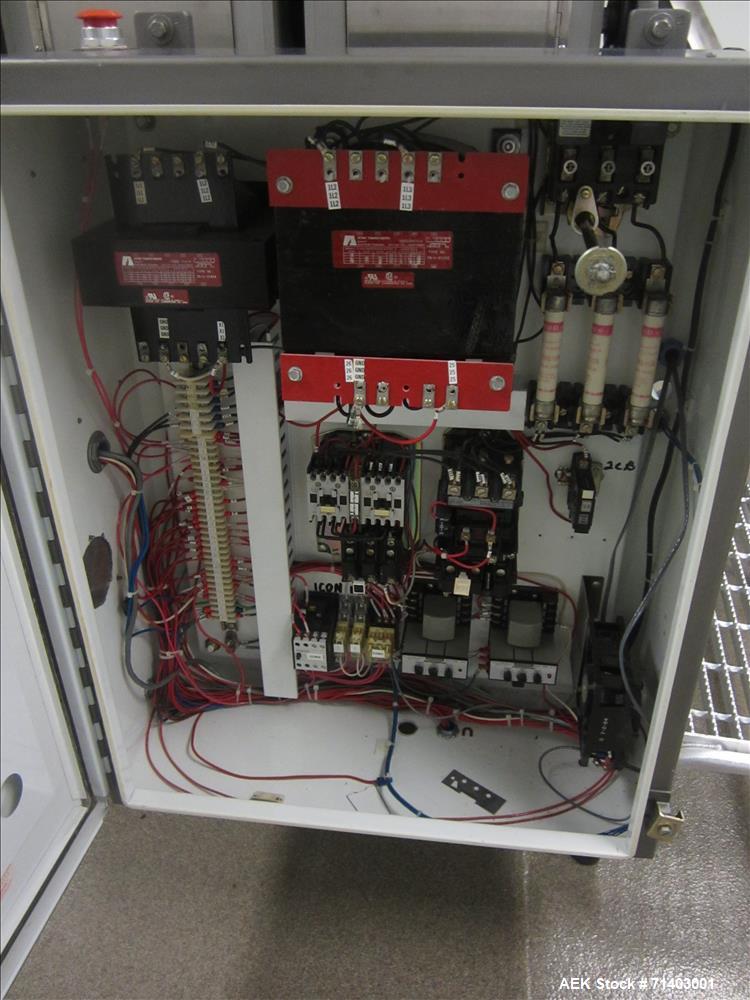

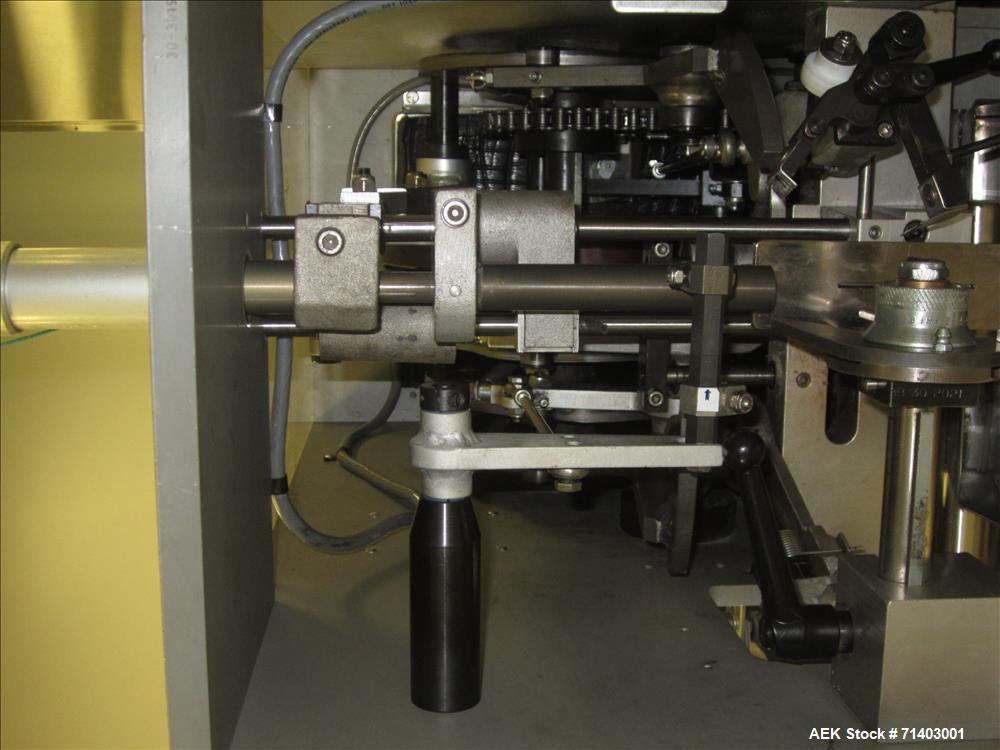

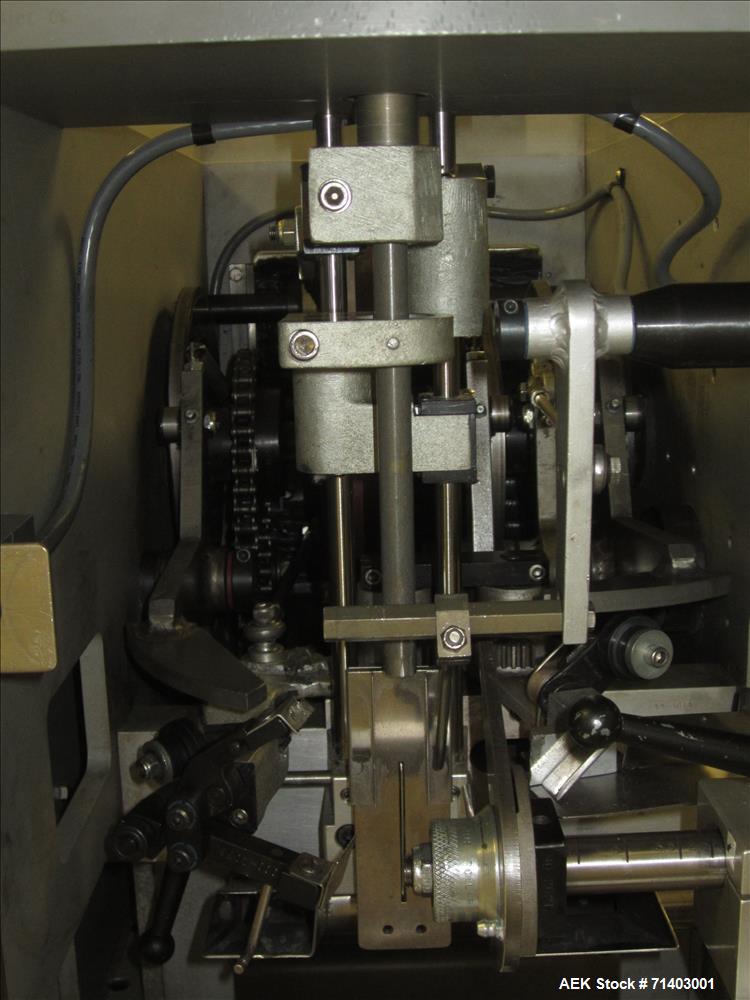

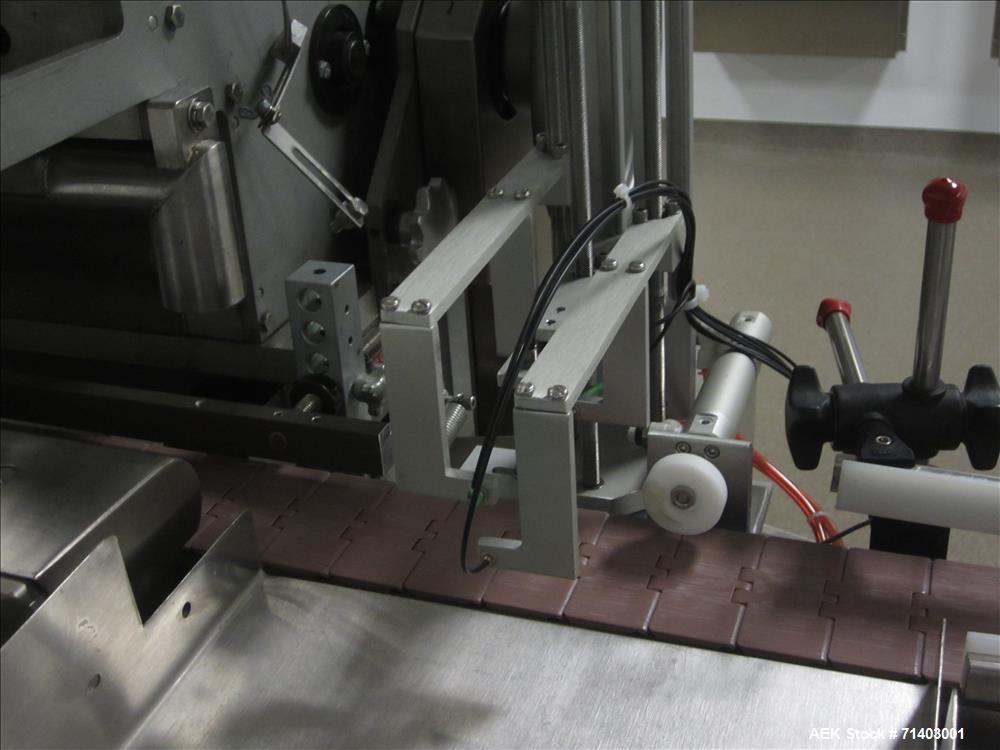

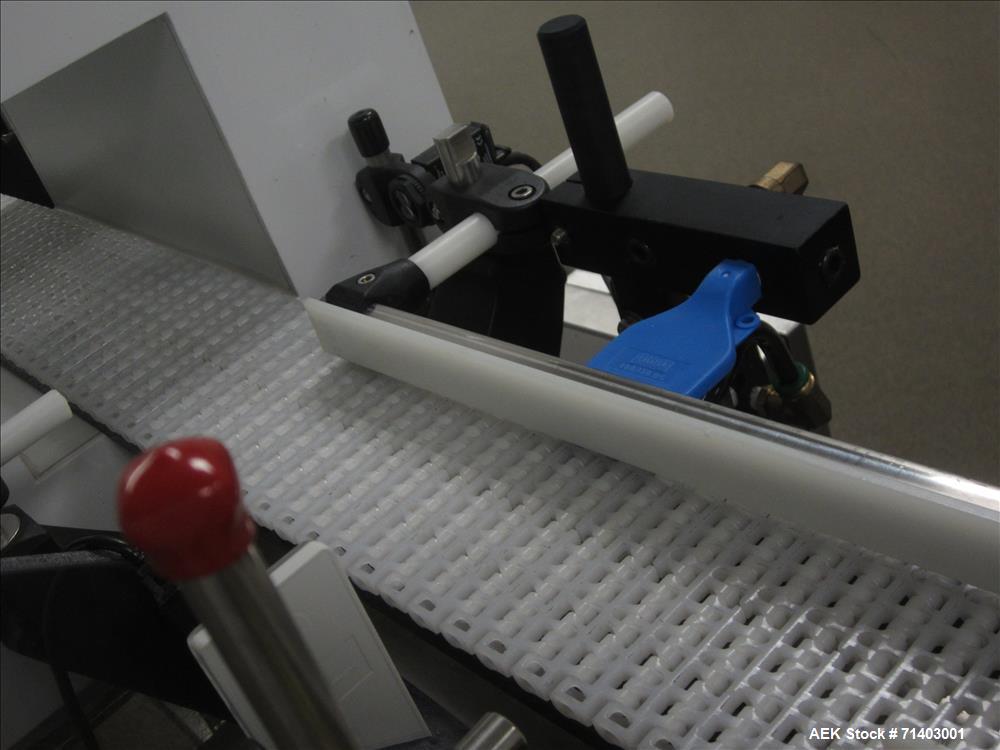

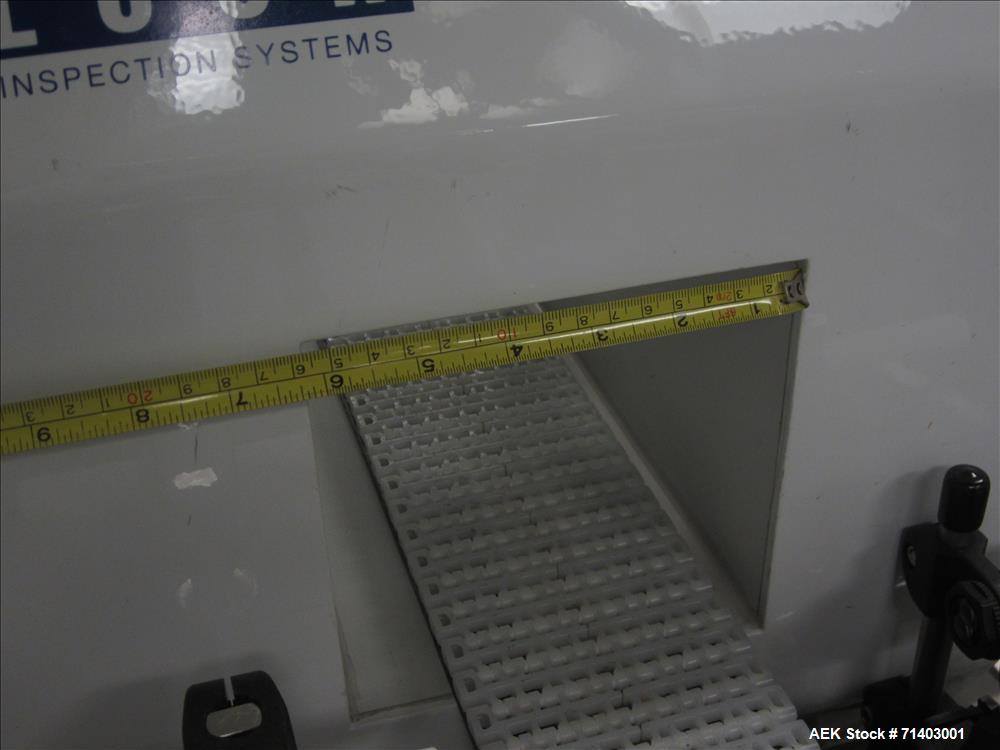

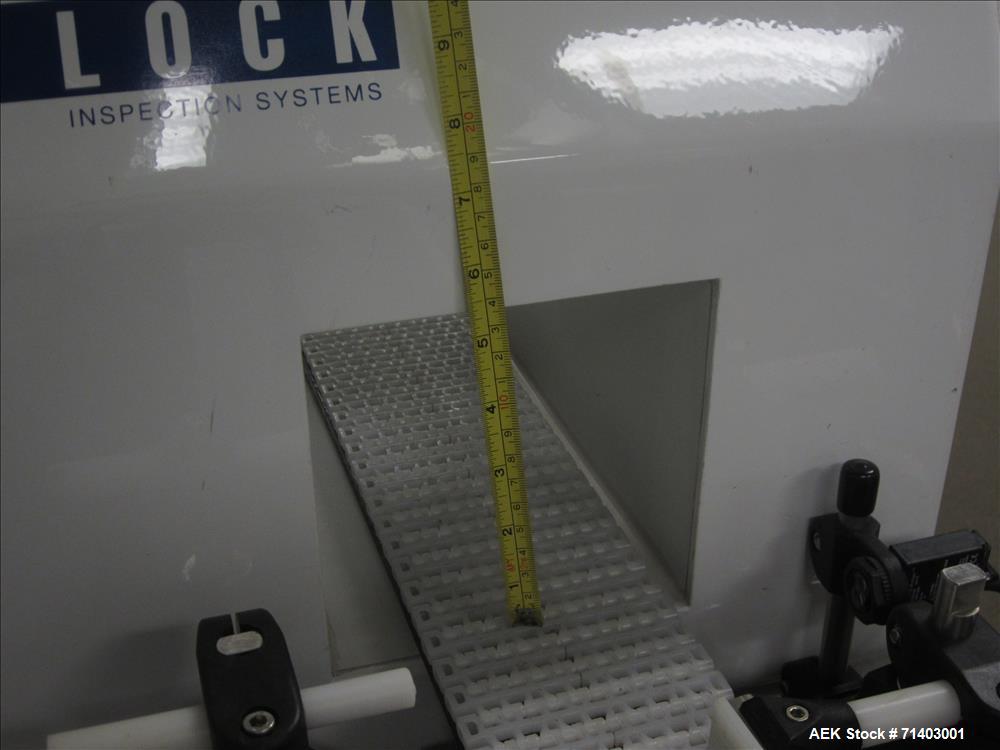

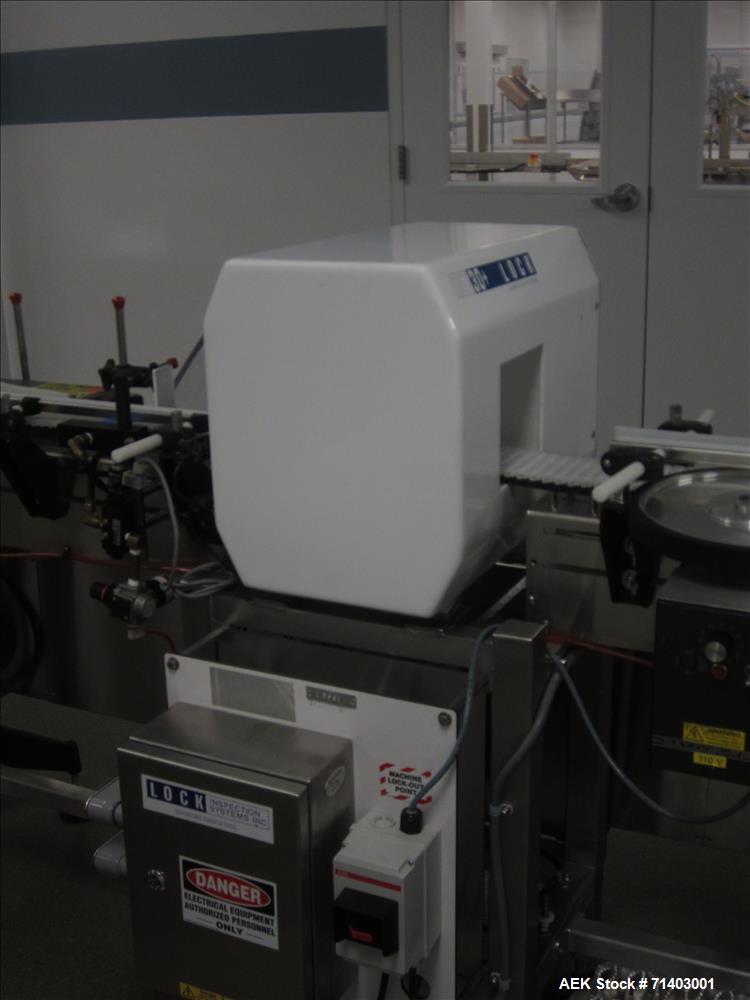

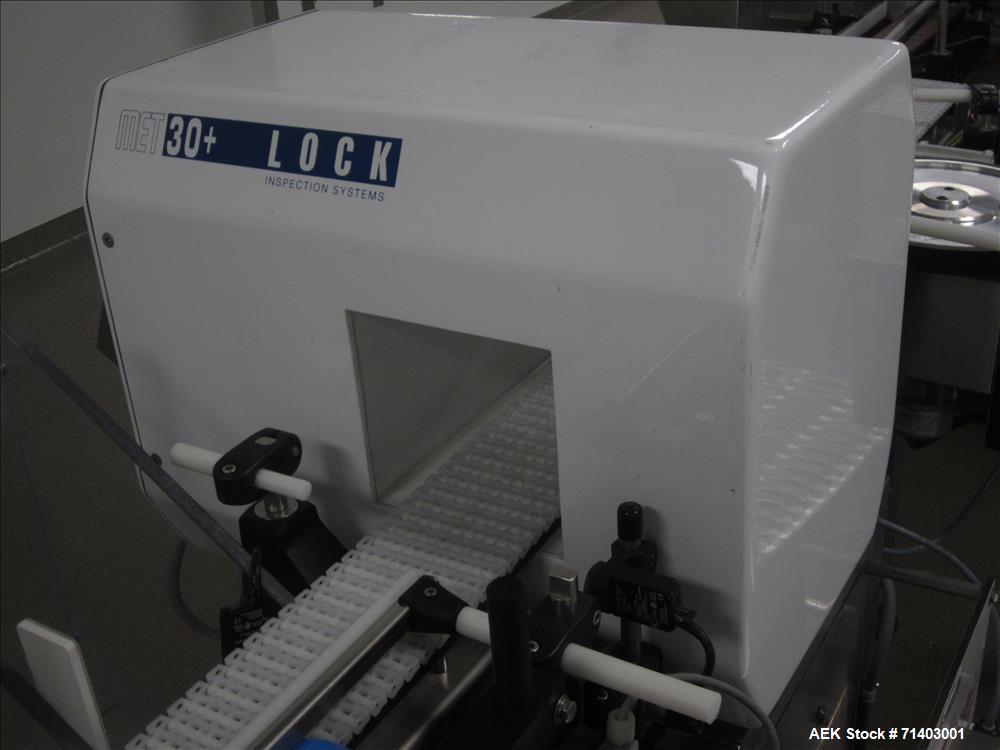

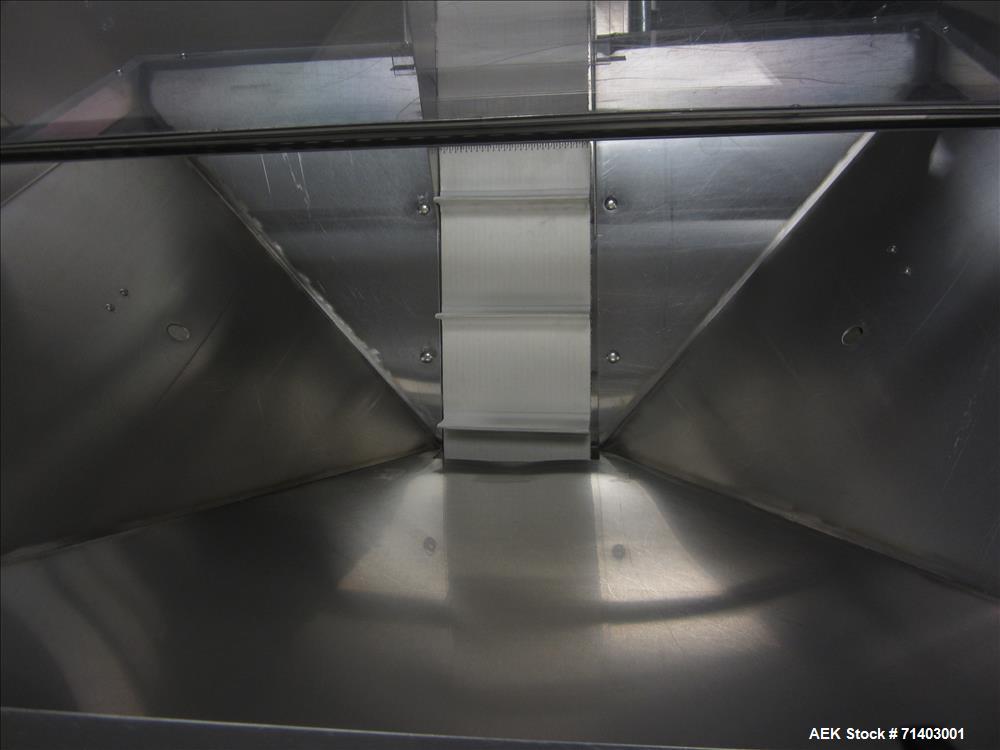

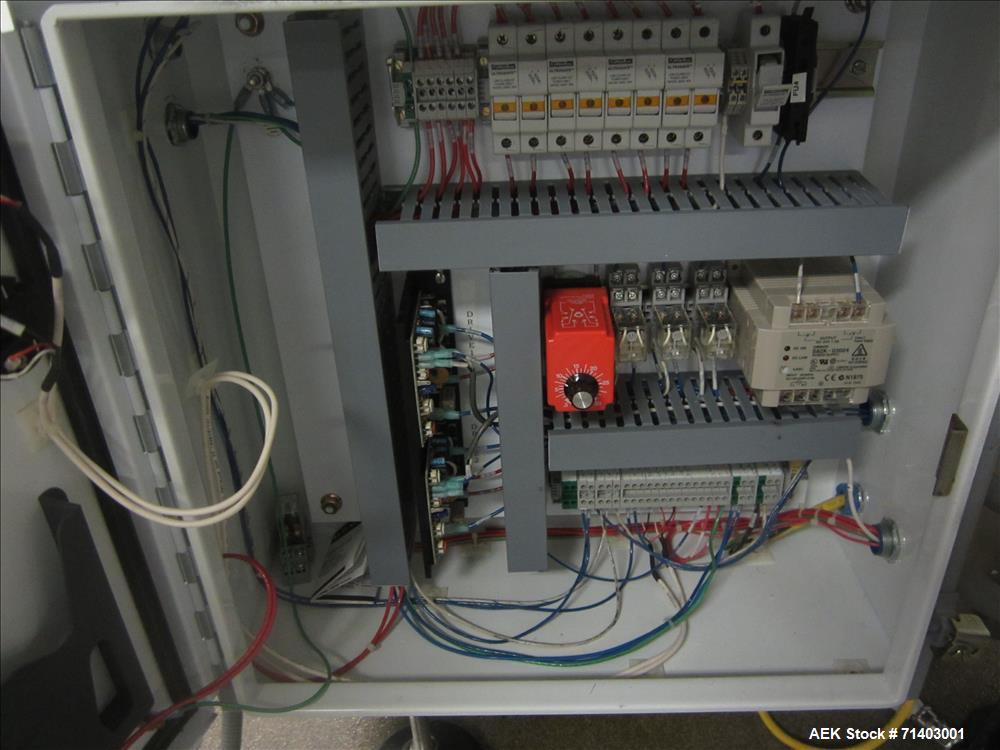

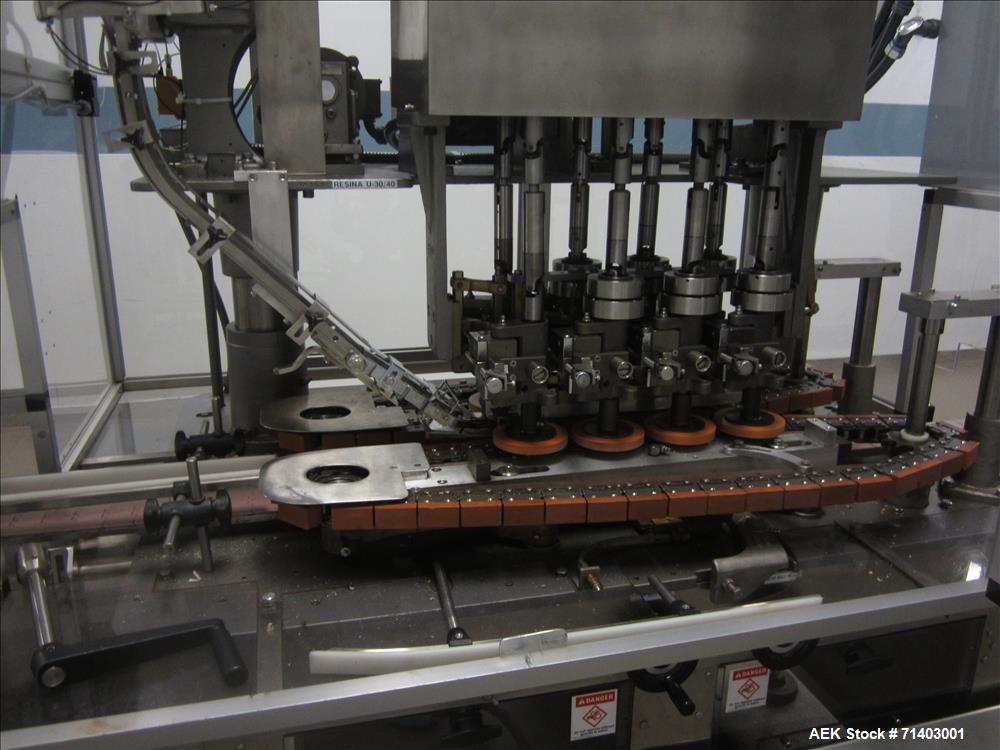

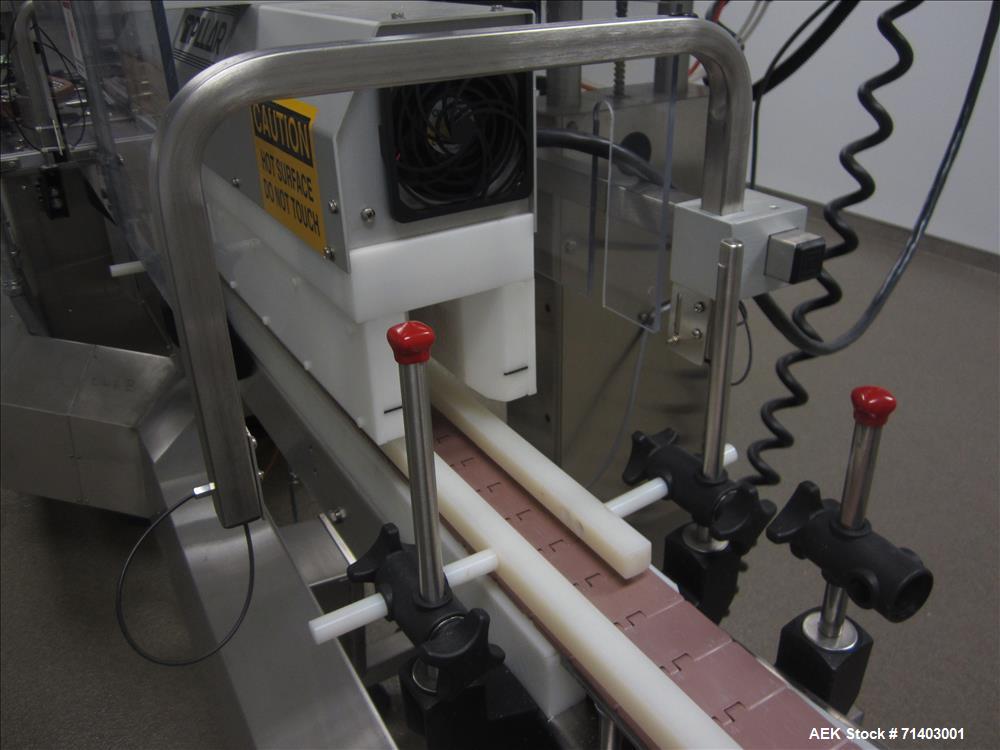

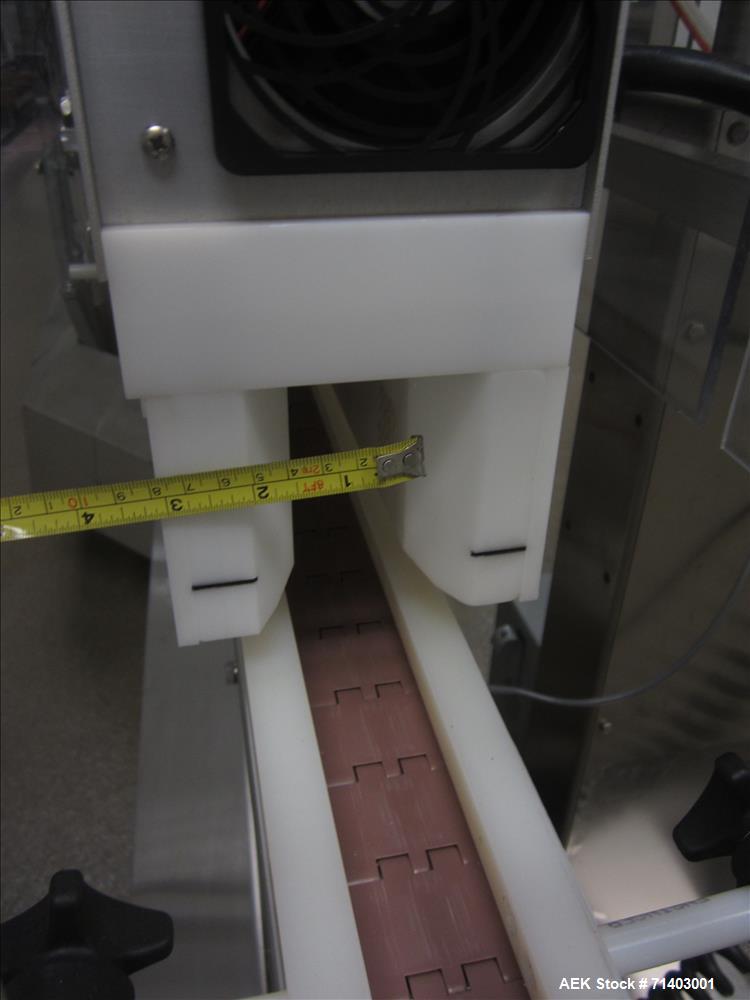

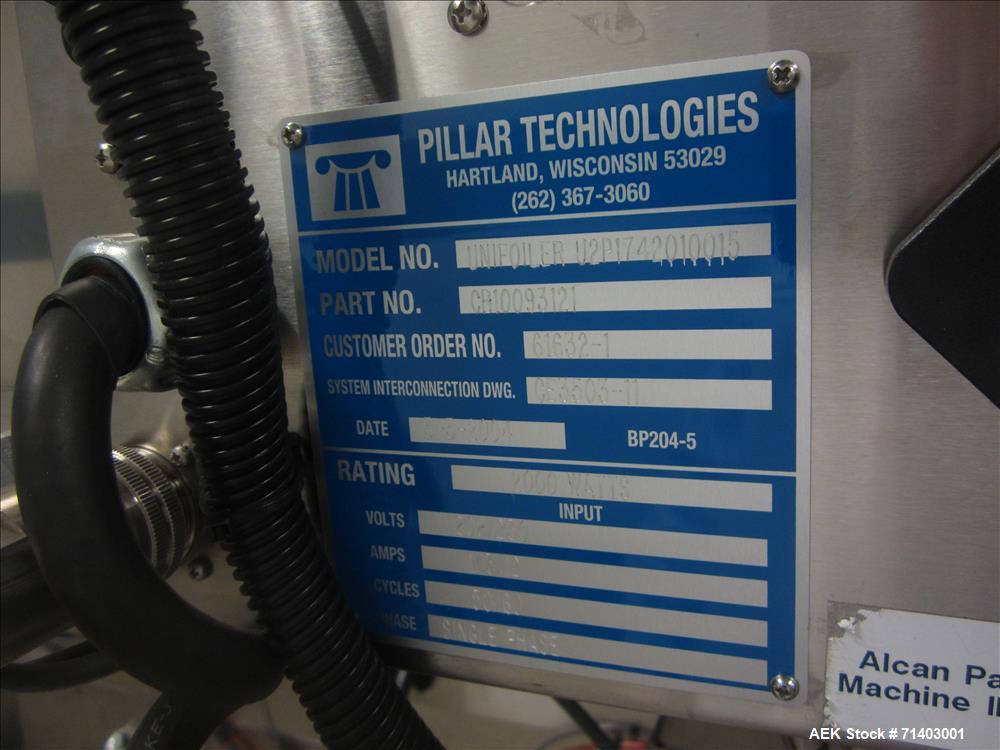

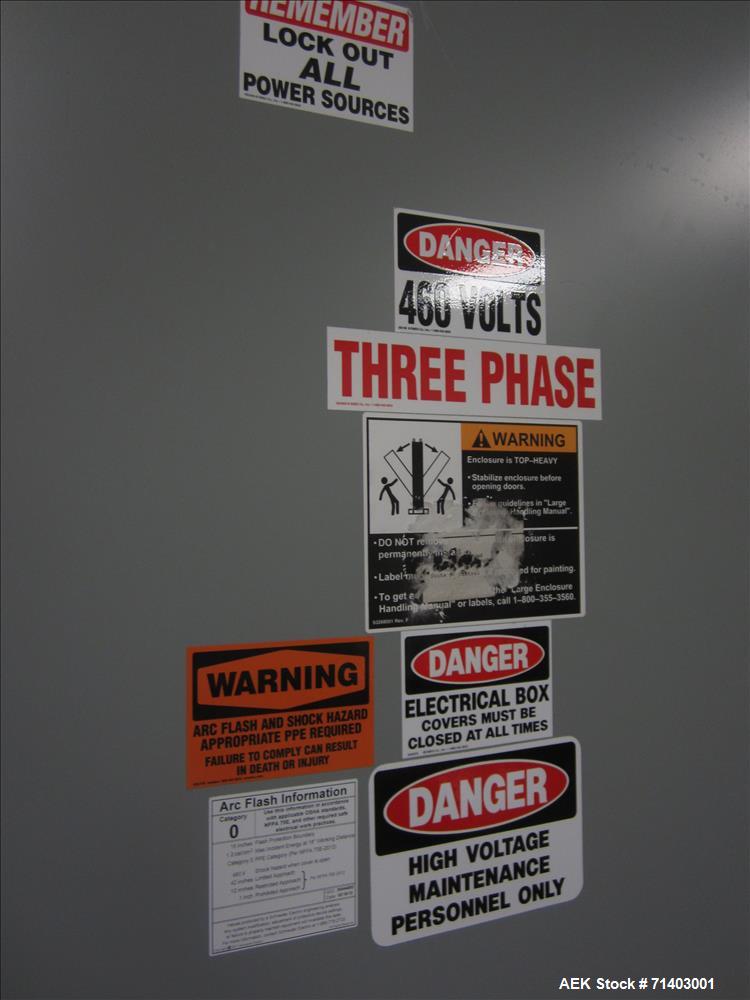

Used Lakso 990 (Model 93) Complete Solid Dose Packaging line. Line consists of a New England Machinery Model NEHAE-CL48 bulk bottle unscrambler with Ionized bottle cleaner and integrated New England HE/40 bulk bottle feeder. Omega Design Model CDF101 canister style desiccant feeder with starwheel indexing set up on 2 gram canisters, Lakso Model 990 reformer slat counter single lane wormscrew infeed and microscan tablet detection, Allen Bradley Micrologix 1200 plc, Allen Bradley panelview 550, with air reject for bottles. Lakso 300 twin head cottoner with wormscrew container handling and missing cotton detection. Lock Met30+ metal detector with 6" x 6" aperature and pneumatic container reject into Resina Model U40 capper with integrated cleated belt cap elevator, bump wheel infeed, single belt container handling. Cap size range: 13mm - 70 mm with changeparts and currently set up for 28mm, 33mm and 43mm diameter caps, Pillar Unifoiler induction sealer with missing cap detection.

Used Lakso 990 (Model 93) Complete Solid Dose Packaging line. Line consists of a New England Machinery Model NEHAE-CL48 bulk bottle unscrambler with Ionized bottle cleaner and integrated New England HE/40 bulk bottle feeder. Omega Design Model CDF101 canister style desiccant feeder with starwheel indexing set up on 2 gram canisters, Lakso Model 990 reformer slat counter single lane wormscrew infeed and microscan tablet detection, Allen Bradley Micrologix 1200 plc, Allen Bradley panelview 550, with air reject for bottles. Lakso 300 twin head cottoner with wormscrew container handling and missing cotton detection. Lock Met30+ metal detector with 6" x 6" aperature and pneumatic container reject into Resina Model U40 capper with integrated cleated belt cap elevator, bump wheel infeed, single belt container handling. Cap size range: 13mm - 70 mm with changeparts and currently set up for 28mm, 33mm and 43mm diameter caps, Pillar Unifoiler induction sealer with missing cap detection.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory