Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Swindell Dressler Electrically Elevated Industrial Kiln – 660 kW | 1130°C Working Temp

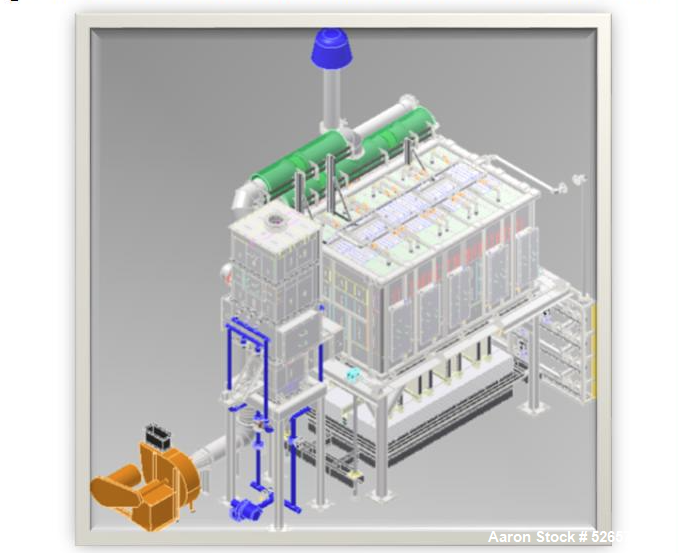

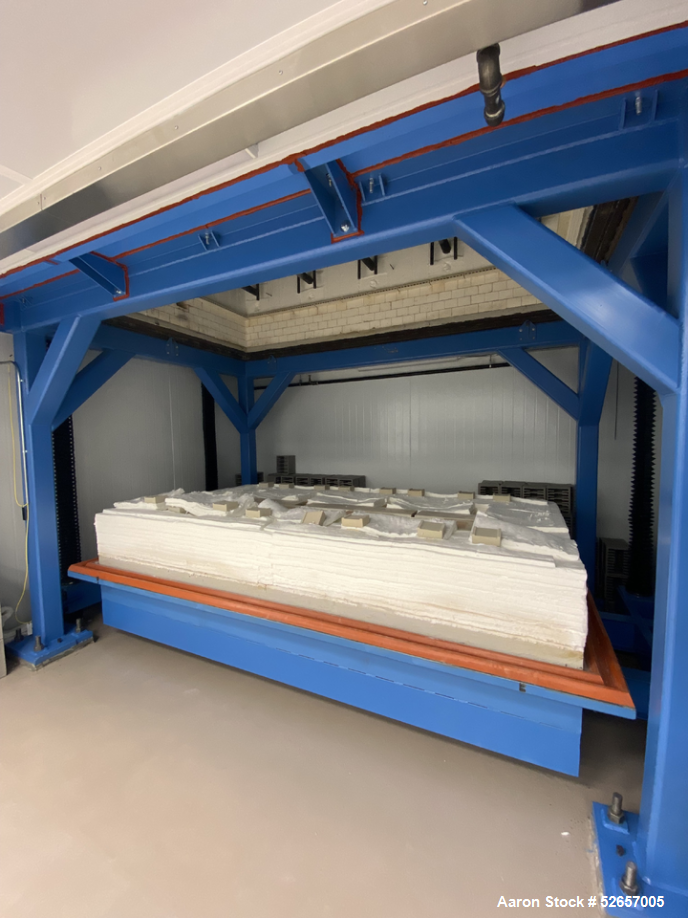

Used Swindell Dressler International Electrically Elevated Kiln, Type: Swindel. Chamber dimensions 6 ft L x 10.5 ft W x 4.25 ft H. Connected power: 660 kW (kiln) 200kW (T.O.). Working temp. 1130 deg. C. (2066 deg. F), Test temp. 1250 deg. C. (2282 deg F.) by a SIC heating system incl. 30 pcs of heating element and 1 pc of Thermal oxidizer. Nitrogen operated cooling. Incl. Control system and additional infrastructure. Unit is reported unused, supposed to be ud in a lithium battery application. New year 2022.

Manufacturer Information

- Brand: Swindell Dressler International

- Type: Swindel

- Condition: Reported Unused

- Year Built: 2022

Specifications

- Chamber Dimensions: 6 ft (L) x 10.5 ft (W) x 4.25 ft (H)

- Connected Power:

- Kiln: 660 kW

- Thermal Oxidizer: 200 kW

- Working Temperature: 1130°C (2066°F)

- Test Temperature: 1250°C (2282°F)

- Heating System: SiC (Silicon Carbide) Heating Elements

- Includes: 30 heating elements & 1 thermal oxidizer

- Cooling System: Nitrogen Operated Cooling

- Includes:

- Control System

- Additional Infrastructure

Description

This unused Swindell Dressler Electrically Elevated Kiln is a high-performance industrial kiln, designed for precise high-temperature processing. With a 660 kW power rating and Silicon Carbide (SiC) heating elements, this kiln ensures consistent and efficient thermal performance. The nitrogen-operated cooling system provides controlled cooling, while the integrated thermal oxidizer (200 kW) enhances process efficiency.

Originally intended for lithium battery material processing, this kiln is ideal for advanced manufacturing applications requiring high-precision heating, sintering, and thermal treatment.

Applications

This high-temperature kiln is suitable for:

- Lithium battery material processing

- Ceramic sintering & firing

- Advanced material development

- Chemical processing

- Heat treatment for specialty materials

Compatible Equipment & Accessories

- Vacuum & atmosphere control systems

- Material handling systems

- Exhaust & air filtration systems

- Advanced temperature monitoring & process control

- Swindell Dressler kiln

- High-temperature industrial kiln

- Electrically heated kiln

- Used Swindell Dressler kiln for sale

- 1130°C sintering kiln

- Unused Swindell Dressler high-temperature kiln for lithium battery processing

- 660 kW electrically heated industrial kiln

- Advanced SiC heating element kiln for ceramics and specialty materials

- Nitrogen cooling kiln for precision heat treatment

Used Swindell Dressler International Electrically Elevated Kiln, Type: Swindel. Chamber dimensions 6 ft L x 10.5 ft W x 4.25 ft H. Connected power: 660 kW (kiln) 200kW (T.O.). Working temp. 1130 deg. C. (2066 deg. F), Test temp. 1250 deg. C. (2282 deg F.) by a SIC heating system incl. 30 pcs of heating element and 1 pc of Thermal oxidizer. Nitrogen operated cooling. Incl. Control system and additional infrastructure. Unit is reported unused, supposed to be ud in a lithium battery application. New year 2022.

Manufacturer Information

- Brand: Swindell Dressler International

- Type: Swindel

- Condition: Reported Unused

- Year Built: 2022

Specifications

- Chamber Dimensions: 6 ft (L) x 10.5 ft (W) x 4.25 ft (H)

- Connected Power:

- Kiln: 660 kW

- Thermal Oxidizer: 200 kW

- Working Temperature: 1130°C (2066°F)

- Test Temperature: 1250°C (2282°F)

- Heating System: SiC (Silicon Carbide) Heating Elements

- Includes: 30 heating elements & 1 thermal oxidizer

- Cooling System: Nitrogen Operated Cooling

- Includes:

- Control System

- Additional Infrastructure

Description

This unused Swindell Dressler Electrically Elevated Kiln is a high-performance industrial kiln, designed for precise high-temperature processing. With a 660 kW power rating and Silicon Carbide (SiC) heating elements, this kiln ensures consistent and efficient thermal performance. The nitrogen-operated cooling system provides controlled cooling, while the integrated thermal oxidizer (200 kW) enhances process efficiency.

Originally intended for lithium battery material processing, this kiln is ideal for advanced manufacturing applications requiring high-precision heating, sintering, and thermal treatment.

Applications

This high-temperature kiln is suitable for:

- Lithium battery material processing

- Ceramic sintering & firing

- Advanced material development

- Chemical processing

- Heat treatment for specialty materials

Compatible Equipment & Accessories

- Vacuum & atmosphere control systems

- Material handling systems

- Exhaust & air filtration systems

- Advanced temperature monitoring & process control

- Swindell Dressler kiln

- High-temperature industrial kiln

- Electrically heated kiln

- Used Swindell Dressler kiln for sale

- 1130°C sintering kiln

- Unused Swindell Dressler high-temperature kiln for lithium battery processing

- 660 kW electrically heated industrial kiln

- Advanced SiC heating element kiln for ceramics and specialty materials

- Nitrogen cooling kiln for precision heat treatment

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory