Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Groninger KVG Single Head Cosmetic Chuck Capper.

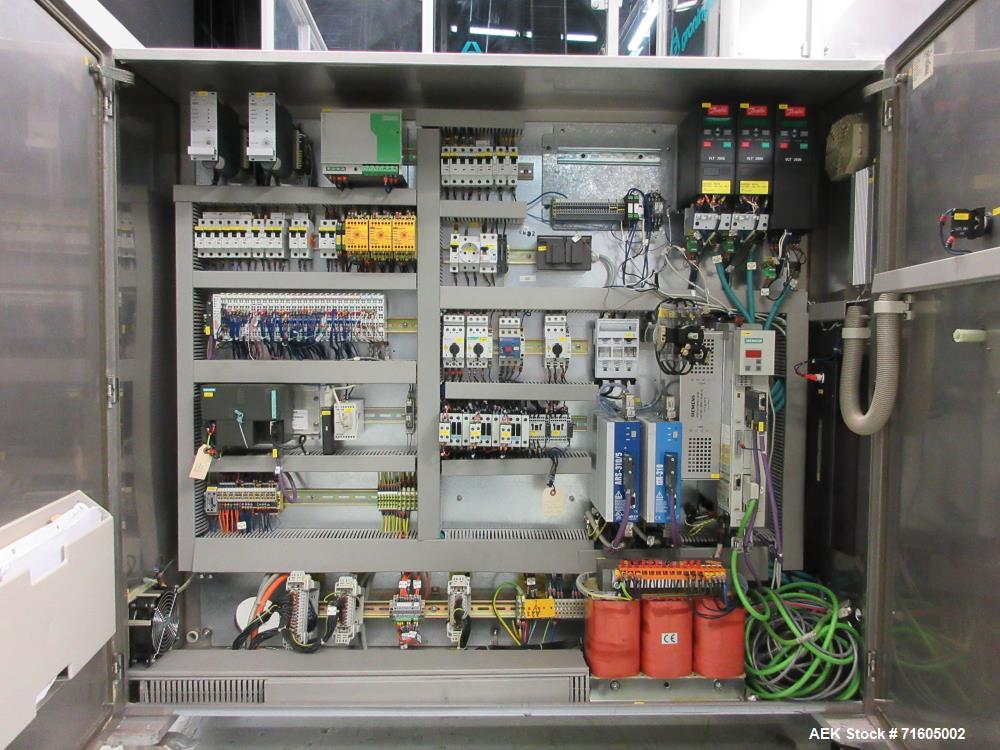

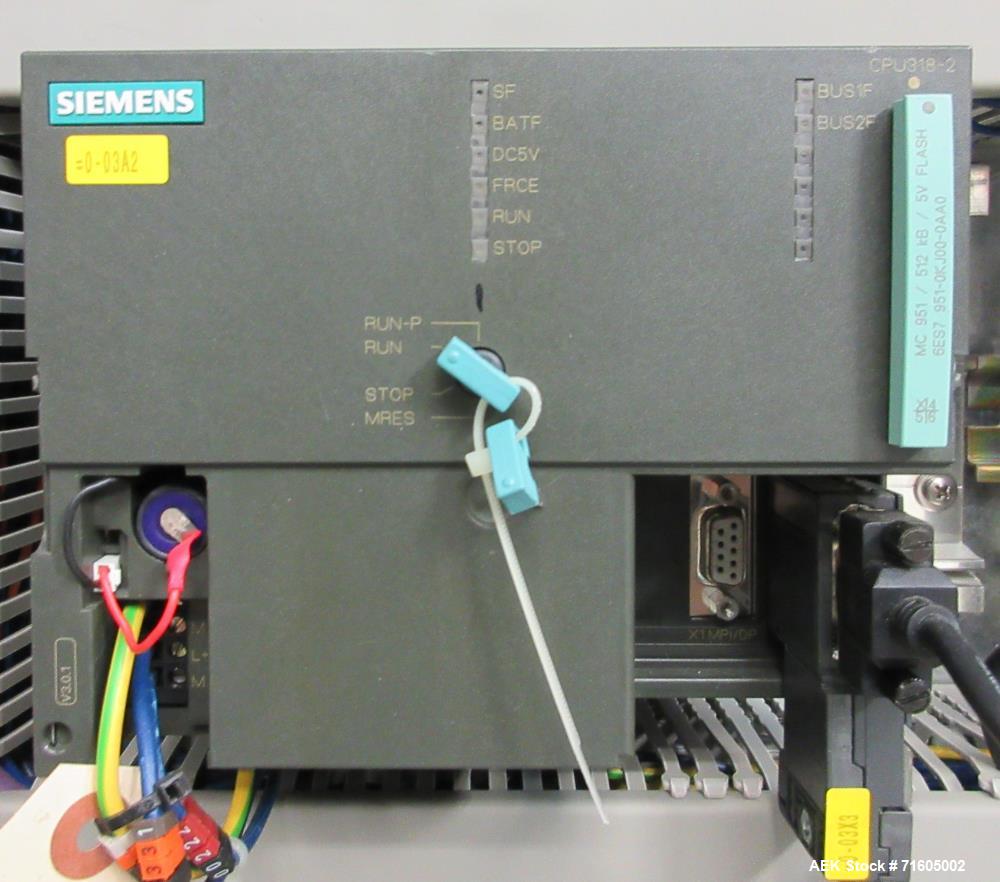

Used Groninger Automatic Press on Capper Model KVG 201, S/N 5854. Last operating on cosmetic product. Caps are manually fed by operator on trays (8 caps across), the process is automatic with tray infeed, the trays are transported to the robotic cap pick station, caps are then transferred to the cap puck conveyor and transported to a secondary pick and compression capping station. Integral controls, main electric panel, Siemens S7-300 controls, typical operating speed is 50 cpm. With 1-Herma Pressure Sensitive Bottom Labeler Model 362MHC with Allen hot stamp coder, S/N 821931. Applying bottom labels to liquid make up bottles. Designed for puck container handling using 3" wide puck conveyor. Caps are fed by 19" wide trays and placed onto 2.25" sqr pucks. Includes controls.

- Used Groninger KVG Single Head Cosmetic Chuck Capper

- Groninger KVG Single Head Cosmetic Chuck Capper

- KVG Single Head Cosmetic Chuck Capper

- Groninger Single Head Cosmetic Chuck Capper

- Single Head Cosmetic Chuck Capper

- Cosmetic Chuck Capper

- Chuck Capper

- Capper

- Groninger Capper

- KVG Capper

- Cosmetic Chuck Capper

- Used Packaging Machinery

- Used Capper

Used Groninger Automatic Press on Capper Model KVG 201, S/N 5854. Last operating on cosmetic product. Caps are manually fed by operator on trays (8 caps across), the process is automatic with tray infeed, the trays are transported to the robotic cap pick station, caps are then transferred to the cap puck conveyor and transported to a secondary pick and compression capping station. Integral controls, main electric panel, Siemens S7-300 controls, typical operating speed is 50 cpm. With 1-Herma Pressure Sensitive Bottom Labeler Model 362MHC with Allen hot stamp coder, S/N 821931. Applying bottom labels to liquid make up bottles. Designed for puck container handling using 3" wide puck conveyor. Caps are fed by 19" wide trays and placed onto 2.25" sqr pucks. Includes controls.

- Used Groninger KVG Single Head Cosmetic Chuck Capper

- Groninger KVG Single Head Cosmetic Chuck Capper

- KVG Single Head Cosmetic Chuck Capper

- Groninger Single Head Cosmetic Chuck Capper

- Single Head Cosmetic Chuck Capper

- Cosmetic Chuck Capper

- Chuck Capper

- Capper

- Groninger Capper

- KVG Capper

- Cosmetic Chuck Capper

- Used Packaging Machinery

- Used Capper

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory