Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

New MKM CD 250 Atomizer – 9000–13,000 RPM, SS316 Spray Disk, RPM Sensors, Insulated Jacket

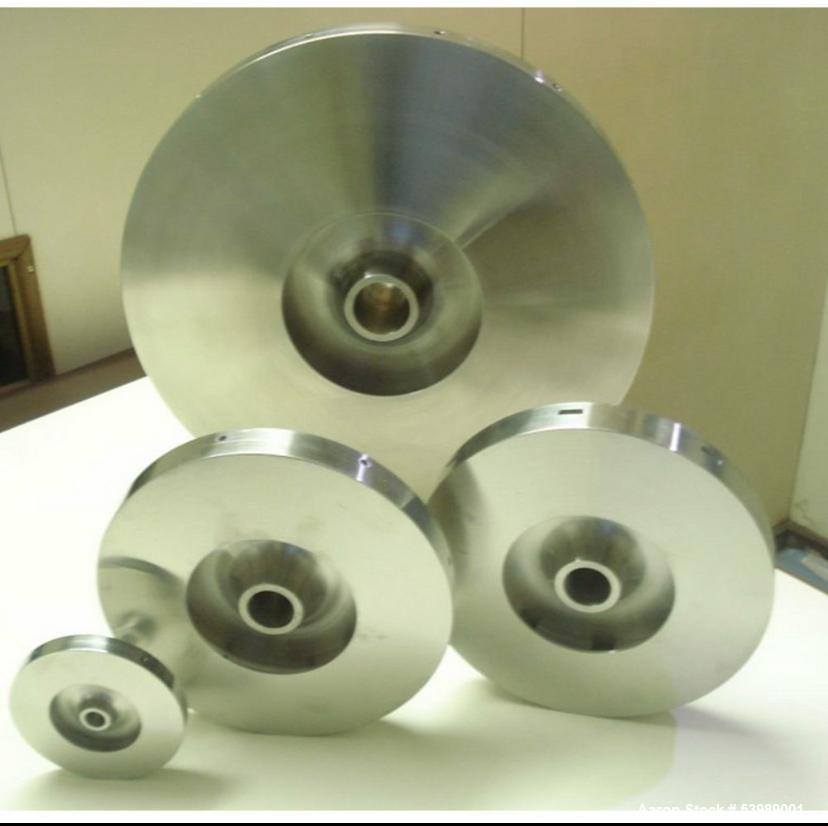

Unused / New MK Manufacturing Co, Atomizer, Model MKM CD 250 features a feeder cover, retainer, sleeve, and feeding pipe made from SS 316 stainless steel, all tested, machined, and balanced as required, the spray disk is also SS 316, precisely machined and balanced, the main shaft is constructed from special spring steel with centerless grinding for high precision, bearing housing is fabricated from mild steel with cylindrical surfaces to accommodate bearing seats, the shaft is driven by a V-belt pulley system, operating speed ranges from 9000 to 13000 RPM and includes RPM sensors and a digital display, the atomizer jacket is insulated with ceramic wool, air purging is provided to prevent sediment buildup and ensure continuous spray dryer operation, lubrication is handled by an MKM make pump with motor, double filters, and gauges for continuous oil flow, the unit is supplied without a motor, compatible with a 25 HP, 2900 RPM flange-mounted Siemens or Hindustan motor, the atomizer pulley is made from SS 304 while the motor pulley is made from cast iron or mild steel. Our freight specialists can assist you with door to door transportation and all customs documents needed to make the process go as smoothly as possible.

| Model | MKM CD 250 |

| Category | Dryers - Drying EquipmentDryers - Drying Equipment |

| Subcategory | Spray Dryer - AtomizerSpray Dryer - Atomizer |

🏭 Manufacturer Information:

-

Manufacturer: MK Manufacturing Co.

-

Model: MKM CD 250

-

Condition: Unused / New

-

Motor Compatibility: Flange-mounted 25 HP, 2900 RPM (Siemens or Hindustan)

📄 Description:

This new MKM CD 250 atomizer is a precision-engineered unit designed for spray dryer systems in industrial applications. Built from high-grade 316 stainless steel, the feeder components and spray disk are meticulously machined, tested, and dynamically balanced to ensure stable high-speed operation between 9,000 and 13,000 RPM.

The atomizer features a spring steel main shaft with centerless grinding for ultra-smooth rotation and precision alignment. The unit also includes RPM sensors with digital display, a ceramic wool insulated jacket, and air purging to prevent material buildup—ensuring extended operation without clogging.

The lubrication system is powered by an MKM-brand oil pump with dual filters, pressure gauges, and a motor, allowing consistent oil circulation during high-speed rotation. Note: the motor is not included, but the design accommodates a 25 HP, 2900 RPM flange-mounted motor (Siemens or Hindustan).

🛠️ Specifications:

-

Model: MKM CD 250

-

Condition: New / Unused

-

Spray Disk: SS316, dynamically balanced

-

Feeder Assembly:

-

Cover, retainer, sleeve, and feed pipe in SS316

-

-

Main Shaft: Special spring steel with centerless grinding

-

Bearings: Mounted in cylindrical mild steel housing

-

Drive Type: V-belt pulley system

-

Atomizer Pulley: SS304

-

Motor Pulley: Cast iron or mild steel

-

-

Operating Speed: 9,000 to 13,000 RPM

-

RPM Monitoring: Sensors with digital RPM display

-

Jacket Insulation: Ceramic wool

-

Air Purge System: Prevents sediment buildup for continuous operation

-

Lubrication System:

-

MKM make pump with motor

-

Double filtration and pressure gauges

-

-

Motor Compatibility:

-

25 HP

-

2900 RPM

-

Flange-mounted Siemens or Hindustan motor

-

(Motor not included)

-

🧩 Applications:

Perfect for integration into high-speed spray drying systems across various industries:

-

Pharmaceutical powder and granule production

-

Dairy and food ingredient spray drying

-

Chemical and specialty material spray systems

-

Ceramic and catalyst powder processing

-

Nutraceutical and vitamin drying lines

-

Detergent and powder coating lines

-

Paint pigment drying

-

Agrochemical formulation drying

-

Thermoplastic resin spray applications

-

Biotech fermentation product recovery

🎯 What Might This Be Used For?

-

Atomizing liquid suspensions into uniform droplets in spray dryers

-

Converting feed solutions or emulsions into dry powders

-

Increasing particle uniformity and surface area in powder production

-

Supporting high-throughput, continuous powder drying operations

-

Optimizing energy transfer in heat-sensitive or reactive material drying

-

Atomizer

-

Spray disk

-

MKM atomizer

-

Spray dryer part

-

SS316 atomizer

-

High-speed atomizer

-

RPM sensor

-

Powder drying

-

Industrial atomizer

-

Drying equipment

-

MKM CD 250 atomizer for spray dryer

-

New industrial atomizer with RPM display

-

SS316 spray disk atomizer

-

13000 RPM spray drying atomizer

-

Ceramic insulated atomizer

-

Spray dryer component with lubrication system

-

Atomizer with air purge and sensor

-

High-speed centrifugal atomizer

-

V-belt drive atomizer unit

-

Atomizer for powder production line

-

Unused MKM CD 250 atomizer for high-speed spray dryer operations

-

Industrial spray dryer atomizer with SS316 feeder, spray disk, and air purging

-

Atomizer system with ceramic wool insulation and dual filter lubrication pump

-

New atomizer with digital RPM monitoring for continuous spray drying

-

Precision balanced 316 SS atomizer disk for pharmaceutical or chemical dryers

-

High-capacity atomizer compatible with 25 HP flange-mounted motors

-

MK Manufacturing Co. spray dryer atomizer for powder processing

-

Spray drying atomizer with spring steel shaft and centerless grinding

-

Laboratory and industrial scale atomizer for fine particle drying

-

Compact high-speed atomizer unit with advanced balancing and airflow design

-

Buy new atomizer for spray dryer

-

MKM CD 250 atomizer for sale

-

Spray disk atomizer unused

-

Atomizer for food/pharma dryer

-

Purchase high-speed atomizer

-

SS316 centrifugal atomizer

-

RPM monitored atomizer equipment

-

Atomizer system with air purge

-

Ceramic insulated spray atomizer

-

Buy industrial atomizer new

Unused / New MK Manufacturing Co, Atomizer, Model MKM CD 250 features a feeder cover, retainer, sleeve, and feeding pipe made from SS 316 stainless steel, all tested, machined, and balanced as required, the spray disk is also SS 316, precisely machined and balanced, the main shaft is constructed from special spring steel with centerless grinding for high precision, bearing housing is fabricated from mild steel with cylindrical surfaces to accommodate bearing seats, the shaft is driven by a V-belt pulley system, operating speed ranges from 9000 to 13000 RPM and includes RPM sensors and a digital display, the atomizer jacket is insulated with ceramic wool, air purging is provided to prevent sediment buildup and ensure continuous spray dryer operation, lubrication is handled by an MKM make pump with motor, double filters, and gauges for continuous oil flow, the unit is supplied without a motor, compatible with a 25 HP, 2900 RPM flange-mounted Siemens or Hindustan motor, the atomizer pulley is made from SS 304 while the motor pulley is made from cast iron or mild steel. Our freight specialists can assist you with door to door transportation and all customs documents needed to make the process go as smoothly as possible.

🏭 Manufacturer Information:

-

Manufacturer: MK Manufacturing Co.

-

Model: MKM CD 250

-

Condition: Unused / New

-

Motor Compatibility: Flange-mounted 25 HP, 2900 RPM (Siemens or Hindustan)

📄 Description:

This new MKM CD 250 atomizer is a precision-engineered unit designed for spray dryer systems in industrial applications. Built from high-grade 316 stainless steel, the feeder components and spray disk are meticulously machined, tested, and dynamically balanced to ensure stable high-speed operation between 9,000 and 13,000 RPM.

The atomizer features a spring steel main shaft with centerless grinding for ultra-smooth rotation and precision alignment. The unit also includes RPM sensors with digital display, a ceramic wool insulated jacket, and air purging to prevent material buildup—ensuring extended operation without clogging.

The lubrication system is powered by an MKM-brand oil pump with dual filters, pressure gauges, and a motor, allowing consistent oil circulation during high-speed rotation. Note: the motor is not included, but the design accommodates a 25 HP, 2900 RPM flange-mounted motor (Siemens or Hindustan).

🛠️ Specifications:

-

Model: MKM CD 250

-

Condition: New / Unused

-

Spray Disk: SS316, dynamically balanced

-

Feeder Assembly:

-

Cover, retainer, sleeve, and feed pipe in SS316

-

-

Main Shaft: Special spring steel with centerless grinding

-

Bearings: Mounted in cylindrical mild steel housing

-

Drive Type: V-belt pulley system

-

Atomizer Pulley: SS304

-

Motor Pulley: Cast iron or mild steel

-

-

Operating Speed: 9,000 to 13,000 RPM

-

RPM Monitoring: Sensors with digital RPM display

-

Jacket Insulation: Ceramic wool

-

Air Purge System: Prevents sediment buildup for continuous operation

-

Lubrication System:

-

MKM make pump with motor

-

Double filtration and pressure gauges

-

-

Motor Compatibility:

-

25 HP

-

2900 RPM

-

Flange-mounted Siemens or Hindustan motor

-

(Motor not included)

-

🧩 Applications:

Perfect for integration into high-speed spray drying systems across various industries:

-

Pharmaceutical powder and granule production

-

Dairy and food ingredient spray drying

-

Chemical and specialty material spray systems

-

Ceramic and catalyst powder processing

-

Nutraceutical and vitamin drying lines

-

Detergent and powder coating lines

-

Paint pigment drying

-

Agrochemical formulation drying

-

Thermoplastic resin spray applications

-

Biotech fermentation product recovery

🎯 What Might This Be Used For?

-

Atomizing liquid suspensions into uniform droplets in spray dryers

-

Converting feed solutions or emulsions into dry powders

-

Increasing particle uniformity and surface area in powder production

-

Supporting high-throughput, continuous powder drying operations

-

Optimizing energy transfer in heat-sensitive or reactive material drying

| Model | MKM CD 250 |

| Category | Dryers - Drying Equipment |

| Subcategory | Spray Dryer - Atomizer |

-

Atomizer

-

Spray disk

-

MKM atomizer

-

Spray dryer part

-

SS316 atomizer

-

High-speed atomizer

-

RPM sensor

-

Powder drying

-

Industrial atomizer

-

Drying equipment

-

MKM CD 250 atomizer for spray dryer

-

New industrial atomizer with RPM display

-

SS316 spray disk atomizer

-

13000 RPM spray drying atomizer

-

Ceramic insulated atomizer

-

Spray dryer component with lubrication system

-

Atomizer with air purge and sensor

-

High-speed centrifugal atomizer

-

V-belt drive atomizer unit

-

Atomizer for powder production line

-

Unused MKM CD 250 atomizer for high-speed spray dryer operations

-

Industrial spray dryer atomizer with SS316 feeder, spray disk, and air purging

-

Atomizer system with ceramic wool insulation and dual filter lubrication pump

-

New atomizer with digital RPM monitoring for continuous spray drying

-

Precision balanced 316 SS atomizer disk for pharmaceutical or chemical dryers

-

High-capacity atomizer compatible with 25 HP flange-mounted motors

-

MK Manufacturing Co. spray dryer atomizer for powder processing

-

Spray drying atomizer with spring steel shaft and centerless grinding

-

Laboratory and industrial scale atomizer for fine particle drying

-

Compact high-speed atomizer unit with advanced balancing and airflow design

-

Buy new atomizer for spray dryer

-

MKM CD 250 atomizer for sale

-

Spray disk atomizer unused

-

Atomizer for food/pharma dryer

-

Purchase high-speed atomizer

-

SS316 centrifugal atomizer

-

RPM monitored atomizer equipment

-

Atomizer system with air purge

-

Ceramic insulated spray atomizer

-

Buy industrial atomizer new

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory