Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Sahara-PAK HC-7000 Heat of Compression Air Dryer Skid – 7000 SCFM, Dual Towers, Shell & Tube Exchanger

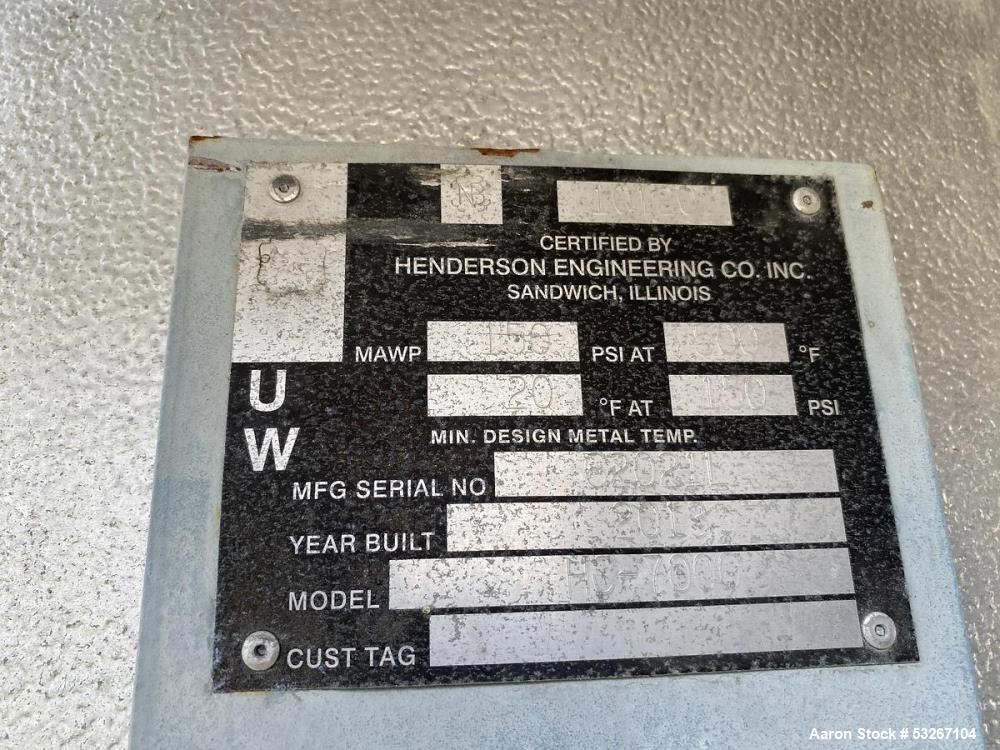

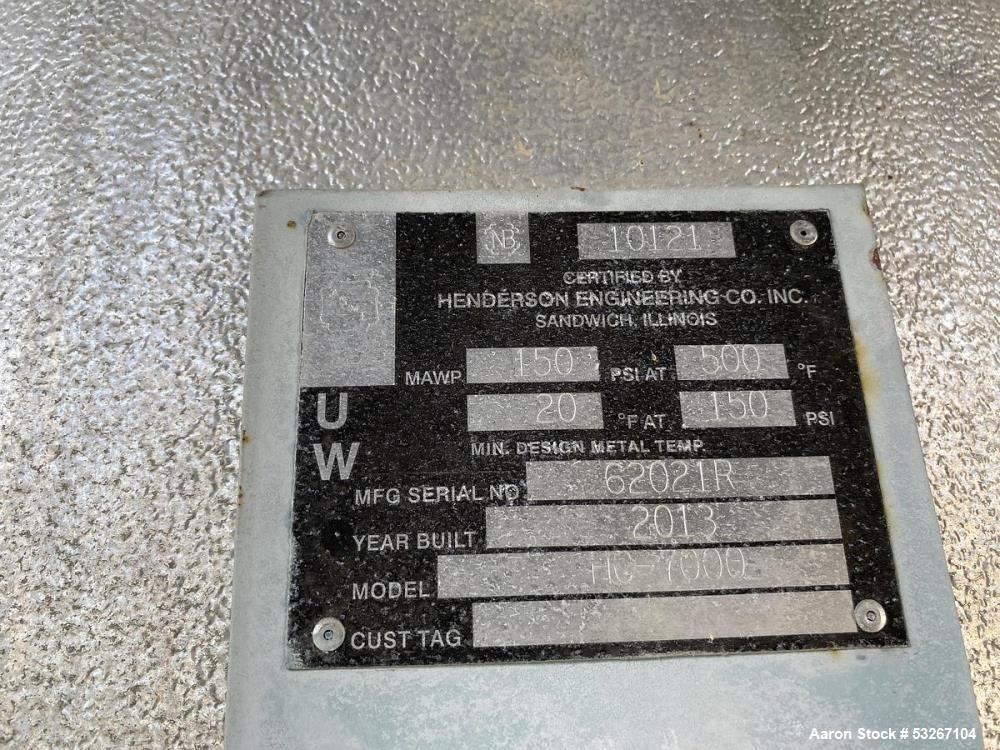

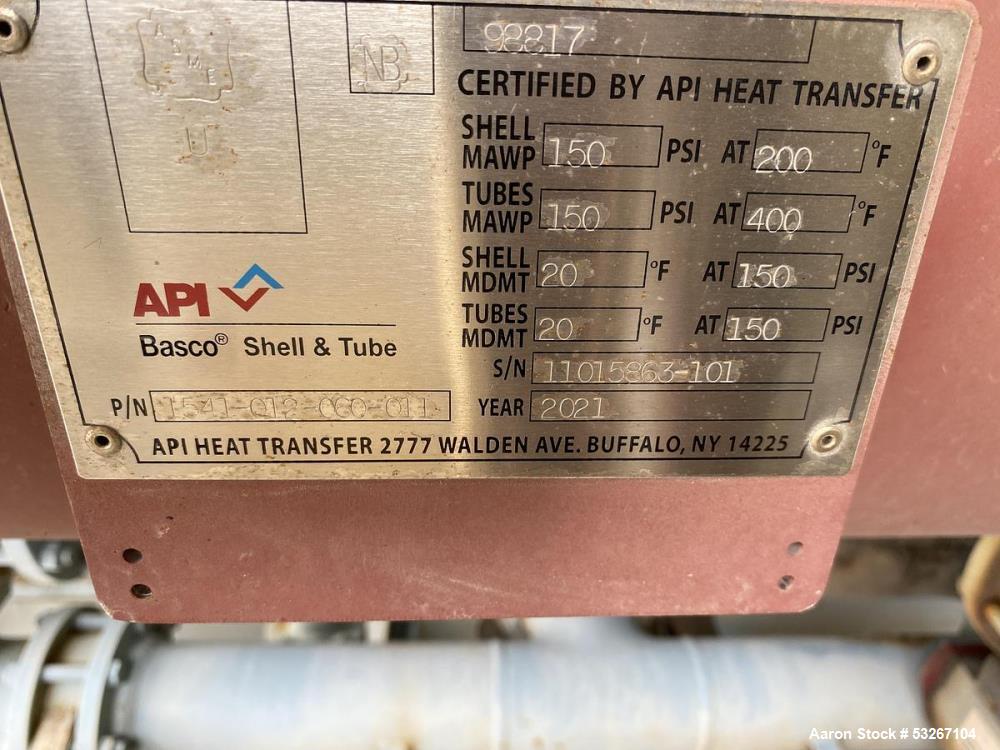

Used Sahara-PAK Heat of Compression Regenerative Air Dryer Skid. Model HC-7000. Equipped with (2) Henderson Engineering Co desiccate towers. Rated for 7000 SCFM at 100#. Units rated for 150 PSI @ 20 to 500 F. NB#'s 10120 and 10121, S/N's 62021L and 62021R. Skid also contains, API Basco shell and tube heat exchanger NB# 98817 shell rated 150 PSI @ 20 to 200 F, Tubes rated 150 PSI @ 20 to 400 F. S/N 11015863-101, coalescing separator NB# 10122, SN 6221 rated 150 PSI @ 20 to 500F, Electro-Heat Inc 50 kW, 3-pahse 460 volt heater, valves, piping , and controls. Skid DIMS: 15'-6" long X 11' wide. Built 2013.

| Category | Dryers - Drying EquipmentDryers - Drying Equipment |

| Subcategory | Air DryersAir Dryers |

🏭 Manufacturer

Sahara-PAK

An established manufacturer of regenerative and desiccant air dryers designed for industrial air systems, including heat of compression and zero air-loss solutions.

📝 Description

This Sahara-PAK Model HC-7000 Heat of Compression Regenerative Air Dryer Skid, built in 2013, is a complete, high-capacity air treatment system designed for critical-duty compressed air drying applications. Rated at 7000 SCFM @ 100 PSI, this industrial skid integrates a suite of components including:

-

(2) Henderson Engineering Co. desiccant towers (NB# 10120 and 10121, S/N 62021L & 62021R)

-

API Basco shell & tube heat exchanger (NB# 98817, S/N 11015863-101)

-

Electro-Heat Inc. 50 kW electric heater (3-phase, 460V)

-

Coalescing separator (NB# 10122, S/N 6221)

-

Piping, valves, and integrated controls

The towers and components are rated for up to 150 PSI and temperature ranges of 20°F to 500°F, with the heat exchanger shell and tubes designed to handle separate temperature limits for fluid transfer and thermal recovery.

⚙️ Specifications

-

Model: HC-7000

-

Manufacturer: Sahara-PAK

-

Capacity: 7000 SCFM @ 100 PSI

-

System Pressure Rating: 150 PSI

-

Temperature Range: 20°F to 500°F

-

Build Year: 2013

-

Components:

-

(2) Henderson Engineering Desiccant Towers

-

NB# 10120 & 10121

-

S/N 62021L & 62021R

-

-

Shell & Tube Heat Exchanger (API Basco)

-

NB# 98817, S/N 11015863-101

-

Shell: 150 PSI @ 20°F to 200°F

-

Tubes: 150 PSI @ 20°F to 400°F

-

-

Coalescing Separator

-

NB# 10122, S/N 6221

-

Rated: 150 PSI @ 20°F to 500°F

-

-

Heater: Electro-Heat Inc., 50 kW, 3-phase, 460V

-

-

Skid Dimensions: 15'-6" L × 11' W

🧩 Applications

Perfect for compressed air drying and moisture removal in:

-

Petrochemical plants

-

Oil & gas processing facilities

-

Large manufacturing plants

-

Automotive and aerospace facilities

-

Power generation sites

-

Mining and mineral processing

-

Steel and foundry industries

-

Pulp and paper mills

-

Food and beverage plants

-

Pharmaceutical production

🔧 What Might This Be Used For?

-

Removing moisture from compressed air in high-volume systems

-

Protecting downstream pneumatic controls and equipment

-

Air preparation before entering desiccant beds

-

Thermal energy recovery through integrated shell & tube exchanger

-

Meeting ISO 8573-1 Class 1 air standards

-

Replacing conventional twin tower air dryers with heat-efficient solution

-

Dehumidifying air for food, pharma, or cleanroom operations

-

Serving as primary air treatment for compressor stations

-

Supporting continuous manufacturing in high-heat settings

-

Preparing air for chemical vapor or catalyst processes

-

Sahara-PAK air dryer

-

HC-7000 dryer

-

Heat of compression dryer

-

Used air dryer skid

-

Regenerative air dryer

-

Desiccant air dryer

-

API Basco heat exchanger

-

Coalescing separator

-

7000 SCFM dryer

-

Air dryer system

-

Used Sahara-PAK HC-7000 air dryer skid

-

Heat of compression regenerative dryer

-

7000 SCFM compressed air dryer system

-

Industrial air treatment skid for sale

-

Dual tower desiccant dryer with heat exchanger

-

Sahara-PAK system with coalescing separator

-

Electro-Heat 50 kW air dryer heater

-

150 PSI regenerative dryer skid

-

Used heat of compression air drying unit

-

Shell and tube exchanger in dryer skid

-

Buy used Sahara-PAK HC-7000 heat of compression air dryer skid

-

7000 SCFM regenerative air dryer with desiccant towers

-

Used air dryer with shell and tube heat exchanger and heater

-

2013 Sahara-PAK dual tower air dryer system for compressed air

-

Industrial air dryer skid with coalescing separator and heater

-

Regenerative air dryer system with 150 PSI and 500°F capability

-

Heat of compression air dryer for manufacturing and processing

-

Turnkey air treatment skid with desiccant, heat exchanger, heater

-

Sahara-PAK compressed air system with NB-rated components

-

Large-capacity industrial dryer system for high humidity air

-

buy Sahara-PAK air dryer skid

-

used HC-7000 air dryer for sale

-

industrial compressed air dryer buy

-

7000 SCFM air dryer system

-

used regenerative dryer for sale

-

heat of compression air dryer purchase

-

complete air dryer skid unit

-

air dryer with shell & tube exchanger

-

Sahara-PAK desiccant tower dryer buy

-

buy industrial air treatment skid

-

sell Sahara-PAK air dryer skid

-

list used regenerative air dryer

-

7000 SCFM dryer resale

-

sell compressed air treatment unit

-

used air dryer system selling

-

Sahara-PAK dryer with coalescing separator

-

second-hand desiccant air dryer

-

surplus heat of compression air dryer

-

industrial air dryer equipment sales

-

air dryer skid with NB-rated components

Used Sahara-PAK Heat of Compression Regenerative Air Dryer Skid. Model HC-7000. Equipped with (2) Henderson Engineering Co desiccate towers. Rated for 7000 SCFM at 100#. Units rated for 150 PSI @ 20 to 500 F. NB#'s 10120 and 10121, S/N's 62021L and 62021R. Skid also contains, API Basco shell and tube heat exchanger NB# 98817 shell rated 150 PSI @ 20 to 200 F, Tubes rated 150 PSI @ 20 to 400 F. S/N 11015863-101, coalescing separator NB# 10122, SN 6221 rated 150 PSI @ 20 to 500F, Electro-Heat Inc 50 kW, 3-pahse 460 volt heater, valves, piping , and controls. Skid DIMS: 15'-6" long X 11' wide. Built 2013.

🏭 Manufacturer

Sahara-PAK

An established manufacturer of regenerative and desiccant air dryers designed for industrial air systems, including heat of compression and zero air-loss solutions.

📝 Description

This Sahara-PAK Model HC-7000 Heat of Compression Regenerative Air Dryer Skid, built in 2013, is a complete, high-capacity air treatment system designed for critical-duty compressed air drying applications. Rated at 7000 SCFM @ 100 PSI, this industrial skid integrates a suite of components including:

-

(2) Henderson Engineering Co. desiccant towers (NB# 10120 and 10121, S/N 62021L & 62021R)

-

API Basco shell & tube heat exchanger (NB# 98817, S/N 11015863-101)

-

Electro-Heat Inc. 50 kW electric heater (3-phase, 460V)

-

Coalescing separator (NB# 10122, S/N 6221)

-

Piping, valves, and integrated controls

The towers and components are rated for up to 150 PSI and temperature ranges of 20°F to 500°F, with the heat exchanger shell and tubes designed to handle separate temperature limits for fluid transfer and thermal recovery.

⚙️ Specifications

-

Model: HC-7000

-

Manufacturer: Sahara-PAK

-

Capacity: 7000 SCFM @ 100 PSI

-

System Pressure Rating: 150 PSI

-

Temperature Range: 20°F to 500°F

-

Build Year: 2013

-

Components:

-

(2) Henderson Engineering Desiccant Towers

-

NB# 10120 & 10121

-

S/N 62021L & 62021R

-

-

Shell & Tube Heat Exchanger (API Basco)

-

NB# 98817, S/N 11015863-101

-

Shell: 150 PSI @ 20°F to 200°F

-

Tubes: 150 PSI @ 20°F to 400°F

-

-

Coalescing Separator

-

NB# 10122, S/N 6221

-

Rated: 150 PSI @ 20°F to 500°F

-

-

Heater: Electro-Heat Inc., 50 kW, 3-phase, 460V

-

-

Skid Dimensions: 15'-6" L × 11' W

🧩 Applications

Perfect for compressed air drying and moisture removal in:

-

Petrochemical plants

-

Oil & gas processing facilities

-

Large manufacturing plants

-

Automotive and aerospace facilities

-

Power generation sites

-

Mining and mineral processing

-

Steel and foundry industries

-

Pulp and paper mills

-

Food and beverage plants

-

Pharmaceutical production

🔧 What Might This Be Used For?

-

Removing moisture from compressed air in high-volume systems

-

Protecting downstream pneumatic controls and equipment

-

Air preparation before entering desiccant beds

-

Thermal energy recovery through integrated shell & tube exchanger

-

Meeting ISO 8573-1 Class 1 air standards

-

Replacing conventional twin tower air dryers with heat-efficient solution

-

Dehumidifying air for food, pharma, or cleanroom operations

-

Serving as primary air treatment for compressor stations

-

Supporting continuous manufacturing in high-heat settings

-

Preparing air for chemical vapor or catalyst processes

| Category | Dryers - Drying Equipment |

| Subcategory | Air Dryers |

-

Sahara-PAK air dryer

-

HC-7000 dryer

-

Heat of compression dryer

-

Used air dryer skid

-

Regenerative air dryer

-

Desiccant air dryer

-

API Basco heat exchanger

-

Coalescing separator

-

7000 SCFM dryer

-

Air dryer system

-

Used Sahara-PAK HC-7000 air dryer skid

-

Heat of compression regenerative dryer

-

7000 SCFM compressed air dryer system

-

Industrial air treatment skid for sale

-

Dual tower desiccant dryer with heat exchanger

-

Sahara-PAK system with coalescing separator

-

Electro-Heat 50 kW air dryer heater

-

150 PSI regenerative dryer skid

-

Used heat of compression air drying unit

-

Shell and tube exchanger in dryer skid

-

Buy used Sahara-PAK HC-7000 heat of compression air dryer skid

-

7000 SCFM regenerative air dryer with desiccant towers

-

Used air dryer with shell and tube heat exchanger and heater

-

2013 Sahara-PAK dual tower air dryer system for compressed air

-

Industrial air dryer skid with coalescing separator and heater

-

Regenerative air dryer system with 150 PSI and 500°F capability

-

Heat of compression air dryer for manufacturing and processing

-

Turnkey air treatment skid with desiccant, heat exchanger, heater

-

Sahara-PAK compressed air system with NB-rated components

-

Large-capacity industrial dryer system for high humidity air

-

buy Sahara-PAK air dryer skid

-

used HC-7000 air dryer for sale

-

industrial compressed air dryer buy

-

7000 SCFM air dryer system

-

used regenerative dryer for sale

-

heat of compression air dryer purchase

-

complete air dryer skid unit

-

air dryer with shell & tube exchanger

-

Sahara-PAK desiccant tower dryer buy

-

buy industrial air treatment skid

-

sell Sahara-PAK air dryer skid

-

list used regenerative air dryer

-

7000 SCFM dryer resale

-

sell compressed air treatment unit

-

used air dryer system selling

-

Sahara-PAK dryer with coalescing separator

-

second-hand desiccant air dryer

-

surplus heat of compression air dryer

-

industrial air dryer equipment sales

-

air dryer skid with NB-rated components

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory