Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Unused MRW Technologies Open Flare – 64'6" Height | Carbon Steel | Allen-Bradley MicroLogix 1100 | Bio-Diesel Application

Unused- MRW Technologies Open Flare, Carbon Steel. Approximate 64'6" overall height. With control panel and Allen-Bradley MicroLogix 1100 controller. Last used In Bio-Diesel.

| Manufacturer | MRWMRW |

| Category | IncineratorsIncinerators |

| Subcategory | IncineratorsIncinerators |

Manufacturer Information:

-

Brand: MRW Technologies

-

Type: Open Flare System

-

Material: Carbon Steel

-

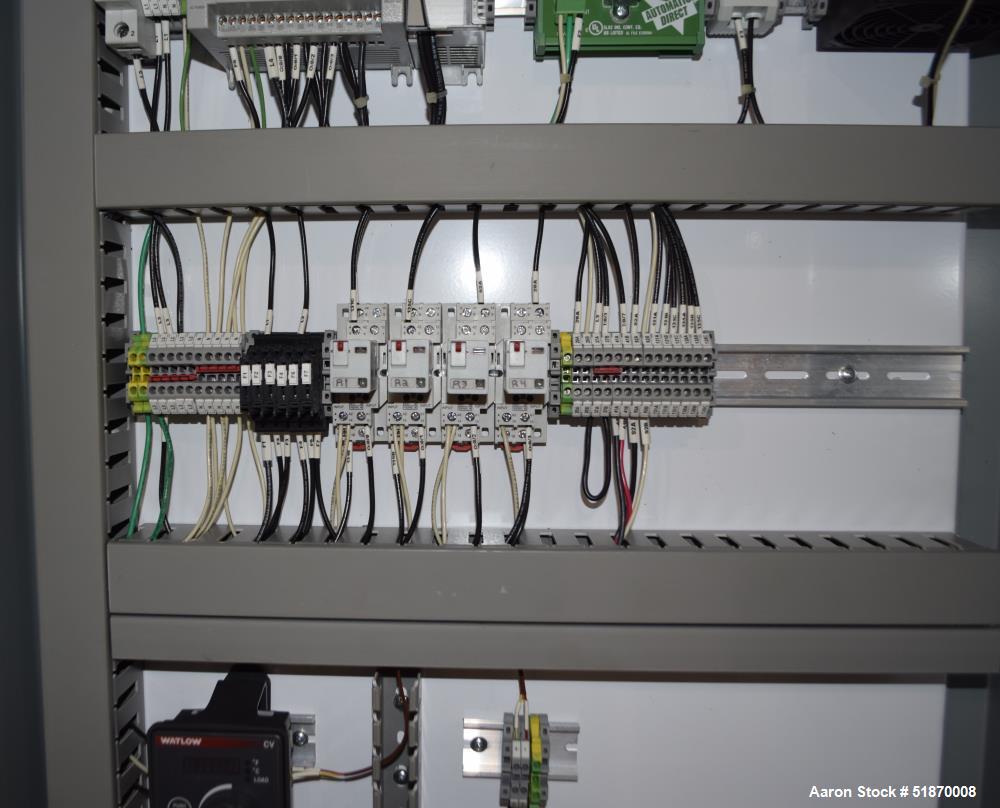

Control Panel: Included

-

PLC Controller: Allen-Bradley MicroLogix 1100

-

Condition: Unused

-

Previous Application: Designed for use in a bio-diesel processing environment

Description:

This Unused MRW Technologies Open Flare System, standing approximately 64 feet, 6 inches tall, is a heavy-duty carbon steel combustion flare designed for safe and efficient waste gas disposal in industrial or biofuel applications. Equipped with a control panel and Allen-Bradley MicroLogix 1100 programmable logic controller (PLC), this unit provides precise control, reliable performance, and easy integration into plant-wide monitoring systems.

Originally installed for a bio-diesel processing operation, this open flare system was never used and remains in excellent condition, ready for immediate deployment in waste gas management, flaring, or off-gas control environments.

Specifications:

-

System Type: Open Flare

-

Material: Carbon Steel

-

Overall Height: Approx. 64'6" (feet-inches)

-

Control System:

-

Control Panel Included

-

Allen-Bradley MicroLogix 1100 PLC

-

-

Condition: Unused

-

Application: Designed for bio-diesel facility (never commissioned)

Features:

-

High-capacity open flare system for industrial or process gas venting

-

Constructed from durable carbon steel for outdoor and high-heat applications

-

Full control system included for remote or local operation

-

Allen-Bradley PLC allows integration into existing plant SCADA or control systems

-

Designed for use in environmentally conscious biofuel operations

-

Tall stack ensures safe flame dispersion and combustion efficiency

-

Ideal for low-pressure waste gas flaring or emergency venting situations

-

Easy installation and commissioning with all controls intact

Applications:

-

Bio-diesel production facilities

-

Petrochemical and refinery waste gas flaring

-

Industrial process vent gas control

-

Chemical manufacturing exhaust handling

-

Biogas plant flare management

-

Emergency venting system for process plants

-

Waste-to-energy or renewable fuel systems

-

Off-gas combustion in remote or high-volume sites

-

Pilot or full-scale clean energy systems

What might this be used for?

-

Burning off low-pressure waste gases during bio-diesel production

-

Replacing or upgrading flare stacks in existing process systems

-

Providing reliable combustion of methane or VOCs in renewable fuel plants

-

Safely disposing of excess hydrocarbon gases in chemical or fuel production

-

Commissioning a new flare system in a compliance-sensitive application

-

Managing off-gas emissions in start-up, upset, or shutdown conditions

-

Creating environmentally sound venting strategies for volatile gas sources

-

Integrating a PLC-monitored open flare into industrial process lines

-

Enhancing site safety and emissions control for renewable energy operations

-

Supporting mobile or modular flaring applications with automation-ready control

-

Open flare

-

Flare system

-

MRW flare

-

Bio-diesel flare

-

Carbon steel flare

-

Industrial flare

-

Gas flare

-

PLC flare

-

Flare stack

-

Allen-Bradley PLC

-

MRW Technologies open flare system

-

Unused carbon steel flare stack

-

64'6" open flare for sale

-

Bio-diesel vent flare

-

Flare with Allen-Bradley MicroLogix 1100

-

Waste gas combustion system

-

PLC controlled flare stack

-

Industrial gas flaring unit

-

Used flare system never commissioned

-

Flare with control panel included

-

Unused MRW Technologies open flare system with Allen-Bradley MicroLogix 1100 controller and 64'6" carbon steel stack

-

Bio-diesel process flare for vent gas combustion, unused and ready for deployment

-

Tall industrial flare stack with PLC control and control panel included for automated operation

-

Carbon steel open flare system for waste gas disposal in chemical and renewable fuel plants

-

Unused flare system for emergency gas venting or routine emissions control in biofuel operations

-

MRW flare with integrated Allen-Bradley PLC and SCADA compatibility

-

Turnkey flare solution for safe off-gas combustion in environmentally regulated industries

-

High-reliability flare stack for safe combustion of low-pressure waste gases

-

Flare system for bio-diesel and industrial chemical facilities, never used

-

Skid-ready flare system for waste-to-energy or biogas plants

-

Buy unused flare system

-

MRW Technologies flare for sale

-

Purchase flare stack with PLC

-

Gas flare for industrial plant

-

Bio-diesel flare system buy

-

Allen-Bradley controlled flare

-

Carbon steel flare system

-

Used but unused flare unit

-

Buy open flare with control panel

-

Flare system for fuel processing plant

-

Sell unused open flare

-

List MRW flare system

-

Resell flare stack with PLC

-

Liquidate unused flare equipment

-

Control panel flare resale

-

Industrial vent flare for sale

-

Open flare for gas disposal resale

-

Sell biofuel process flare

-

Used flare equipment listing

-

Resell carbon steel flare system

Unused- MRW Technologies Open Flare, Carbon Steel. Approximate 64'6" overall height. With control panel and Allen-Bradley MicroLogix 1100 controller. Last used In Bio-Diesel.

Manufacturer Information:

-

Brand: MRW Technologies

-

Type: Open Flare System

-

Material: Carbon Steel

-

Control Panel: Included

-

PLC Controller: Allen-Bradley MicroLogix 1100

-

Condition: Unused

-

Previous Application: Designed for use in a bio-diesel processing environment

Description:

This Unused MRW Technologies Open Flare System, standing approximately 64 feet, 6 inches tall, is a heavy-duty carbon steel combustion flare designed for safe and efficient waste gas disposal in industrial or biofuel applications. Equipped with a control panel and Allen-Bradley MicroLogix 1100 programmable logic controller (PLC), this unit provides precise control, reliable performance, and easy integration into plant-wide monitoring systems.

Originally installed for a bio-diesel processing operation, this open flare system was never used and remains in excellent condition, ready for immediate deployment in waste gas management, flaring, or off-gas control environments.

Specifications:

-

System Type: Open Flare

-

Material: Carbon Steel

-

Overall Height: Approx. 64'6" (feet-inches)

-

Control System:

-

Control Panel Included

-

Allen-Bradley MicroLogix 1100 PLC

-

-

Condition: Unused

-

Application: Designed for bio-diesel facility (never commissioned)

Features:

-

High-capacity open flare system for industrial or process gas venting

-

Constructed from durable carbon steel for outdoor and high-heat applications

-

Full control system included for remote or local operation

-

Allen-Bradley PLC allows integration into existing plant SCADA or control systems

-

Designed for use in environmentally conscious biofuel operations

-

Tall stack ensures safe flame dispersion and combustion efficiency

-

Ideal for low-pressure waste gas flaring or emergency venting situations

-

Easy installation and commissioning with all controls intact

Applications:

-

Bio-diesel production facilities

-

Petrochemical and refinery waste gas flaring

-

Industrial process vent gas control

-

Chemical manufacturing exhaust handling

-

Biogas plant flare management

-

Emergency venting system for process plants

-

Waste-to-energy or renewable fuel systems

-

Off-gas combustion in remote or high-volume sites

-

Pilot or full-scale clean energy systems

What might this be used for?

-

Burning off low-pressure waste gases during bio-diesel production

-

Replacing or upgrading flare stacks in existing process systems

-

Providing reliable combustion of methane or VOCs in renewable fuel plants

-

Safely disposing of excess hydrocarbon gases in chemical or fuel production

-

Commissioning a new flare system in a compliance-sensitive application

-

Managing off-gas emissions in start-up, upset, or shutdown conditions

-

Creating environmentally sound venting strategies for volatile gas sources

-

Integrating a PLC-monitored open flare into industrial process lines

-

Enhancing site safety and emissions control for renewable energy operations

-

Supporting mobile or modular flaring applications with automation-ready control

| Manufacturer | MRW |

| Category | Incinerators |

| Subcategory | Incinerators |

-

Open flare

-

Flare system

-

MRW flare

-

Bio-diesel flare

-

Carbon steel flare

-

Industrial flare

-

Gas flare

-

PLC flare

-

Flare stack

-

Allen-Bradley PLC

-

MRW Technologies open flare system

-

Unused carbon steel flare stack

-

64'6" open flare for sale

-

Bio-diesel vent flare

-

Flare with Allen-Bradley MicroLogix 1100

-

Waste gas combustion system

-

PLC controlled flare stack

-

Industrial gas flaring unit

-

Used flare system never commissioned

-

Flare with control panel included

-

Unused MRW Technologies open flare system with Allen-Bradley MicroLogix 1100 controller and 64'6" carbon steel stack

-

Bio-diesel process flare for vent gas combustion, unused and ready for deployment

-

Tall industrial flare stack with PLC control and control panel included for automated operation

-

Carbon steel open flare system for waste gas disposal in chemical and renewable fuel plants

-

Unused flare system for emergency gas venting or routine emissions control in biofuel operations

-

MRW flare with integrated Allen-Bradley PLC and SCADA compatibility

-

Turnkey flare solution for safe off-gas combustion in environmentally regulated industries

-

High-reliability flare stack for safe combustion of low-pressure waste gases

-

Flare system for bio-diesel and industrial chemical facilities, never used

-

Skid-ready flare system for waste-to-energy or biogas plants

-

Buy unused flare system

-

MRW Technologies flare for sale

-

Purchase flare stack with PLC

-

Gas flare for industrial plant

-

Bio-diesel flare system buy

-

Allen-Bradley controlled flare

-

Carbon steel flare system

-

Used but unused flare unit

-

Buy open flare with control panel

-

Flare system for fuel processing plant

-

Sell unused open flare

-

List MRW flare system

-

Resell flare stack with PLC

-

Liquidate unused flare equipment

-

Control panel flare resale

-

Industrial vent flare for sale

-

Open flare for gas disposal resale

-

Sell biofuel process flare

-

Used flare equipment listing

-

Resell carbon steel flare system

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory