Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

IDI Automation Fanuc Robotic Pick and Place Product Loader

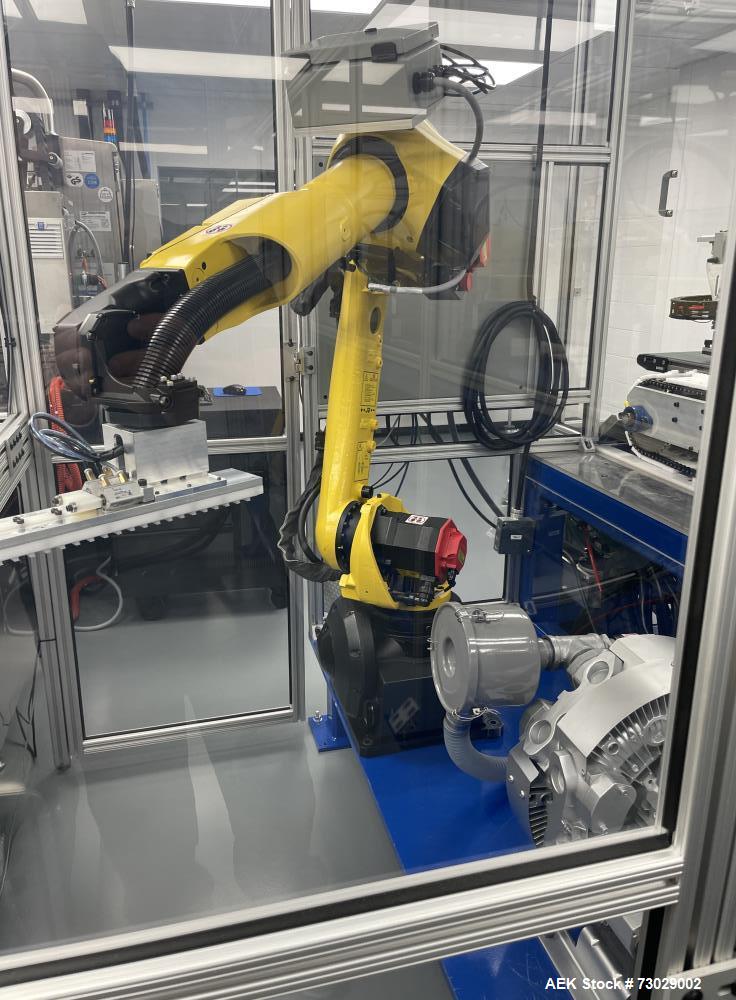

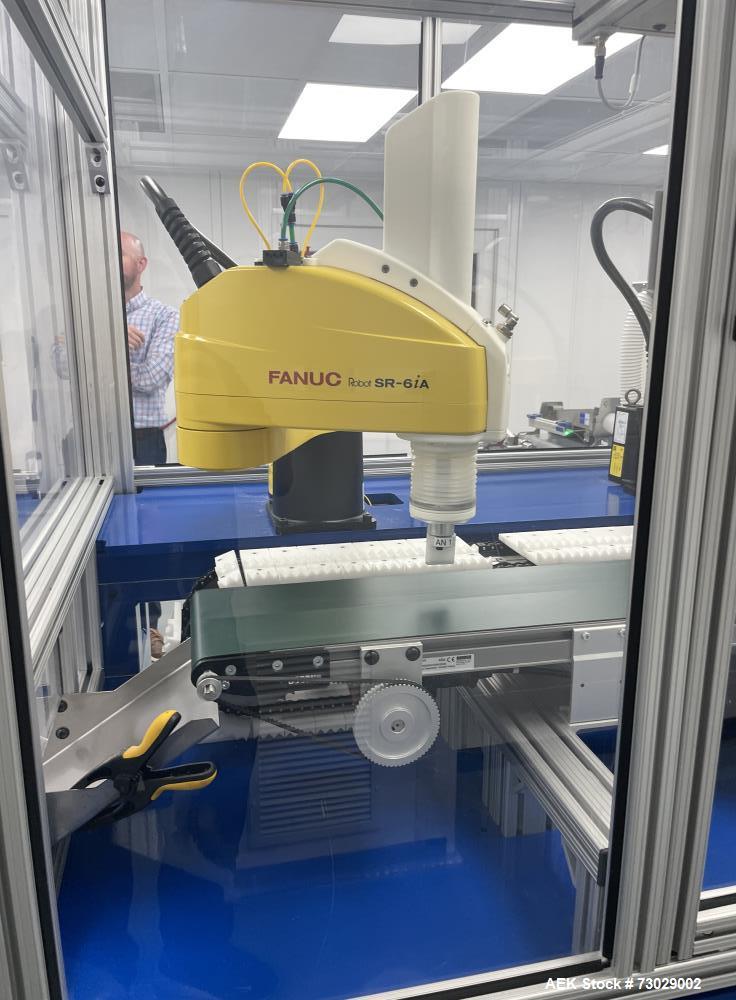

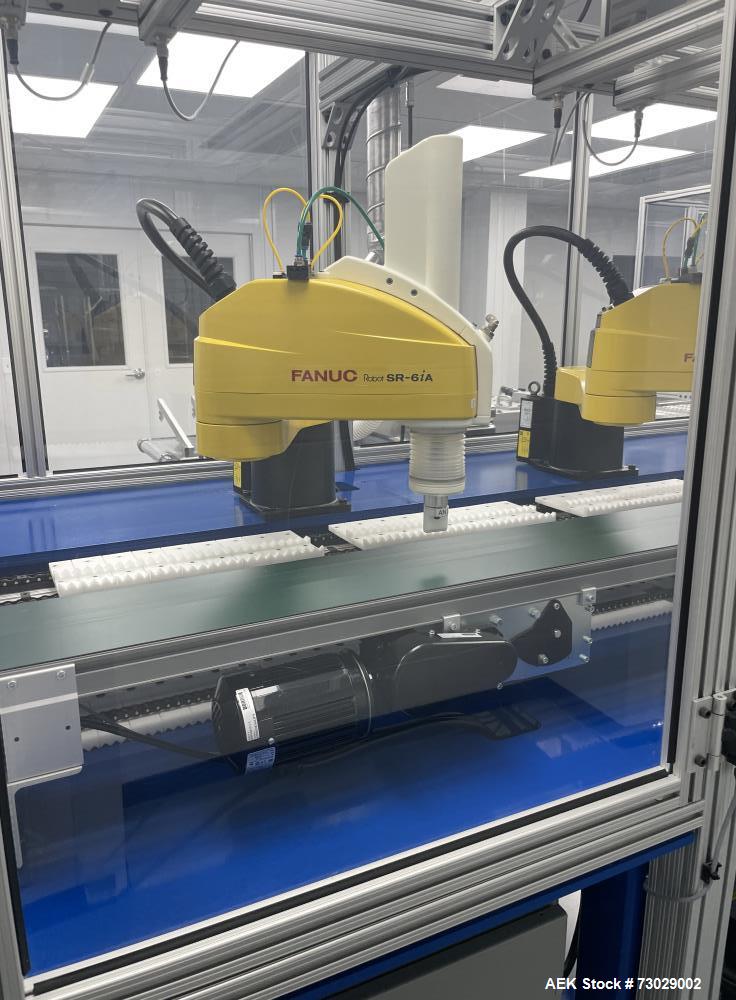

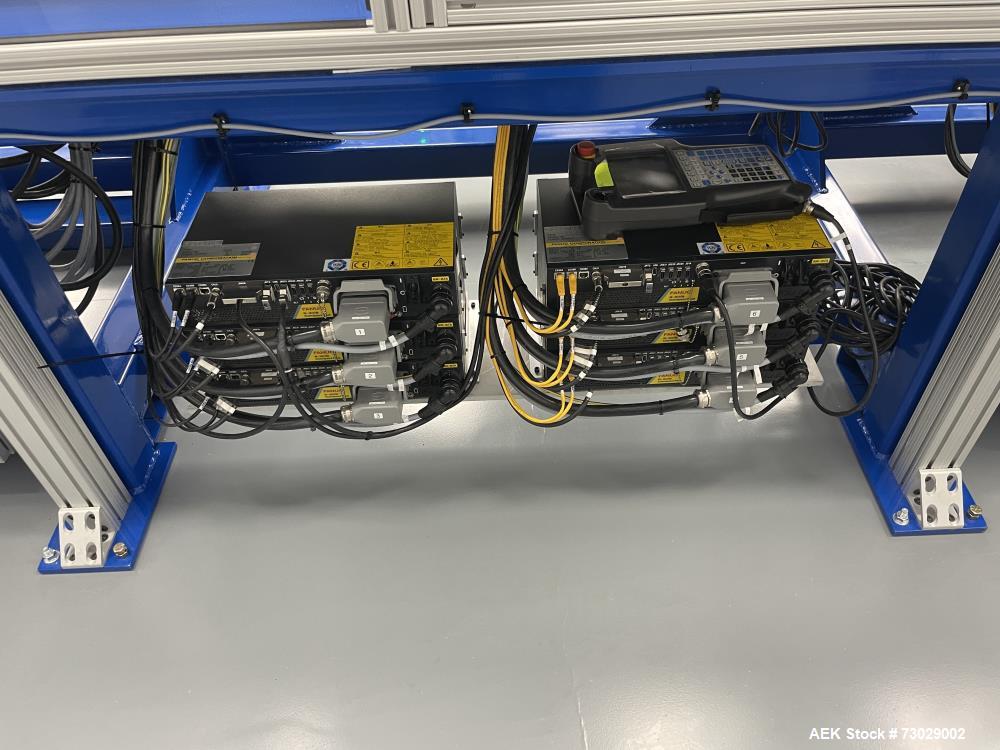

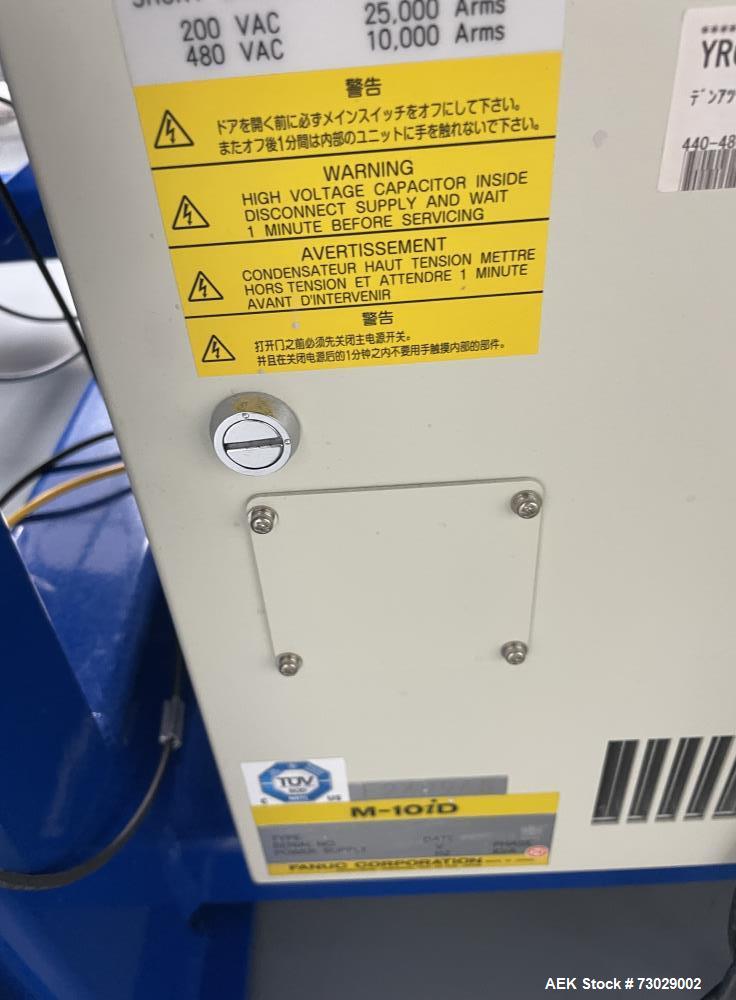

Used IDI Automation Fanuc Robotic Pick and Place Product Loader for Medical Device Diagnostic Swab Sticks. IDI Automated System:Automated loading system to receive swabs and load them into the pockets of aMultivac machine. The IDI automation receives groups of swabs that aremanually placed in the vibratory trays of the IDI feed system. These swabs are then separated and conveyed under machine visionguided robots where cameras locate the parts on the conveyor. The locationinformation is communicated to the robots. The robots pick the parts from theconveyor and place them on an intermediate conveyor. Another robot picks an array of swabs from this conveyor and loads them into the pockets of the Multivac machine. System includes: (6) Fanuc Scara Robots to pick swabs from the feed conveyor and load them onto the intermediate conveyor(6) Anubis Covers to cover the quill on each of the scara robots(1) Fanuc M-10iA Robot to pick an array of swabs from the intermediateconveyor and load them into formed pockets on the Multivac machine(6) Robot End of Arm Tools designed as needed to handle swabs(1) M-10 End of Arm Tool designed to handle an array of swabsMachine Vision System for robot guidance in picking the swabs from the swabfeed conveyor(7) Machine Vision Camera w/ lensDedicated LightingComponent mounting frameworkSystem Base painted/powder coated steel base on which to mount the majorcomponentsSwab Feed and Separation System operator places groups of 1000 swabs onthis system conveyor.System feeds swabs from bulk hoppers to the feeding belt.The system createsseparation between the parts and conveys them past the scara robots. Therobots pick from this conveyor system.Intermediate Conveyor the robots place swabs on this conveyor and the M-10robot picks an array from this conveyorAllen-Bradley CompactLogix PLC to serve as the system controllerTouchscreen Operator Interface on which to display system run timeinformationAdditional Touchscreen Operator Interface this screen is to be mounted in asmaller enclosure.System Safety Guarding safety devices, safety interlocks and relays, and EStopcontrols to enclose the IDI provided robot work area. Extruded aluminumfencing is mounted directly to the system base. Electrical Enclosure to houseIDI provided to system electrical components, robot

Medical Device, Medical Device Development, Medical Goods, Medicine, Packaging, Packaging Equipment

Used IDI Automation Fanuc Robotic Pick and Place Product Loader for Medical Device Diagnostic Swab Sticks. IDI Automated System:Automated loading system to receive swabs and load them into the pockets of aMultivac machine. The IDI automation receives groups of swabs that aremanually placed in the vibratory trays of the IDI feed system. These swabs are then separated and conveyed under machine visionguided robots where cameras locate the parts on the conveyor. The locationinformation is communicated to the robots. The robots pick the parts from theconveyor and place them on an intermediate conveyor. Another robot picks an array of swabs from this conveyor and loads them into the pockets of the Multivac machine. System includes: (6) Fanuc Scara Robots to pick swabs from the feed conveyor and load them onto the intermediate conveyor(6) Anubis Covers to cover the quill on each of the scara robots(1) Fanuc M-10iA Robot to pick an array of swabs from the intermediateconveyor and load them into formed pockets on the Multivac machine(6) Robot End of Arm Tools designed as needed to handle swabs(1) M-10 End of Arm Tool designed to handle an array of swabsMachine Vision System for robot guidance in picking the swabs from the swabfeed conveyor(7) Machine Vision Camera w/ lensDedicated LightingComponent mounting frameworkSystem Base painted/powder coated steel base on which to mount the majorcomponentsSwab Feed and Separation System operator places groups of 1000 swabs onthis system conveyor.System feeds swabs from bulk hoppers to the feeding belt.The system createsseparation between the parts and conveys them past the scara robots. Therobots pick from this conveyor system.Intermediate Conveyor the robots place swabs on this conveyor and the M-10robot picks an array from this conveyorAllen-Bradley CompactLogix PLC to serve as the system controllerTouchscreen Operator Interface on which to display system run timeinformationAdditional Touchscreen Operator Interface this screen is to be mounted in asmaller enclosure.System Safety Guarding safety devices, safety interlocks and relays, and EStopcontrols to enclose the IDI provided robot work area. Extruded aluminumfencing is mounted directly to the system base. Electrical Enclosure to houseIDI provided to system electrical components, robot

Medical Device, Medical Device Development, Medical Goods, Medicine, Packaging, Packaging Equipment

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory