Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Doyle & Roth Shell & Tube Heat Exchanger | 1963 Sq. Ft. | Alloy 400 Tubes | 300 PSI | 2006/2018

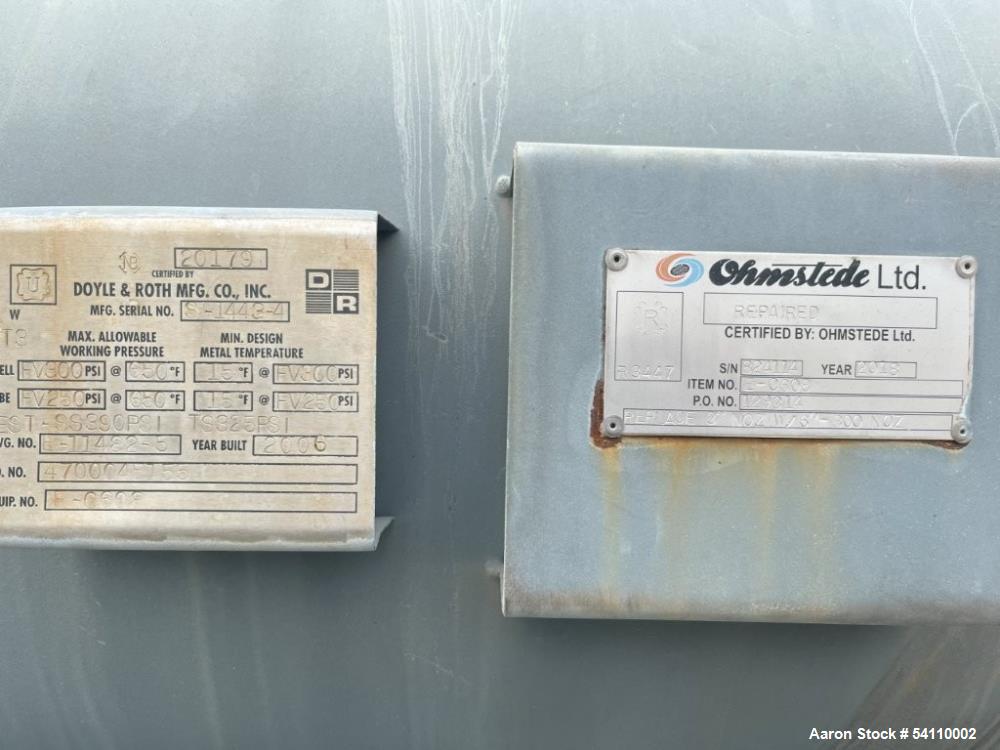

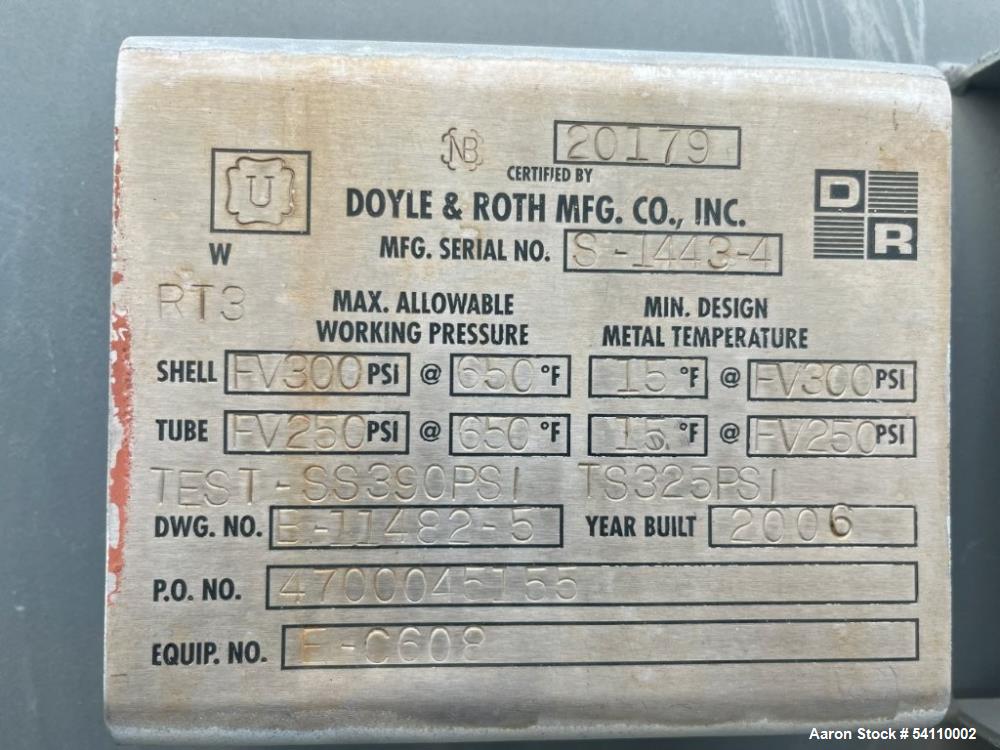

Used Doyle & Roth Shell & Tube Heat Exchanger | 1963 Sq. Ft. | Alloy 400 Tubes | 300 PSI | 2006/2018. Monel/Alloy 400 tube side construction. Full vac/300 psig shell side design pressure; 390 psig shell side test pressure; 650/15 degrees F shell side max./min. design temp.; 1 pass shell side. Full vac/250 psig tube side design pressure; 325 psig tube side test pressure; 650/15 degrees F tube side max./min. design temp.; 3 pass shell side. OAD: 32" D x approx. 248" L. (300) 1.25" D x 240" L tubes. Built 2006, Repaired by Ohmstede in 2018. NB #20179. Original SN S-1443-4, new SN 824114.

| Manufacturer | Doyle & RothDoyle & Roth |

| Serial # | 824114 |

| Category | Heat ExchangersHeat Exchangers |

| Subcategory | Shell & Tube - CarbonShell & Tube - Carbon |

Manufacturer Information

Brand: Doyle & Roth

Type: Shell and Tube Heat Exchanger

Original Serial #: S-1443-4

New Serial #: 824114

National Board #: 20179

Year Built: 2006

Repaired: 2018 by Ohmstede

Tube Material: Monel / Alloy 400

Configuration: 1 pass shell side / 3 pass tube side

Description

This Used Doyle & Roth Shell and Tube Heat Exchanger features 1963 square feet of heat transfer surface area and Monel/Alloy 400 tube side construction for superior corrosion resistance, making it ideal for harsh chemical, seawater, and brine applications.

Built in 2006 and professionally repaired in 2018 by Ohmstede, the unit is rated for full vacuum and up to 300 psig shell side and 250 psig tube side design pressures, with design temperatures up to 650°F. It contains 300 tubes measuring 1.25" diameter × 240" length in a 1 pass shell / 3 pass tube configuration, optimizing thermal performance.

Specifications

-

Surface Area: 1963 sq. ft.

-

Tube Material: Monel / Alloy 400

-

Shell Side:

-

Design Pressure: 300 psig

-

Test Pressure: 390 psig

-

Design Temp: 650°F max / 15°F min

-

Passes: 1

-

Full vacuum rated

-

-

Tube Side:

-

Design Pressure: 250 psig

-

Test Pressure: 325 psig

-

Design Temp: 650°F max / 15°F min

-

Passes: 3

-

Full vacuum rated

-

-

Tube Count & Size: 300 tubes, 1.25" D × 240" L

-

Dimensions: 32" diameter × ~248" length

-

Year Built: 2006

-

Repaired: 2018 (Ohmstede)

-

NB #: 20179

-

SN: S-1443-4 (original), 824114 (new)

What Might This Be Used For?

-

Chemical plant process heat exchange

-

Offshore seawater cooling

-

Petrochemical process heating or cooling

-

Desalination plant heat recovery

-

Power generation condenser applications

-

Brine and saltwater process cooling

-

Oil refinery heat exchanger service

-

Marine engine cooling systems

-

Corrosive fluid heat transfer applications

-

High-temperature industrial heating/cooling

-

Doyle & Roth exchanger

-

Alloy 400 tubes

-

Monel heat exchanger

-

Shell & tube exchanger

-

Industrial heat exchanger

-

High pressure exchanger

-

Process heat exchanger

-

Tube bundle exchanger

-

ASME exchanger

-

Used heat exchanger

-

Used Doyle & Roth shell and tube heat exchanger

-

Alloy 400 tube heat transfer unit

-

300 psi industrial heat exchanger

-

Monel tube bundle for corrosive applications

-

1 pass shell 3 pass tube exchanger

-

High temperature chemical plant exchanger

-

Repaired shell and tube heat exchanger

-

ASME coded Alloy 400 heat exchanger

-

Power plant or refinery heat transfer unit

-

Offshore seawater cooling heat exchanger

-

Used Doyle & Roth 1963 sq ft shell and tube heat exchanger with Alloy 400 Monel tube construction

-

High pressure 300 psi shell and 250 psi tube side heat exchanger for industrial and marine applications

-

Corrosion-resistant Monel heat exchanger for seawater, brine, and chemical process systems

-

ASME-coded shell and tube exchanger built 2006 and repaired in 2018 by Ohmstede

-

Industrial heat exchanger with 1 pass shell side and 3 pass tube side configuration

-

Large capacity heat exchanger for petrochemical and offshore oil platform service

-

Alloy 400 tube bundle exchanger for high temperature up to 650°F

-

Chemical plant heat transfer equipment with Monel tubes and steel shell

-

Long tube length exchanger for maximum surface area and thermal efficiency

-

Industrial process cooling and heating exchanger with repair history

-

Doyle & Roth heat exchanger

-

Monel tube heat exchanger

-

Alloy 400 industrial exchanger

-

Shell and tube process equipment

-

ASME heat exchanger

-

High temperature heat exchanger

-

Used industrial exchanger

-

300 psi heat transfer unit

-

Large capacity tube bundle

-

Corrosion resistant heat exchanger

-

Buy Doyle & Roth shell and tube heat exchanger

-

Purchase Alloy 400 tube bundle exchanger

-

Find Monel industrial heat exchanger for sale

-

Order corrosion-resistant process heat exchanger

-

Buy used high pressure heat exchanger

-

Purchase chemical plant heat transfer unit

-

Get ASME coded shell and tube exchanger

-

Acquire large capacity process heat exchanger

-

Shop industrial heating/cooling equipment

-

Buy repaired industrial exchanger

-

Sell Doyle & Roth heat exchanger

-

List Monel tube exchanger for sale

-

Offer Alloy 400 process heat exchanger

-

Post industrial heat transfer unit listing

-

Market used shell and tube exchanger

-

Resell high capacity corrosion resistant exchanger

-

Promote ASME coded Monel exchanger

-

Auction large capacity process exchanger

-

Sell chemical plant heat transfer equipment

-

Secondhand heat exchanger sales

Used Doyle & Roth Shell & Tube Heat Exchanger | 1963 Sq. Ft. | Alloy 400 Tubes | 300 PSI | 2006/2018. Monel/Alloy 400 tube side construction. Full vac/300 psig shell side design pressure; 390 psig shell side test pressure; 650/15 degrees F shell side max./min. design temp.; 1 pass shell side. Full vac/250 psig tube side design pressure; 325 psig tube side test pressure; 650/15 degrees F tube side max./min. design temp.; 3 pass shell side. OAD: 32" D x approx. 248" L. (300) 1.25" D x 240" L tubes. Built 2006, Repaired by Ohmstede in 2018. NB #20179. Original SN S-1443-4, new SN 824114.

Manufacturer Information

Brand: Doyle & Roth

Type: Shell and Tube Heat Exchanger

Original Serial #: S-1443-4

New Serial #: 824114

National Board #: 20179

Year Built: 2006

Repaired: 2018 by Ohmstede

Tube Material: Monel / Alloy 400

Configuration: 1 pass shell side / 3 pass tube side

Description

This Used Doyle & Roth Shell and Tube Heat Exchanger features 1963 square feet of heat transfer surface area and Monel/Alloy 400 tube side construction for superior corrosion resistance, making it ideal for harsh chemical, seawater, and brine applications.

Built in 2006 and professionally repaired in 2018 by Ohmstede, the unit is rated for full vacuum and up to 300 psig shell side and 250 psig tube side design pressures, with design temperatures up to 650°F. It contains 300 tubes measuring 1.25" diameter × 240" length in a 1 pass shell / 3 pass tube configuration, optimizing thermal performance.

Specifications

-

Surface Area: 1963 sq. ft.

-

Tube Material: Monel / Alloy 400

-

Shell Side:

-

Design Pressure: 300 psig

-

Test Pressure: 390 psig

-

Design Temp: 650°F max / 15°F min

-

Passes: 1

-

Full vacuum rated

-

-

Tube Side:

-

Design Pressure: 250 psig

-

Test Pressure: 325 psig

-

Design Temp: 650°F max / 15°F min

-

Passes: 3

-

Full vacuum rated

-

-

Tube Count & Size: 300 tubes, 1.25" D × 240" L

-

Dimensions: 32" diameter × ~248" length

-

Year Built: 2006

-

Repaired: 2018 (Ohmstede)

-

NB #: 20179

-

SN: S-1443-4 (original), 824114 (new)

What Might This Be Used For?

-

Chemical plant process heat exchange

-

Offshore seawater cooling

-

Petrochemical process heating or cooling

-

Desalination plant heat recovery

-

Power generation condenser applications

-

Brine and saltwater process cooling

-

Oil refinery heat exchanger service

-

Marine engine cooling systems

-

Corrosive fluid heat transfer applications

-

High-temperature industrial heating/cooling

| Manufacturer | Doyle & Roth |

| Serial # | 824114 |

| Category | Heat Exchangers |

| Subcategory | Shell & Tube - Carbon |

-

Doyle & Roth exchanger

-

Alloy 400 tubes

-

Monel heat exchanger

-

Shell & tube exchanger

-

Industrial heat exchanger

-

High pressure exchanger

-

Process heat exchanger

-

Tube bundle exchanger

-

ASME exchanger

-

Used heat exchanger

-

Used Doyle & Roth shell and tube heat exchanger

-

Alloy 400 tube heat transfer unit

-

300 psi industrial heat exchanger

-

Monel tube bundle for corrosive applications

-

1 pass shell 3 pass tube exchanger

-

High temperature chemical plant exchanger

-

Repaired shell and tube heat exchanger

-

ASME coded Alloy 400 heat exchanger

-

Power plant or refinery heat transfer unit

-

Offshore seawater cooling heat exchanger

-

Used Doyle & Roth 1963 sq ft shell and tube heat exchanger with Alloy 400 Monel tube construction

-

High pressure 300 psi shell and 250 psi tube side heat exchanger for industrial and marine applications

-

Corrosion-resistant Monel heat exchanger for seawater, brine, and chemical process systems

-

ASME-coded shell and tube exchanger built 2006 and repaired in 2018 by Ohmstede

-

Industrial heat exchanger with 1 pass shell side and 3 pass tube side configuration

-

Large capacity heat exchanger for petrochemical and offshore oil platform service

-

Alloy 400 tube bundle exchanger for high temperature up to 650°F

-

Chemical plant heat transfer equipment with Monel tubes and steel shell

-

Long tube length exchanger for maximum surface area and thermal efficiency

-

Industrial process cooling and heating exchanger with repair history

-

Doyle & Roth heat exchanger

-

Monel tube heat exchanger

-

Alloy 400 industrial exchanger

-

Shell and tube process equipment

-

ASME heat exchanger

-

High temperature heat exchanger

-

Used industrial exchanger

-

300 psi heat transfer unit

-

Large capacity tube bundle

-

Corrosion resistant heat exchanger

-

Buy Doyle & Roth shell and tube heat exchanger

-

Purchase Alloy 400 tube bundle exchanger

-

Find Monel industrial heat exchanger for sale

-

Order corrosion-resistant process heat exchanger

-

Buy used high pressure heat exchanger

-

Purchase chemical plant heat transfer unit

-

Get ASME coded shell and tube exchanger

-

Acquire large capacity process heat exchanger

-

Shop industrial heating/cooling equipment

-

Buy repaired industrial exchanger

-

Sell Doyle & Roth heat exchanger

-

List Monel tube exchanger for sale

-

Offer Alloy 400 process heat exchanger

-

Post industrial heat transfer unit listing

-

Market used shell and tube exchanger

-

Resell high capacity corrosion resistant exchanger

-

Promote ASME coded Monel exchanger

-

Auction large capacity process exchanger

-

Sell chemical plant heat transfer equipment

-

Secondhand heat exchanger sales

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory