Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used DCI 800 Gallon Twin Motion Kettle – 316 Stainless Steel, Jacketed, Industrial Mixer

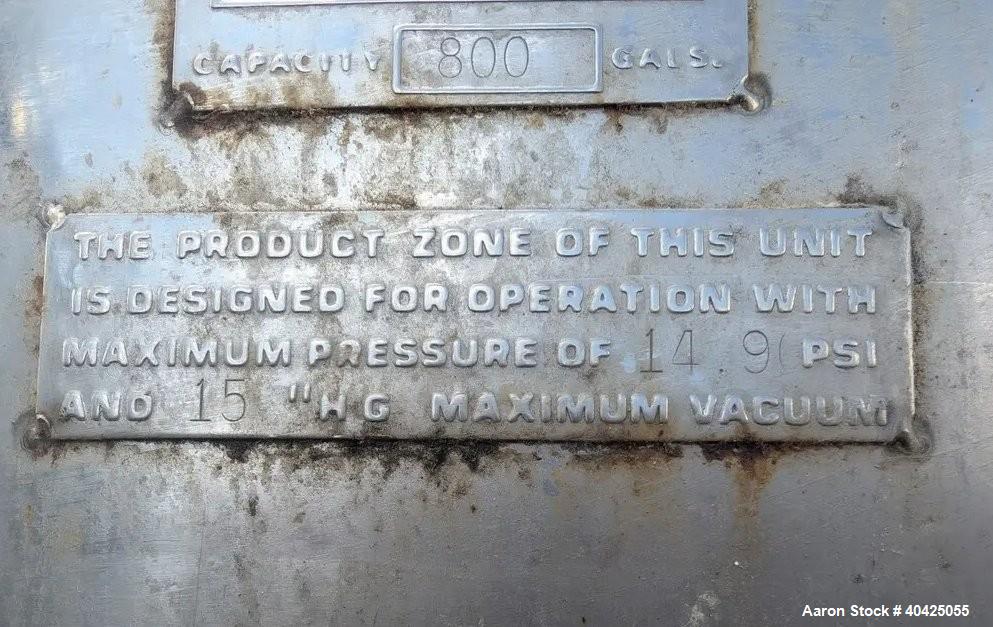

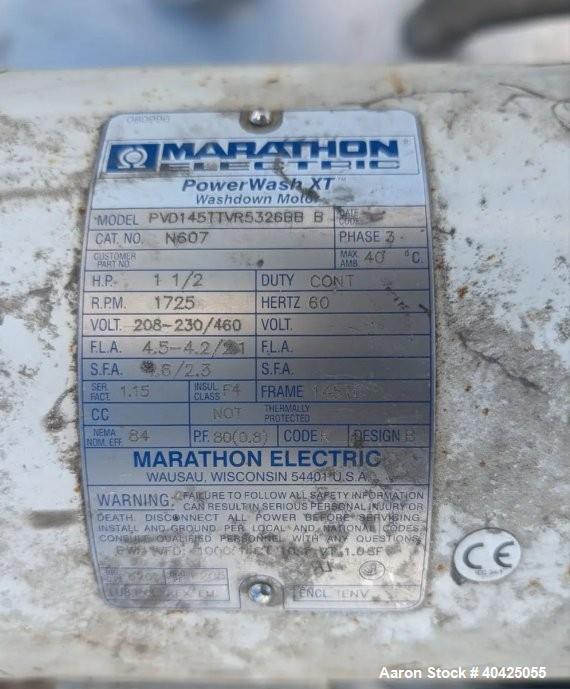

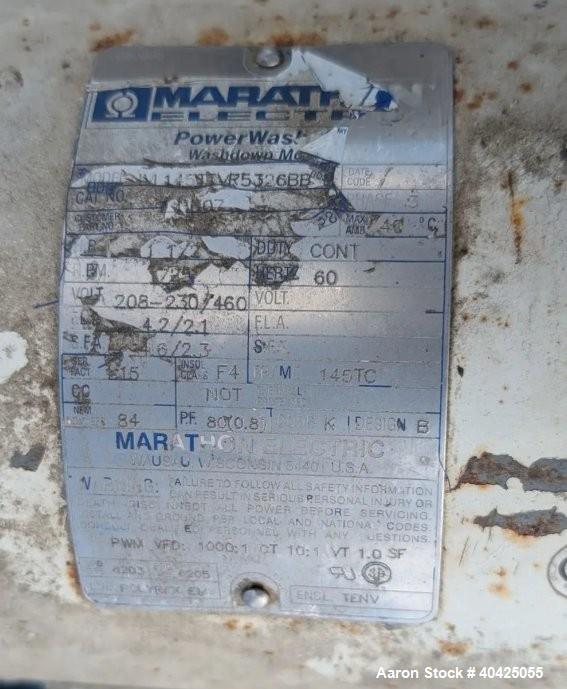

Used DCI 800 Gallon 316 Stainless Steel Vertical Twin Motion Kettle. Approximate 66" Diameter x 40" straight side. Dish top and bottom. Internal rated 14.9 psi/-15 vacuum internal at 300 degrees F. Jacketed rated 60 psi/-15 vacuum at 250 degrees F. Twin motion agitation with 1HP center anchor agitator with motor drive. Off-center 4-blade pitched turbine agitator driven by 1HP motor drive. Openings: 18" manway; 2" center bottom outlet. Mounted on (3) legs. Serial# 91-PH42252-D. Built 1991.

Description

The Used DCI 800 Gallon Twin Motion Kettle is a high-performance, stainless steel processing vessel designed for mixing, heating, and vacuum processing in food, pharmaceutical, and industrial applications. Constructed from 316 stainless steel, the kettle ensures corrosion resistance, durability, and sanitary processing.

This vertical kettle features a 66” diameter x 40” straight side with a dish top and bottom for efficient heating and agitation. The internal chamber is rated for 14.9 psi/-15 vacuum at 300°F, while the jacket is rated for 60 psi/-15 vacuum at 250°F, providing versatile heating and cooling capabilities.

The twin motion agitation system includes:

- A 1 HP center anchor agitator with a motor drive

- An off-center 4-blade pitched turbine agitator powered by a 1 HP motor drive

Designed for easy access and operation, the kettle includes an 18" manway, a 2" center bottom outlet, and is mounted on three sturdy legs for stability.

Specifications

- Capacity: 800 Gallons

- Construction: 316 Stainless Steel

- Orientation: Vertical

- Dimensions:

- Diameter: 66”

- Straight Side Height: 40”

- Pressure Ratings:

- Internal: 14.9 psi/-15 vacuum at 300°F

- Jacket: 60 psi/-15 vacuum at 250°F

- Agitation System:

- Twin motion agitation

- 1 HP center anchor agitator with motor drive

- Off-center 4-blade pitched turbine agitator with 1 HP motor drive

- Openings:

- 18" manway

- 2" center bottom outlet

- Mounting: (3) stainless steel legs

Applications

This DCI twin motion kettle is ideal for:

- Food and beverage processing (soups, sauces, dairy, syrups)

- Pharmaceutical and nutraceutical production

- Cosmetic and personal care manufacturing

- Chemical and industrial mixing

- Vacuum mixing and batch processing

What Products Would This Be Used For?

- Soups, sauces, and gravies

- Dairy products (yogurt, custards, creams)

- Pharmaceutical creams, gels, and ointments

- Cosmetic lotions and skincare products

- Chemical and industrial liquid formulations

- Used DCI kettle

- 800-gallon stainless steel mixing tank

- 316 SS vertical mix tank

- twin motion agitator kettle

- pharmaceutical-grade mixing vessel

- food-grade stainless steel tank

- chemical processing kettle

- used batch mixer

- industrial blending tank

- vacuum-rated mixing tank

- Used DCI 800-gallon stainless steel twin motion kettle for sale

- High-efficiency mixing tank for food and pharmaceutical applications

- Industrial 316 stainless steel mixing vessel with twin motion agitation

- Jacketed mixing kettle with vacuum and pressure ratings

- Used stainless steel batch mixer with turbine and anchor agitators

- Vertical stainless steel processing tank for chemical and cosmetic production

- Pre-owned DCI liquid mixing kettle with 1 HP agitators

- Heavy-duty industrial kettle with 18-inch manway and 2-inch bottom outlet

- Used pharmaceutical-grade vacuum mixing tank for sale

- Large-scale stainless steel mixing vessel for nutraceutical and industrial applications

Used DCI 800 Gallon 316 Stainless Steel Vertical Twin Motion Kettle. Approximate 66" Diameter x 40" straight side. Dish top and bottom. Internal rated 14.9 psi/-15 vacuum internal at 300 degrees F. Jacketed rated 60 psi/-15 vacuum at 250 degrees F. Twin motion agitation with 1HP center anchor agitator with motor drive. Off-center 4-blade pitched turbine agitator driven by 1HP motor drive. Openings: 18" manway; 2" center bottom outlet. Mounted on (3) legs. Serial# 91-PH42252-D. Built 1991.

Description

The Used DCI 800 Gallon Twin Motion Kettle is a high-performance, stainless steel processing vessel designed for mixing, heating, and vacuum processing in food, pharmaceutical, and industrial applications. Constructed from 316 stainless steel, the kettle ensures corrosion resistance, durability, and sanitary processing.

This vertical kettle features a 66” diameter x 40” straight side with a dish top and bottom for efficient heating and agitation. The internal chamber is rated for 14.9 psi/-15 vacuum at 300°F, while the jacket is rated for 60 psi/-15 vacuum at 250°F, providing versatile heating and cooling capabilities.

The twin motion agitation system includes:

- A 1 HP center anchor agitator with a motor drive

- An off-center 4-blade pitched turbine agitator powered by a 1 HP motor drive

Designed for easy access and operation, the kettle includes an 18" manway, a 2" center bottom outlet, and is mounted on three sturdy legs for stability.

Specifications

- Capacity: 800 Gallons

- Construction: 316 Stainless Steel

- Orientation: Vertical

- Dimensions:

- Diameter: 66”

- Straight Side Height: 40”

- Pressure Ratings:

- Internal: 14.9 psi/-15 vacuum at 300°F

- Jacket: 60 psi/-15 vacuum at 250°F

- Agitation System:

- Twin motion agitation

- 1 HP center anchor agitator with motor drive

- Off-center 4-blade pitched turbine agitator with 1 HP motor drive

- Openings:

- 18" manway

- 2" center bottom outlet

- Mounting: (3) stainless steel legs

Applications

This DCI twin motion kettle is ideal for:

- Food and beverage processing (soups, sauces, dairy, syrups)

- Pharmaceutical and nutraceutical production

- Cosmetic and personal care manufacturing

- Chemical and industrial mixing

- Vacuum mixing and batch processing

What Products Would This Be Used For?

- Soups, sauces, and gravies

- Dairy products (yogurt, custards, creams)

- Pharmaceutical creams, gels, and ointments

- Cosmetic lotions and skincare products

- Chemical and industrial liquid formulations

- Used DCI kettle

- 800-gallon stainless steel mixing tank

- 316 SS vertical mix tank

- twin motion agitator kettle

- pharmaceutical-grade mixing vessel

- food-grade stainless steel tank

- chemical processing kettle

- used batch mixer

- industrial blending tank

- vacuum-rated mixing tank

- Used DCI 800-gallon stainless steel twin motion kettle for sale

- High-efficiency mixing tank for food and pharmaceutical applications

- Industrial 316 stainless steel mixing vessel with twin motion agitation

- Jacketed mixing kettle with vacuum and pressure ratings

- Used stainless steel batch mixer with turbine and anchor agitators

- Vertical stainless steel processing tank for chemical and cosmetic production

- Pre-owned DCI liquid mixing kettle with 1 HP agitators

- Heavy-duty industrial kettle with 18-inch manway and 2-inch bottom outlet

- Used pharmaceutical-grade vacuum mixing tank for sale

- Large-scale stainless steel mixing vessel for nutraceutical and industrial applications

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory